A kind of preparation method of tc6 titanium alloy large size bar

A titanium alloy and large-scale technology, which is applied in the field of preparation of large-scale titanium alloy rods of TC6, can solve the problems of reducing the number of forging fires in large-scale titanium alloy processing, low production efficiency, and reducing the number of fires, etc., to achieve excellent product quality, Good tissue uniformity and the effect of reducing the number of fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

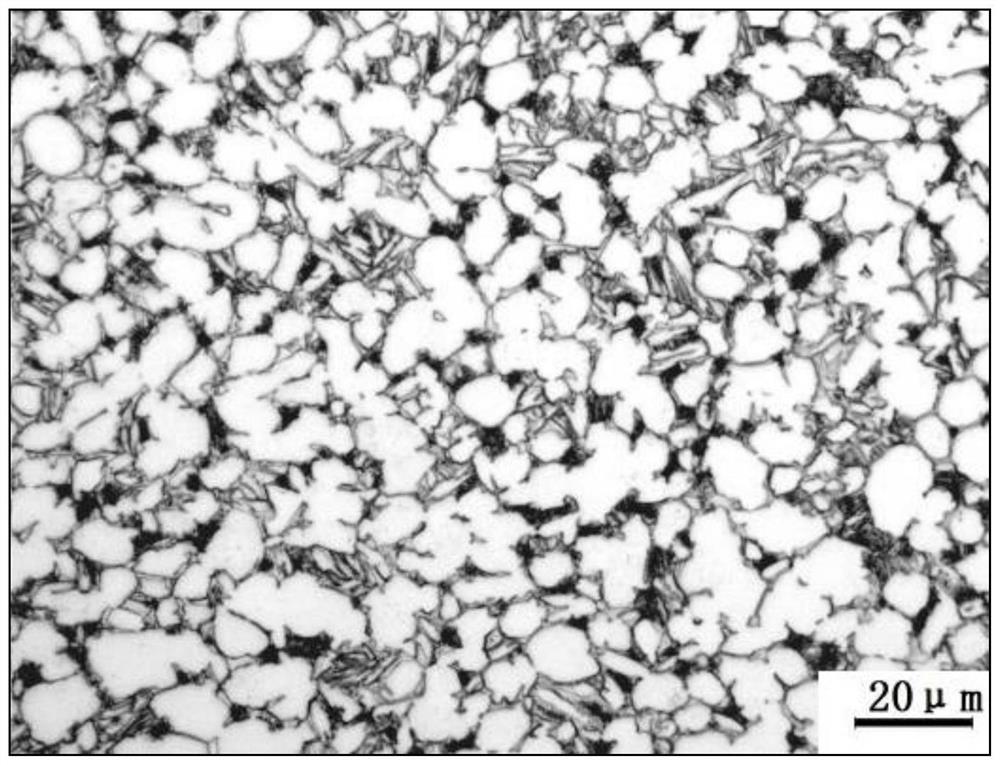

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] Step 1, the TC6 titanium alloy ingot is subjected to one-fire square billet forging to obtain a primary billet; the TC6 titanium alloy ingot is a cylindrical ingot with a cross-sectional diameter of 690 mm, and the transverse The section is a square with a side length of 500mm, the initial forging temperature in the billet forging is 1150°C, the forging ratio is 2.4, the material-width ratio is 1.2, and the reduction ratio is 15%;

[0032] Step 2: Slitting and blanking the primary billet described in Step 1, and then carrying out the first firing of the primary billet after slitting and blanking under the condition that the initial forging temperature is (Tβ+50) ℃ Lengthening and spheronizing forging to obtain an intermediate billet; the Tβ is the β phase transition temperature of the TC6 titanium alloy, and the unit of Tβ is °C; The cutting rate is 15%, and the surface grinding treatment is carried out after the f...

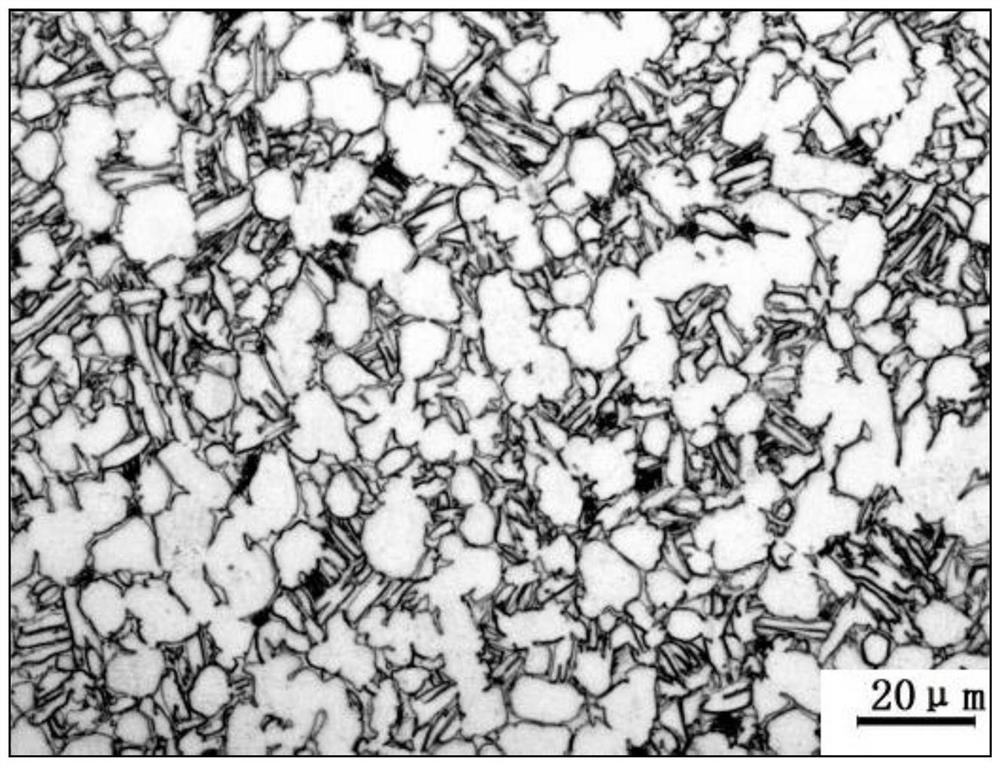

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] Step 1, the TC6 titanium alloy ingot is subjected to one-fire square billet forging to obtain a primary billet; the TC6 titanium alloy ingot is a cylindrical ingot with a cross-sectional diameter of 720 mm, and the transverse The section is a square with a side length of 410mm, the initial forging temperature in the billet forging is 1100°C, the forging ratio is 1.8, the material-width ratio is 0.8, and the reduction ratio is 40%;

[0040] Step 2: Slitting and blanking the primary billet described in Step 1, and then carrying out the first firing of the primary billet after slitting and blanking under the condition that the initial forging temperature is (Tβ+40) ℃ Lengthening and spheronizing forging to obtain an intermediate billet; the Tβ is the β phase transition temperature of the TC6 titanium alloy, and the unit of Tβ is °C; The reduction rate is 40%, and the surface grinding treatment is performed after the f...

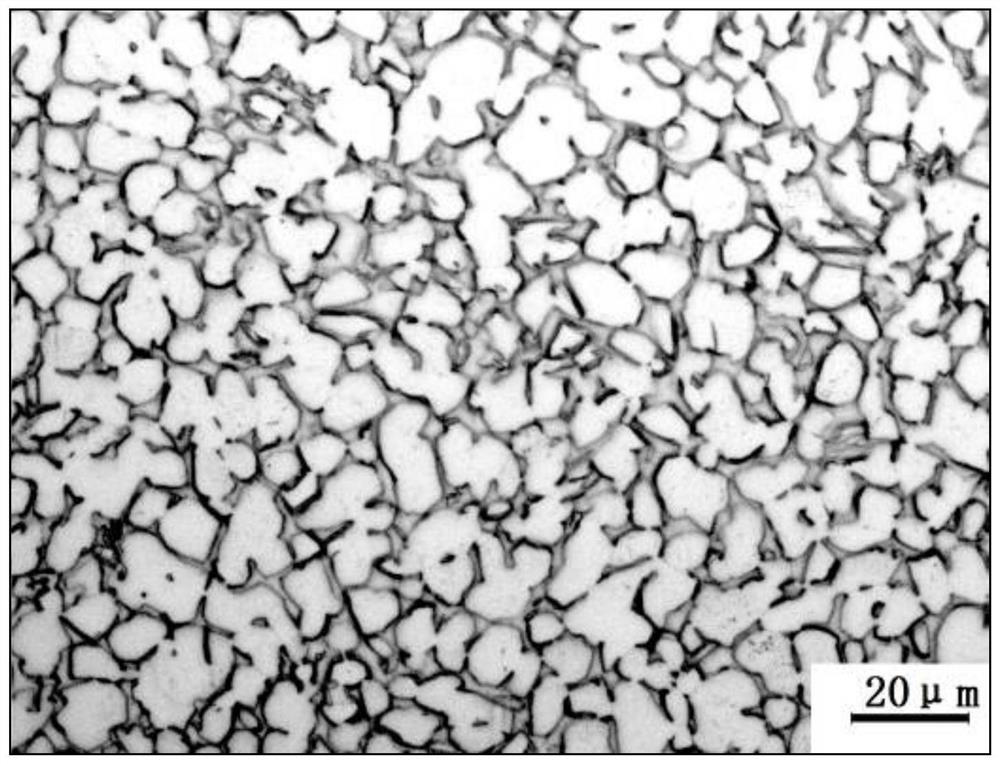

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] Step 1, the TC6 titanium alloy ingot is subjected to one-fire square billet forging to obtain a primary billet; the TC6 titanium alloy ingot is a cylindrical ingot with a cross-sectional diameter of 540 mm, and the transverse The cross section is a square with a side length of 300mm, the initial forging temperature in the billet forging is 1000°C, the forging ratio is 2, the material-width ratio is 1, and the reduction ratio is 20%;

[0048] Step 2: Slitting and blanking the primary billet described in Step 1, and then carrying out the first firing of the primary billet after slitting and blanking under the condition that the initial forging temperature is (Tβ+30) ℃ Lengthening and spheronizing forging to obtain an intermediate billet; the Tβ is the β phase transition temperature of the TC6 titanium alloy, and the unit of Tβ is °C; The cutting rate is 20%, and the surface grinding treatment is carried out after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com