Inorganic crystal adhesive fire-proof decorative board, and production method and application of decorative board

An inorganic crystal glue powder, decorative board technology, applied in fire prevention, building components, construction and other directions, can solve the problems of wasting resources, prolonging the escape time, etc., to reduce labor costs, improve people's income, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

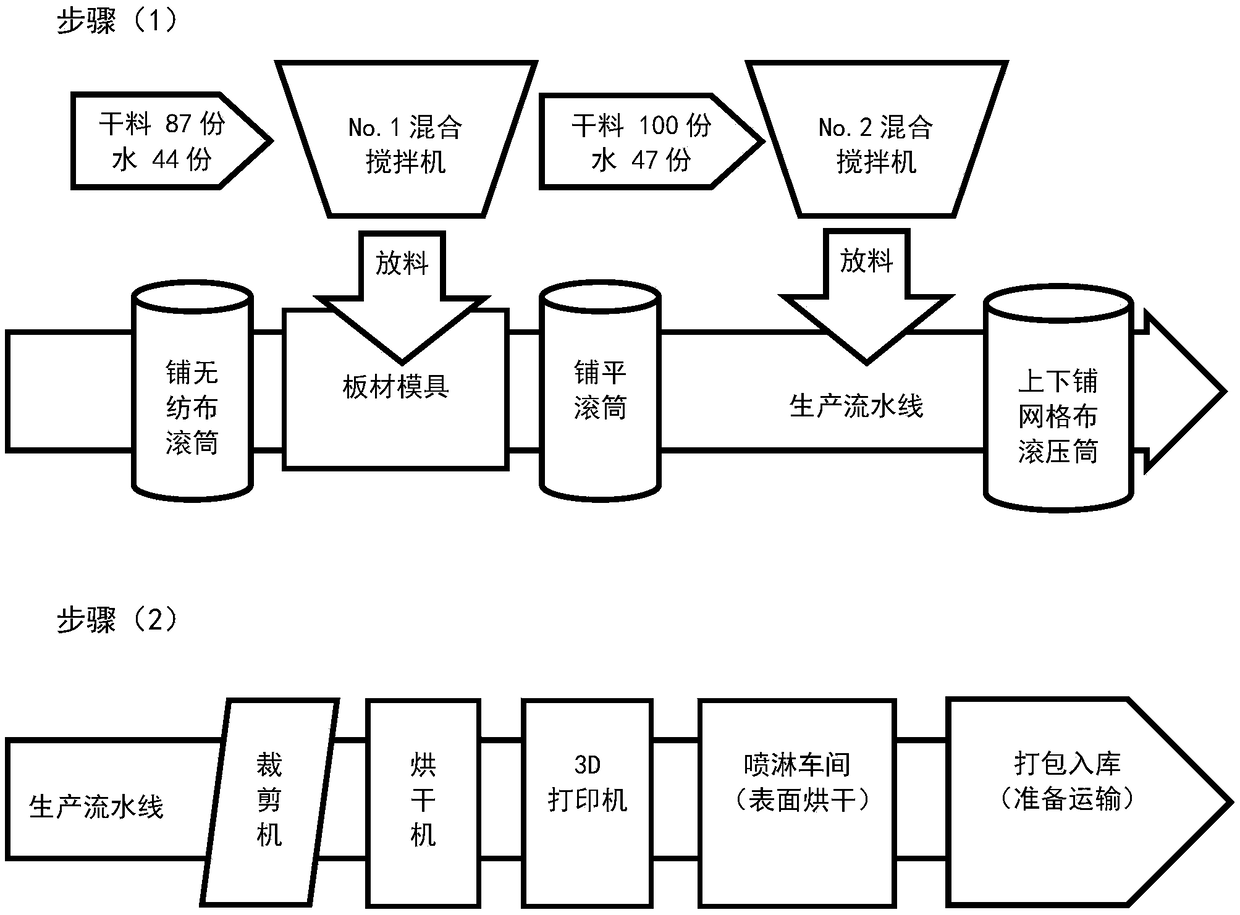

[0033] The present invention also provides a method for preparing an inorganic crystal glue fireproof decorative board, comprising the following steps:

[0034] (1) Preparation of the first batch of materials

[0035] According to the ratio, take 87 parts of inorganic crystal powder, silicate, oxidized metal salt, sulfate and silicon dioxide and 44 parts of water, mix and stir to form a paste, and then pour the paste into a mold with non-woven fabrics ,pave;

[0036] (2) Preparation of the second batch of materials

[0037]Lay a layer of alkali-free mesh glass fiber cloth or basalt fiber cloth on the above paste, and take inorganic crystal powder, silicate, oxidized metal salt, sulfate, vitrified microbeads or bamboo fiber, dioxide A total of 100 parts of silicon and modified polypropylene crude fibers are mixed with 47 parts of water and fully stirred into a thick paste state, poured on the paste covered with alkali-free mesh glass fiber cloth or basalt fiber cloth, and rol...

Embodiment 1

[0042] An inorganic crystal glue fireproof decorative board, including the first batch of materials and the second batch of materials, the first batch of materials includes 12 parts of inorganic crystal glue powder, 29 parts of silicate, 12 parts of oxidized metal salt, 5 parts of sulfate, two 29 parts of silicon oxide, a total of 87 parts; the second batch of materials includes 12 parts of inorganic crystal powder, 29 parts of silicate, 12 parts of metal oxide salt, 5 parts of sulfate, 29 parts of silicon dioxide, modified polypropylene crude fiber 1 part, vitrified microbeads 12 parts, a total of 100 parts.

[0043] Among them, the silicate is 42.5# Portland cement, the oxidized metal salt is 85 type magnesium oxide, the sulfate is magnesium sulfate, the particle size of vitrified microbeads or bamboo fiber is about 20 mesh, and the mesh size of basalt fiber cloth is 5mm ×5mm.

[0044] Inorganic crystal powder is prepared from the following materials: 20-40 parts of oxidize...

Embodiment 2

[0054] An inorganic crystal glue fireproof decorative board, including the first batch of materials and the second batch of materials, the first batch of materials includes 7 parts of inorganic crystal glue powder, 35 parts of silicate, 16 parts of oxidized metal salt, 9 parts of sulfate, two 20 parts of silicon oxide, a total of 87 parts; the second batch of materials includes 10 parts of inorganic crystal powder, 25 parts of silicate, 16 parts of metal oxide salt, 6.7 parts of sulfate, 32 parts of silicon dioxide, modified polypropylene crude fiber 1.3 parts, 9 parts of vitrified microbeads, a total of 100 parts.

[0055] Among them, the silicate is 42.5# Portland cement, the oxidized metal salt is 85 type magnesium oxide, the sulfate is magnesium sulfate, the particle size of vitrified microbeads or bamboo fiber is about 20 mesh, and the mesh size of basalt fiber cloth is 5mm ×5mm.

[0056] Inorganic crystal powder is prepared from the following materials: 20-40 parts of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com