Die forging and forming method of large-scale disc type forging piece

A forming method and forging technology are applied in the production field of large disc forgings, which can solve the problems affecting the forming and quality performance of large discs, the large load required for forging, the number of fires required for forging, etc. The effect of reducing forging times and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

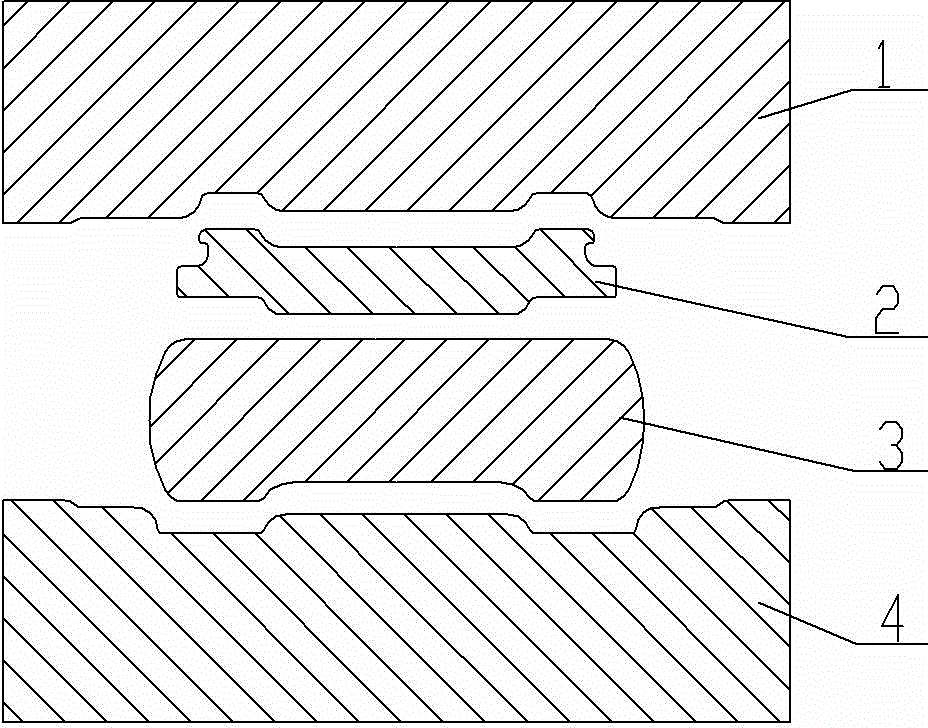

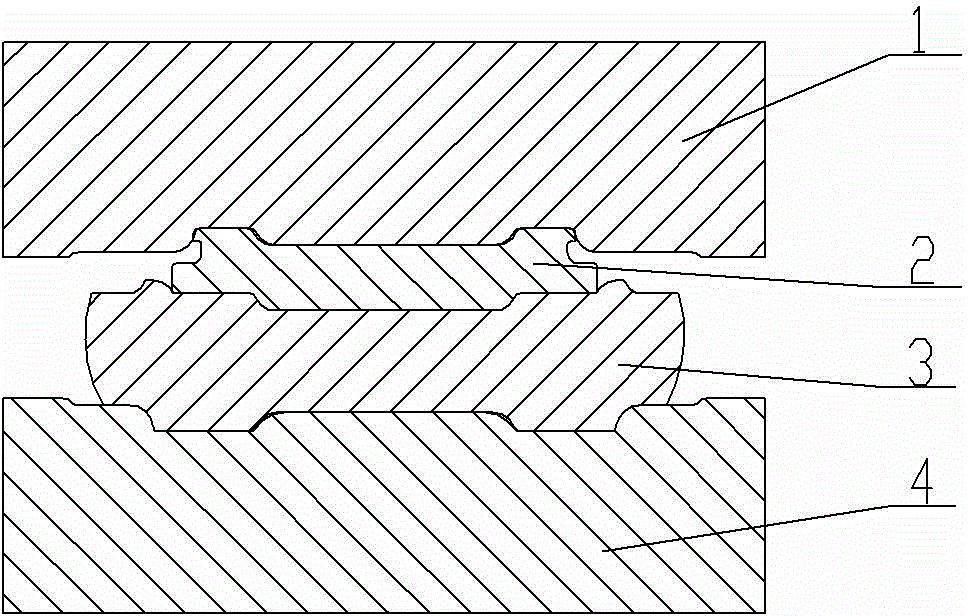

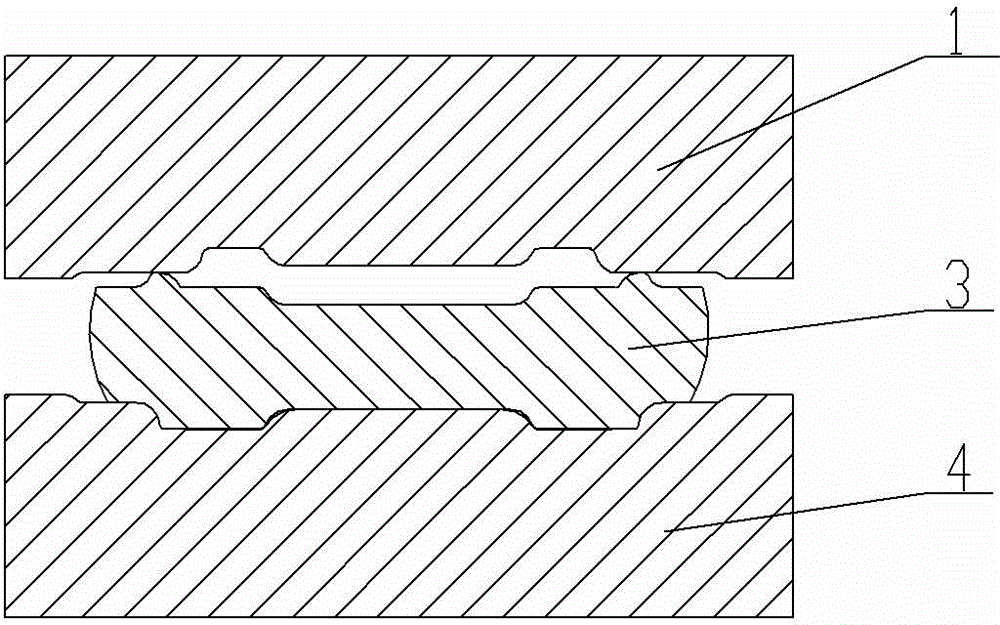

[0014] See figure 1 , the die forging forming method of large-scale disk-like forgings of the present invention, it first assembles the forging block 2 and the upper die 1, and then carries out the partial forming of the center of the forging 3 by cooperating the forging block 2 and the lower die 4, see figure 2 , and then unload the forging block 2 from the upper die 1, through the cooperation of the upper die 1 and the lower die 4, the edge part of the forging that has been partially formed in the center is partially formed until the forging is formed in place as a whole, see image 3 with Figure 4 , wherein the upper part of the forging block is provided with a profile that matches the cavity of the upper die, and the lower part is provided with a cavity for forming the core of the disc forging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com