Grain refining processing method of titanium alloy tube blank for spinning

A processing method, the technology of titanium alloy tubes, applied in the field of titanium alloy material processing, can solve the problems of low material utilization rate, high production cost, difficult processing, etc., and achieve the effect of simplifying the production process, shortening the processing process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

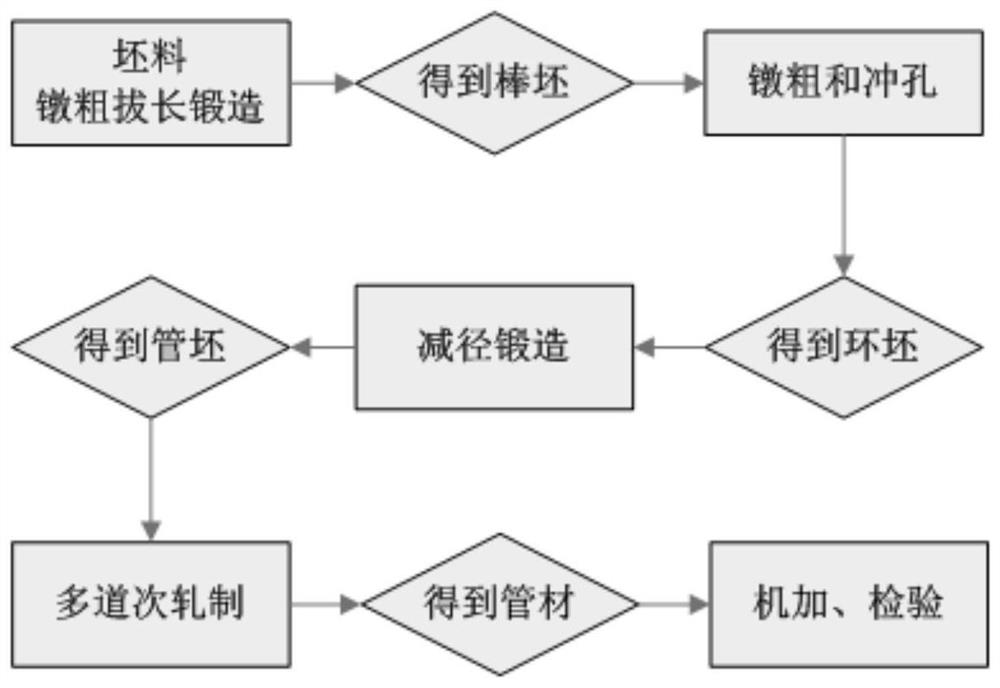

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, a TC4 titanium alloy ingot with a diameter of 180 mm and a length of 200 mm is used. The riser and bottom pad of the ingot are cut off by machining, and the scale and defects on the surface of the ingot are removed by peeling, and pouring is carried out at both ends of the ingot. horn. After testing, the phase transition point of the TC4 titanium alloy used in this embodiment is T β =995°C.

[0049] Adopt a kind of fine-grain processing method of the titanium alloy pipe material for spinning of the present invention, take TC4 titanium alloy ingot as raw material, the step of producing the TC4 titanium alloy fine-grain pipe material for spinning is as follows:

[0050] Step 1. Firstly, heat the TC4 titanium alloy ingot at 1170°C, heat it for 90 minutes, and then perform one upsetting and one pulling out forging. The total deformation of upsetting is completed by n=5 pressing deformations, and the deformation coefficients of each pressing are respecti...

Embodiment 2

[0056] In this embodiment, a TC4 titanium alloy coarse-grained bar with a diameter of 150 mm and a length of 160 mm is used to remove oxide scales and defects on the surface by machining, and chamfer at both ends. After testing, the phase transition point (T β ) for T β =995°C.

[0057] Adopt a kind of fine-grain processing method of titanium alloy pipe material for spinning of the present invention, the steps of producing qualified TC4 titanium alloy pipe material for spinning are as follows:

[0058] Step 1. First, heat the TC4 titanium alloy coarse-grained rod at 1175°C, hold it for 80 minutes, and perform one upsetting and one drawing forging. The total deformation of upsetting is completed by n=6 times of pressing deformation, and the deformation coefficient of each pressing is respectively for alpha 1 =0.05, α 2 =0.05, α 3 =0.06, α 4 =0.06, α 5 =0.07, α 6 = 0.07, the total deformation of upsetting Q = 31%, the length after elongation is the same as the initial le...

Embodiment 3

[0064] In this embodiment, a TC4 titanium alloy ingot with a diameter of 230mm and a length of 300mm is used, the riser and bottom pad of the ingot are removed by machining, the scale and defects on the surface of the ingot are removed by peeling, and the ingot is reversed at both ends of the ingot. horn. After testing, the phase transition point (T β ) for T β =995°C.

[0065] Adopt a kind of fine-grain processing method of titanium alloy pipe material for spinning of the present invention, the steps of producing qualified TC4 titanium alloy pipe material for spinning from TC4 titanium alloy ingot casting are as follows:

[0066] Step 1. First heat the TC4 titanium alloy ingot at 1180°C, heat it for 105 minutes, and then perform one upsetting and one drawing forging. The total deformation of upsetting is completed by n=7 pressing deformations, and the deformation coefficients of each pressing are α 1 =0.05, α 2 =0.05, α 3 =0.05, α 4 =0.06, α 5 =0.06, α 6 =0.06, α 7 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com