A method for electroslag remelting to prepare hollow steel ingots of nickel-based superalloys

A technology of nickel-based superalloy and electroslag remelting, which is applied in the field of metallurgy, can solve the problems of the proportion difference, inclusion and shrinkage cavity of alloy elements that cannot be prepared, so as to suppress the occurrence of macro segregation, reduce the degree of segregation and improve the yield of metal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

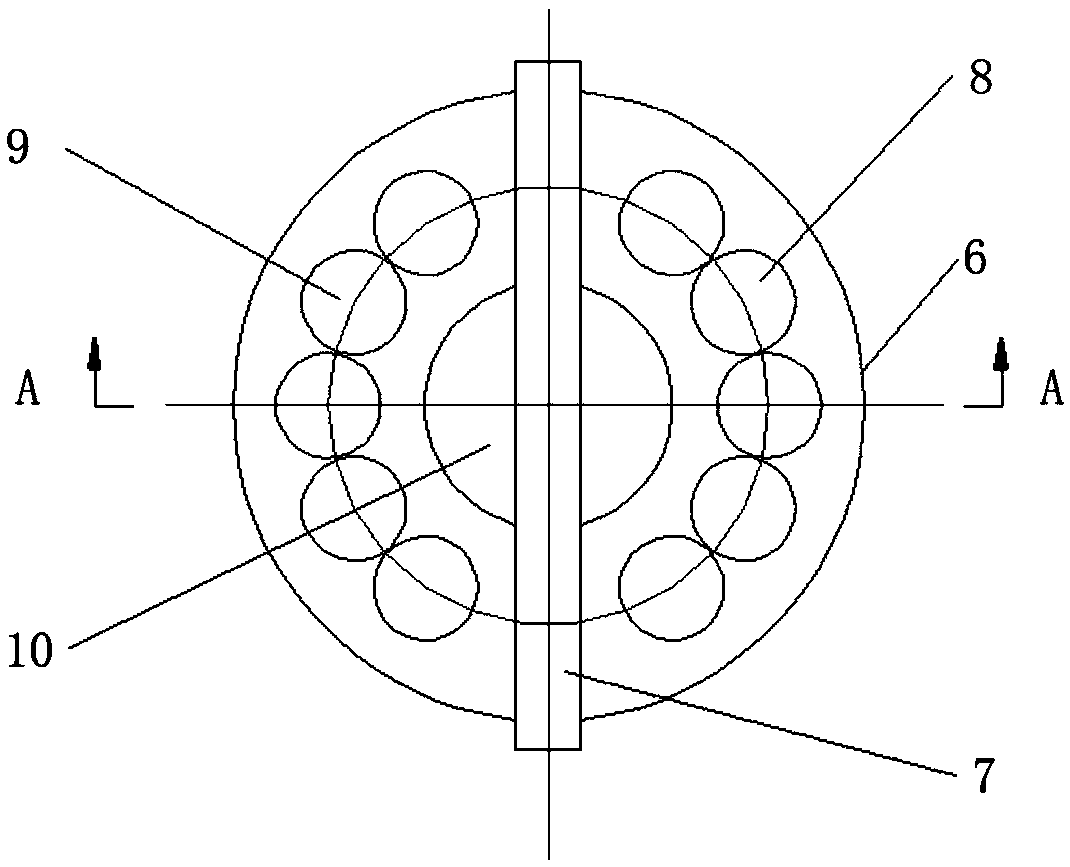

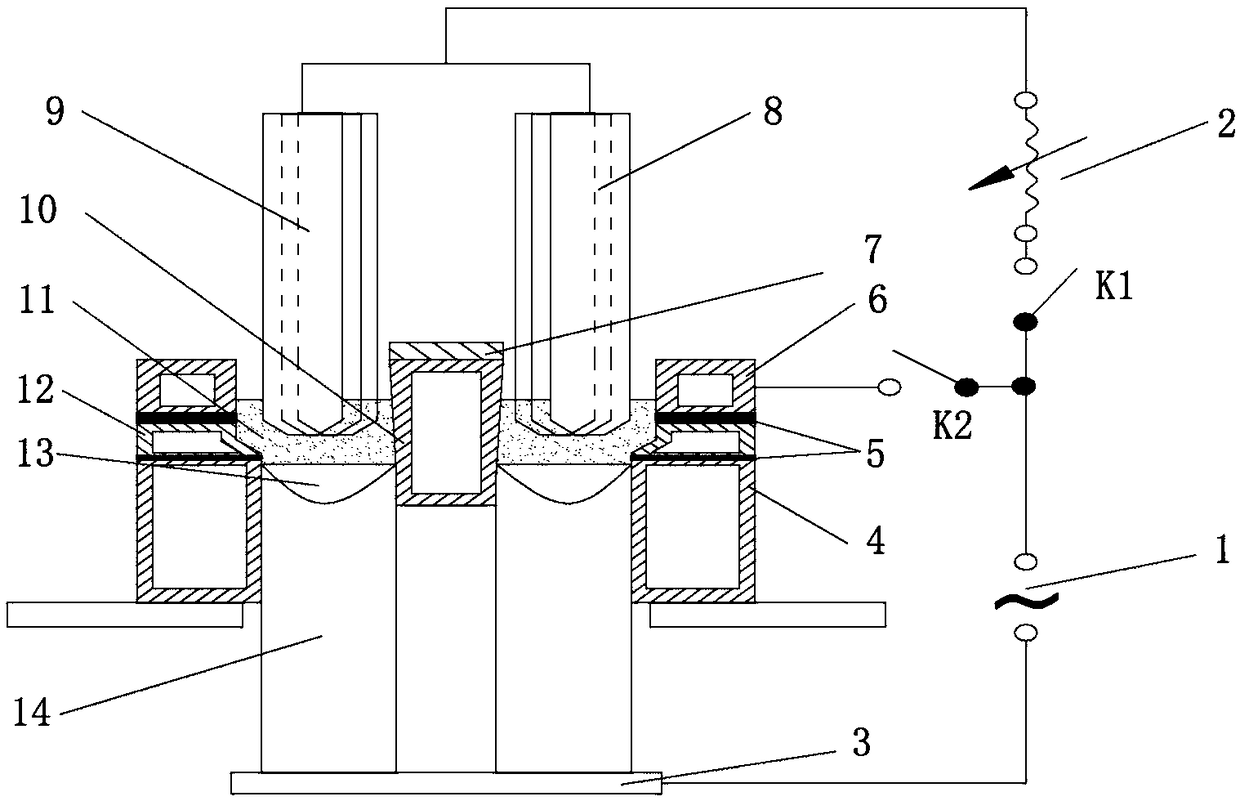

[0026] Using the electroslag remelting nickel-based superalloy hollow steel ingot equipment with a single power supply and double-circuit conductive mold as mentioned above, the following method is used to prepare the Inconel740H nickel-based superalloy hollow steel ingot. The specific steps are as follows:

[0027](1) First, prepare a plurality of Inconel740H nickel-based superalloy consumable electrode groups. The amount of each consumable electrode is 370kg. The row electrode group is left and right symmetrical;

[0028] (2) Preparation of pre-melted slag material, according to CaF 2 : 41%, Al 2 o 3 : 20%, CaO: 30%, MgO: 2.0%, TiO 2 : 5.0%, SiO 2 : 2.0% mixed and stirred evenly, melted in an electric arc furnace, refined at 1560-1580°C for 40 minutes, then cast in a cast iron pan to cool, and crushed and sieved by a crusher to get 1-10mm parts, After being bagged, it can be used in an electroslag furnace;

[0029] (3) Put the pre-melted slag into an electric resistanc...

Embodiment 2

[0037] Using the electroslag remelting nickel-based superalloy hollow steel ingot equipment with a single power supply and double-circuit conductive mold as described above, the following method is used to prepare the Inconel617B nickel-based superalloy hollow steel ingot. The specific steps are as follows:

[0038] (1) First, prepare a plurality of Inconel617B nickel-based high-temperature composite consumable electrode groups. Each electrode group consists of two parts: the right consumable electrode group 8 and the left consumable electrode group 9, so that it can be fixed by internal crystallization. the beam of the device;

[0039] (2) Pre-melted slag material, according to CaF 2 : 41%, Al 2 o 3 : 20%, CaO: 30%, MgO: 2.0%, TiO 2 : 5.0%, SiO 2 : 2.0% mixed and stirred evenly, melted in an electric arc furnace, and refined at 1550-1580°C for 50 minutes, then cast in a cast iron pan to cool, and crushed and screened by a crusher to get 1-10mm parts, After being bagged, ...

Embodiment 3

[0048] Using the electroslag remelting nickel-based superalloy hollow steel ingot equipment with a single power supply and double-circuit conductive mold as mentioned above, the following method is used to prepare a GH984G nickel-based superalloy hollow steel ingot. The specific steps are as follows:

[0049] (1) First, prepare a plurality of GH984G nickel-based superalloy consumable electrode groups, each electrode group consists of two symmetrical parts, so that it can pass through the beam that fixes the inner mold;

[0050] (2) Pre-melted slag material, according to CaF 2 : 41%, Al 2 o 3 : 20%, CaO: 30%, MgO: 2.0%, TiO 2 : 5.0%, SiO 2 : 2.0% mixed and stirred evenly, melted in an electric arc furnace, refined at 1550-1580°C for 45 minutes, then cast in a cast iron pan to cool, and crushed and screened by a crusher to get 1-10mm parts, After being bagged, it can be used in an electroslag furnace;

[0051] (3) Put the pre-melted slag into an electric resistance furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com