Forging method for high-microstructure-uniformity titanium alloy cake material

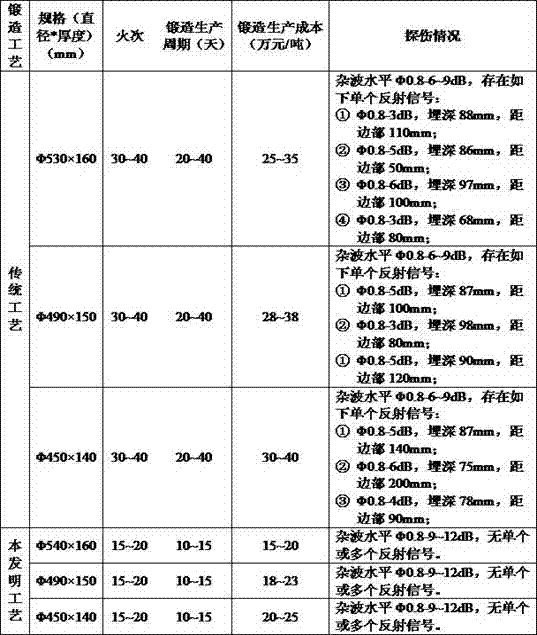

A technology of uniform structure and titanium alloy, applied in metal processing equipment and other directions, can solve the problems of poor structure uniformity, many forging times, and long production cycle, so as to improve chemical composition uniformity, reduce forging times, and save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] TC6 cake material manufacturing:

[0024] Step 1, blank forging:

[0025] Use an electric furnace to heat the ingot of Φ650mm and specification TC6 to 150°C above the β phase transition temperature, and do a high-temperature homogenization treatment for ≥20 hours, that is, heat and keep it in the high-temperature zone for not less than 20 hours. After the end, use a 45MN fast forging machine for one fire twice twice Upsetting and two-drawing forging requires uniform upsetting, the upsetting rate is controlled at 15~20mm / s, and the upsetting deformation is about 45%, so as to break the original cast structure;

[0026] Step 2, intermediate forging:

[0027] Step 2.1. The TC6 forging billet completed in Step 1 is subjected to two-upsetting and two-drawing forging three times at 30-100°C above the β-phase transition temperature. In the case of obvious cracking, the hot material is returned to the furnace for 2 times of continuous forging, and the thermal insulation coeff...

example 2

[0034] Example 2 Manufacturing of TC11 cake material:

[0035] Step 1, blank forging:

[0036] Heat the ingot of Φ550mm size TC11 to 1200°C in an electric furnace, and do high-temperature homogenization treatment for more than or equal to 20 hours, that is, heat and hold in the high-temperature zone for not less than 20 hours. It is required to upsetting at a uniform speed, the upsetting rate is controlled at 15~20mm / s, and the upsetting deformation is controlled at 40~45%, so as to break the original cast structure;

[0037] Step 2, intermediate forging:

[0038] Step 2.1. The TC11 forging blank completed in step 1 is subjected to two-upsetting and two-drawing forging at 30-100°C above the β-phase transition temperature for 2-3 times. In the case of no obvious cracks on the surface, the hot material is returned to the furnace for 2~3 times of continuous forging. The thermal insulation coefficient of the hot material is 0.4~0.5; Controlled at 15~20mm / s, the final forging te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com