Low-cost efficient preparation method for two-phase titanium alloy round rod

A titanium alloy, low-cost technology, applied in the field of low-cost and high-efficiency preparation of two-phase titanium alloy round rods, can solve the problems of long forging processing routes, large material losses, and high costs of standard round rods, and improve processing technology and yield , reduce the invisible loss of materials, and compress the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

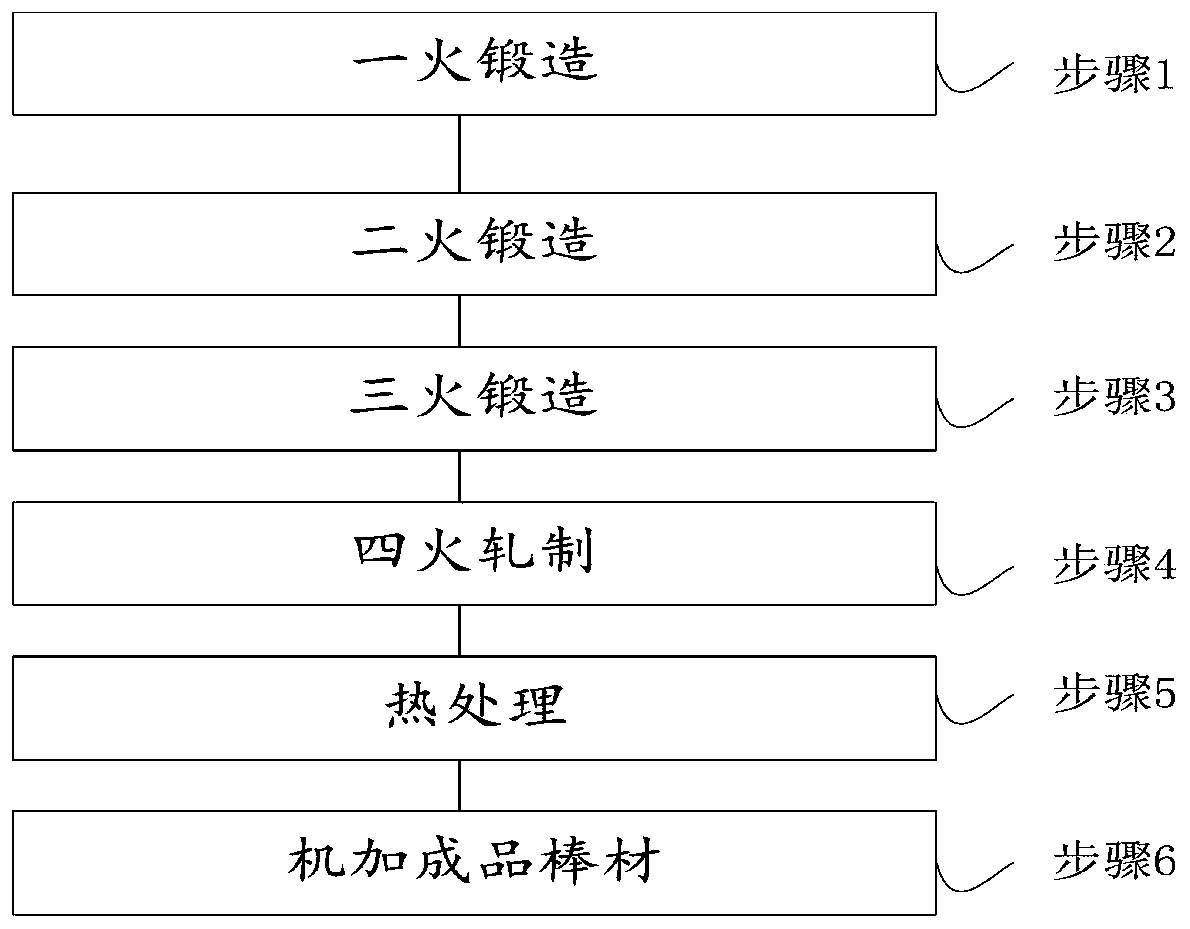

[0038] See Figure 1-Figure 7 . The embodiment of the present invention provides a low-cost and high-efficiency preparation method for a two-phase titanium alloy round rod, which includes the following steps:

[0039] Step 1, one fire forging:

[0040]Take the columnar ingot and place it in a box-type resistance furnace, heat it, and carry out upsetting and drawing forging for three times. After the last upsetting and drawing, forge and press the four edges in the long direction, and then take it out and air-cool it to obtain a rectangular parallelepiped with a regular octagonal cross section. forged billet.

[0041] Among them, the ingot is a two-phase titanium alloy ingot that has undergone vacuum self-consumption melting for three times. The weight of the ingot is 2800kg-3200kg, the cross-sectional diameter of the ingot is 590mm-610mm, and the ingot is cut into several equal parts. 510mm, the weight of a single ingot is about 650kg.

[0042] The ingot heating temperatur...

Embodiment 2

[0061] Take a Ф590×505 ingot, and measure the phase transition point T of the ingot β =995°C, put it in a box-type resistance furnace, and perform the first fire forging process: first forge a billet of (420×420×780)mm, and then pass through (420×420×780)mm→(560×560× 438)mm three-upsetting and three-drawing forging, the heating temperature of the ingot is 1150°C, and the holding time is 340min. After the last upsetting and drawing forging is completed, the drawing and drawing are directly carried out, and the four edges in the long direction are forged. The size of the cuboid is: the cross section is square The side length of the polygon is 152mm, the length of the cuboid is 1240mm, the final forging temperature is 885°C, air-cooled after forging, the length direction is divided into 620mm, and the first forging blank of (octagonal shape 152×620)mm is obtained.

[0062] Polish the oxide skin on the surface of the first forging billet, place it in a box-type resistance furnace,...

Embodiment 3

[0068] Take a Ф595×510 ingot, and measure the phase transition point T of the ingot β =988°C, placed in a box-type resistance furnace, for the first fire forging process: first forge a billet of (430×430×767) mm, and then pass through (430×430×767) mm→(565×565× 444)mm three-upsetting and three-drawing forging, the heating temperature of the ingot is 1130°C, and the holding time is 340min. After the last upsetting and drawing forging is completed, the drawing-length forging is directly carried out, and the four edges in the long direction are forged. The size of the cuboid is: the cross-section is square The side length of the polygon is 156mm, the length of the cuboid is 1210mm, the final forging temperature is 870°C, air-cooled after forging, the length direction is divided into 605mm, and the first forging blank of (octagonal shape 156×605)mm is obtained.

[0069] Polish the oxide skin on the surface of the first forging billet, place it in a box-type resistance furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com