Assembling box for green roof and assembled intelligent green roof

An assembly box and assembly technology, applied in roof drainage, roof insulation materials, roofing and other directions, can solve the problems of rotten roots of roof plants, a lot of labor, uneven construction products, etc., to avoid rotten roots of plants, save labor, Avoid uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

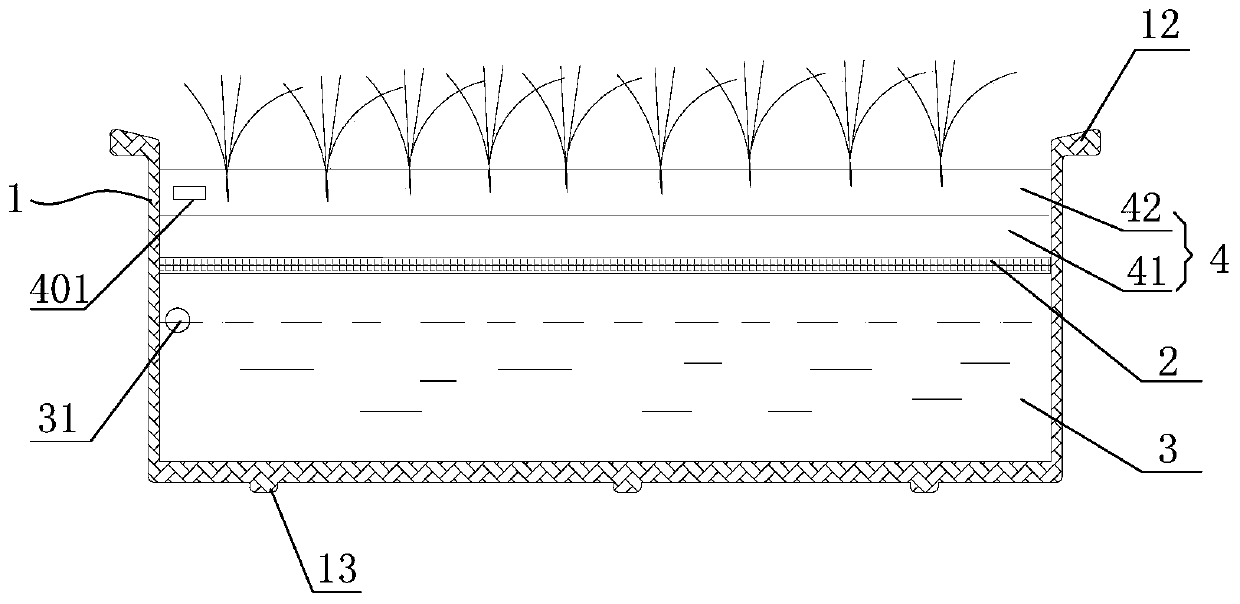

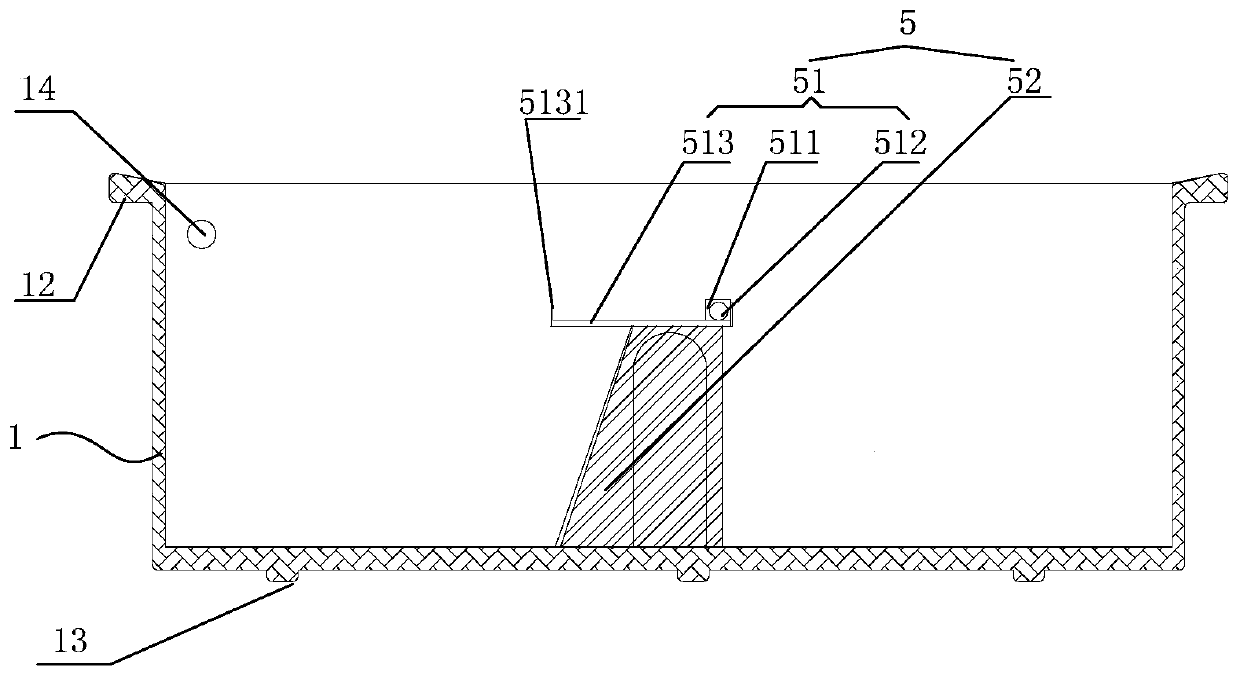

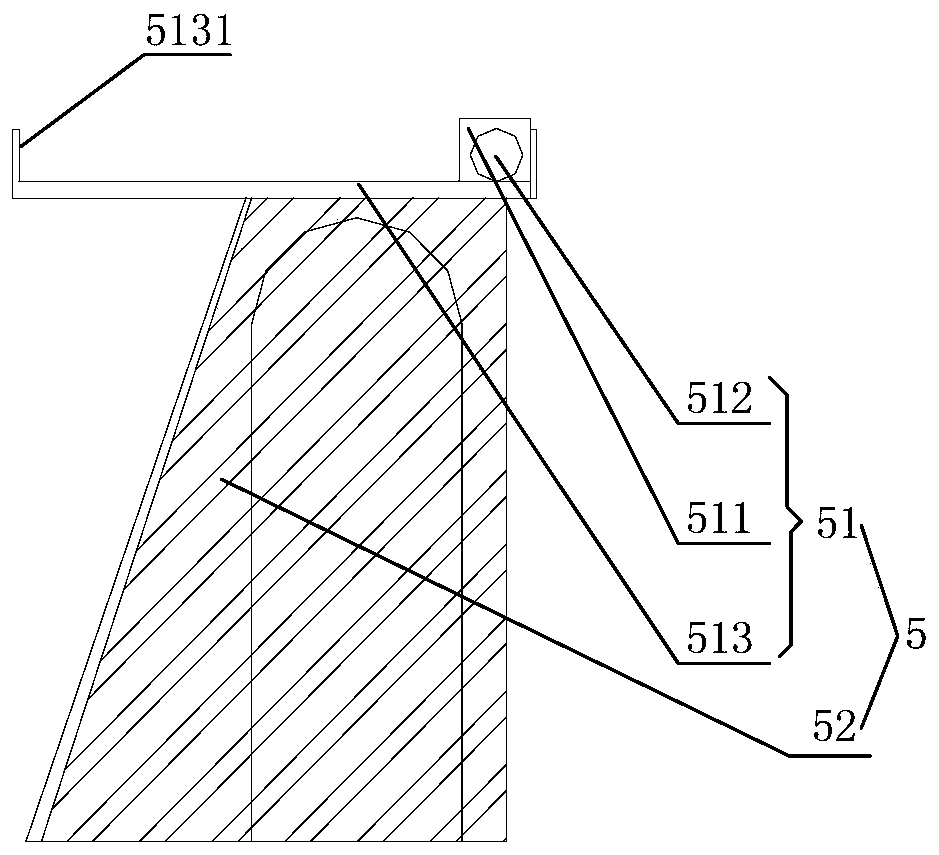

[0045] This embodiment provides an assembly box for a green roof, please refer to figure 1 with figure 2 , the green roof assembly box includes a box 1; in the box 1, a drainage board 2 is installed; in the box 1, the space below the drainage board 2 forms an aquifer 3, and in the box 1, the drainage board 2 The space above forms the planting layer 4; the drainage board 2 can drain the excess water in the planting layer 4 to the aquifer 3; the box body 1 is provided with a water outlet 11 that communicates the aquifer 3 with the external environment; The inside of the water layer 3 is provided with a water level sensor 31; and a water output adjustment mechanism 5 is installed on the box body 1, and the water output adjustment mechanism 5 is connected with the water level sensor 31, and is configured to receive the water storage according to the water level sensor 31. The signal adjusts the water output of the water outlet hole 11.

[0046] In particular, the above-mentione...

Embodiment 2

[0061] This embodiment provides a prefabricated smart green roof, which includes a box fixing bracket 6 and an assembly box for the green roof;

[0062] The assembly box for the green roof includes a box body 1; a drainage board 2 is installed in the box body 1; The space in the space forms the planting layer 4; the drainage board 2 can drain the excess water in the planting layer 4 to the water storage layer 3; the box body 1 is provided with a water outlet 11 that connects the water storage layer 3 with the external environment; A water level sensor 31 is provided inside the layer 3; and a water output adjustment mechanism 5 is installed on the tank body 1, and the water output adjustment mechanism 5 is connected to the water level sensor 31, and is configured to receive the water storage amount signal sent by the water level sensor 31. Regulate the water output of the water outlet hole 11; especially, the aforementioned drainage board 2 can be formed as a structure with dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com