Glass single-side thinning method and glass thinning equipment

A glass thinning and equipment technology, applied in the field of glass single-sided thinning method and glass thinning equipment, can solve the problems of affecting the thinning quality, uneven glass thinning, uneven etching, etc., to avoid uneven thinning treatment Uniformity, wide processing range and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

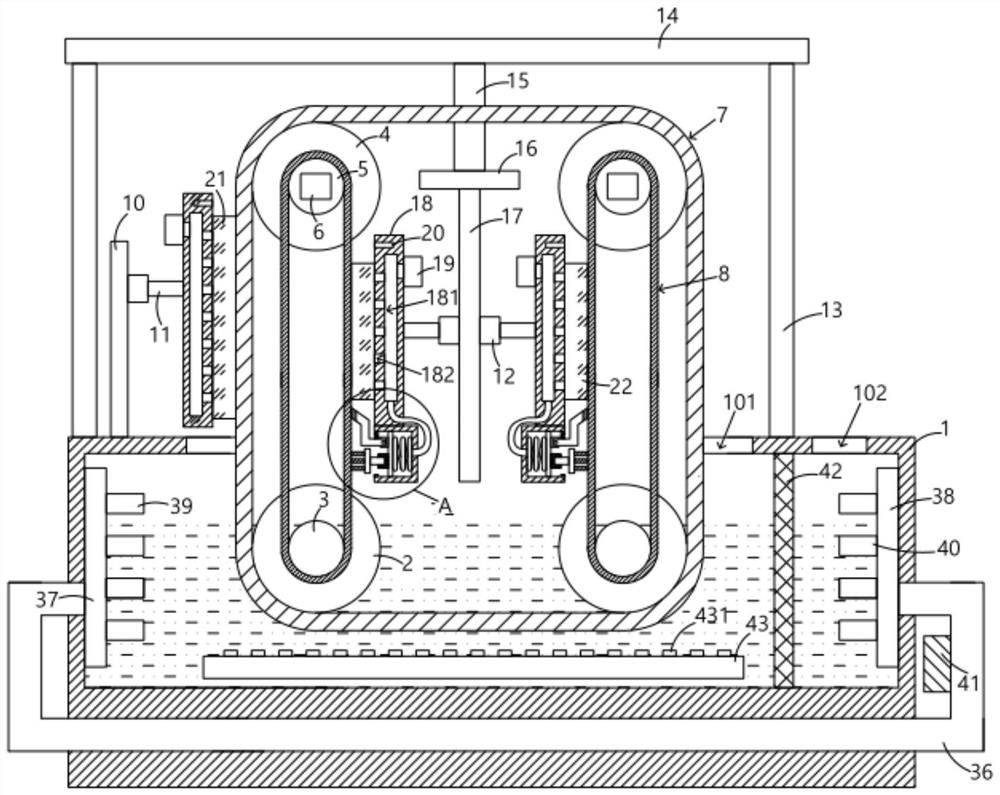

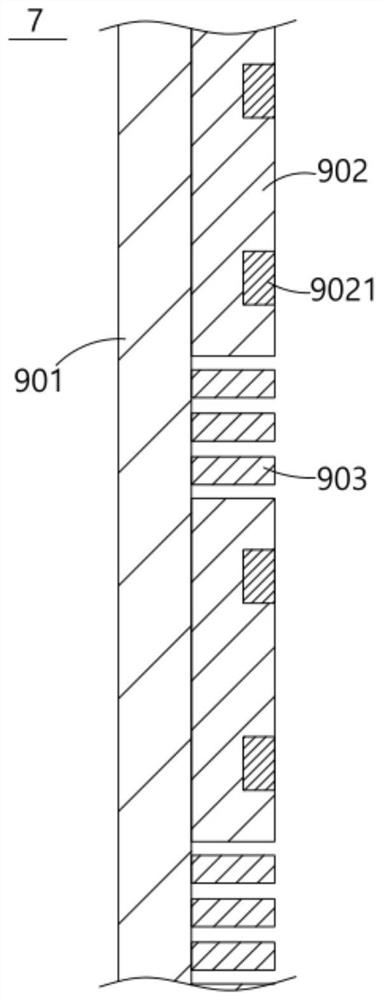

[0038] A glass thinning device, comprising a box body 1, the top of the box body 1 is provided with an operation port 101, the first water-absorbing transmission belt 7 and its internal structure are all arranged in the operation port 101, and the inner cavity of the box body 1 is symmetrically hinged. There is a lower external gear 2, the center of the lower external gear 2 is fixedly provided with a lower internal gear 3, the upper part of the lower external gear 2 is vertically provided with an upper external gear 4, and the center of the upper external gear 4 is fixedly provided with an upper internal gear 5, In this embodiment, the diameter of the lower external gear 2 is greater than the diameter of the lower internal gear 3, the diameter of the upper external gear 4 is greater than the diameter of the upper internal gear 5, and the upper internal gear 5 can be driven to rotate by the driving motor 6. In this embodiment , the drive motor 6 is a motor that can rotate in bo...

Embodiment 2

[0042] On the basis of Embodiment 1, this embodiment further defines and discloses the specific structure of the support device: the support device includes uprights 13, and there are two uprights 13 fixedly arranged on the top of the box body 1, the uprights 13 An integrated horizontal plate 14 is fixedly arranged on the top, an extension plate 15 is fixedly arranged below the horizontal plate 14, and an installation platform 16 is fixedly arranged below the extension plate 15. The installation platform 16 has a large area and is located on the second water-absorbing transmission belt 8 In the enclosed area, the bottom of the installation platform 16 is fixedly provided with a bearing plate 17, and the non-piston rod ends of the second cylinder 12 are all fixedly arranged on the bearing plate 17, where the two second cylinders 12 are arranged oppositely, and can Independent control, so the glass can be thinned according to different requirements. The side of the adsorption pla...

Embodiment 3

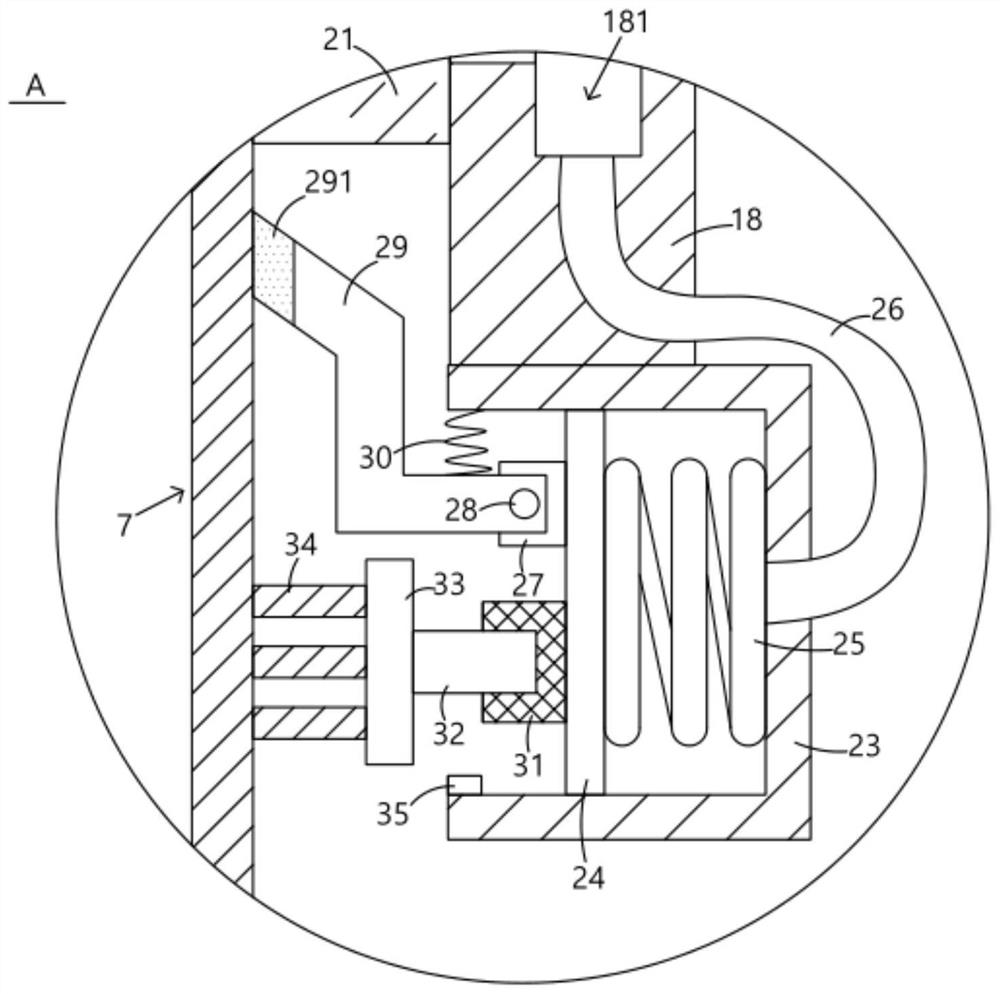

[0044] On the basis of Embodiment 1, this embodiment further defines and discloses the specific structure of the dust scraping device: the dust scraping device includes a base block 27, on which a rotating shaft 28 is fixedly arranged, and on the rotating shaft 28 is hingedly arranged There is a scraper 29, and the end of the scraper 29 away from the rotating shaft 28 is provided with a silica gel segment 291. The quality of the silica gel segment 291 is softer, which can avoid damage to the second water-absorbing transmission belt 8 in the process of scraping off impurities. The scraper 29 and the operation A compression spring 30 is connected between the inner walls of the frame 23, so that the scraper 29 can rotate around the rotating shaft 28 in a small range, and its function is to further protect the second water-absorbing transmission belt 8 from being scratched and damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com