Forging method of battery pole piece roll blank

A battery pole piece and roll technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of raw material waste, increase the waste of forging secondary energy, increase production costs, etc., to reduce the waste of raw materials, and not produce shoulder cuts. The effect of surplus material and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] by figure 1 Shown product is example, and new forging method of the present invention is:

[0027] (1) Elongate the roll blank to a diameter of 650mm. At this time, the diameter of the roll blank is smaller than the technical diameter of the roll body; the technical diameter of the roll body is the diameter of the blank of the roll body required by the forging process;

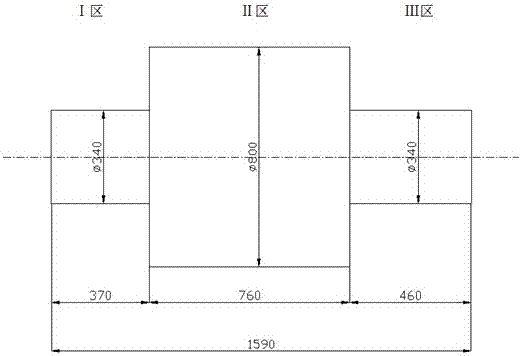

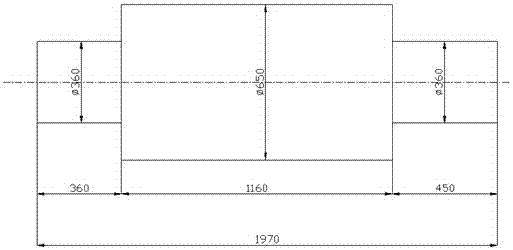

[0028] (2) Cut the shoulders of the rolled billets after the elongation, and forge the roll necks at both ends after the shoulders are cut, such as figure 2 shown;

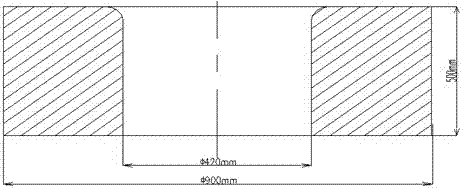

[0029] (3) Use the upper and lower upsetting leaky discs to locally upset the roll body to a diameter of 950mm. At this time, the diameter of the roll body is larger than the process diameter of the roll body; the structure of the upsetting leaky disc is as follows image 3 As shown, it is an upsetti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com