A multi-functional high-efficiency lubricating oil purification process device

A technology for purifying device and lubricating oil, applied in the direction of lubricating composition, etc., can solve problems such as premature aging of oil, equipment failure, inability to clean, etc., and achieve the effect of prolonging service life, improving efficiency and improving oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

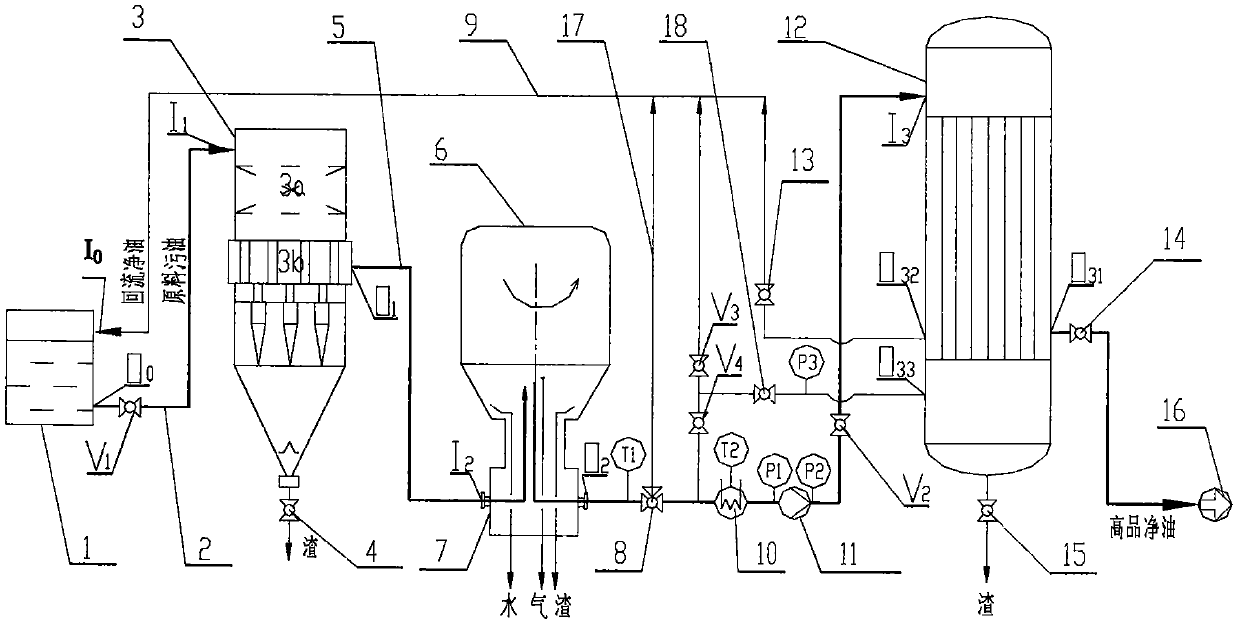

[0062] 1.2m from the power plant 3 The polluted 36# turbine oil is put into the oil storage tank 1, and under the action of the negative pressure pump in the centrifuge 6, the 3 The flow rate of / h flows into the magnetic cyclone 3 through the suction pipe 2 for initial slag removal, and then enters the centrifuge 6 through the first connecting pipe 5, and separates at a speed of 8000-12000r / min. The separated oil From outlet O of centrifuge 6 2 Return to the oil storage tank 1 through the first circuit and circulate and purify again. After running like this for 30 minutes, stop the machine and take samples for detection. Filter out 12.5 grams of coarse slag from the sewage valve 4 of the slag discharge port of the magnetic cyclone 3. 85.2 grams of water and slag were taken out from 7 places. After testing, the pollution degree of the oil decreased from 12 to 8, the water content decreased from 0.6% to 0.005%, the dissolved gas content decreased from 2% to 0.15%, and the chr...

Embodiment 2

[0064] 1.5m from the rolling mill of the iron and steel plant 3 The contaminated 525 rolling mill oil is put into the oil storage tank 1, and under the action of the negative pressure pump in the centrifuge 6, the 3 The flow rate of / h flows into the magnetic cyclone 3 through the suction pipe 2 for initial slag removal, and then enters the centrifuge 6 through the first connecting pipe 5, and separates at a speed of 8000-12000r / min. The separated oil Switch to the heater 10 through the three-way valve 8, after being heated by the heater to 30-80°C, pressurized by the circulation pump 11, and go to the fine filter 12, and the finely filtered oil flows from the liquid outlet O of the fine filter 32 Return to the oil storage tank 1 through the second circuit for circulation treatment, after running for 60 minutes like this, stop and take a sample for detection, filter out 15.2 grams of coarse slag from the blowdown valve 4 of the slag discharge port of the magnetic cyclone 3, an...

Embodiment 3

[0066] Take Steel Plant BP46#1.2m 3 The contaminated 525 hydraulic oil is put into the oil storage tank 1, and under the action of the negative pressure pump in the centrifuge 6, it is 3 The flow rate of / h flows into the magnetic cyclone 3 through the suction pipe 2 for initial slag removal, and then enters the centrifuge 6 through the first connecting pipe 5, and separates at a speed of 8000-12000r / min. The separated oil Switch to the heater 10 through the three-way valve 8. After being heated to 30-80°C by the heater, the circulation pump 11 pressurizes and goes to the fine filter 12. Liquid port O 32 Return to the oil storage tank 1 through the second loop for circulation treatment, and the other path passes through the liquid outlet O of the fine filter 12 33 Regulate the reflux pressure P3 through the reflux valve 18 to control the total reflux flow, and then return to the reflux pipe 9 and the heater 10 through the check valves V3 and V4. After running for 60 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com