Fabrication process for energy storage spring conductor rod

A production process and technology of energy storage springs, which are applied in metal processing equipment, power devices inside switches, electrical components, etc., can solve the problems of high technical requirements and difficult manufacturing of energy storage spring guide rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

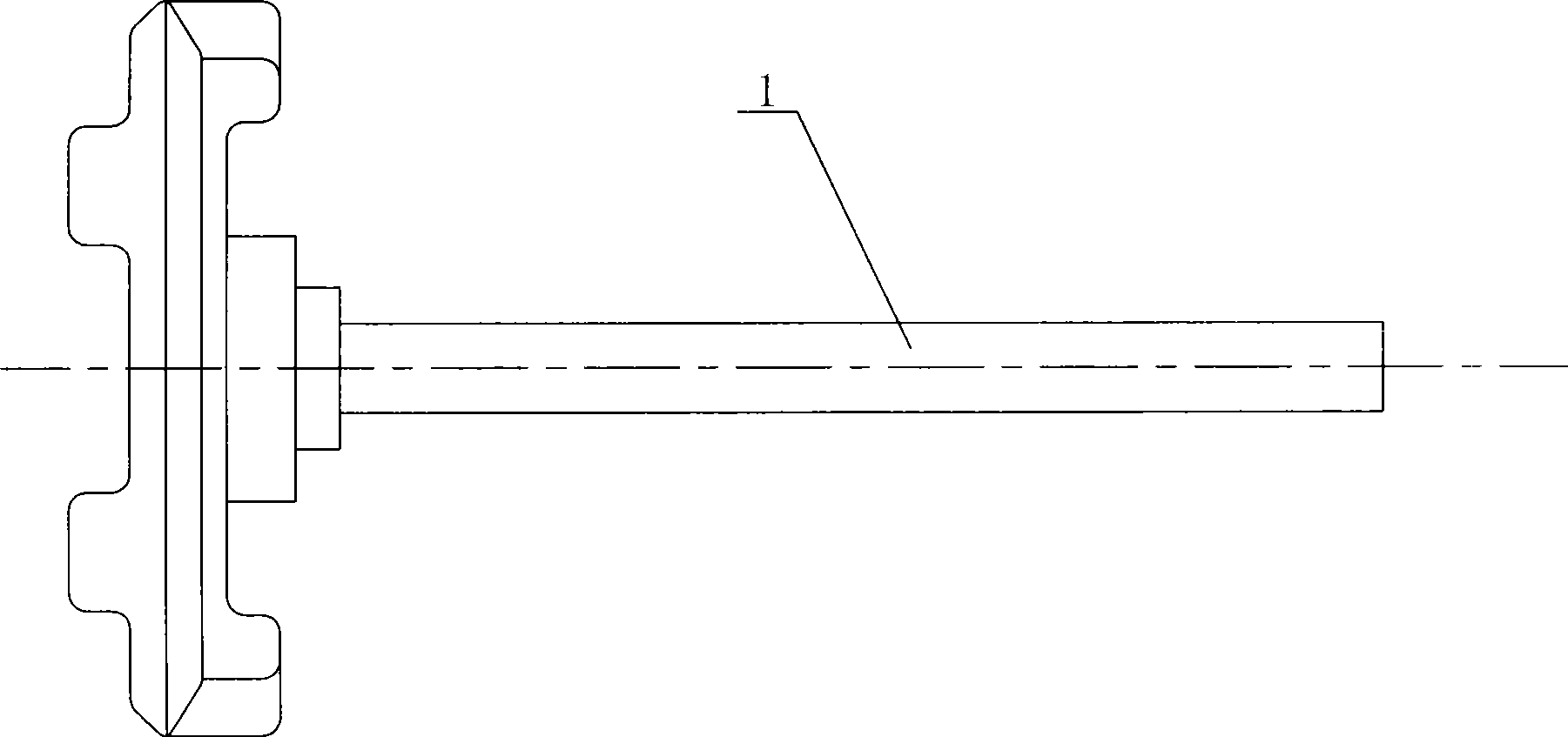

[0010] Reference attached figure 1 The energy storage spring guide rod is a combined forging with insert 1, the body material is brass of CuZn39Pb2, and the insert 1 is a stainless steel rod made of 1Cr18Ni9Ti-Q. The manufacturing process of the guide rod is: first, copper material According to a certain weight requirement, the material is cut on the sawing machine. The stainless steel rod is first turned and then groundlessly; then the copper material is heated in an intermediate frequency induction furnace, and the heating temperature is controlled at 700~750℃; then the stainless steel rod Place it on the lower mold of the mold, then put the heated copper material, and at the same time heat the mold through the carbon silicon rod, keep the mold temperature at 250-300℃, and forge the copper material and stainless steel rod together on a 200-ton punch. Two guide angle locks are designed on the mold, and the fit gap of the upper and lower mold locks is controlled within 0.02~0.05mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com