Copper alloy die machining device and machining process

A mold processing and copper alloy technology, applied in the field of mechanical equipment, can solve the problems of low production efficiency, large consumption of profiles, high production cost, etc., and achieve the effects of high production efficiency, low production cost and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Processing YSW lead-free DR copper alloy faucet square body casting as an example:

[0028] YSW lead-free DR copper alloy faucet square body casting,

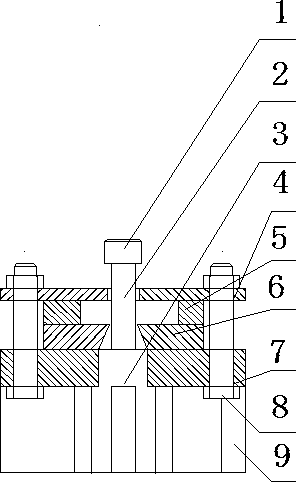

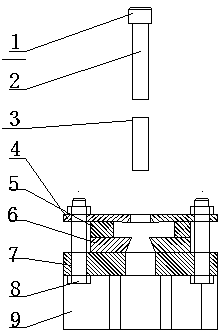

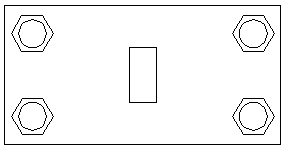

[0029] The mold installation adopts the coincidence of the pressure center and the center line of the hydraulic power mold shank to fix the lower mold base, which effectively eliminates the error caused by the bending moment movement of the blank during the cutting process. The structure of the mold processing device is as follows: figure 1 , 2 , 3, 4", this copper alloy mold processing device is divided into the upper part and the lower part, the upper part includes: hydraulic power mold handle 1, pressurized movable copper punch 2; the lower part includes: The upper fixed guide plate 4 , the chip discharge pad 5 , the cutting edge die 6 , the lower fixed cutting edge cushion 7 , the fixing bolts and nuts 8 , and the workpiece discharge cavity support 9 .

[0030] The upper fixed guide plate 4, the chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com