Patents

Literature

75results about How to "Guaranteed technical requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

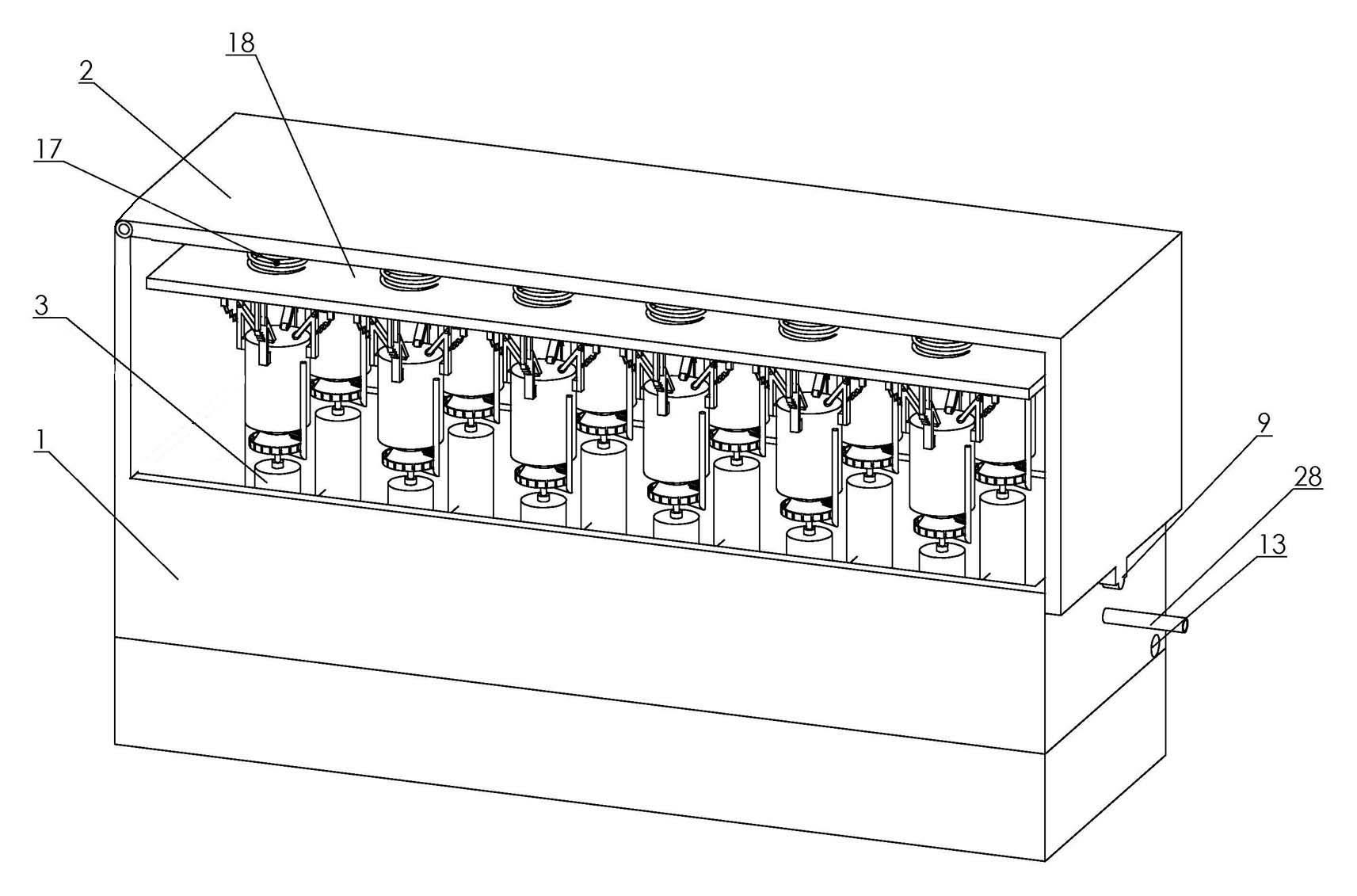

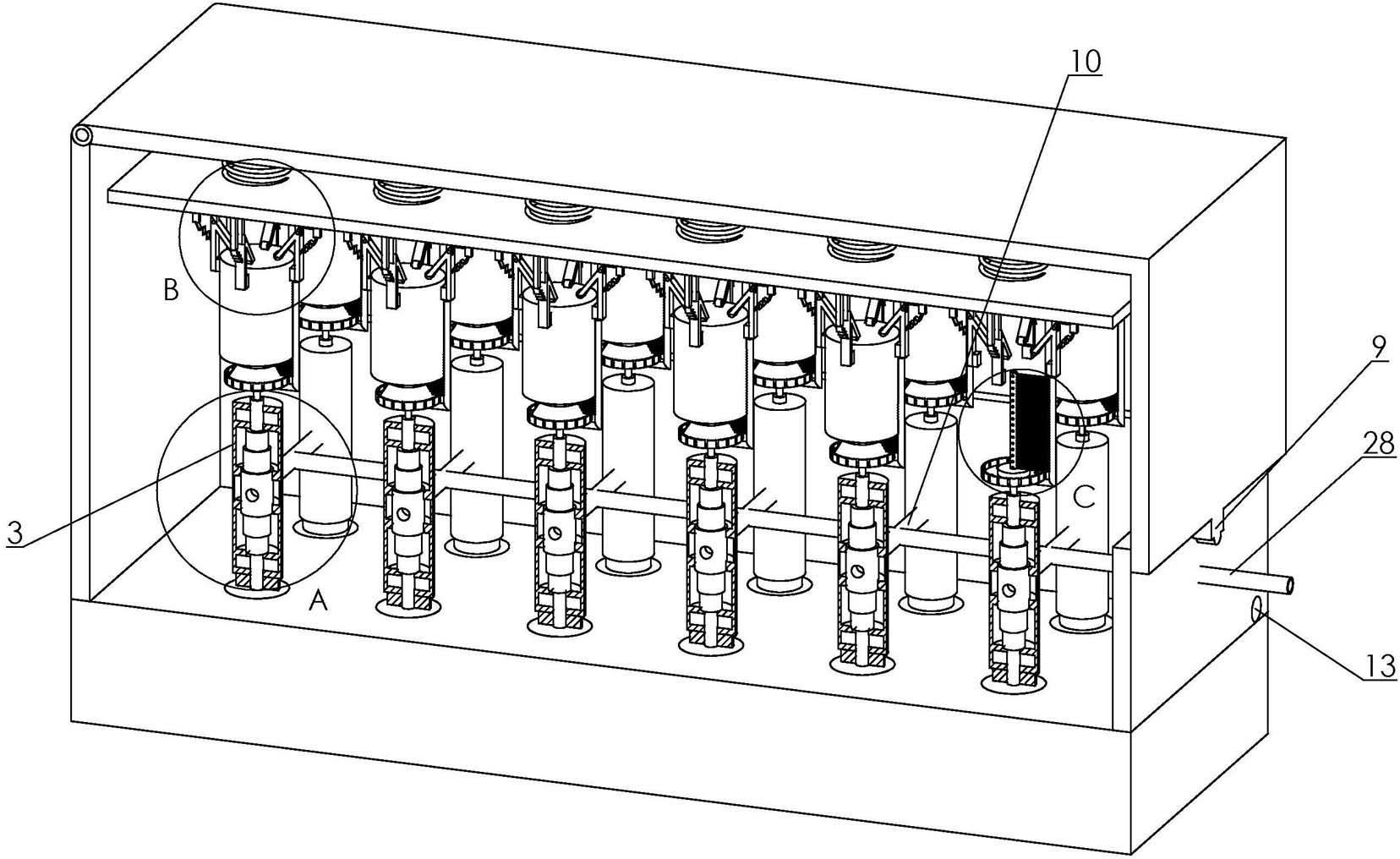

Automatic efficient bottle washer

ActiveCN102580969AGuaranteed washing cleanlinessReduce consumptionHollow article cleaningDistilled waterProcess engineering

The invention relates to an automatic efficient bottle washer, which comprises a cleaning device, a pressing device, a transmission device and a waterway control device. The automatic efficient bottle washer can be used for batch washing of bottle-like utensils, and washing effect is guaranteed while operating efficiency is improved by means of standard flow control and automatic mechanical operation during use. The automatic efficient bottle washer is convenient in operation, effective in cleaning and small in occupied area, and normal washing water and distilled water are driven by different water pumps.

Owner:STATE GRID CORP OF CHINA +1

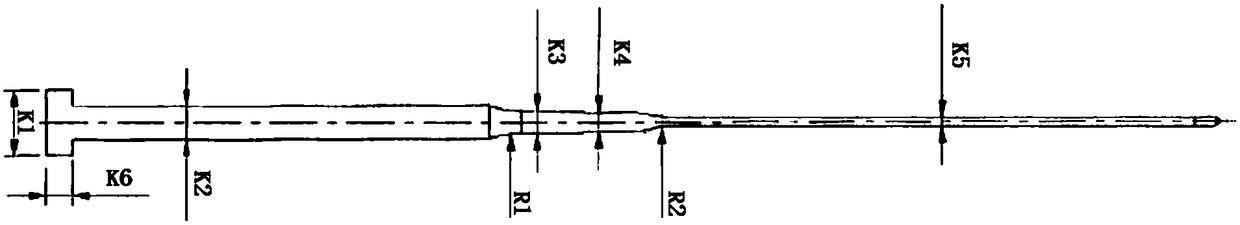

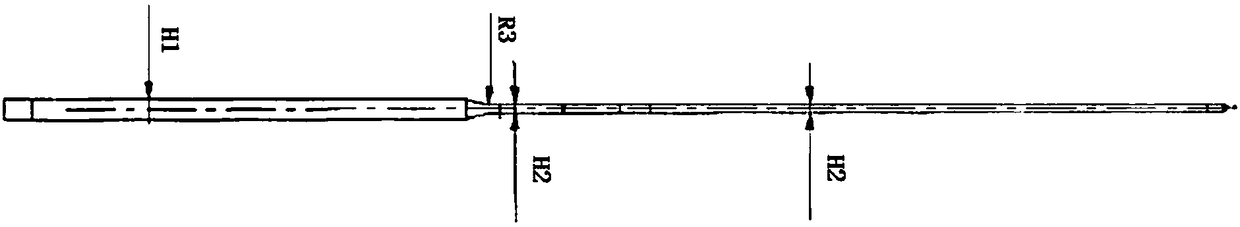

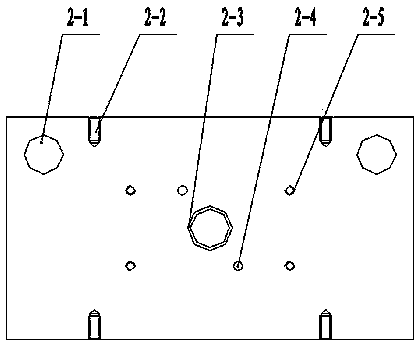

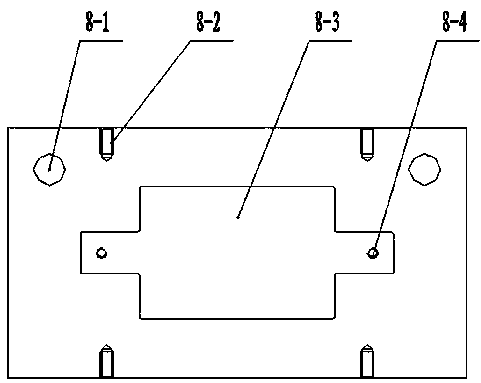

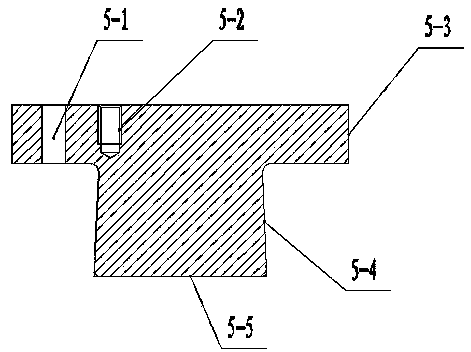

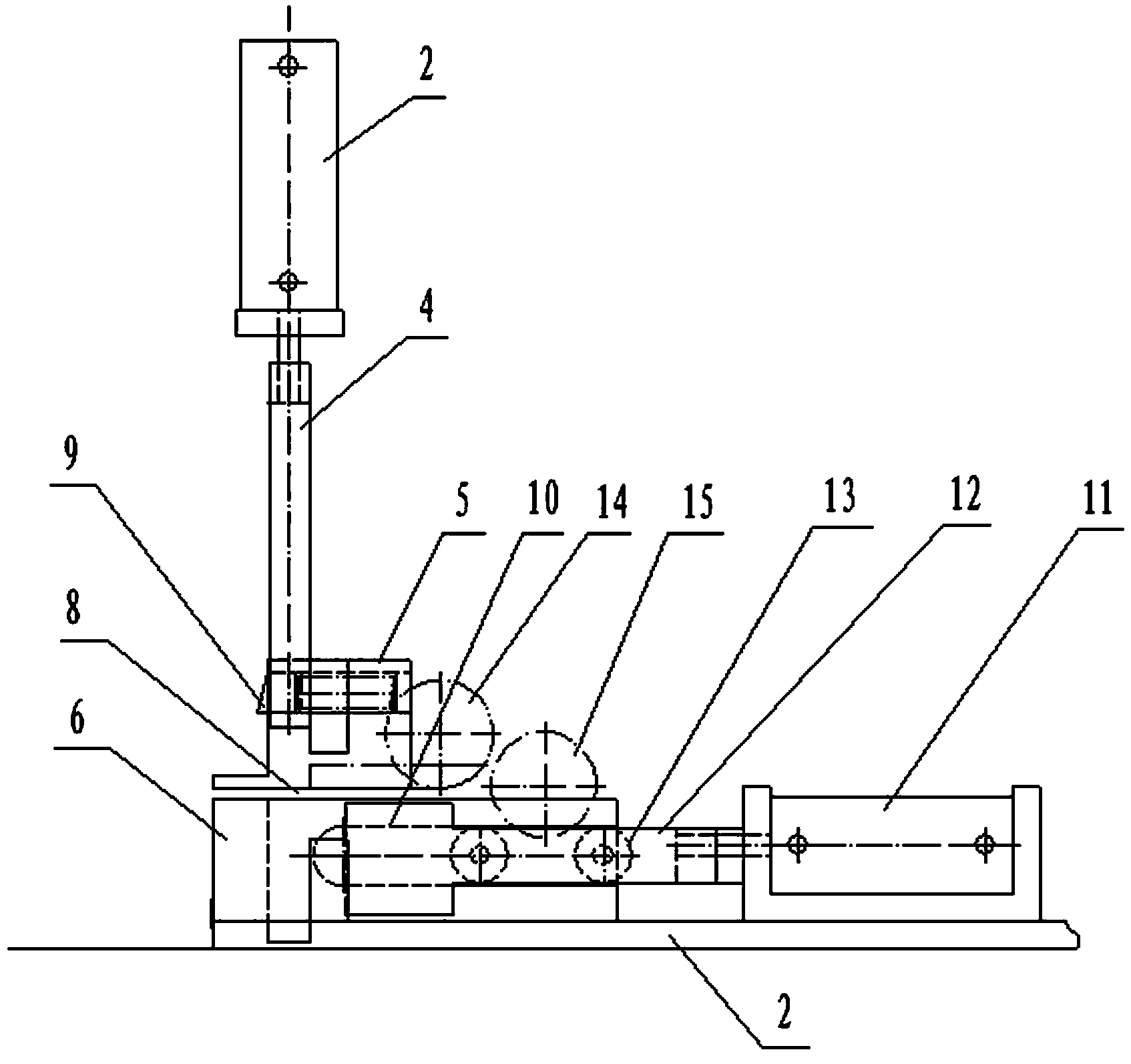

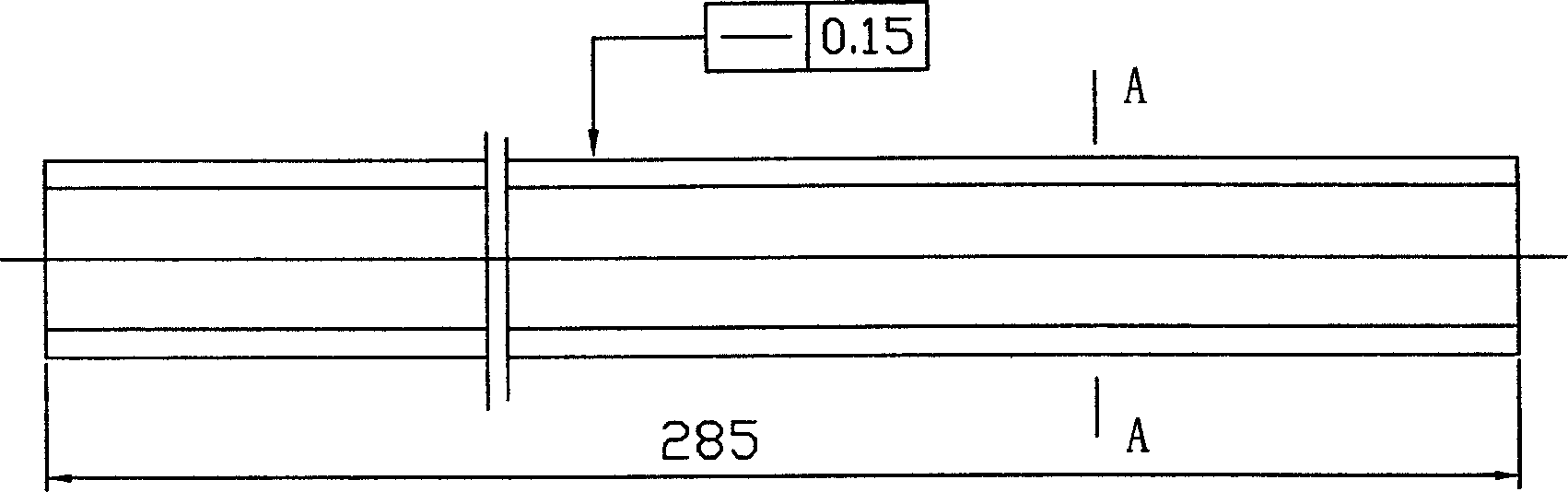

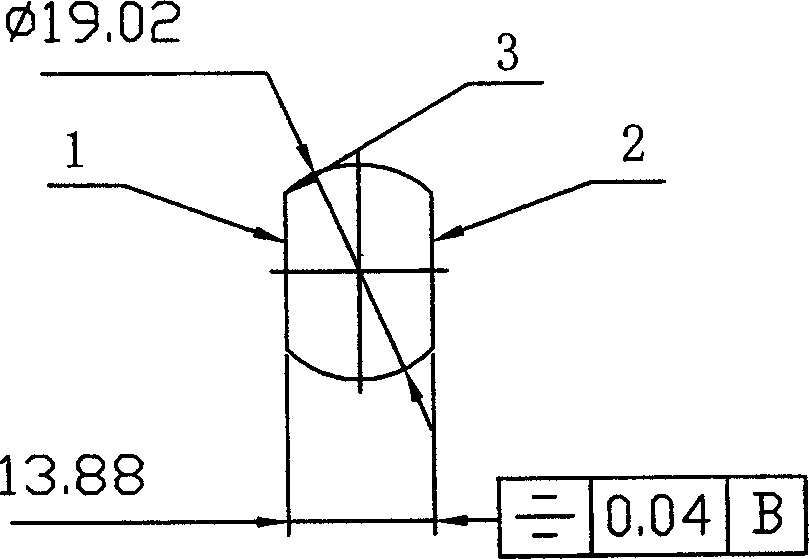

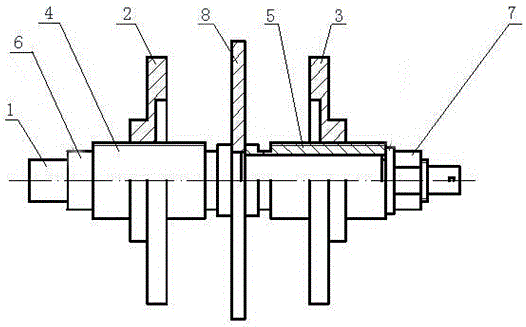

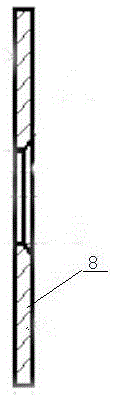

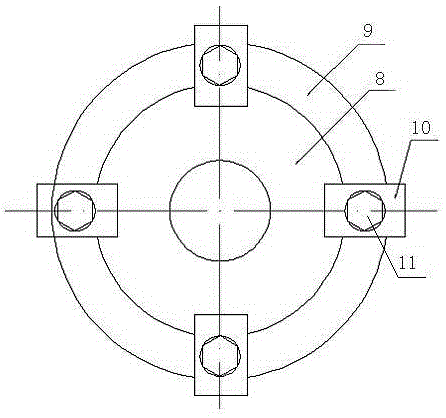

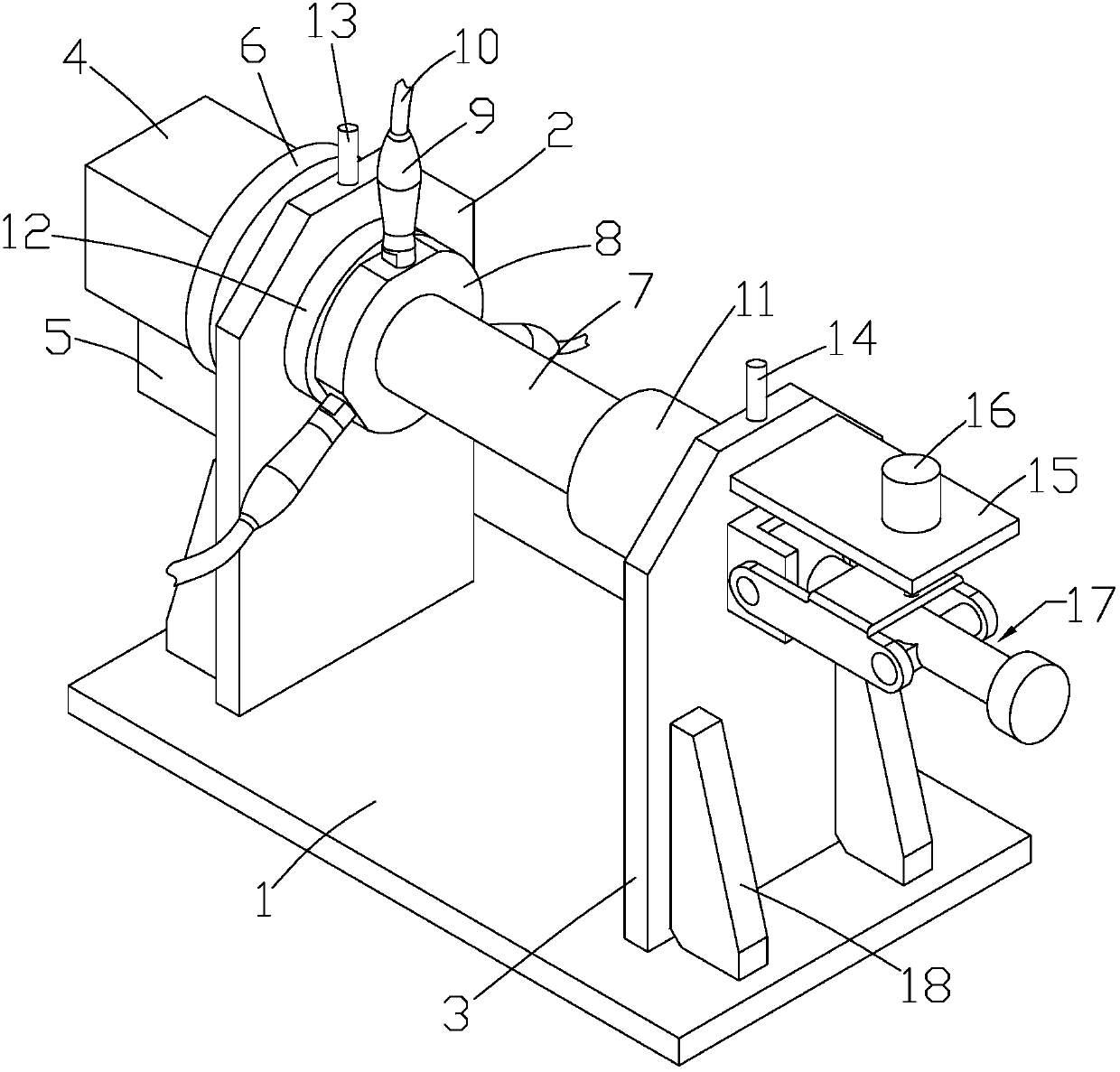

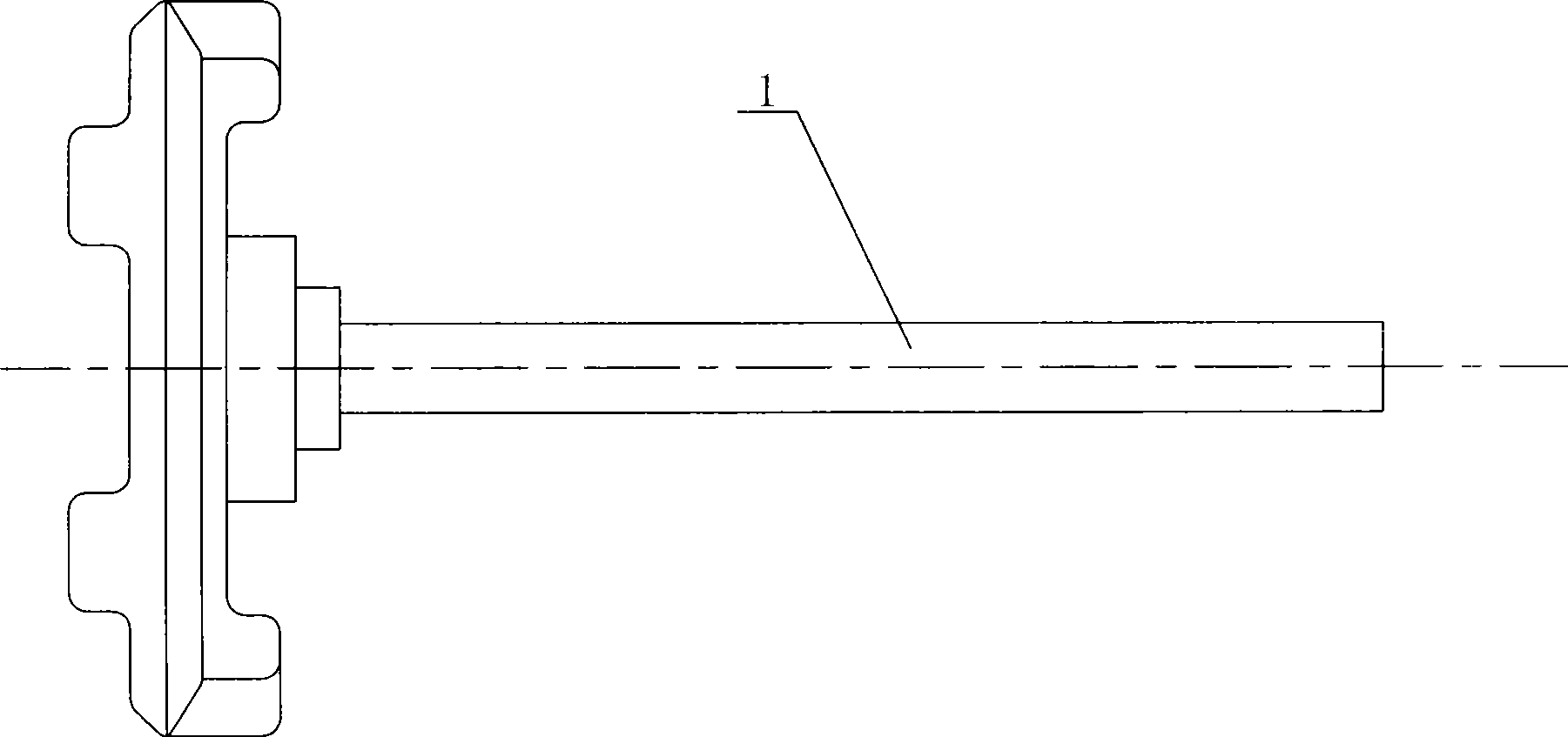

Method and system for machining slender molded contact pin of glasses leg

PendingCN108436605ASolve the problem that it is difficult to guarantee its technical requirementsSimple processing technologyPolishing machinesRevolution surface grinding machinesMachining systemMachining process

The invention belongs to the eyewear industry and particularly relates to a machining technology for a slender molded contact pin of a glasses leg. A system for machining the slender molded contact pin of the glasses leg is adopted to perform a series of fine machining including plane abrasion, polishing and the like on all parts of a product. The machining process and system are simple, and the machining method is feasible and can guarantee technical requirements. Not only is the problem that a domestic contact pin is difficult to guarantee the technical requirements solved, but also the machining difficulty and the production cost are reduced. More enterprises in China can produce the product that meets the technical requirements. Thus, the product is more competitive in the market.

Owner:PUNCH IND DALIAN

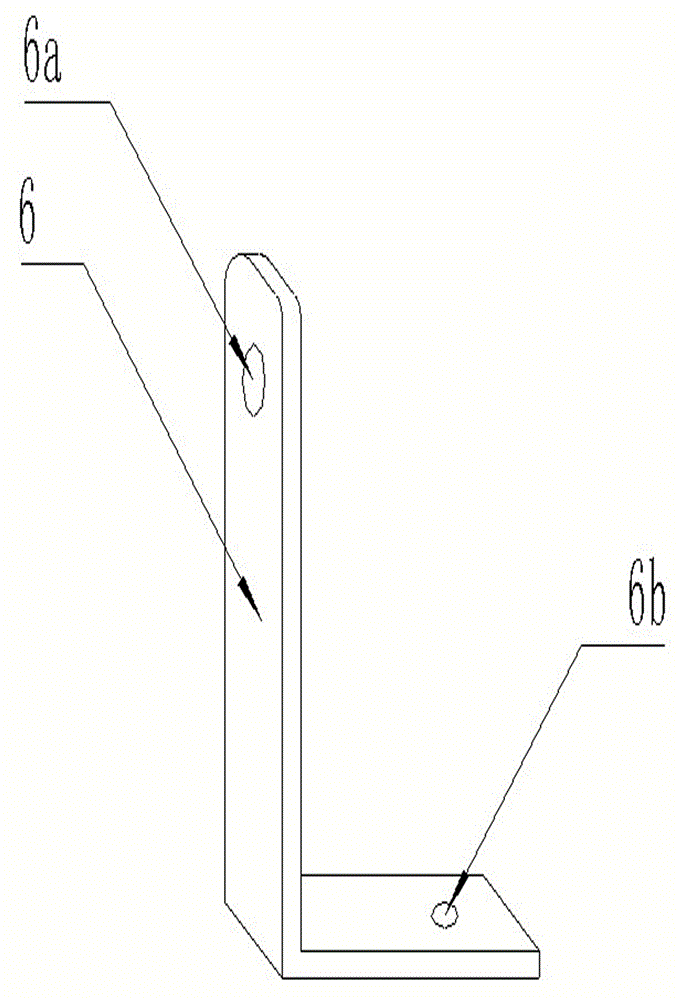

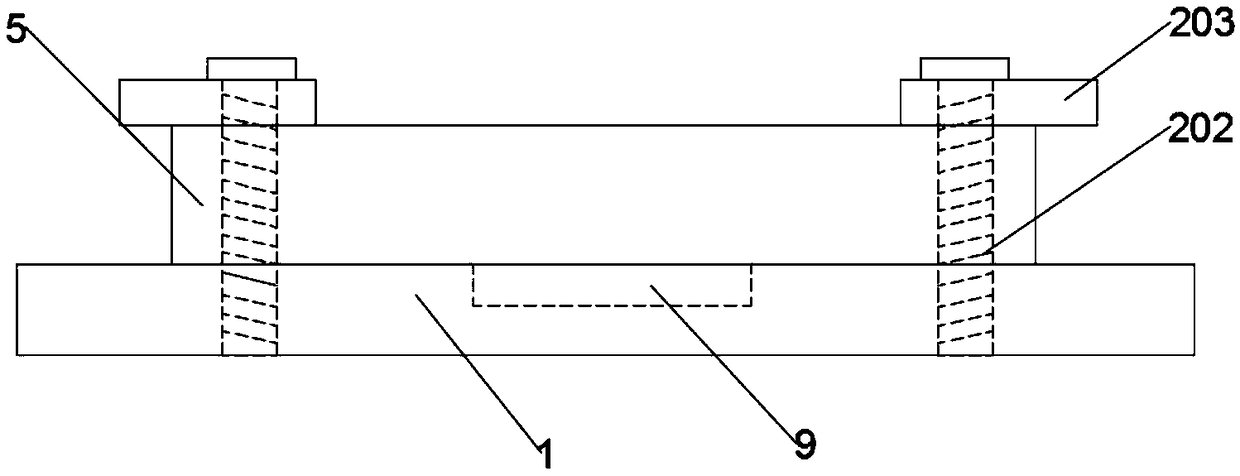

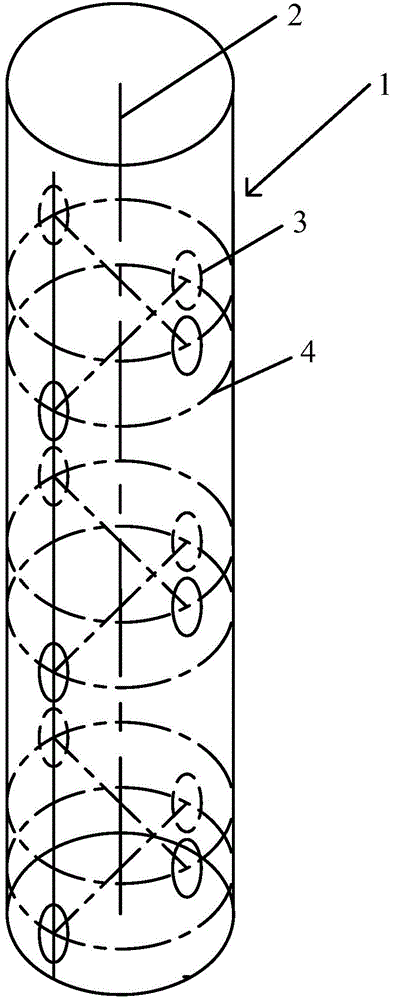

Barrel transformation preventing vertical lifting device

The invention discloses a barrel transformation preventing vertical lifting device for lifting a barrel. The barrel transformation preventing vertical lifting device comprises a lifting beam body, a fixed back shore block, an adjustable back shore block and a pair of shelf parts, wherein the fixed back shore block is fixedly connected to one end of the lifting beam body; the adjustable back shore block is flexibly connected to the other end of the lifting beam body; the pair of shelf parts are respectively arranged on the two ends of the lifting beam body and are arranged on the upper parts of the fixed back shore block and the adjustable back shore block; the adjustable back shore block has a plurality of waist-shaped holes; the device also comprises a plurality of bolts which respectively penetrate through the waist-shaped holes; and the adjustable bolts are connected with the adjustable back shore block and the lifting beam body, so that the adjustable back shore block can radially move along the barrel. The device provided by the invention has the advantages that the operation is convenient, the manufacture is simple, the device is safe and reliable and can reused, the various sizes of the different barrels are met, the technical requirements are guaranteed, and the processing cost is low.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

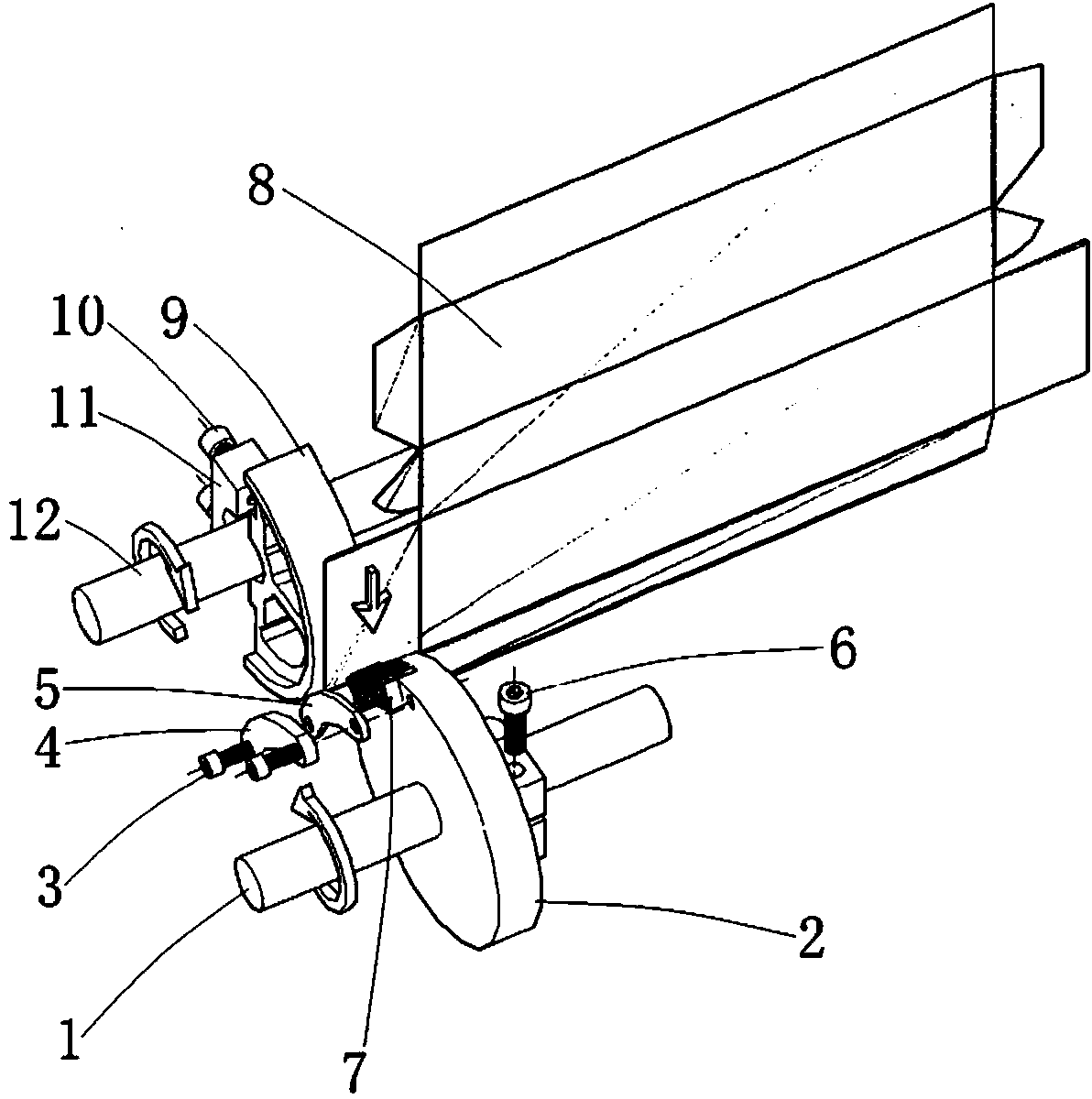

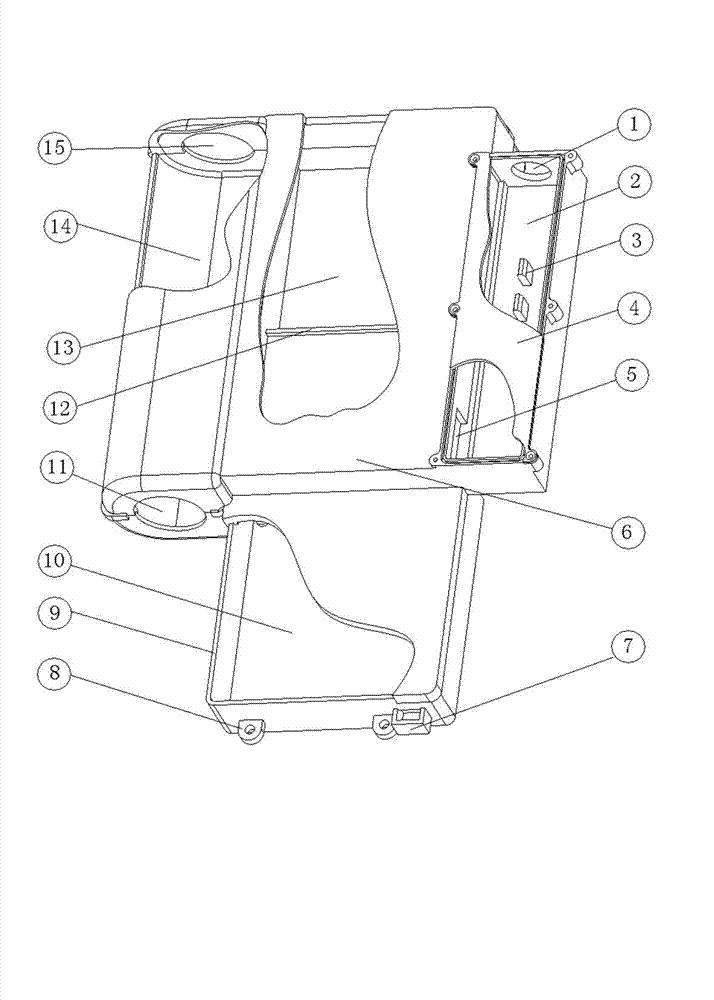

Quick change type cigarette case tracing code printing device of CT type packing machine

ActiveCN104029868AWith quick conversion functionOvercoming functional shortcomings of interconvertingPackagingDrive shaftEngineering

The invention discloses a quick change type cigarette case tracing code printing device of a CT type packing machine. A steel stamp seat transmission shaft is provided with a steel stamp base and an arch seat used for mounting steel stamp combinations, the upper edge is provided with three groups of steel stamp combination mounting grooves circumferentially and uniformly, the steel stamp combinations are correspondingly fixed in the three groups of steel stamp combination mounting grooves through small arc clamping plates, a circumferential slide way is formed through a convex clamping strip of the arch seat, and a large clamping plate is arranged on one side of the arch seat and is provided with a positioning pin; the arch seat can be positioned between the steel stamp base and the large clamping plate, and a steel stamp corresponded seat and a locking block are locked onto a corresponded block transmission shaft; a steel stamp corresponded block is connected to the side of the steel stamp corresponded seat, the upper portion of the steel stamp corresponded block is protruded from the steel stamp corresponded seat, and the steel stamp corresponded block is capable of sliding on the steel stamp corresponded seat and being locked; the corresponded block transmission shaft is arranged parallel to a steel stamp seat transmission shaft, and the steel stamp corresponded block corresponds to the steel stamp combinations in positions in the radial direction of the transmission shaft.

Owner:CHINA TOBACCO ANHUI IND CO LTD

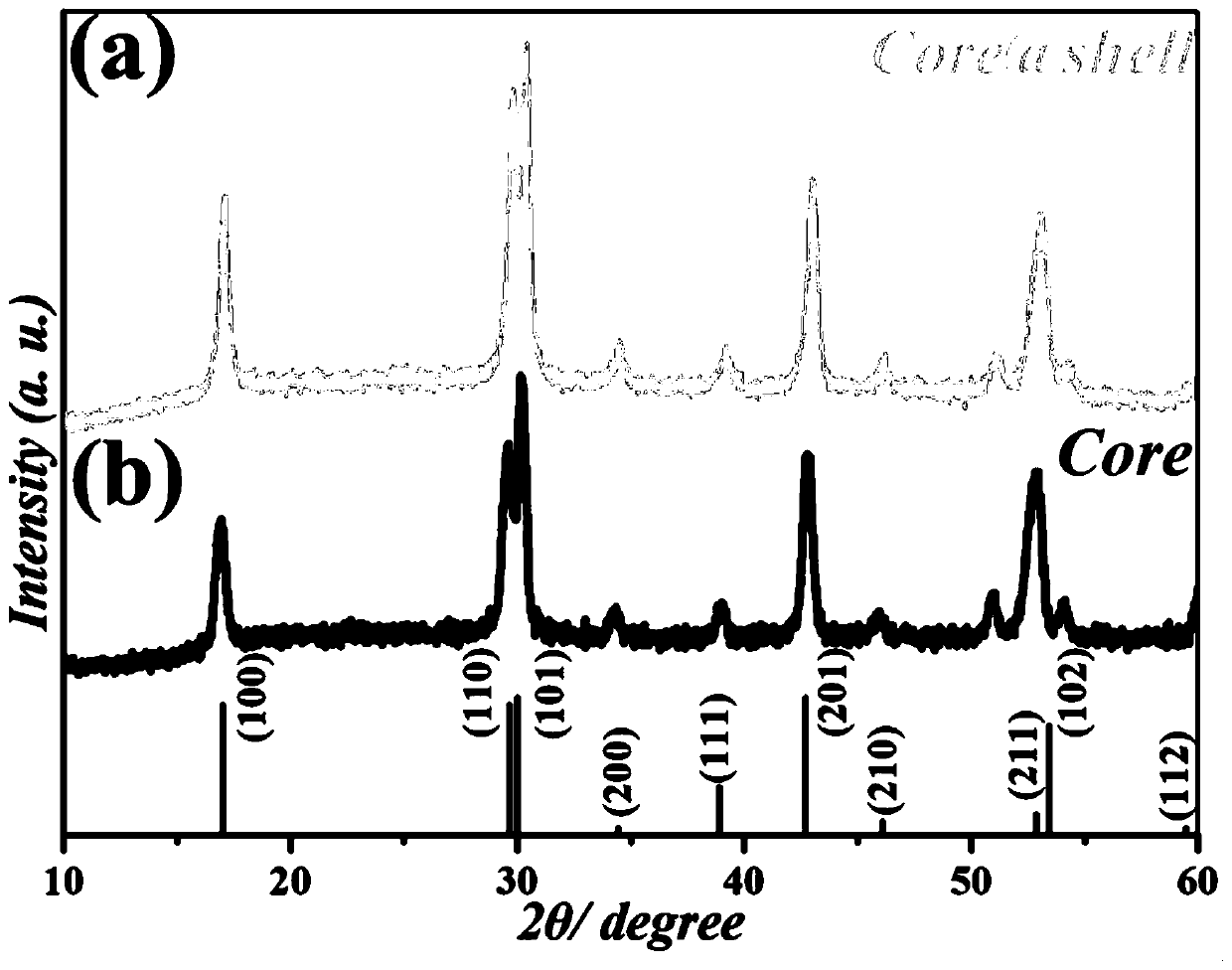

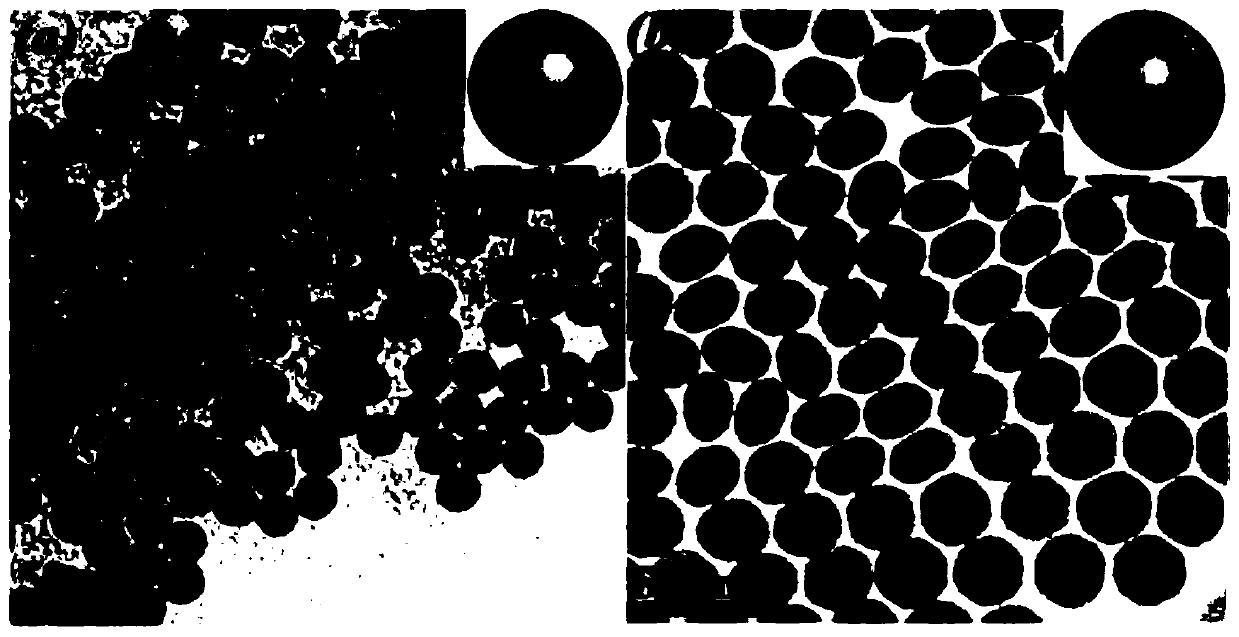

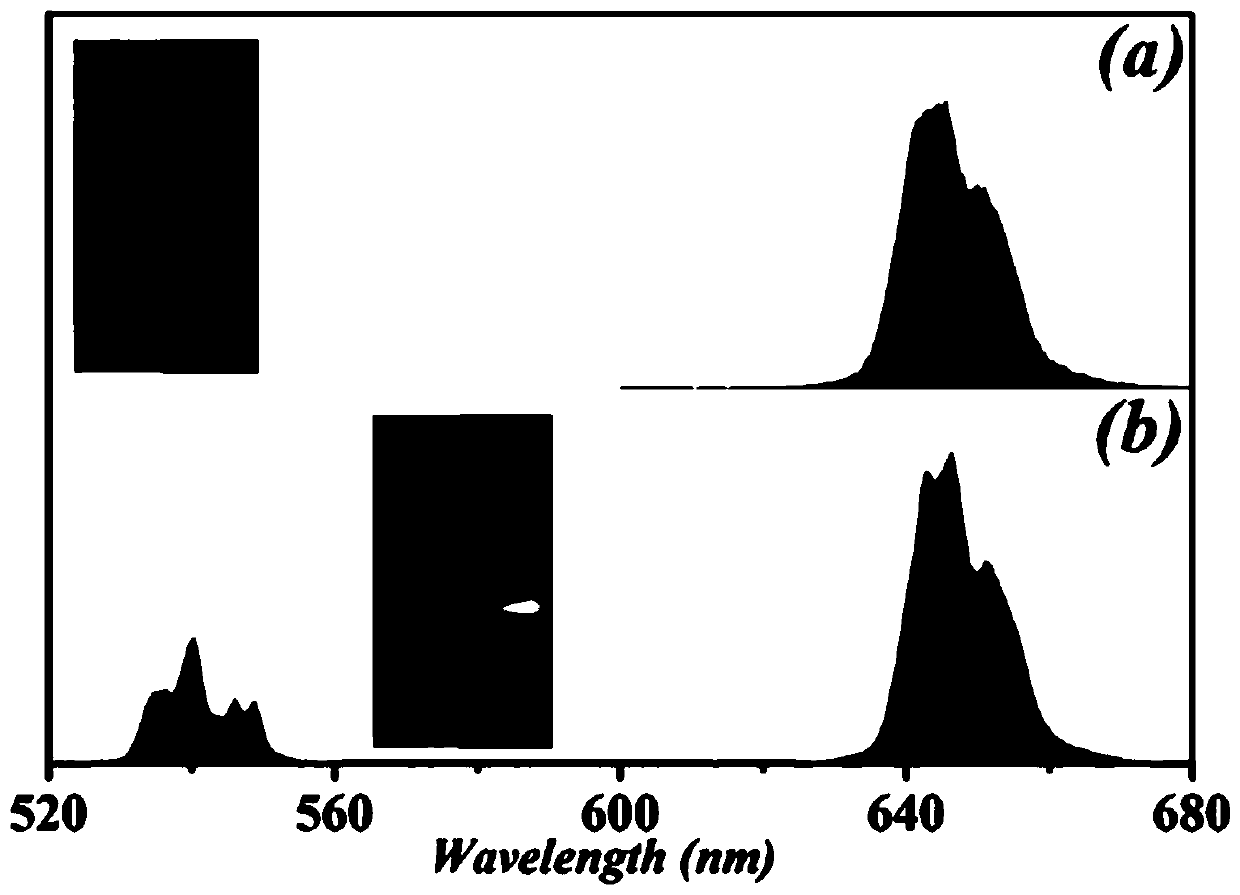

Dual-mode fluorescent anti-counterfeiting material and preparation method thereof

ActiveCN110982528ASimple preparation processGood repeatabilityLuminescent compositionsInfrared lampFluorescence

The invention relates to the technical field of light emitting and displaying and discloses a dual-mode fluorescent anti-counterfeiting material and a preparation method thereof. The chemical composition of the dual-mode fluorescent anti-counterfeiting material is NaGdF4: Yb / Ho / Ce@NaYF4: X (wherein X is Eu, Tb, Sm or Dy), and the dual-mode fluorescent anti-counterfeiting material emits multi-colorlight with adjustable performance under the excitation of 980-nm near-infrared light and 254-nm ultraviolet light. According to the dual-mode fluorescent anti-counterfeiting material and the preparation method thereof in the invention, prepared rare earth-doped heterogeneous fluoride core-shell nanoparticles realize the dual-mode luminescence characteristic of efficient multi-color regulation andcontrol for the first time; i.e., high-efficiency up-conversion luminescence of green light, yellow light, red light and light of other colors can be realized under the excitation of a 980-nm near-infrared lamp, and multi-color down-conversion luminescence of red light, green light, yellow light and the like is realized under the excitation of a 254-nm ultraviolet lamp; the anti-counterfeiting dual-mode rare earth luminescent material is different from traditional single-mode luminescence, meets the technical requirement of fluorescence anti-counterfeiting, and greatly improve anti-counterfeiting safety; and meanwhile, the preparation method for the material provided by the invention is simple and convenient in process, relatively good in repeatability and easy for mass production.

Owner:NANJING FORESTRY UNIV

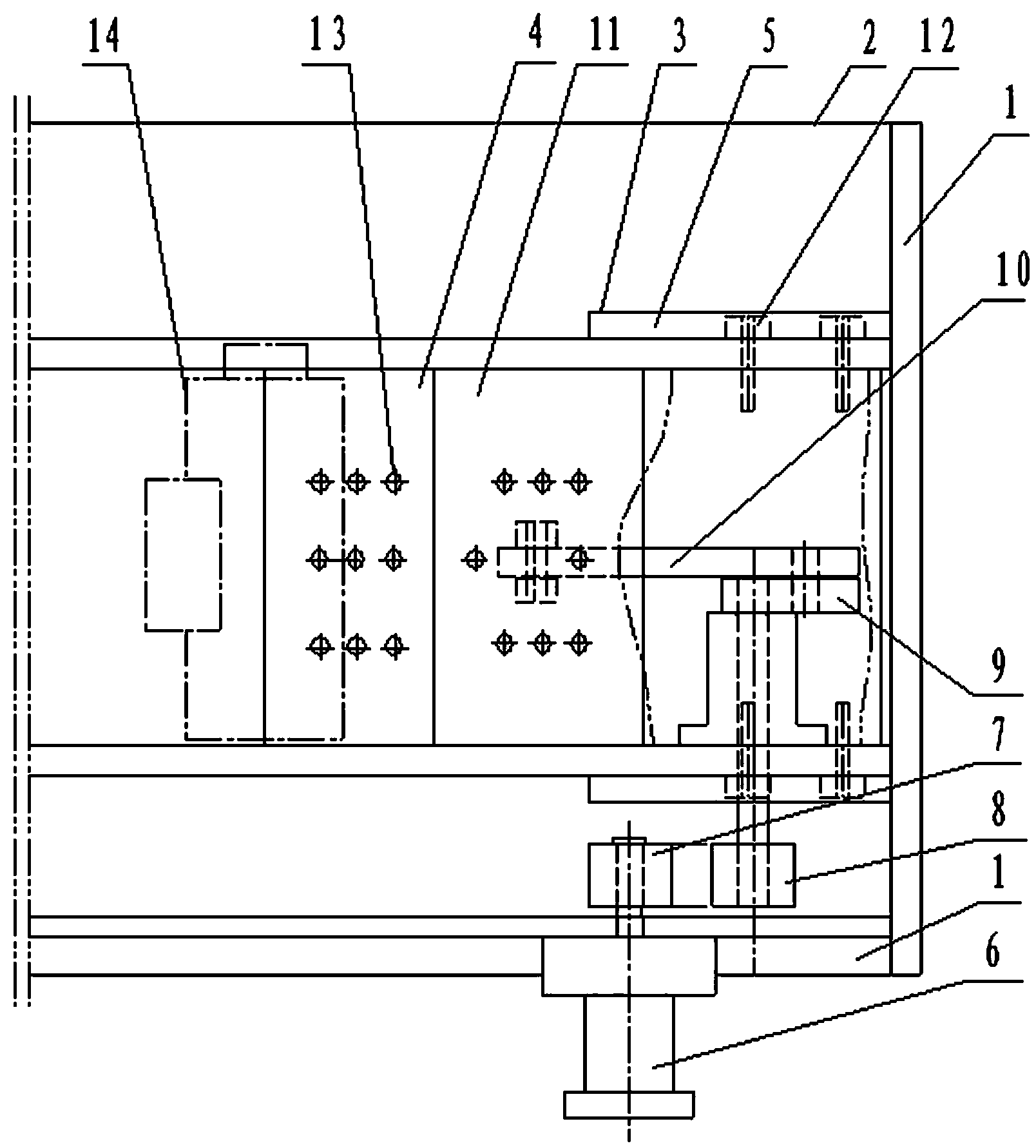

Plastic lifting handle eyeleting device of full-automatic carton lifting handle eyeleting machine

ActiveCN103350800ASolve the technical problem on the handle buckleSolve technical problemsPackagingCartonEngineering

The invention discloses a plastic lifting handle eyeleting device of a full-automatic carton lifting handle eyeleting machine. The device is composed of a rack, an air cylinder, an eyeleting support, a sizing assembly and a shaping assembly. The sizing assembly is composed of a sizing block shaped like a question mark, a locating block shaped like an inverted L, a sizing block tension spring and a ratchet. The shaping assembly is composed of a shaping block with an inclined face at the lower end, a shaping bearing and a shaping tension spring. According to the technical scheme, technical problems in plastic lifting handle eyeleting of the carton lifting handle eyeleting machine are solved, automation of plastic lifting handle eyeleting can be achieved, production cost is reduced, production efficiency is improved greatly, and technical demands of plastic carton lifting handles in the eyeleting process are met.

Owner:嘉善县临沪新城实业有限公司

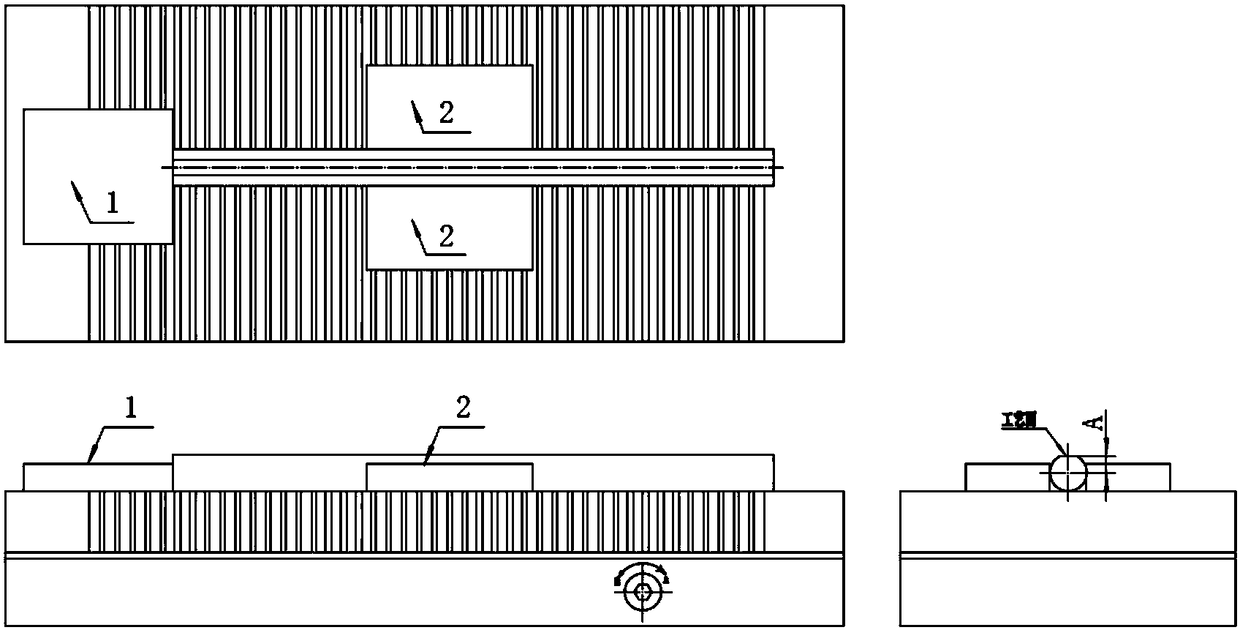

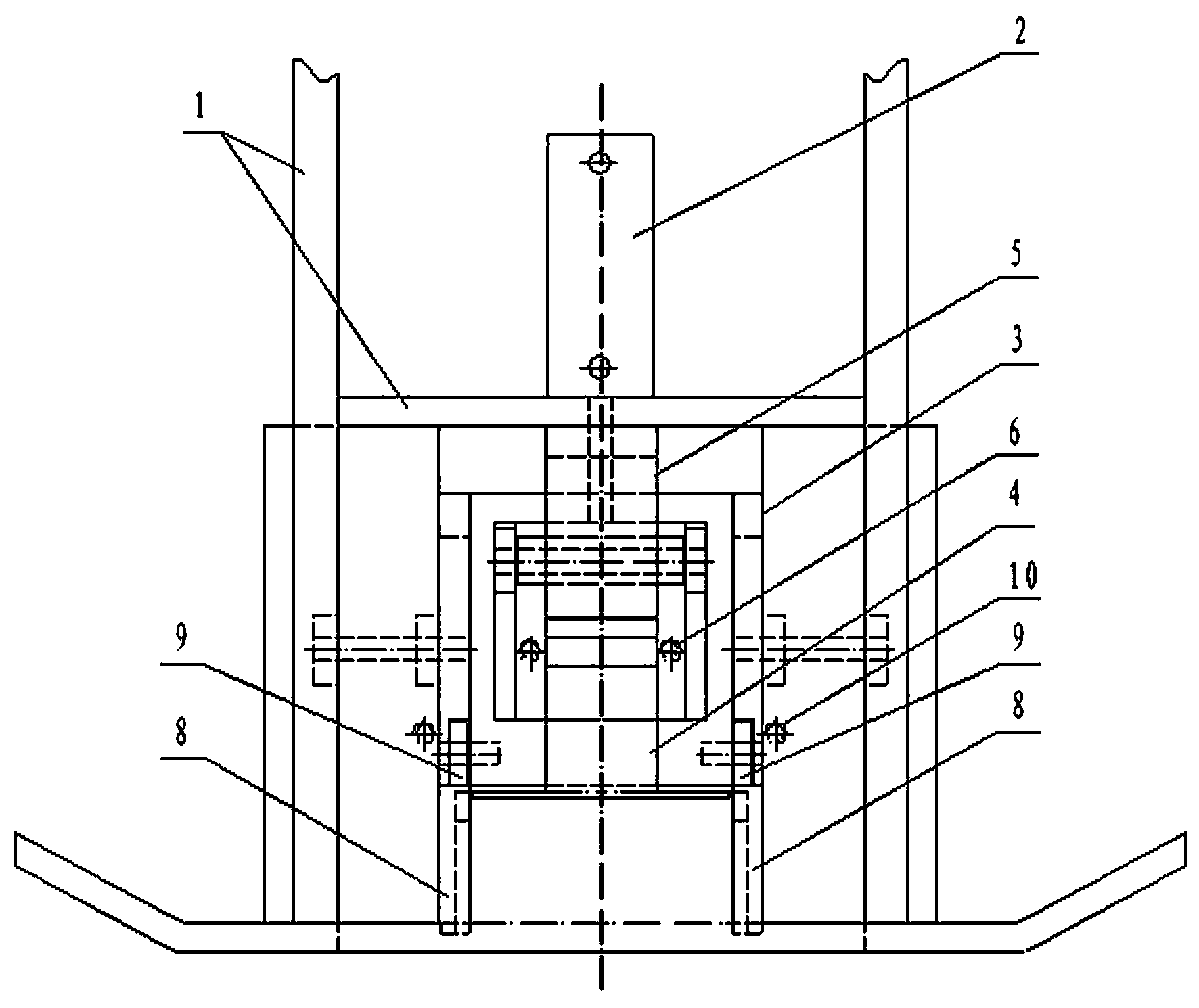

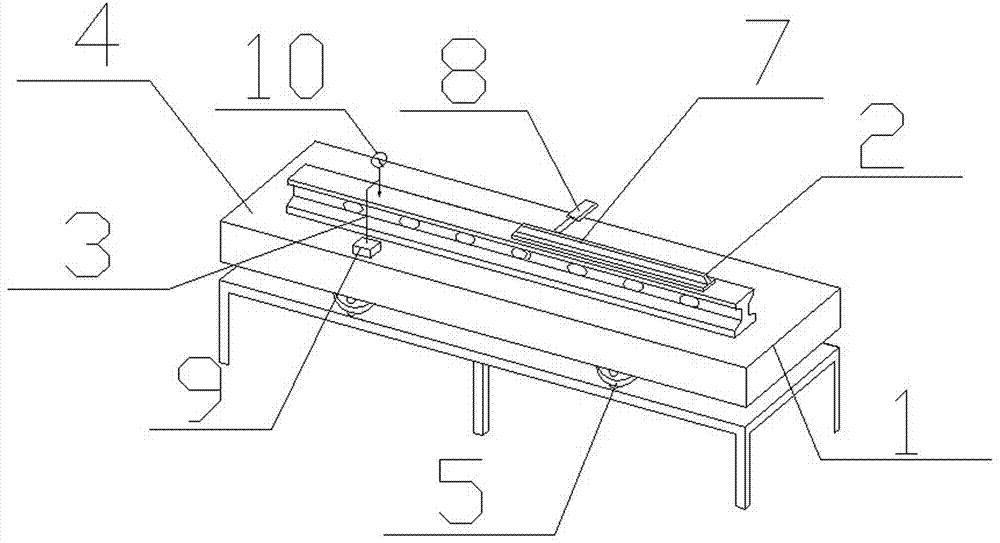

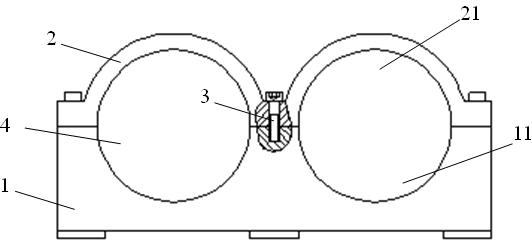

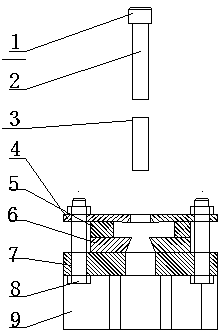

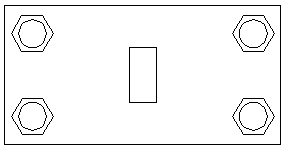

Processing tooling for motor seat

InactiveCN102350641AGuaranteed concentricityGuaranteed parallelism on both sidesPositioning apparatusMetal-working holdersEngineeringMachining time

The invention provides a processing tooling for a motor seat, which has the advantages that the positioning is rapid and reliable, and the processing time of the motor seat can be effectively shortened. The processing tooling comprises a bottom plate, wherein counter bores corresponding to projected circular rings arranged on the motor seat are arranged on the upper surface of the bottom plate, and four plate pressing devices for tightly pressing four corner parts of the motor seat are also arranged on the bottom plate.

Owner:江苏新华机电设备制造有限公司

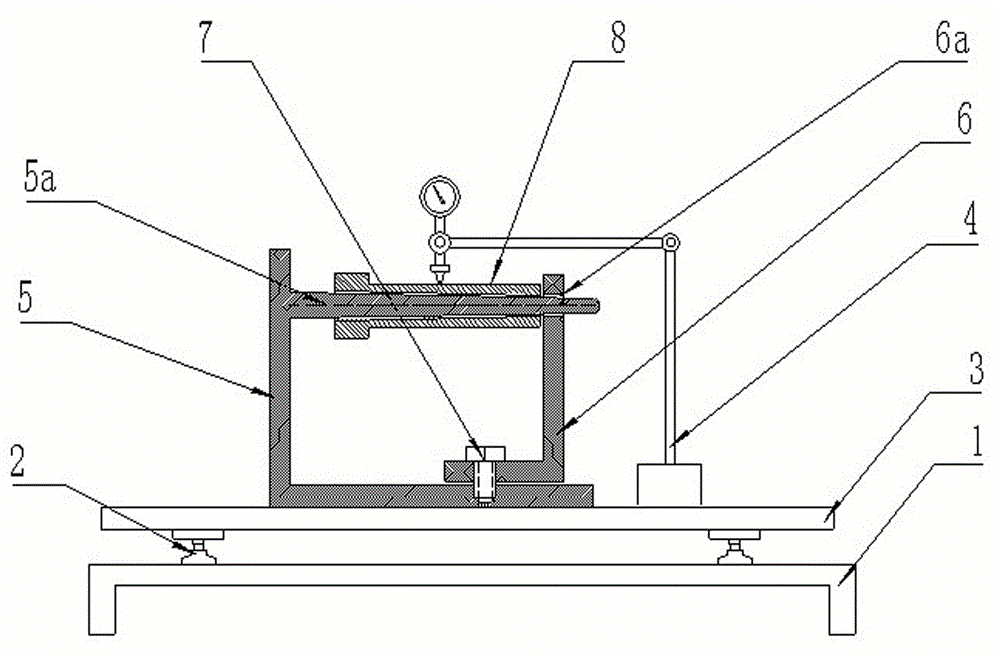

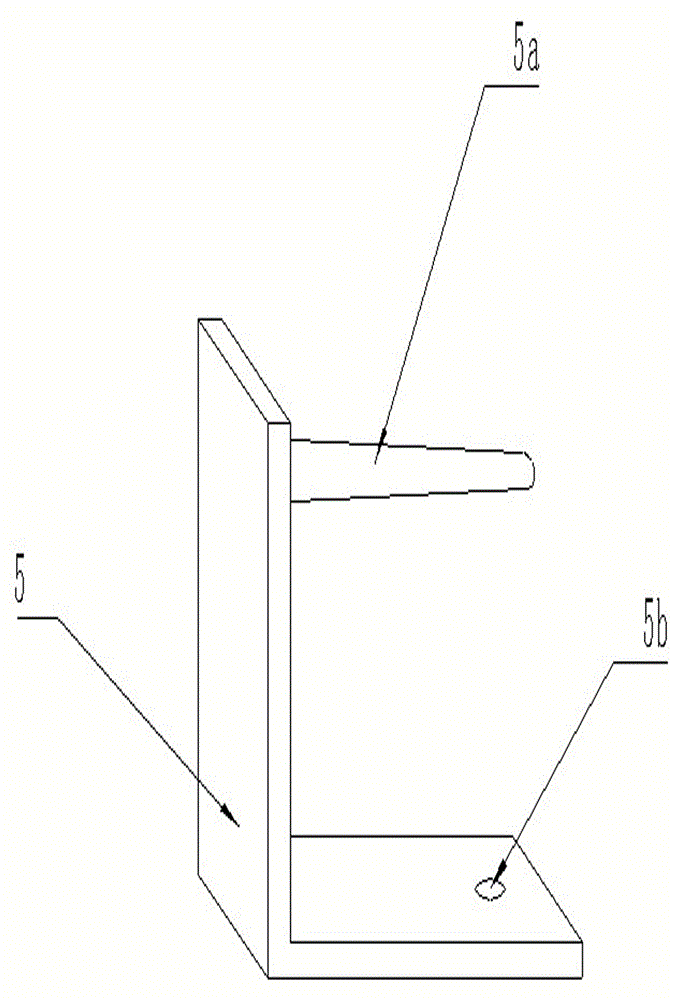

Checkout device for special textile level ruler and use method thereof

InactiveCN104776788AMeet production requirementsGuaranteed technical requirementsMechanical roughness/irregularity measurementsLeveling mechanismEngineering

The invention discloses a checkout device for a special textile level ruler. The checkout device comprises a detection platform assembly, a levelness detection assembly and a parallelism detection assembly. The detection platform assembly comprises a detection platform, leveling mechanisms installed at the four bottom corners of the detection platform and a frame level arranged on the detection platform. The levelness detection assembly comprises a line scale and a plug gauge. The parallelism detection assembly is a measurement frame with a dial gauge. The checkout device is simple in structure and convenient to operate; by performing testing and calibration through the checkout device, inaccuracy of the special textile level ruler can be prevented, and enterprise production can be reliably guaranteed.

Owner:ANHUI HUAMAO TEXTILE

Method for producing microwave vulcanization rubber-sheathed cable

InactiveCN101197201APrevent oversulfurizationGuaranteed technical requirementsInsulated cablesInsulated conductorsMicrowaveVulcanization

The invention relates to a production method for microwave vulcanization cabtyre cables, belonging to the cable production technical field. The main process of the method is that: conductors are let off evenly and steadily through a pay-off stand; sheaths of the cables are extruded through an extruder; the cables coated with sheaths are heated up to 130-160 DEG C through microwave for vulcanization; the vulcanization temperature of 130-160 DEG C is kept, and the cables are vulcanized continuously through hot-air vulcanization equipment; after the vulcanization is finished, the cables are cooled in normal temperature; the microwave vulcanization cabtyre cables can be obtained by passing a take-up reel and a take-up spool. The microwave vulcanization technology is adopted to replace the prior steam curing process, thereby reducing production cost and improving production efficiency; the microwave vulcanization is combined with the hot-air vulcanization, not only the technical requirements of the cables can be guaranteed, but also waste of energy is reduced; an infrared temperature controller is used to monitor vulcanized objects, thereby preventing the sheaths of the cables from being overvulcanized.

Owner:长江高科电缆有限公司

Drawing-out method for high-speed steel cold roll neck

The invention relates to a drawing-out method for a high-speed steel cold roll neck, and belongs to the technical field of forging. The drawing-out method includes the following process steps that back necking is preheated; then starting from the necking, a lower anvil is sequentially drawn out to the end in the axial direction of a blank; after each plane is drawn out, the blank is turned over by 90 degrees, a next adjacent plane is drawn out, and as well, starting from the necking, the lower anvil is sequentially drawn out to the end in the axial direction of the blank; and finally, chamfering is carried out on the blank which is drawn out to be in the size meeting the process requirement. By means of the drawing-out method, deformation of a forge piece can be more even in the axial direction, the stress state of the surface and the core can be changed, defects are prevented, and the percent of pass of the forge piece is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

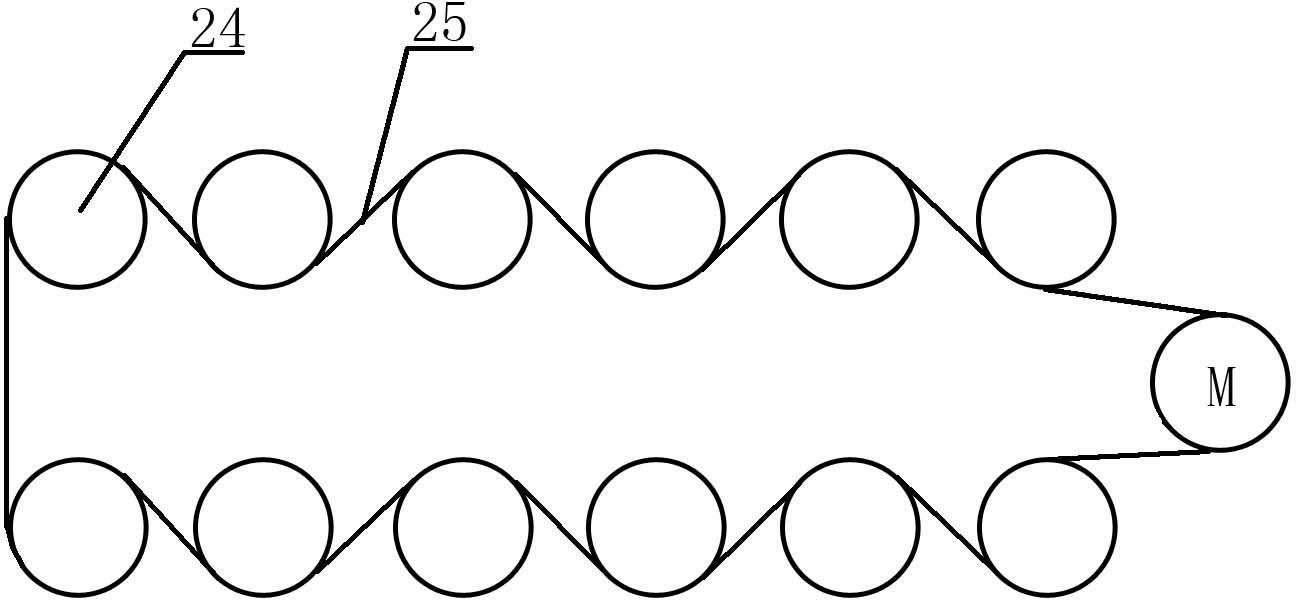

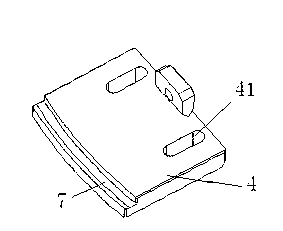

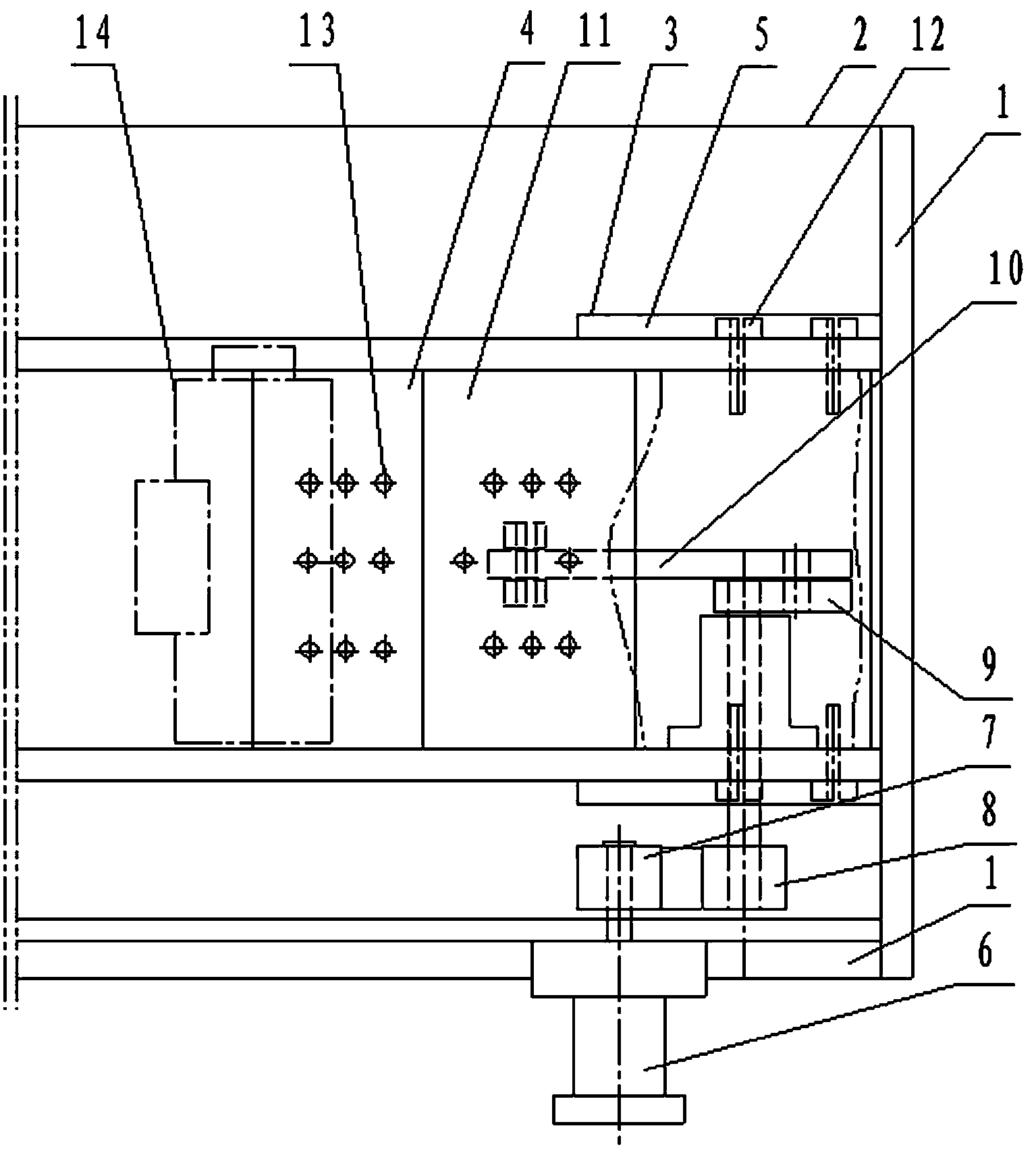

Plastic lifting handle sizing device of full-automatic carton lifting handle eyeleting machine

ActiveCN103350524AFully automatedGuaranteed technical requirementsPaper-makingBox making operationsCartonEngineering

The invention discloses a plastic lifting handle sizing device of a full-automatic carton lifting handle eyeleting machine. The device is composed of a rack, a motor, a motor belt wheel, conveying assemblies and sizing assemblies. The conveying assemblies are two in number and of the same structure, and the sizing assemblies are two in number and of the same structure. The two conveying assemblies and the two sizing assemblies are respectively fixed on the rack in parallel. Each conveying assembly is composed of an upper driving gear, a lower driving gear, an upper driving belt wheel, a lower driving belt wheel, an upper driven belt wheel, a lower driven belt wheel, an upper adjusting wheel and a lower adjusting wheel. Each sizing assembly is composed of a baffle block shaped like an inverted L, an upper sizing block and a lower sizing block. According to the technical scheme, technical problems in plastic lifting handle sizing of the carton lifting handle eyeleting machine are solved, sizing effect is good, automation of the sizing device is achieved, production cost is reduced, production efficiency is improved greatly, and technical demands of plastic carton lifting handles in the sizing process are met.

Owner:嘉善县临沪新城实业有限公司

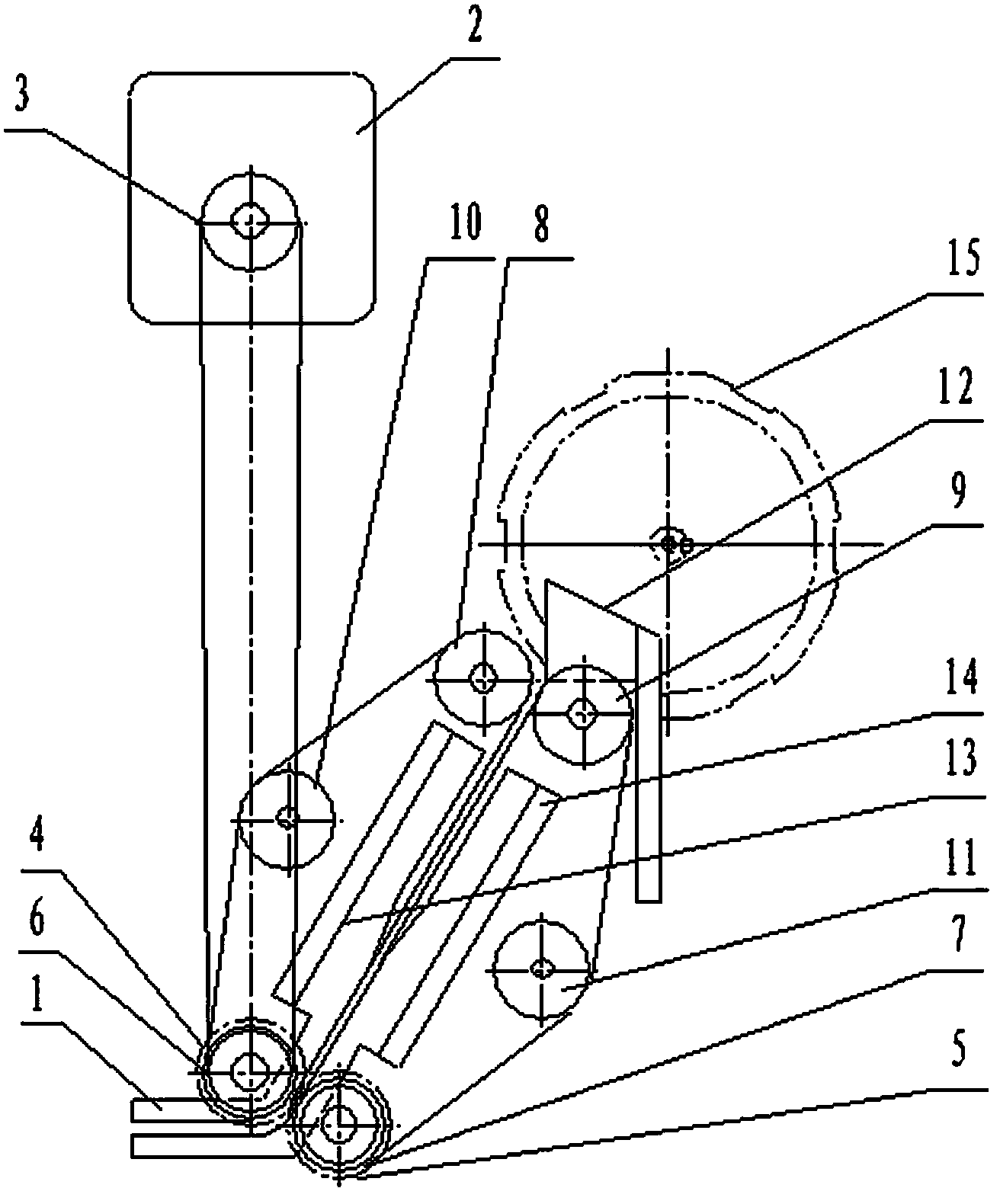

Plastic lifting handle conveying device of full-automatic carton lifting handle eyeleting machine

ActiveCN103350523AFully automatedGuaranteed mobilityBox making operationsPaper-makingDrive wheelCarton

The invention discloses a plastic lifting handle conveying device of a full-automatic carton lifting handle eyeleting machine. The device is composed of a rack, an outer cover, a conveying assembly, a locating plate and a stop platform, wherein the conveying assembly, the locating plate and the stop platform are arranged on the rack. Both the locating plate and the stop platform are fixedly arranged on the rack 1 in an inclined and paralleled mode, and a rail is arranged in the middle of the locating plate. The conveying assembly is composed of a motor, a motor belt wheel fixed on a motor shaft, a driving wheel, an eccentric wheel, a transmission connection rod, a conveying platform and a pulley. According to the technical scheme, technical problems in plastic lifting handle conveying of the carton lifting handle eyeleting machine are solved, automation in plastic lifting handle conveying is achieved, production cost is reduced, production efficiency is improved greatly, and technical demands of plastic carton lifting handles in the conveying process are met.

Owner:嘉善县临沪新城实业有限公司

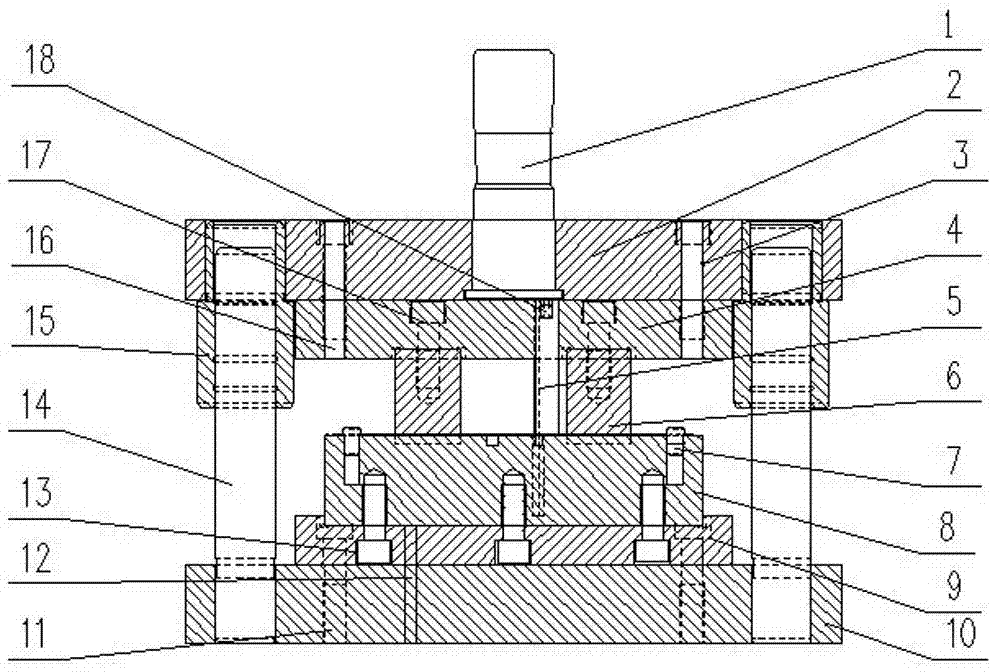

Wire harness support forming die

InactiveCN103480735AGuaranteed technical requirementsGood size consistencyShaping toolsStructural engineeringMechanical engineering

The invention discloses a wire harness support forming die which comprises an upper die assembly and a lower die assembly. The upper die assembly comprises a die shank, an upper die holder, a base plate, a screw, a male die, a cylindrical pin, a positioning pin, an inner hexagon bolt and two guide sleeves; the lower die assembly comprises an ejector plate, an ejector pin, a lower die holder, an insert, inner hexagon screws, two female dies, a positioning plate, positioning rings, a bolt and two guide columns; the die shank is positioned in the middle of the upper die holder, the base plate is positioned in the middle of the lower side of the upper die holder, the male die is positioned in the middle of the lower side of the base plate, the two guide sleeves are respectively positioned on the left and the right of the front of the upper die holder, the insert is positioned in an I concave table of the lower die holder, the two female dies are respectively positioned on two sides of the middle of the insert, the ejector plate is positioned in the middle of the insert, one end of the ejector pin is positioned on the lower side of the ejector plate, the other end of the ejector pin is penetratingly arranged in an ejector pin hole of the insert, the positioning plate is positioned above the female dies, and the two guide columns are respectively positioned on the left and the right of the front of the lower die holder. The wire harness support forming die has the advantages that four products can be formed by the wire harness support forming die at one step, and the wire harness support forming die can be operated easily and conveniently and is high in production efficiency.

Owner:HENGYANG FENGSHUN AXLE CO LTD

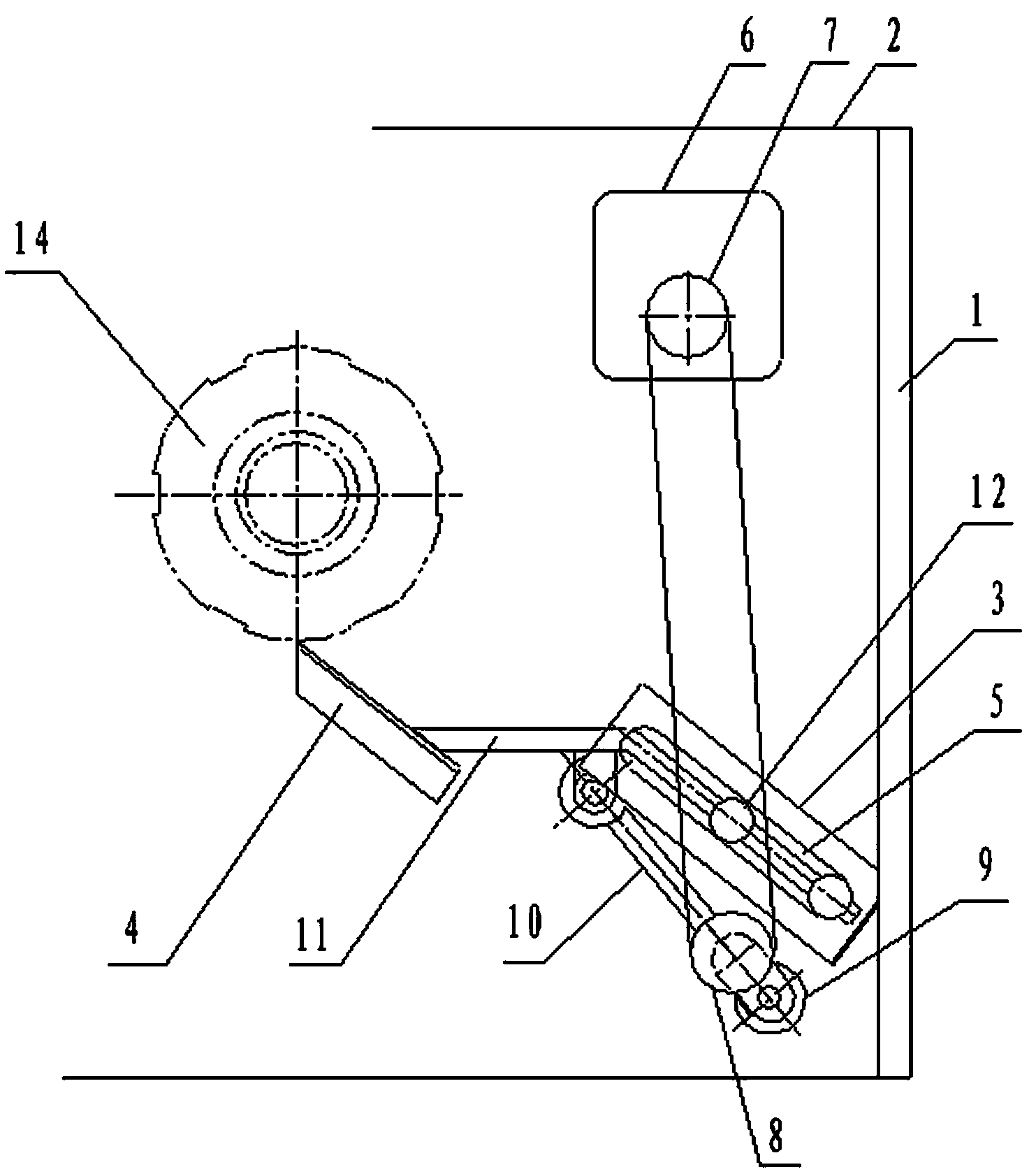

Full-automatic plastic lifting handle deformation device of carton lifting handle buckling machine

ActiveCN103359332AGuaranteed technical requirementsSolving technical issues on handle variantsPackagingCartonEngineering

The invention discloses a full-automatic plastic lifting handle deformation device of a carton lifting handle buckling machine, which comprises a machine frame, a deformation component and a material pushing component, wherein the deformation component comprises a deformation cylinder, a positioning cylinder, an n-shaped deformation pressing block, an upper mould block, a lower mould block and a positioning pin; a track groove is formed between the upper mould block and the lower mould block; chutes are formed in the front side surface and the rear side surface of the lower mould block respectively; the material pushing component comprises a material pushing cylinder and a right turned n-shaped material pushing block; front claws on two sides at the left end of the material pushing block are arranged in the chutes in the side surfaces of the lower mould block through bearings respectively. Through the adoption of the technical scheme, the plastic lifting handle deformation device has the advantages that the technical problem of plastic lifting handle deformation of the carton lifting handle buckling machine is solved; the formation device can be automatic; the manufacturing cost is reduced; the production efficiency is greatly improved; technical requirements of a plastic lifting handle during deformation are met.

Owner:嘉善县临沪新城实业有限公司

Textile spinning machine fixed gauge casing radial runout detection device

InactiveCN105066809AGuaranteed accuracy requirementsGuaranteed technical requirementsMechanical measuring arrangementsLeveling mechanismEngineering

The invention discloses a textile spinning machine fixed gauge casing radial runout detection device, which comprises a base. The base is provided with a detection platform; a leveling mechanism is arranged between the base and the detection platform; a left L-shaped support and a right L-shaped support which are arranged in an opposite and staggered mode are arranged on the detection platform; a cone bar is arranged above the left L-shaped support, and a positioning screw hole is arranged in the bottom part of the left L-shaped support; a limiting hole is arranged above the right L-shaped support, and a positioning hole is arranged in the bottom part of the right L-shaped support; after the screw hole and the positioning hole are connected via a screw, the right L-shaped support is movably arranged on the left L-shaped support; a dial indicator is also arranged on the detection platform; and the limiting hole is arranged on the axis of the cone bar. According to the textile spinning machine fixed gauge casing radial runout detection device, the structure is simple and the operation is convenient; and the precision of the spinning machine fixed gauge casing and the technical requirements can be ensured, the flat machine quality of the textile industry main engine equipment can be improved, and enhancement of the textile industry product quality can be promoted.

Owner:ANHUI HUAMAO TEXTILE

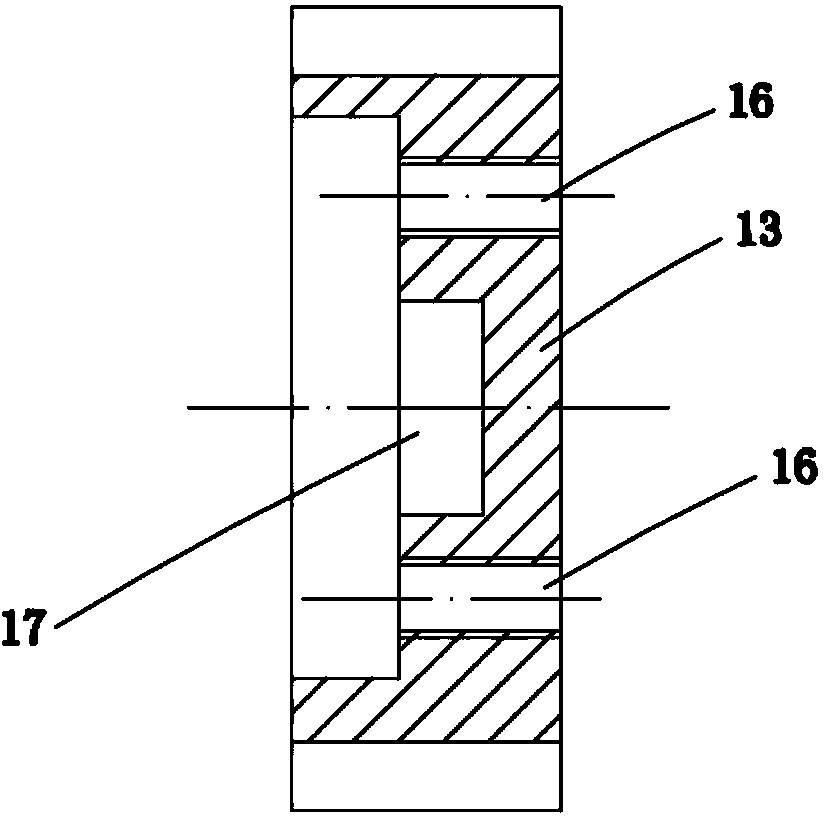

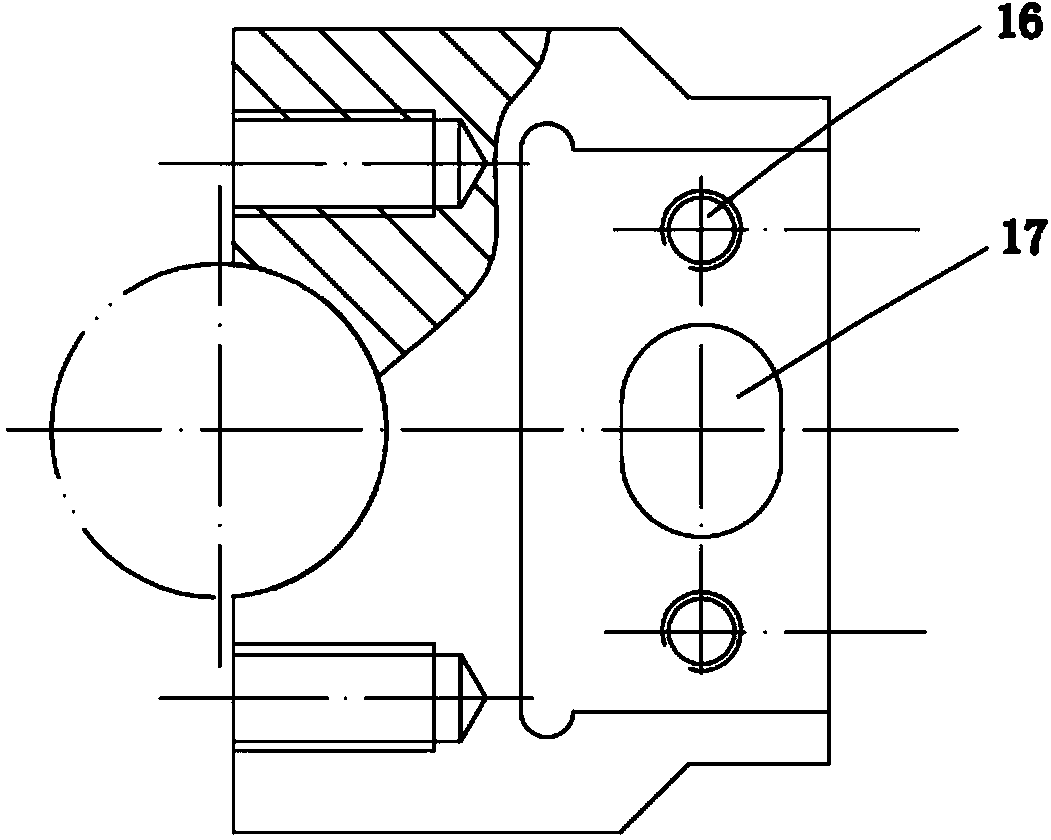

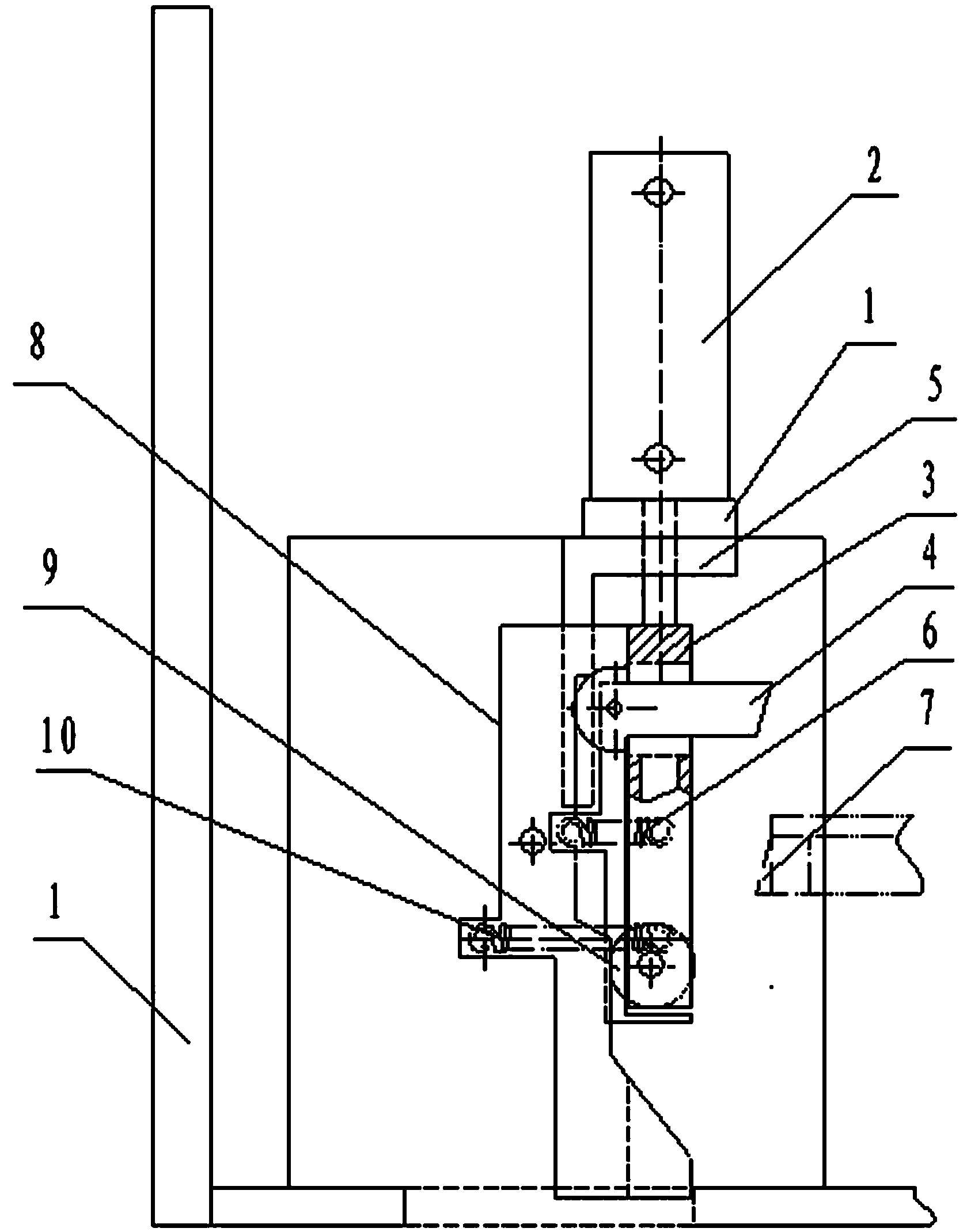

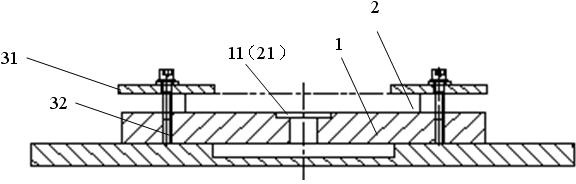

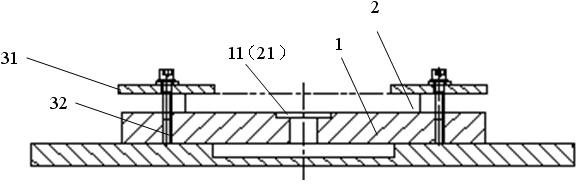

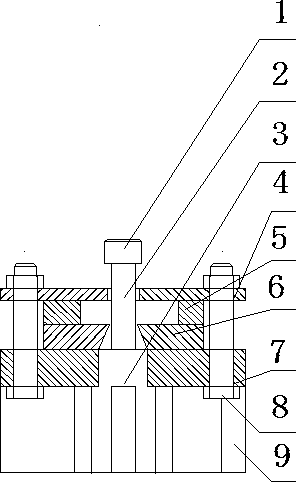

Device and method for pressing rubber joints to electric motor

ActiveCN106334926ASimple structureEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention discloses a device and method for pressing rubber joints to an electric motor. The device comprises a bottom plate, a pressing block, a pressing sleeve, a first guide plate, a second guide plate, a clamping plate and a guide bar, wherein the bottom plate, the first guide plate, the second guide plate and the clamping plate are sequentially arranged in spaced and coaxial modes; the guide bar is arranged in the bottom plate, the first guide plate, the second guide plate and the clamping plate in a penetrating mode; a space for containing rubber joint installation holes is reserved between the second guide plate and the clamping plate; the pressing block is arranged in the position, facing one side of the bottom plate, of the first guide plate; the pressing sleeve is arranged in the through hole of the first guide plate in a penetrating mode and makes contact with the pressing block; and the pressing sleeve is provided with inner holes used for containing the flat portions of one end of the rubber joints. When the joints are to be pressed, a stress application mechanism arranged between the bottom plate and the first guide plate is used for transferring pressing force to the rubber joints sequentially through the pressing block and the pressing sleeve, the pressing block, the pressing sleeve and the first guide plate move towards the side where the second guide plate is located, and accordingly the rubber joints are pressed into the rubber joint installation holes. The device and method can achieve the technical purpose of directly pressing the rubber joints onto the electric motor.

Owner:襄阳中车电机技术有限公司 +1

Machining method for irregular key axis blank

InactiveCN1745962AShort processReduce processing costsOther manufacturing equipments/toolsEngineeringMechanical engineering

A technology for manufacturing the shaped key shaft blank includes such steps as providing cold-drawn circular steel, annealing, pickling, bonderizing, sharpening, cold die drawing, repeating said steps one or two times, and cutting short by needle length. Its advantages are low cost and improved internal structure.

Owner:LIFENG AUTO SPARES YUNXIAN

Carburizing and quenching heat treatment method

InactiveCN112593183AGuaranteed technical requirementsEnsure carburizing efficiencySolid state diffusion coatingHeat treatment process controlTemperingCarbon potential

The invention discloses a carburizing and quenching heat treatment method which is applied to gas carburizing and quenching production normally required by common low-carbon steel and low-carbon alloysteel workpieces. The carburizing and quenching heat treatment method specifically comprises the following steps of S1, firstly, putting the workpieces into a carburizing furnace, and strong carburizing section treatment and diffusion section treatment are performed on the workpieces in the carburizing furnace, wherein the carburizing temperature of the strong carburizing section treatment is 915DEG C-925 DEG C, the carbon potential of the strong carburizing section treatment is 1.1%-1.2%, the carburization temperature of the diffusion section treatment is 905 DEG C-915 DEG C, the carbon potential of the diffusion section treatment is 0.8%-0.9%, and the carburizing heat preservation time ratio of the strong carburizing section treatment to the diffusion section treatment is 11: 9; S2, performing cooling and quenching along with the carburizing furnace; S3, performing quenching oil cooling; and S4, performing tempering. By means of the method, the hardness and the hardened layer depthof the low-carbon alloy steel workpieces are guaranteed, meanwhile, it is guaranteed that the refined metallographic structure meets the national standard, and the carburizing and quenching quality is stably improved.

Owner:JIANGSU JUYUAN ELECTRICAL

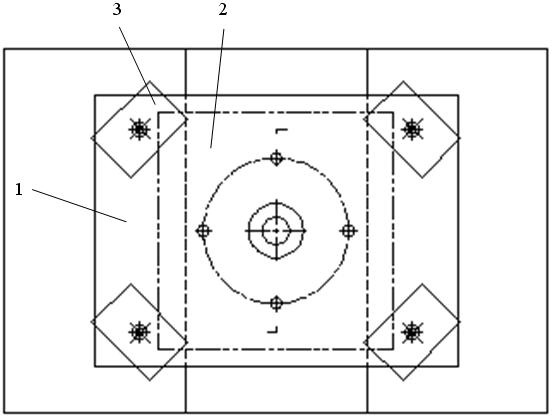

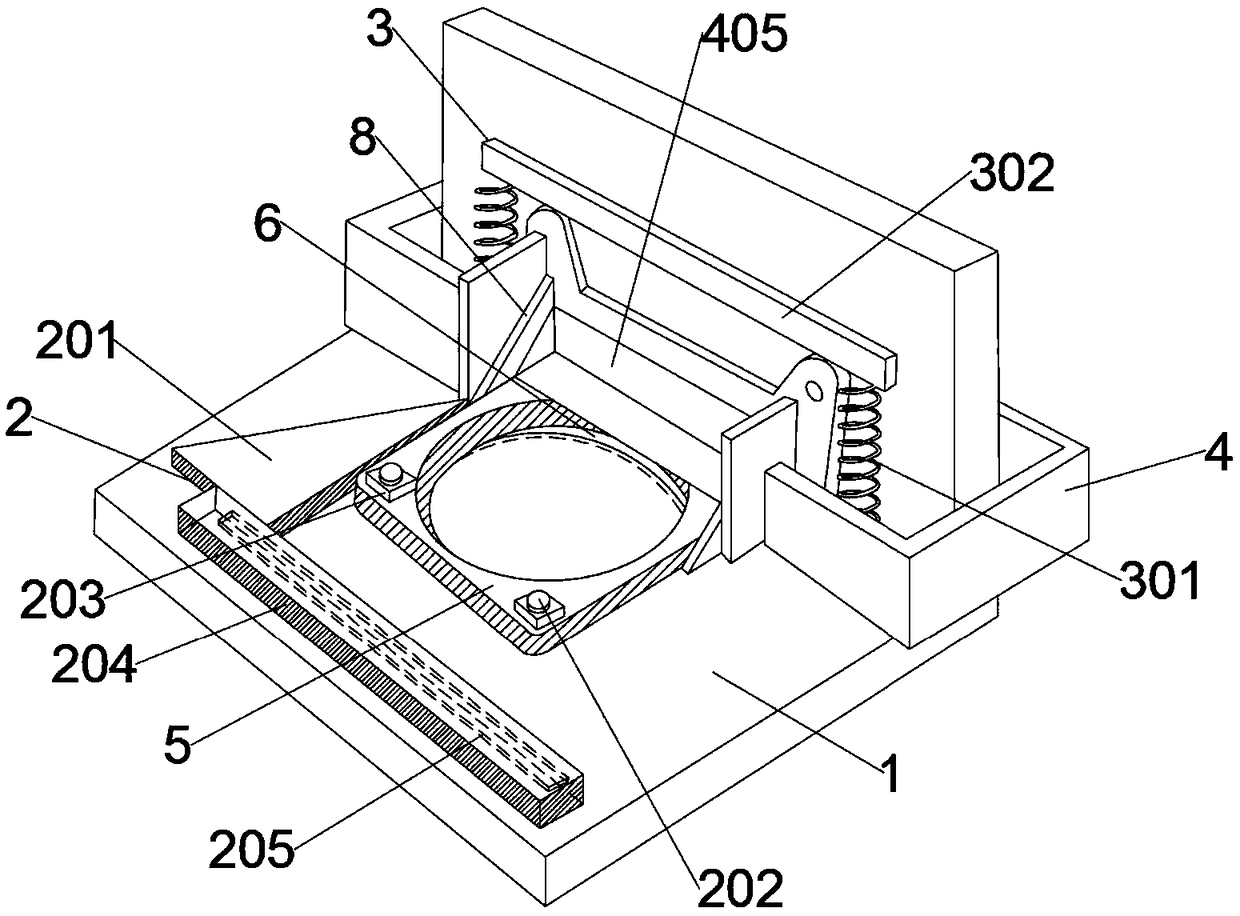

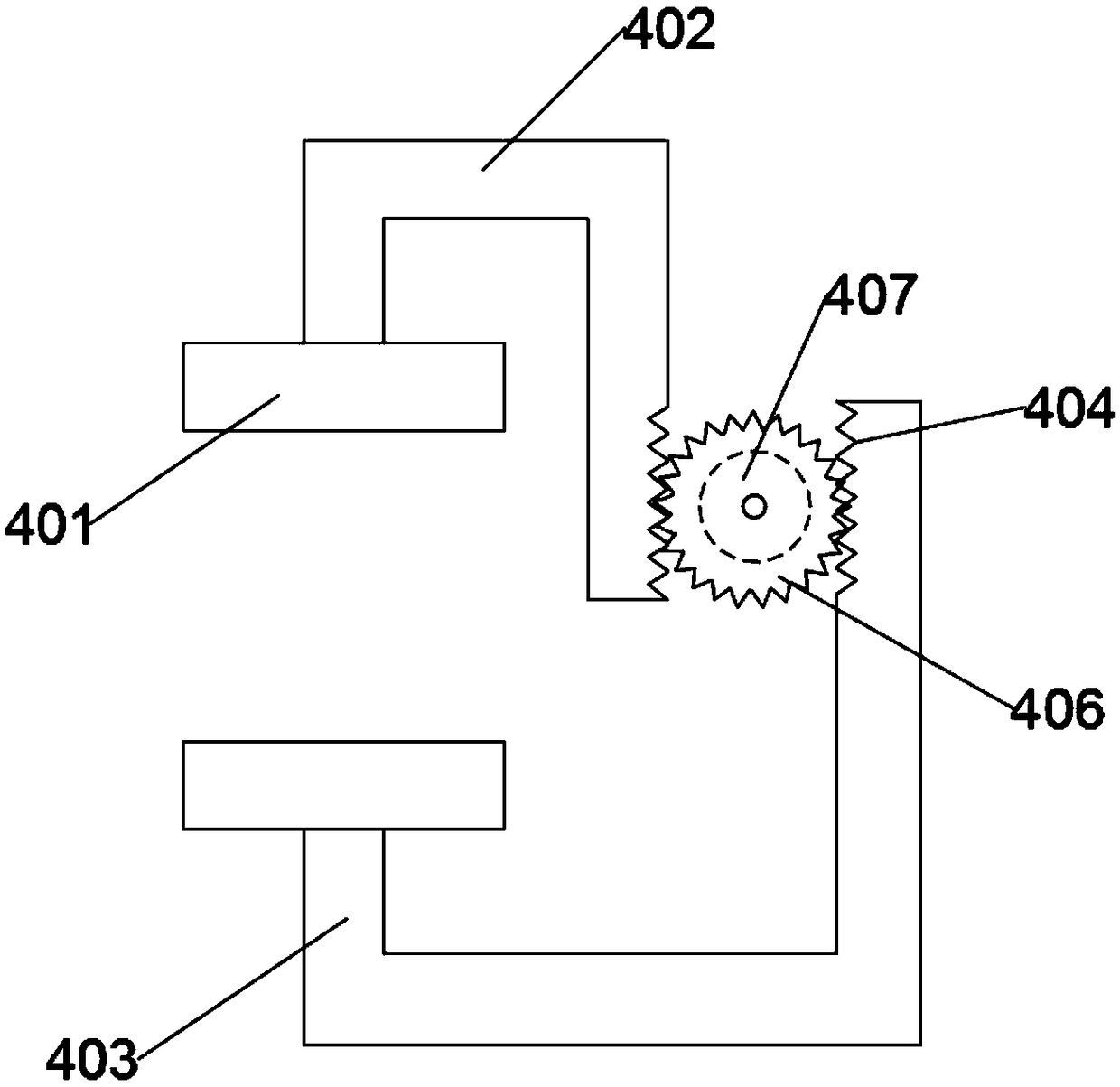

Forming device for machining of motor support

ActiveCN109175853AGuaranteed concentricityGuaranteed utilizationWelding/cutting auxillary devicesAuxillary welding devicesHorizontal and verticalMachining

The invention discloses a forming device for machining of a motor support. The forming device comprises an L-shaped bottom plate, a motor seat is arranged on the L-shaped bottom plate, the motor seatcomprises a machine frame bottom plate, a machine frame side plate and side limiting plates, the machine frame bottom plate and the machine frame side plate are welded in a perpendicular mode, and theside limiting plates are perpendicularly welded to the two sides of the machine frame bottom plate; a horizontal limiting device is arranged on the L-shaped bottom plate, the machine frame bottom plate is arranged on the horizontal limiting device in a sleeving mode, a convex circular ring is arranged on the lower surface of the machine frame bottom plate, and a circular groove for allowing the convex circular ring to be embedded is formed in the L-shaped bottom plate; and the side surface of the L-shaped bottom plate is provided with a vertical limiting device, the machine frame side plate is arranged on the vertical limiting device in a sleeving mode, and the two ends of the side limiting plates are connected with fixing devices. Thus, the concentricity of a front face circle and a backface circle and the parallelism degree of the two faces are guaranteed, and the levelness and the perpendicularity of welding among motor support elements of are improved.

Owner:ANHUI RUIYAN NEW MATERIAL TECH RES INST

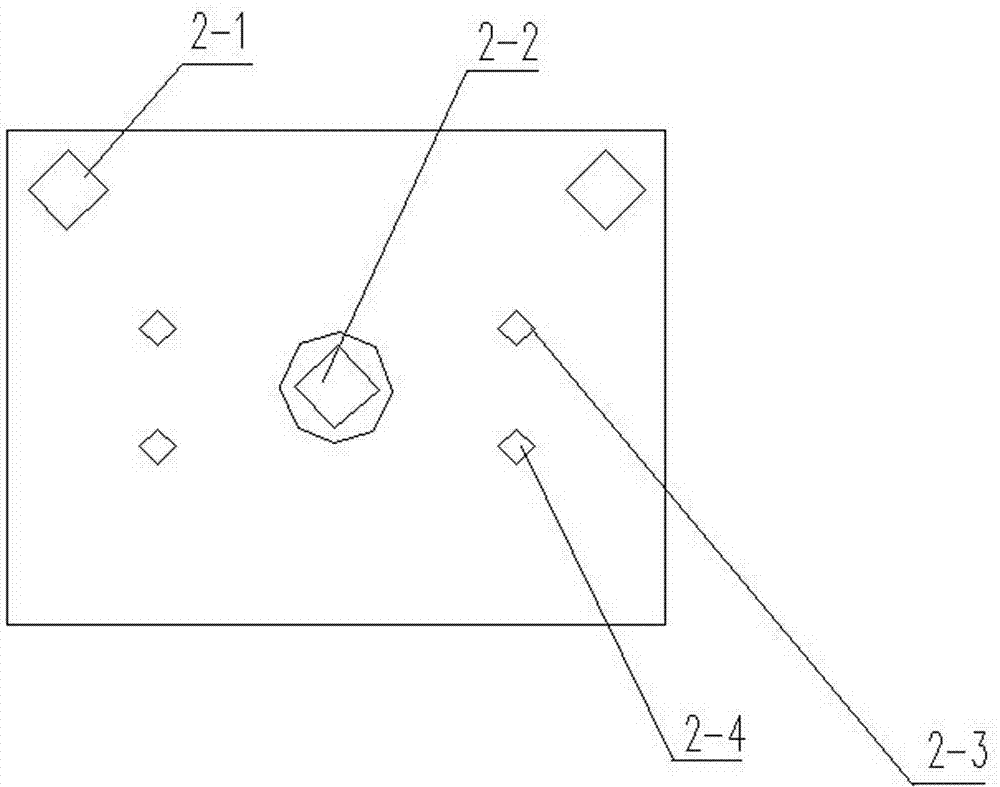

Forming and flanging die for U-shaped support frame of automobile

InactiveCN102921810ASimple structureSimple and fast operationShaping toolsEngineeringMechanical engineering

The invention relates to a forming and flanging die for a U-shaped support frame of an automobile, which comprises an upper die part and a lower die part, wherein the upper die part comprises a die handle, an upper die base, an upper cushion plate, a forming concave die, a flanging convex die, guide sleeves, fixed screws, fixed pins and a square pin; two guide sleeve mounting holes are formed in the left side and the right side in the front of the upper die base; a die handle mounting hole, four countersunk head fixed screw holes and two fixed pin holes are formed in the middle of the upper die base; the lower die part comprises a lower die base, a lower die cushion plate, a lower die, guide posts, a positioning pin, fixed screws and fixed pins; two guide post mounting holes are formed in the left side and the right side in the front of the lower die base; four countersunk head mounting holes connected with the lower die cushion plate and two fixed pin holes connected with the lower die cushion plate are formed in the middle of the lower die base; a lower die base mounting screw hole is formed in the lower part of the lower die cushion plate; a flanging concave die hole is formed in the middle of the lower die cushion plate; and in addition, a square groove hole is formed in the upper part of the lower die cushion plate. The forming and flanging die has the benefit that the forming and flanging process of the U-shaped support frame can be finished at one step by the forming and flanging composite die.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Tool fixture and process for machining measuring orifice plate part

InactiveCN105058134AReduce vibrationGuaranteed not to deformWork clamping meansPositioning apparatusVena contracta diameterMachining

The invention provides a tool fixture and process for machining a measuring orifice plate part, and belongs to the field of machining. The tool fixture comprises a central spindle, and further comprises a first ejection plate and a second ejection plate. The first ejection plate and the second ejection plate are provided with threaded holes. The central spindle is provided with an external thread. The first ejection plate and the second ejection plate are in threaded connection with the central spindle and are perpendicular to the central spindle. The tool fixture and process are used for solving the problems that in the existing process of machining the measuring orifice plate part, due to the poor rigidity of the part, the part is prone to deformation in machining, the parallelism error between the two end faces of the part is large, machining efficiency is extremely low, the machining dimensional tolerance and the geometric accuracy error are large, and the technical requirements of the part can not be met.

Owner:GUIZHOU CHITIANHUA ZHENGTAI ENG

Microwave-vulcanized water-swelling rubber used for continuous extrusion and production method thereof, and extrusion molding device used for producing microwave-vulcanized water-swelling rubber

The invention discloses microwave-vulcanized water-swelling rubber used for continuous extrusion and a production method thereof, and an extrusion molding device used for producing the microwave-vulcanized water-swelling rubber. The microwave-vulcanized water-swelling rubber comprises the following components in parts by mass: 32.9 to 40.2 parts of chloroprene rubber, 40.2 to 42.8 parts of a preformed polymer, 8 to 8.2 parts of an inorganic reinforcing filler, 2.4 to 3.0 parts of a curing agent, 0.4 to 2.0 parts of an accelerator, 5 to 10 parts of an auxiliary processing agent, 3.2 to 3.9 parts of calcium oxide, 0.8 to 1.0 part of an anti-aging agent, 1.2 to 2.3 parts of zinc oxide and 0.6 to 1.0 part of magnesium oxide. The production method comprises the following steps: mixed rubber processing, placement and standing, remixing, extrusion molding, microwave vulcanization, coil rolling, and inspection and warehousing. The microwave-vulcanized water-swelling rubber provided by the invention has significant social benefits. The microwave vulcanization process for the microwave-vulcanized water-swelling rubber provided by the invention has the following advantages: processing procedures are few; edge trimming is saved; labor and raw materials are saved; and a product has the advantages of stable quality, high yield, high work efficiency and applicability to large-scale production; etc.

Owner:ZHEJIANG SHENZHOU TECH CHEM IND

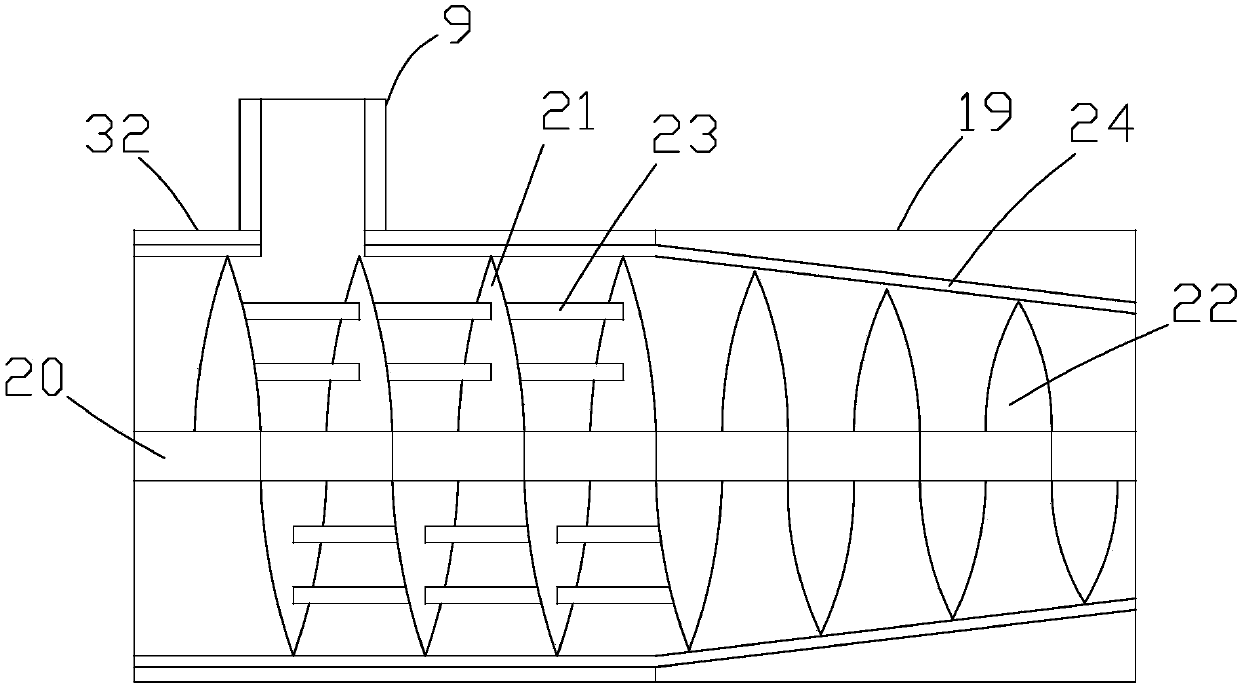

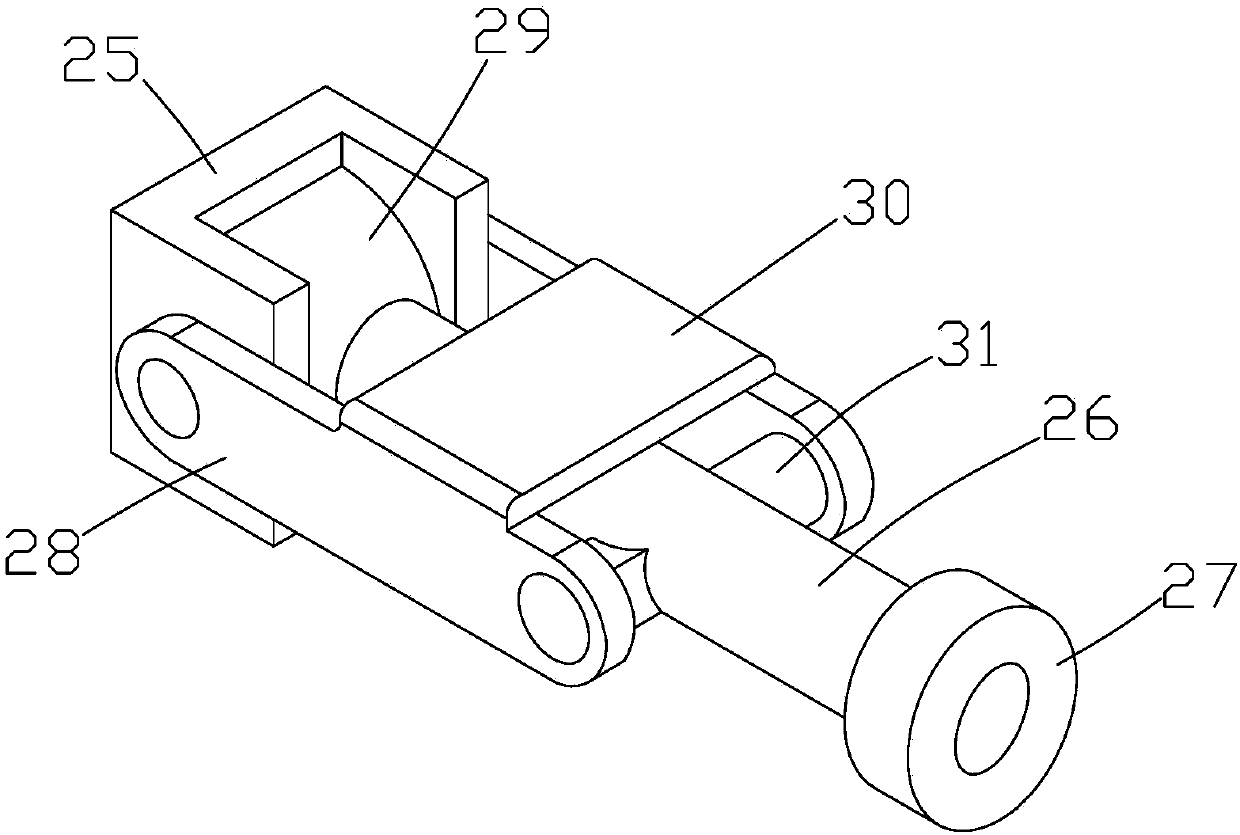

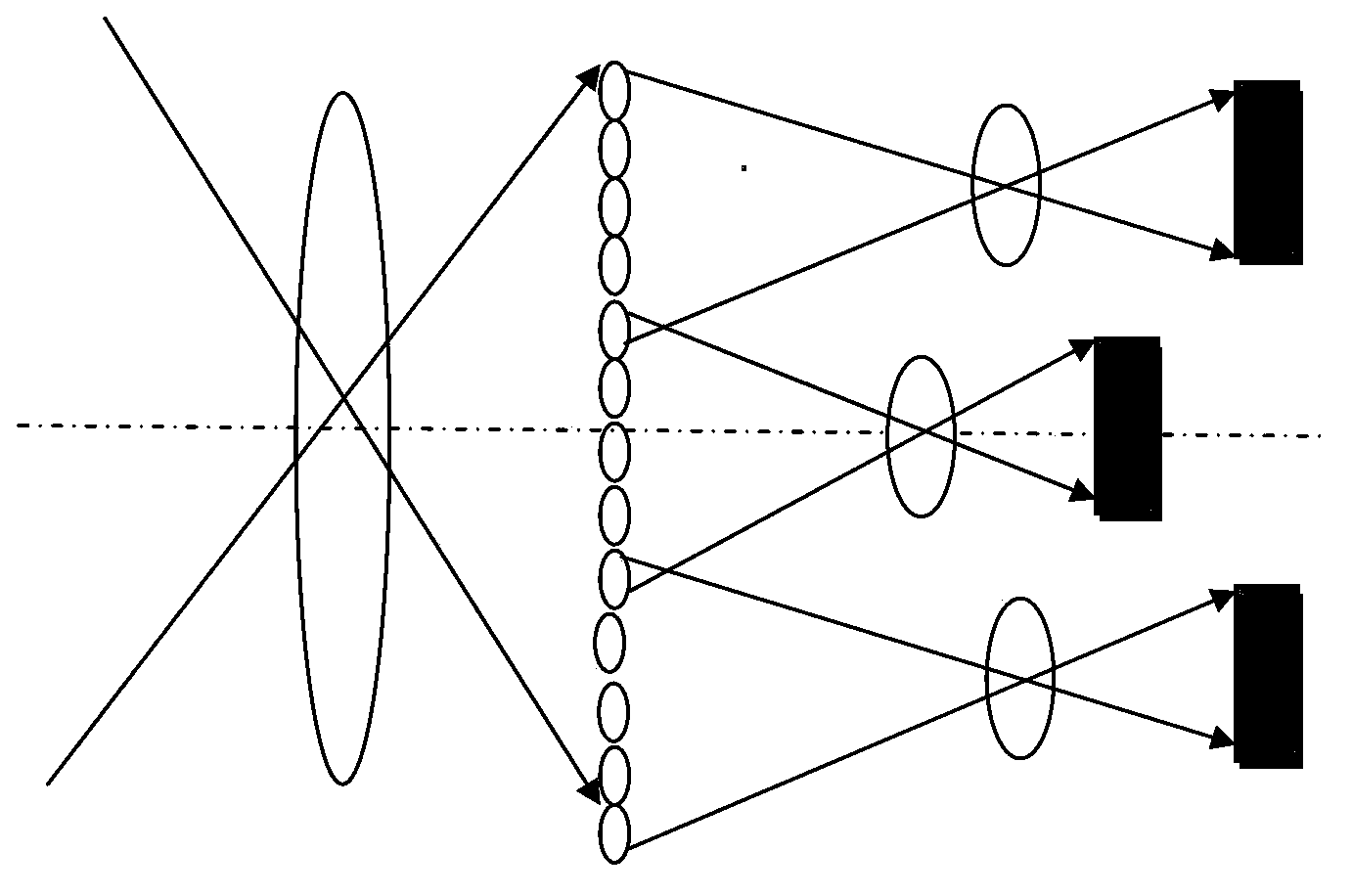

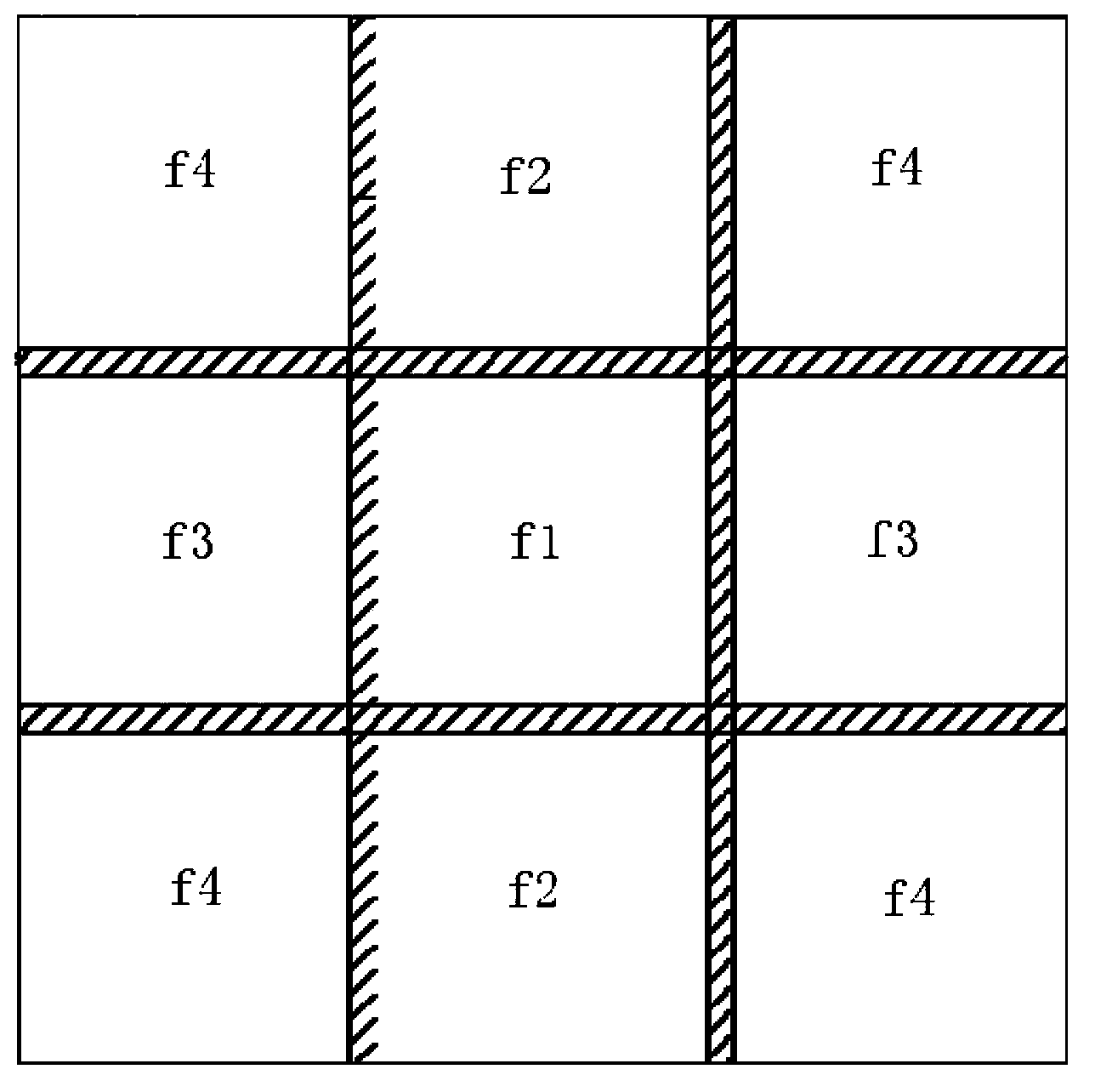

Switchover imaging photographic device and method

ActiveCN103412392AReduce resolutionLow cost requirementsTelevision system detailsColor television detailsLight sensingImaging quality

The invention relates to a switchover imaging photographic device which comprises an imaging photographic system which does not comprise light sensing devices, a micro lens array, switchover imaging photographic lenses and light sensing devices. The micro lens array is arranged on an imaging position of the imaging photographic system and fully covers an image plane of the imaging photographic system. Multiple sets of switchover imaging photographic lenses with different focal distances are arranged behind the micro lens array according to the principle that the focal distances of adjacent lenses are different and emitting light rays of the micro lens array are fully covered. The switchover imaging photographic lenses image the image plane of the imaging photographic system on the light sensing devices after the image plane is kept equal or amplified according to the geometry conjugation relationship. Each switchover imaging photographic lens corresponds to a light sensing device. Image stacking zones of all the light sensing devices are spliced and compounded to be an integral image. With the imaging photographic system, the micro lens array, the switchover imaging photographic lenses and the light sensing devices are combined to obtain an image which has equal or higher image quality and resolution and high geometric precision and a large complete image.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Pin pile leg for offshore lifting platform

ActiveCN103953020AIncrease the cross-sectional areaImprove bending abilityArtificial islandsUnderwater structuresStructural engineeringSection modulus

The invention discloses a pin pile leg for an offshore lifting platform and belongs to the technical field of offshore engineering equipment. A plurality of stages of pin holes are arranged on the pin pile leg along the axis direction of the pin pile leg, each stage of pin holes comprises a plurality of pin holes, each stage of pin holes is arranged at intervals along the direction of the outer contour line of the cross section of the pin pile leg, distance between every two pin holes of two adjacent stages of pin holes on the same line towards the axis direction of the pin pile leg is equal, each stage of pin holes is divided into at least two layers and the cross sections of the pin pile leg with the pin holes at different layers are different. By distributing each stage of pin holes which are distributed in the same cross section of the pin pile leg at at least two layers, the number of pin holes in the same cross section is reduced and the section area and the section modulus of the cross section of the pin pile leg is increased, so that reinforcing measures such as increasing the wall thickness of the pin pile leg for guaranteeing the technical requirement on the pin pile leg are not needed and the weight and the cost of the pin pile leg are reduced.

Owner:WUHAN MARINE MACHINERY PLANT

Inner casing of electric water heater

The invention relates to an electric appliance, in particular to an inner casing of an electric water heater. The inner casing of the electric water heater is of an upper casing and lower casing buckling structure, a converter cavity, a controller cavity and a heating device cavity are separately arranged in the sealed upper casing and lower casing, another independent power line lead-in cavity is communicated with other cavities through a hole which serves as a power line lead-in hole, a waterproof connector fixing hole for leading in power lines is arranged on the wall of the outer side, and a sealed cover plate seals up the power line lead-in cavity. A binding post clamping base is arranged in the power line lead-in cavity, and the cover plate is arranged on the power line lead-in cavity. A user interface plate cable lead-in port convenient to seal is arranged on the wall on the outer side of the controller cavity formed by the sealed upper casing and lower casing, a converter and a heater can be installed in other cavities formed by the upper casing and the lower casing, and a fixing support is arranged at the edge of the outside of a lower casing. The inner casing of the electric water heater is good in sealed protection, insulating and waterproof effects and high in safety coefficient and accords with the technical requirements of national standard II-class fast-heating type water heaters.

Owner:邸弋

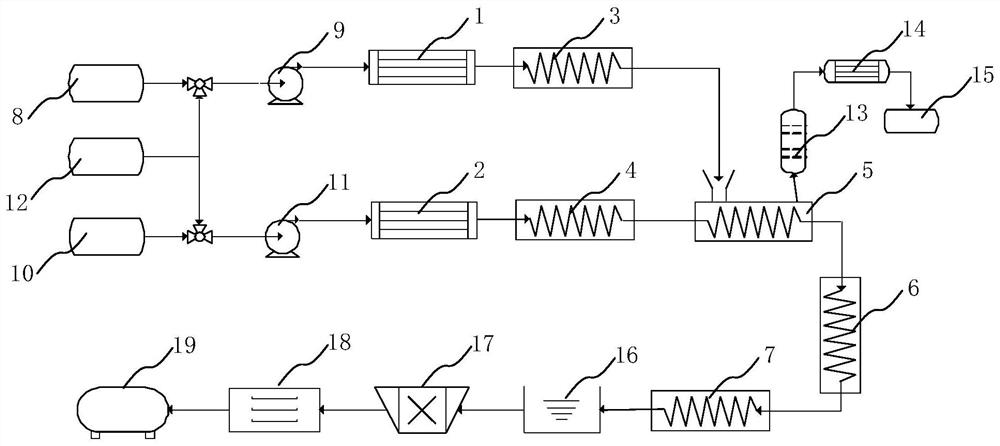

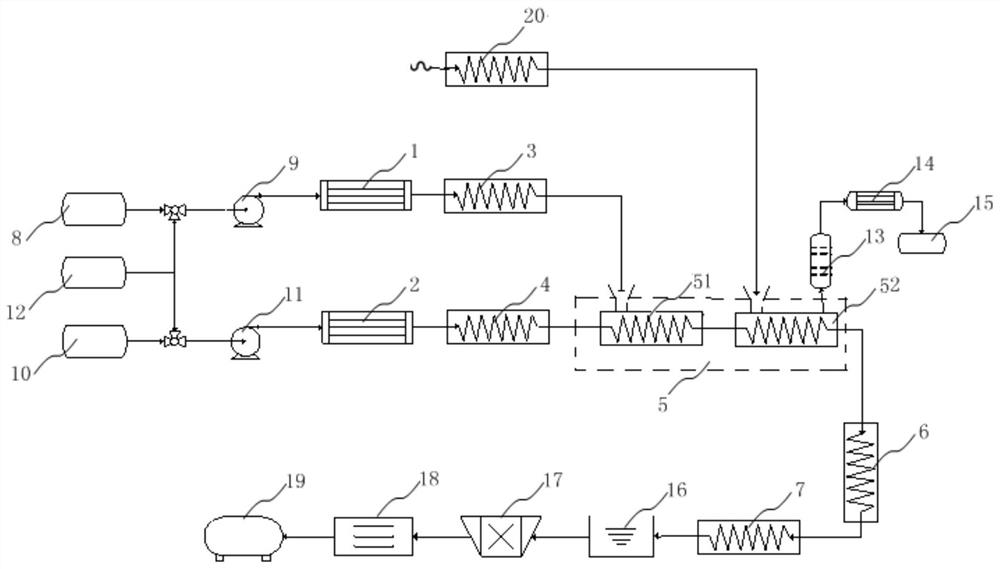

Method and system for continuously preparing liquid crystal polymer with adjustable molecular structure

ActiveCN112225884ARealize continuous productionHigh purityChemical/physical/physico-chemical microreactorsAcetic acidPolymer science

The invention relates to the technical field of polymer material preparation, in particular to a method and system for continuously preparing a liquid crystal polymer with a controllable molecular structure. The method at least comprises the following steps: 1) carrying out multistage tandem acetylation reaction and / or pre-polymerization reaction on a first acetylation reaction material to providea first acetylation monomer and / or a prepolymer with a polymerization degree of Xn; 2) carrying out multistage tandem acetylation reaction and / or pre-polymerization reaction on the second acetylationreaction material to provide a second acetylation monomer and / or a prepolymer with a polymerization degree of X'n; and 3) carrying out polymerization reaction on the first acetylated monomer and / or the prepolymer with the polymerization degree of Xn in the step 1) and the second acetylated monomer and / or the prepolymer with the polymerization degree of X'n in the step 2), removing small moleculesand acetic acid in vacuum, and performing extruding and pelletizing to provide the liquid crystal polymer. According to the invention, the molecular structure can be regulated and controlled; and meanwhile, the generation of small molecular by-products and branched chains is inhibited, and the product performance is improved.

Owner:惠生(中国)投资有限公司

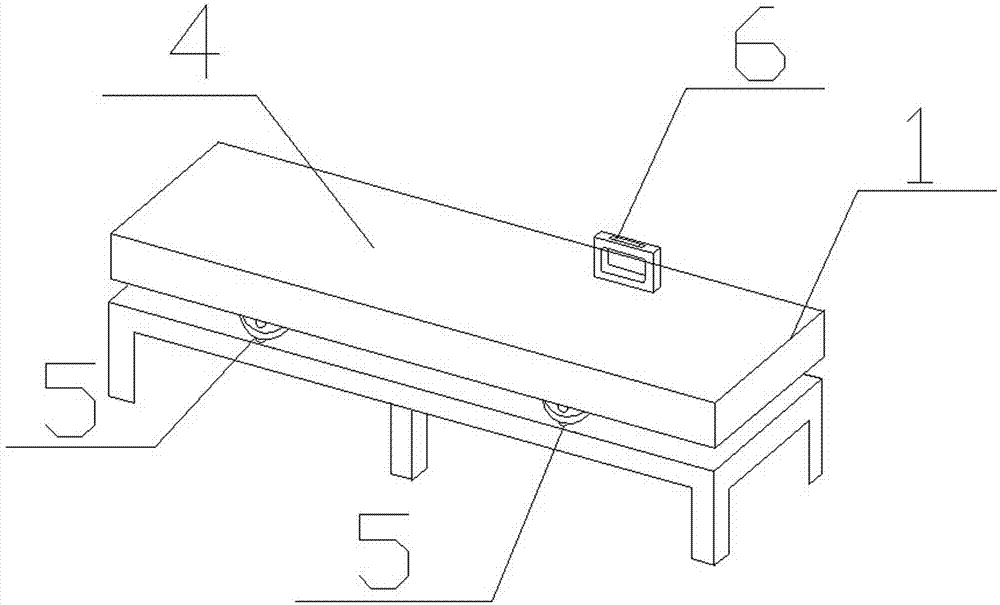

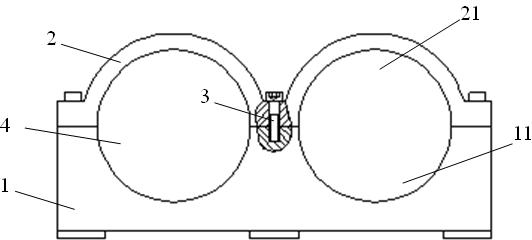

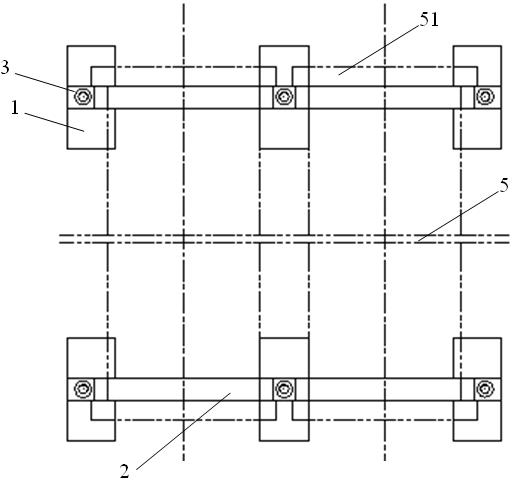

Crystal pulling furnace sub-chamber body machining tool

InactiveCN102350640AEasy to useEasy to operatePositioning apparatusMetal-working holdersEngineeringMachining time

The invention provides a crystal pulling furnace sub-chamber body machining tool which can perform positioning fast and reliably and effectively shorten the machining time of a sub-chamber body of a crystal pulling furnace. The crystal pulling furnace sub-chamber machining tool comprises two bases, as well as pressure plates, two grooves with semicircular sections are arranged at the upper part of each base, the pressure plates are detachably connected with the bases, each pressure plate is also provided with two grooves with semicircular sections, and the grooves on the pressure plates and the grooves on the bases form through holes with circular sections.

Owner:江苏新华机电设备制造有限公司

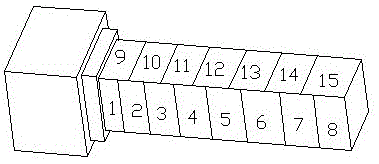

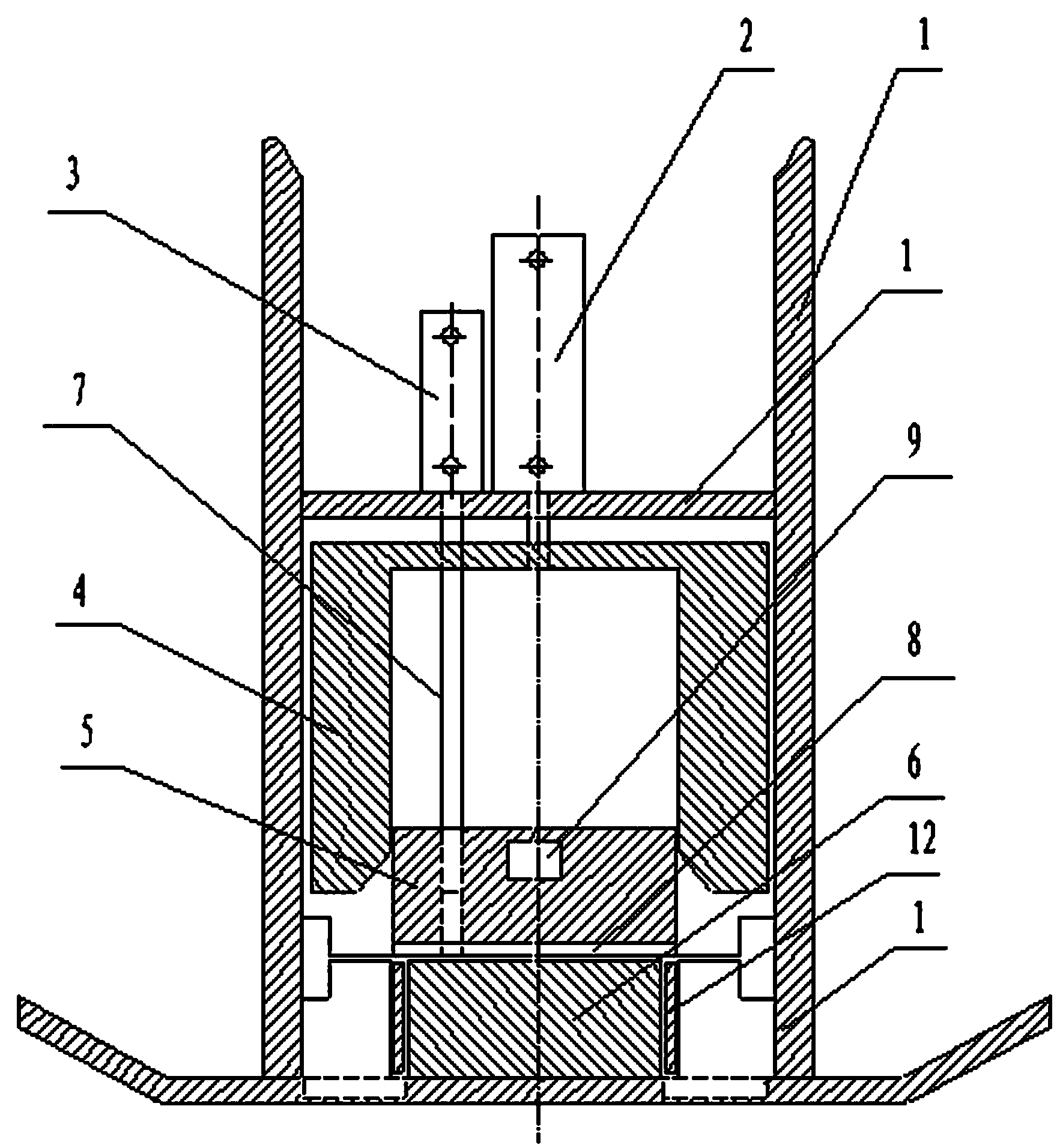

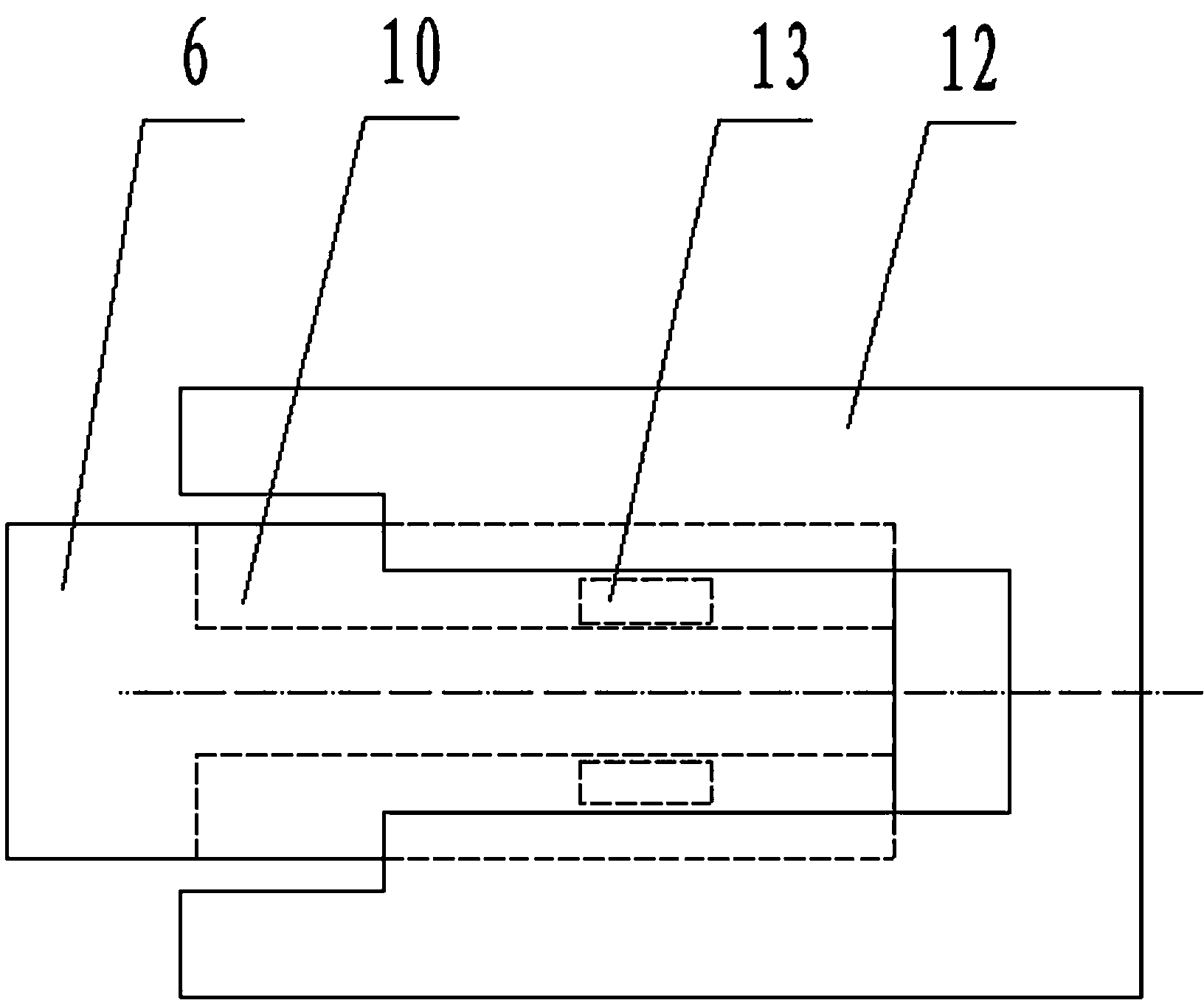

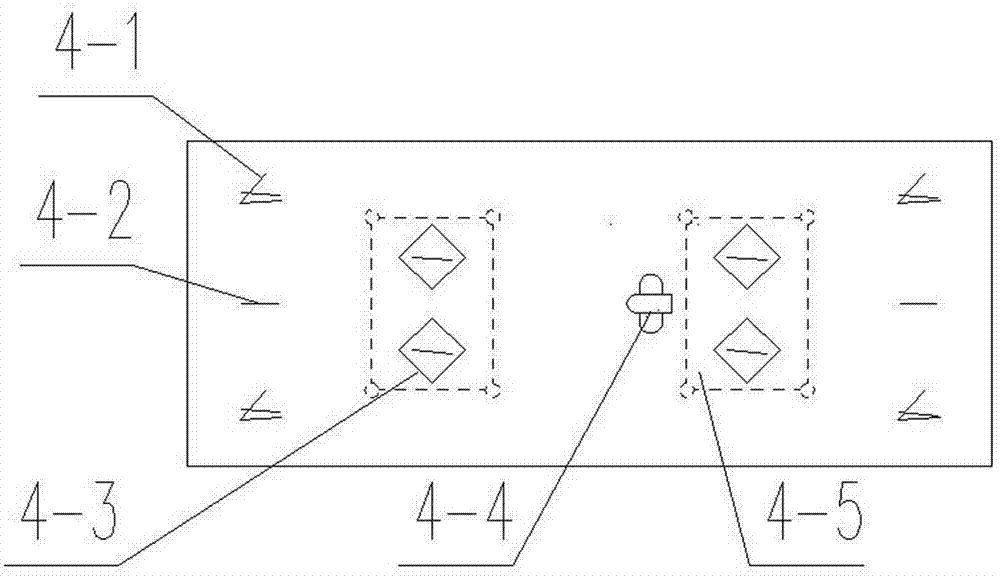

Copper alloy die machining device and machining process

The invention discloses a copper alloy die machining device and machining process. The copper alloy die machining device comprises an oil pressure power die handle (1), a cutting edge female die (6), a lower fixing cutting edge pedestal (7) and a workpiece discharging cavity support (9). The bottom end of the oil pressure power die handle (1) is connected with a pressurization movable copper male die (2). The cutting edge female die (6) is clamped between an upper fixing guide plate (4) and the lower fixing cutting edge pedestal (7). An upper through hole is formed in the center of the upper fixing guide plate (4). A cutting formed edge is formed in the center of the cutting edge female die (6). A lower through hole is formed in the center of the lower fixing cutting edge pedestal (7). The size of the upper through hole, the size of the lower through hole and the size of a cutting formed edge cavity are larger than the size of a die body of the pressurization movable copper male die (2). The pressurization movable copper male die (2) is guided into and can vertically move in the upper through hole, the lower through hole and the cutting formed edge. The lower fixing cutting edge pedestal (7) is installed on the workpiece discharging cavity support (9). A modern numerical control milling machine is replaced by the copper alloy die machining device to conduct machining, production efficiency is improved by multiple times, production, manufacturing and machining cost is reduced, and the quality of products is stable.

Owner:FUZHOU YINSHENGWANG SANITARY WARE

Fabrication process for energy storage spring conductor rod

InactiveCN101393806AGuaranteed technical requirementsHighlight substantiveMetal-working apparatusSwitch power arrangementsPunch pressSteel bar

The invention discloses a manufacture process for an energy-storing spring guide bar, which is characterized in that the guide bar takes a brass combined forging with an insert as a body material, and the insert is a stainless steel bar taking 1Cr18Ni9Ti-Q as the material. The manufacture process comprises the following steps: a. blanking the brass material, and fine-processing the stainless steel bar; b. heating the brass material at the heating-up temperature to be 700-750 DEG C; c. placing the stainless steel bar and the brass material into a die, and die-forging the brass material and the stainless steel bar together on a punch, heating the die during the die-forging process at the heating temperature to be 250-300 DEG C; d. removing the stress and annealing the forging after the die-forging; and e. cold-trimming the forging . The manufacture process efficiently solves the problems of high technical requirements and great manufacture difficulties of the energy-storing spring guide bar.

Owner:ZHEJIANG ZHENGCHANG FORGING

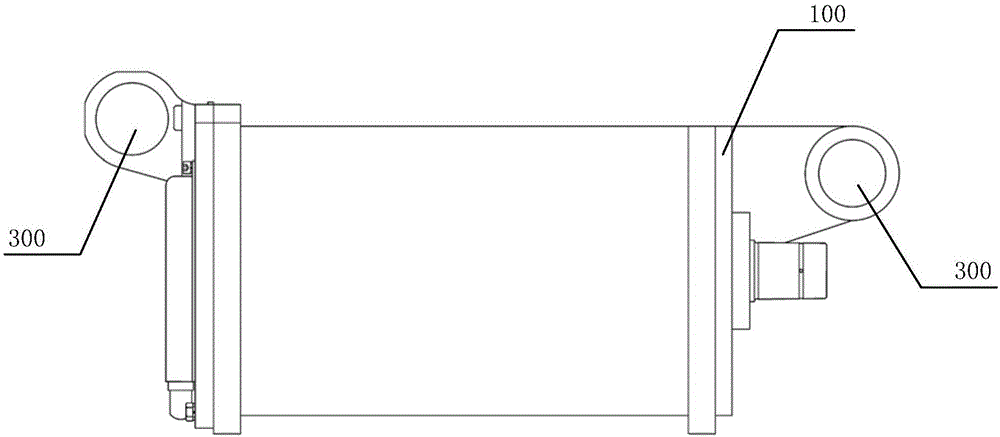

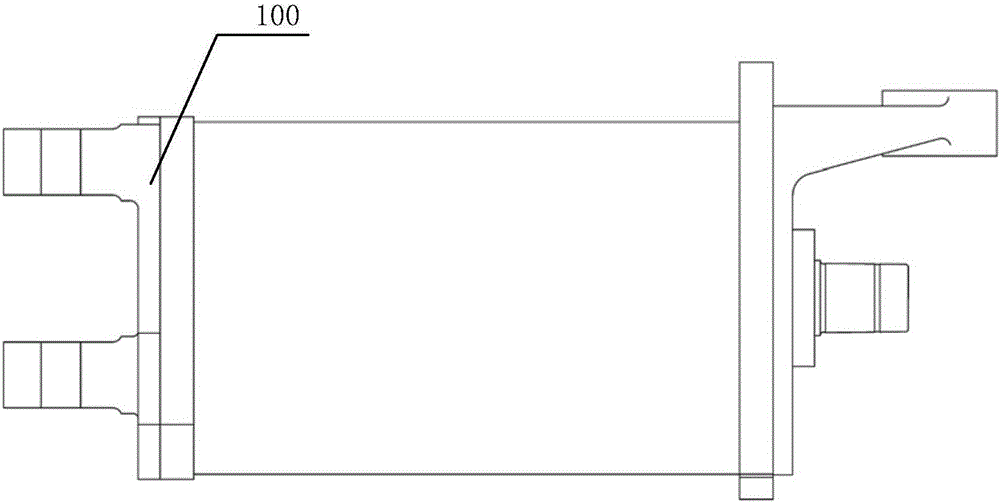

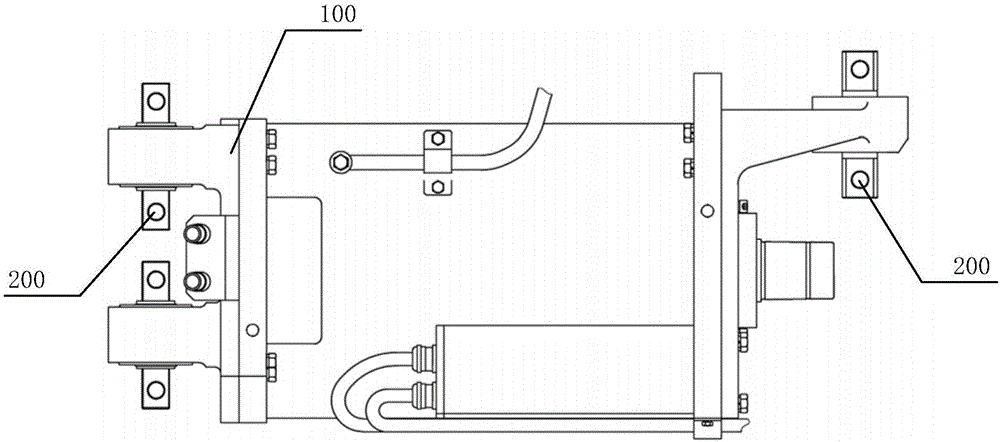

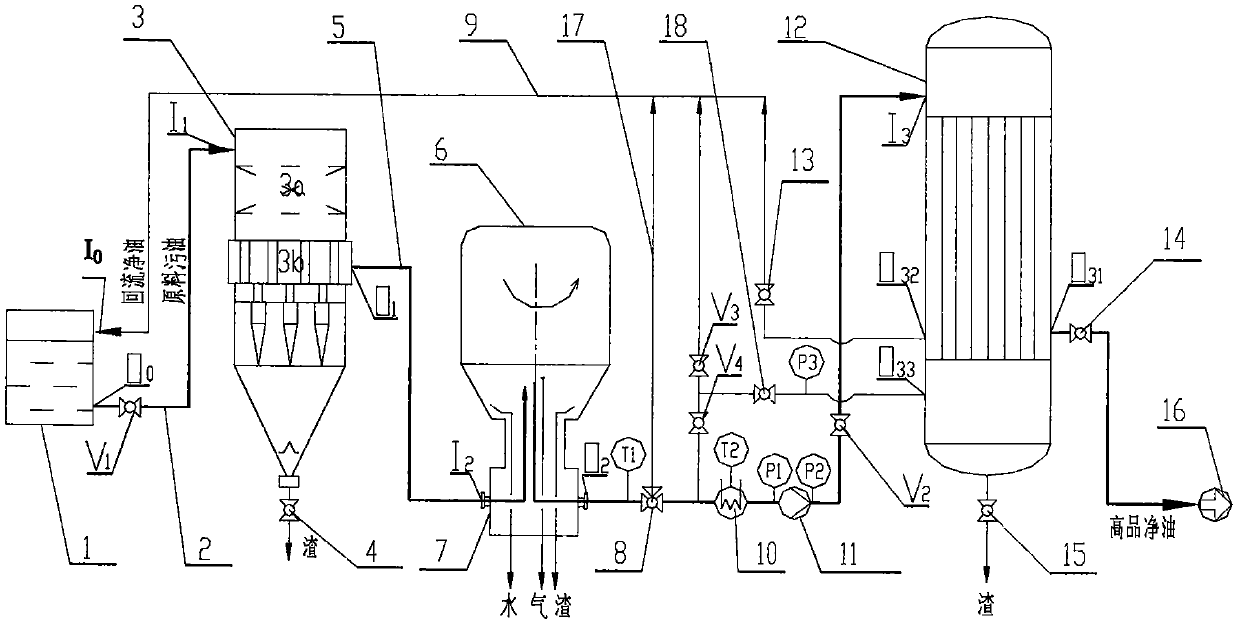

A multi-functional high-efficiency lubricating oil purification process device

The invention relates to a purifying device and method for polluted lubricating oil (i.e., dirty oil). The device comprises a magnetic rotator, a centrifuge and a fine filter which are connected sequentially, wherein a liquid outlet of the magnetic rotator is connected with a liquid inlet of the centrifuge through a first adapting pipe, and a liquid outlet of the centrifuge is connected with a liquid inlet of the fine filter through a pipeline. According to the device and the method disclosed by the invention, methods such as rotating-magnetic coagulation, centrifugal separation and membrane type refined filtration are organically combined, so that deep purification of the polluted lubricating oil is achieved; and the restraint, i.e., singleness of the existing equipment is overcome, various impurities such as enginery, water, air and oxidative colloids generated during the use of various kinds of lubricating oil can be effectively removed, the liquid quality of the lubricating oil is remarkably improved, running equipment is reliably guaranteed, the service life of liquid oil is substantially prolonged, the consumption of the lubricating oil is lowered, the cost of the lubricating oil is reduced, the environmental pollution caused by waste liquid oil is reduced, and great direct or indirect economic benefit is produced.

Owner:BAOTOU RUINUO JINGTU NEO MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com