Plastic lifting handle sizing device of full-automatic carton lifting handle eyeleting machine

A technology for a handle threading machine and a carton handle, applied in the field of machinery and equipment, can solve problems such as high labor costs, damage to packaging boxes and box bodies, and inability to ensure high efficiency and high quality production operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

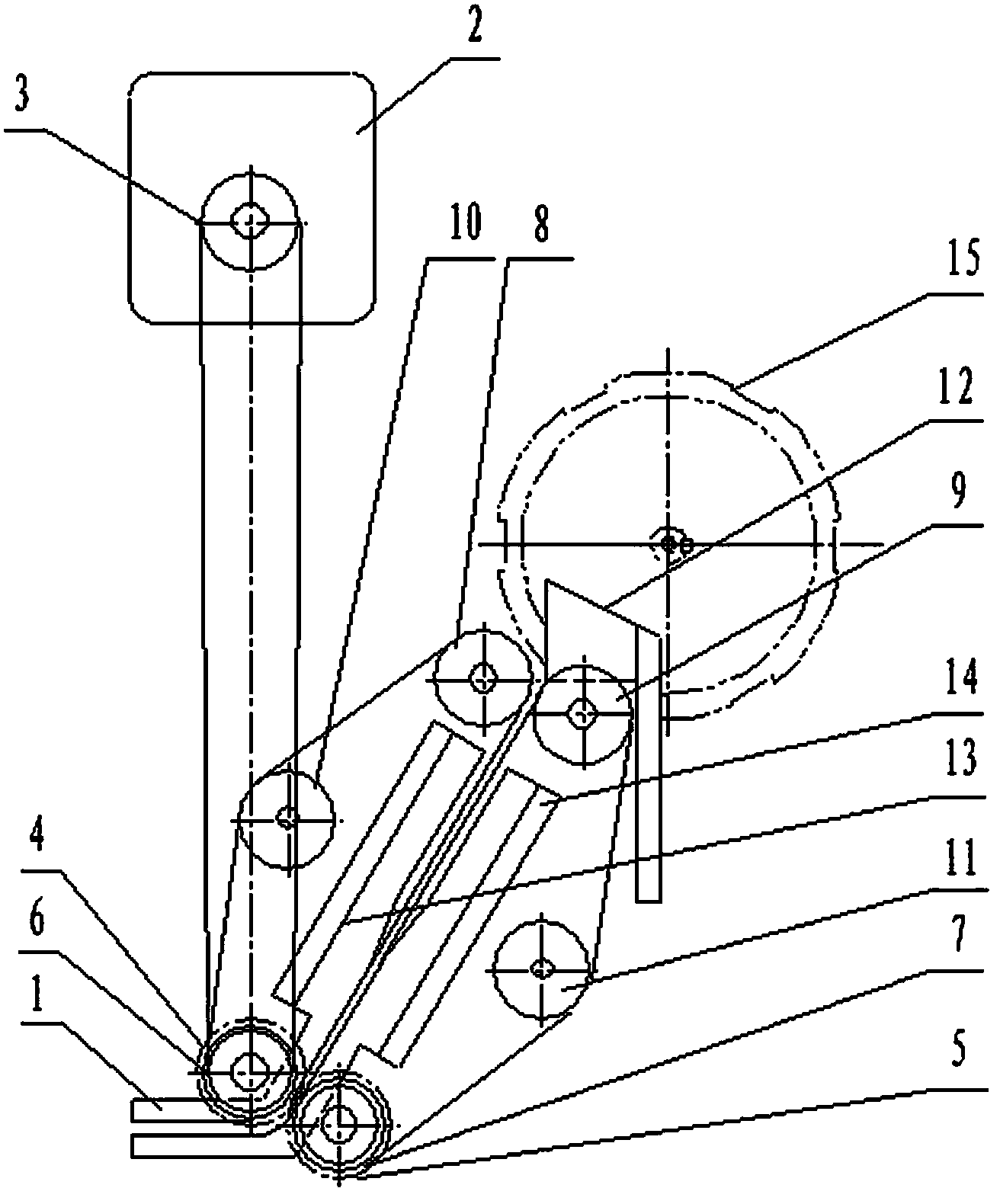

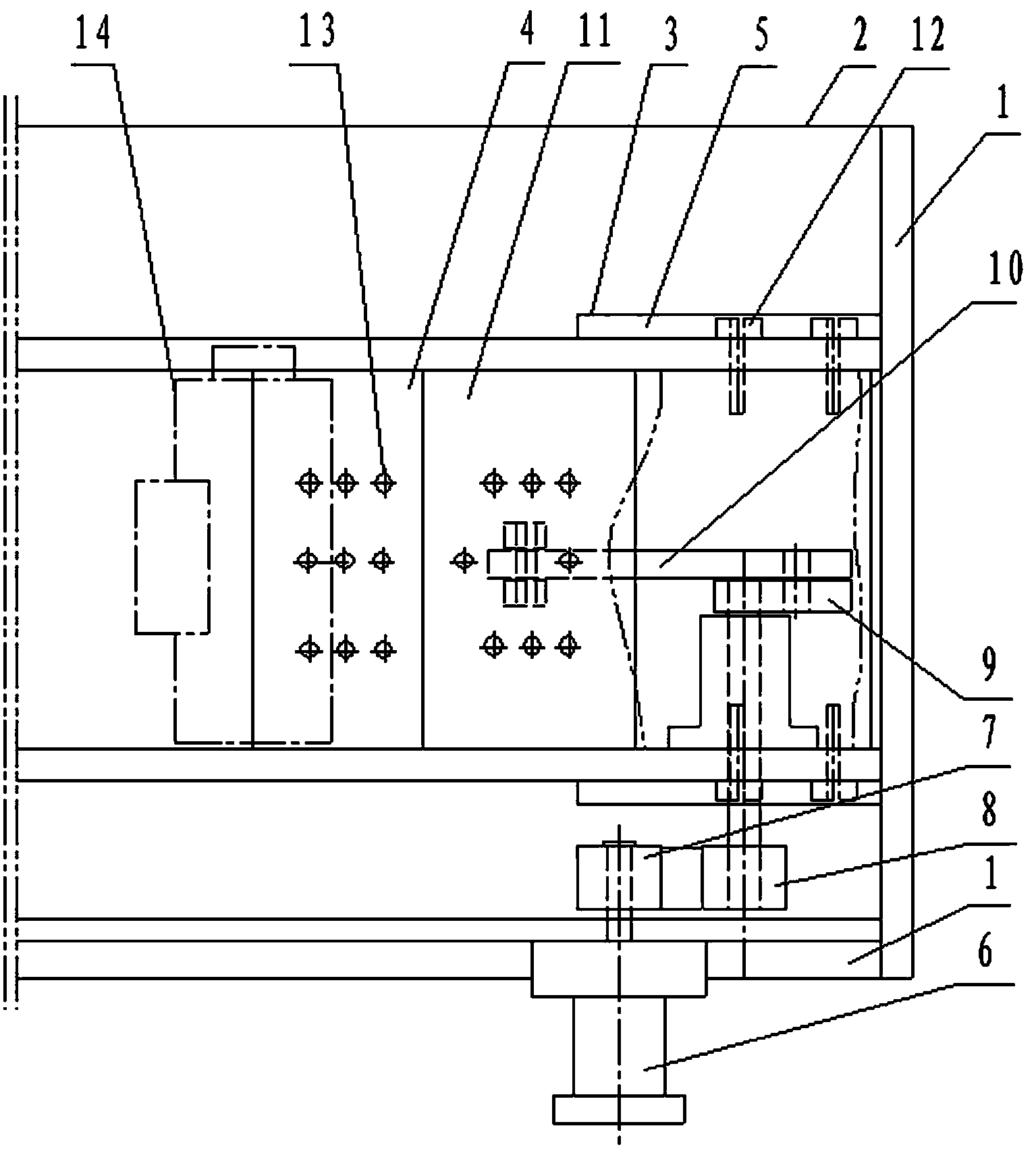

[0010] The plastic handle forming device of a fully automatic carton handle threading and buttoning machine of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0011] Depend on figure 1 , figure 2 It can be seen that the plastic handle shaping device of a fully automatic carton handle threading and buttoning machine in this embodiment is composed of a frame 1, a motor 2 fixed on the frame 1, and a motor pulley 3 fixed to the motor 2 shaft and set The conveying assembly on the frame 1 and the shaping assembly are composed. The conveying assembly is provided with two groups with the same structure, and the two groups are fixed on the frame 1 in parallel. Driving gear Ⅰ5, upper driving pulley Ⅰ6, lower driving pulley Ⅰ7, upper driven pulley Ⅰ8, lower driven pulley Ⅰ9, upper adjusting wheel Ⅰ10 and lower adjusting wheel Ⅰ11, the other group is composed of fixed frame 1 Upper driving gear II 4', lower driving gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com