Device and method for pressing rubber joints to electric motor

A technology of rubber joints and press-fitting devices, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of strong versatility, guaranteeing parallelism requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

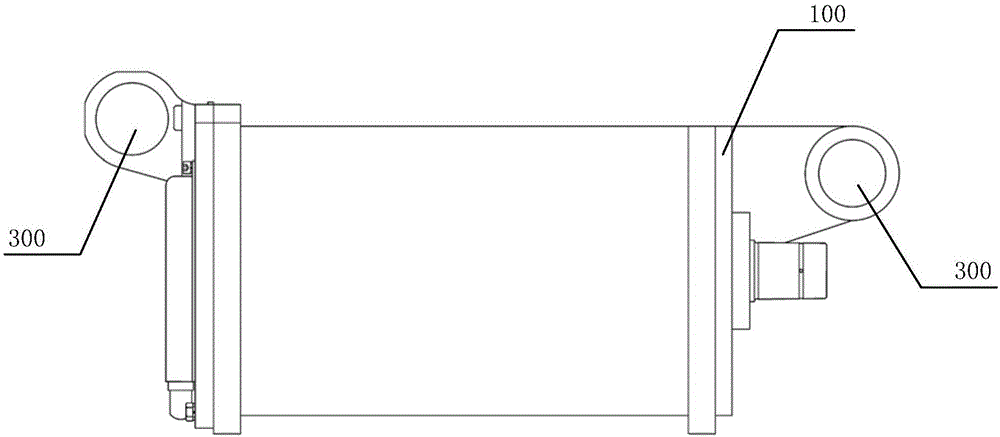

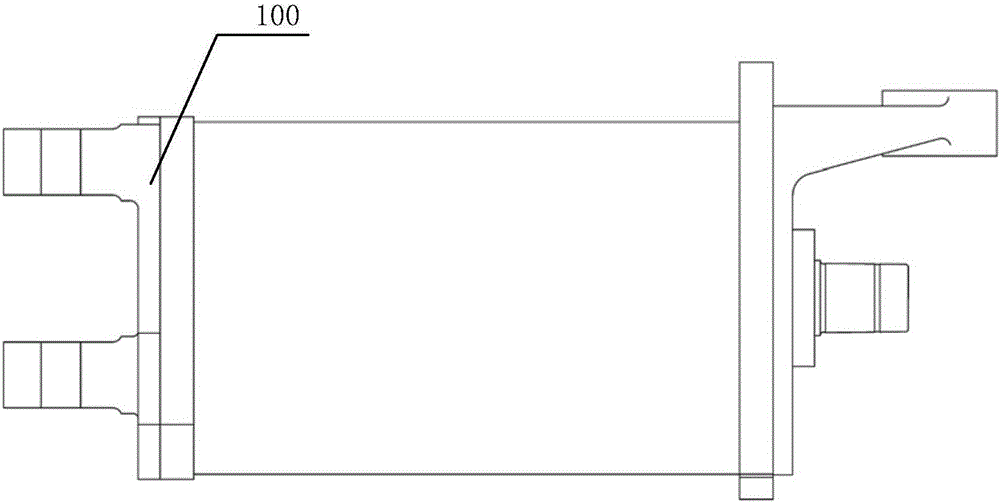

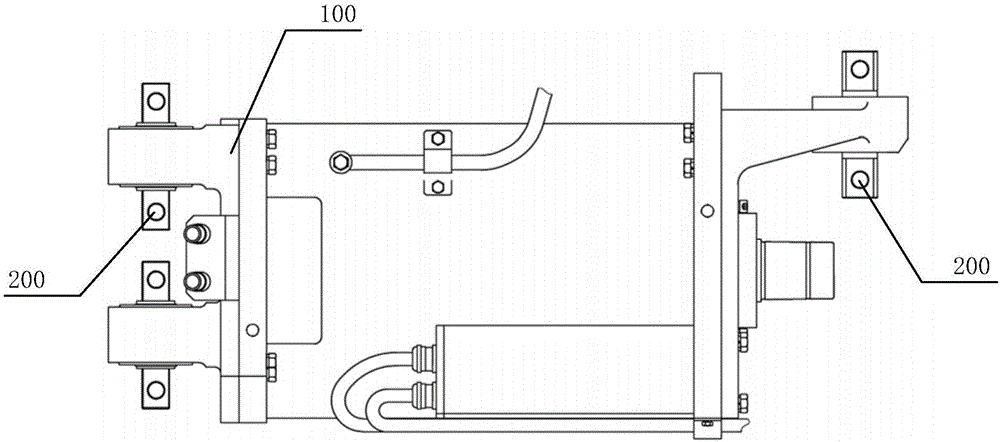

[0053] as attached Figure 7 As shown, a specific embodiment of a motor rubber node press-fitting device is used to press-fit the rubber node 200 into the rubber node installation hole 300 of the motor end cover 100. The press-fitting device includes:

[0054] The bottom plate 1, the guide plate 1, the guide plate 2 5 and the splint 7 are spaced apart and coaxially arranged in sequence according to the assembly positions, and the guide plate 1 4, the guide plate 2 5 and the splint 7 are all provided with through holes, such as attached Figure 9 And attached Figure 10 Shown is the schematic diagram of the structure of the base plate 1, as attached Figure 13 And attached Figure 14 Shown is the structural diagram of the splint 7; there is a space for arranging the force-applying mechanism 10 between the bottom plate 1 and the guide plate 1, and a space for accommodating the rubber node installation hole 300 is arranged between the guide plate 2 5 and the splint 7;

[0055...

Embodiment 2

[0067] A specific embodiment of a method for press-fitting a rubber node of a motor using the device described above includes the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com