Checkout device for special textile level ruler and use method thereof

A straightedge and calibration technology, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of inability to detect or calibrate the inspection tool, affect the straightness of the straightedge, and rust the scale surface, etc., and achieve a simple structure , easy to operate, and promote the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

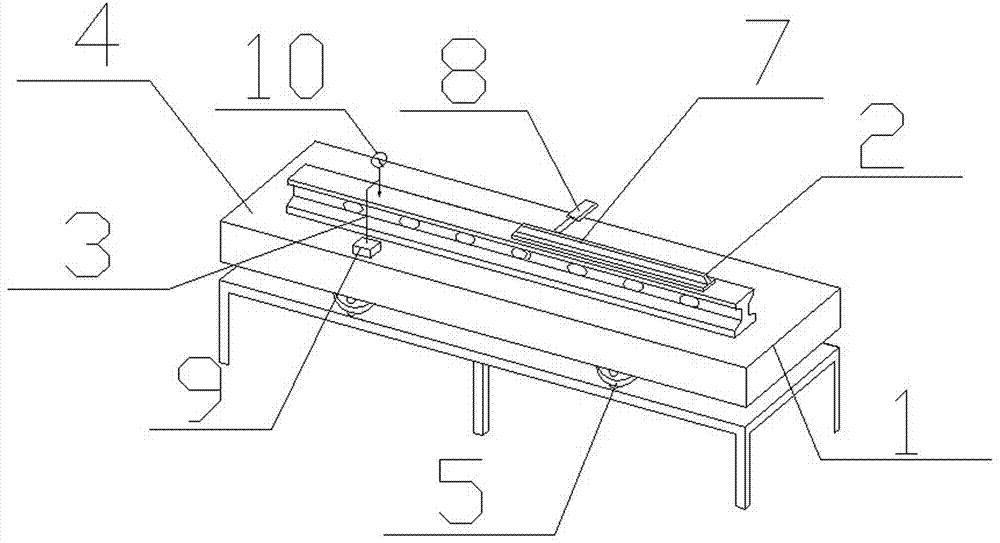

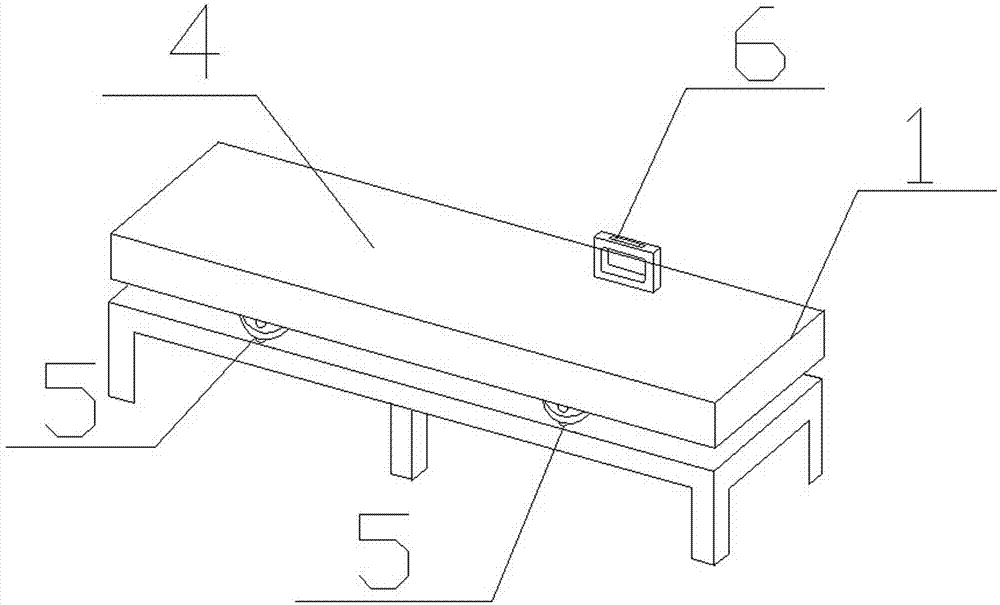

[0013] Depend on figure 1 and figure 2 It can be seen that a kind of verification device for a textile-specific straight ruler of the present invention includes a detection platform assembly 1, a flatness detection assembly 2, and a parallelism detection assembly 3;

[0014] The detection platform assembly 1 includes a detection platform 4, a leveling mechanism 5 installed at the four bottom corners of the detection platform 4, and a frame level 6 arranged on the detection platform 4;

[0015] The flatness detection assembly 2 includes a thread ruler 7 and a plug gauge 8;

[0016] The parallelism detection assembly 3 is a measuring frame 9 with a dial indicator 10 .

[0017] The leveling mechanism 5 is a height-adjustable screw assembly with feet.

[0018] A method for using a calibration device for a special textile straightedge, the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com