Textile spinning machine fixed gauge casing radial runout detection device

A textile spinning frame and radial runout technology, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of inability to detect and calibrate the accuracy of such special inspection tools, the influence of the quality of equipment flat cars, and the decline in the accuracy of gauge inspection, etc. problems, to achieve the effect of simple structure, promotion of product quality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

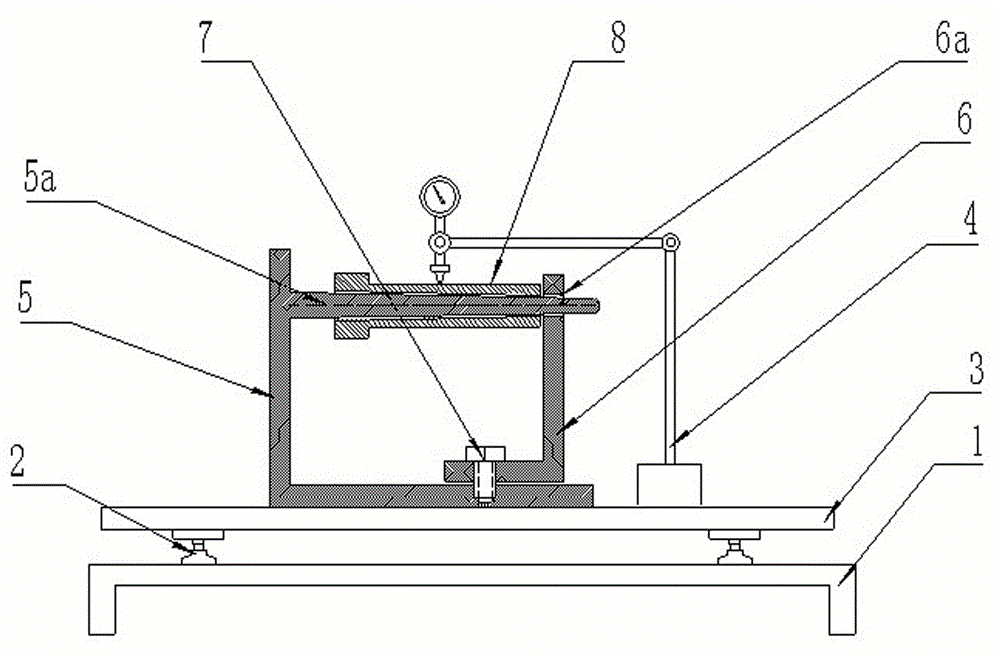

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

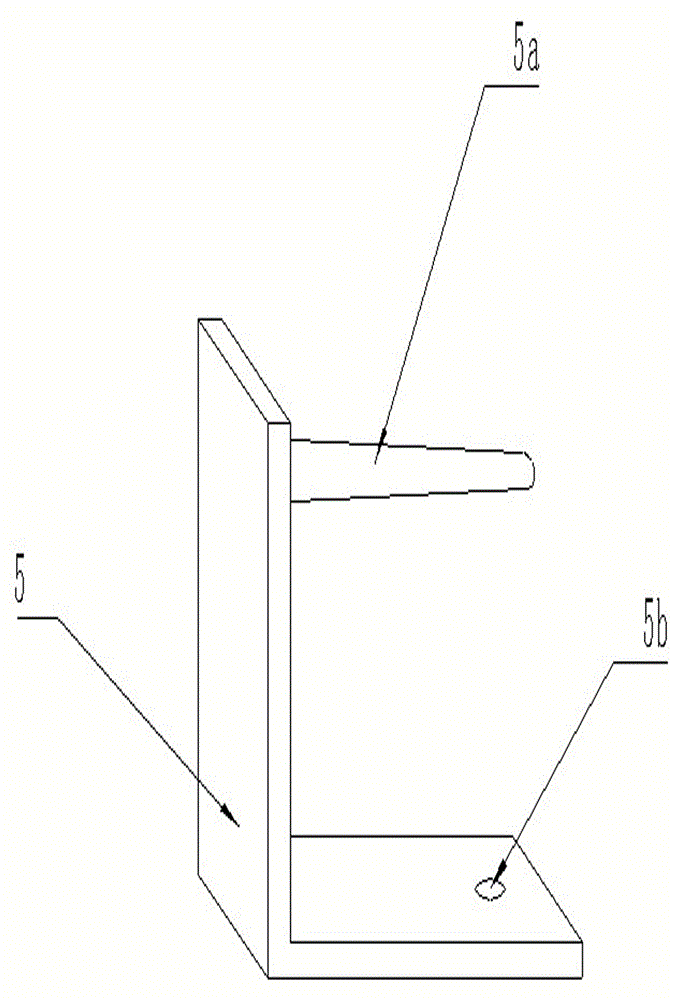

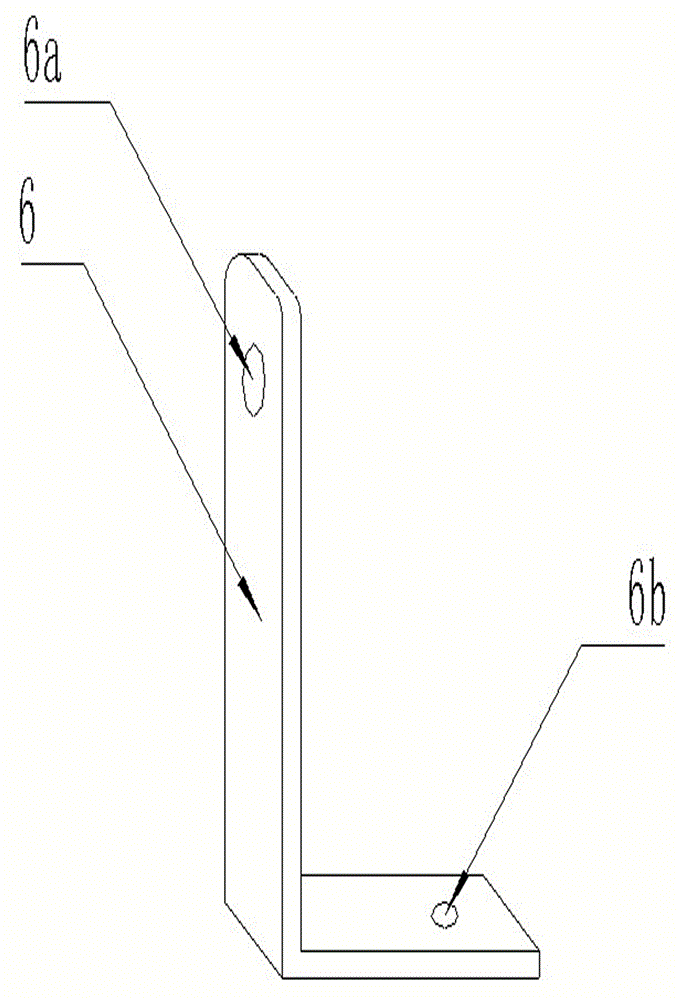

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a radial runout detection device of a textile spinning frame sizing casing according to the present invention comprises a base 1 on which a detection platform 3 is arranged; a leveling mechanism 2 is arranged between the base 1 and the detection platform 3; On the detection platform 3, a left "L"-shaped bracket 5 and a right "L"-shaped bracket 6 are arranged opposite and staggered; The bottom of the bracket 5 is provided with a positioning screw hole 5b; the top of the right "L"-shaped bracket 6 is provided with a limiting hole 6a, and the bottom of the right "L"-shaped bracket 6 is provided with a positioning hole 6b; the right "L"-shaped bracket 6 is provided with a positioning hole 6b; 6 After connecting the screw hole 5b and the positioning hole 6b through the screw 7, the right "L"-shaped support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com