Wire harness support forming die

A technology for forming molds and wire harness brackets, which is applied in the field of mechanical processing, can solve the problems that the dimensional accuracy cannot meet the technical requirements, the parts cannot reach the matching state, and the consistency of the parts is poor, so as to achieve good consistency, easy operation and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

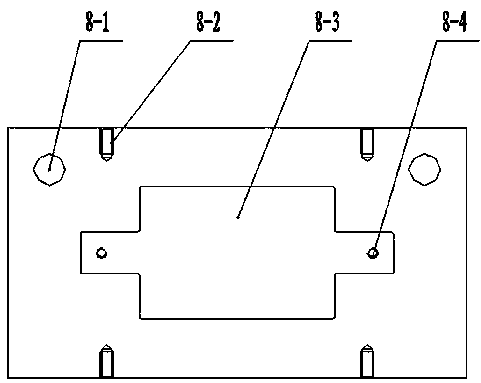

[0031] As shown in the accompanying drawings: a wire harness bracket molding die, which includes an upper die assembly and a lower die assembly.

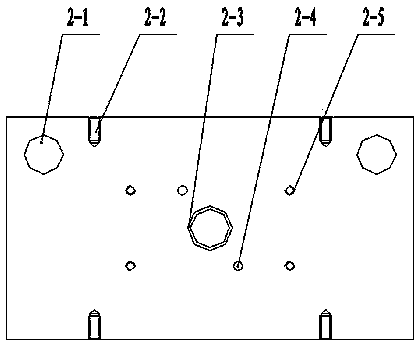

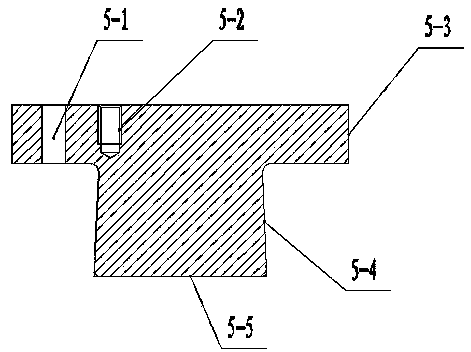

[0032] The upper mold assembly includes: a mold handle 1, an upper mold base 2, a backing plate 3, a screw 4, a punch 5, a cylindrical pin 12, a positioning pin 18, a hexagon socket bolt 19, and a guide sleeve 17.

[0033] The upper mold base 2 includes: guide sleeve installation hole 2-1, upper mold hoisting hole 2-2, mold handle installation hole 2-3, backing plate positioning hole 2-4, backing plate installation hole 2-5, guide Sleeve mounting holes 2-1 are located on both sides of the front of the upper die base, upper die lifting holes 2-2 are located on the four corners of the upper die base side, mold handle installation holes 2-3 are located in the center of the upper die base, pads Plate mounting holes 2-5 are located around the mold handle mounting holes, and backing plate positioning holes 2-4 are located near the backing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com