Crystal pulling furnace sub-chamber body machining tool

A crystal pulling furnace and auxiliary chamber technology, applied in the field of processing tooling for the auxiliary chamber body of the crystal pulling furnace, can solve the problems of unguaranteed processing quality, affecting the use of the whole machine, and difficult processing, so as to save manpower, increase production capacity, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below with reference to the accompanying drawings.

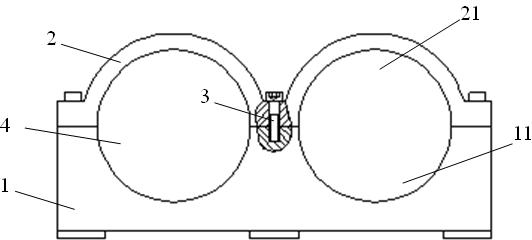

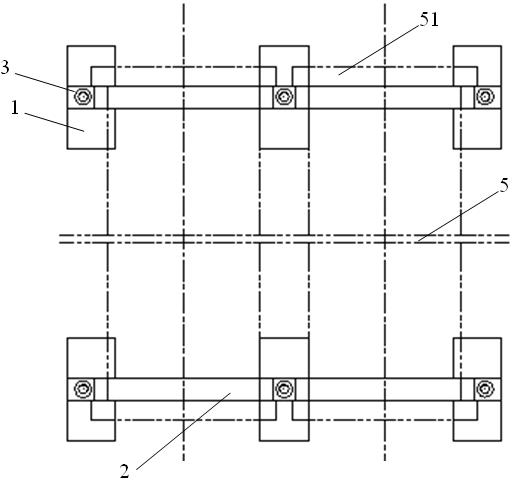

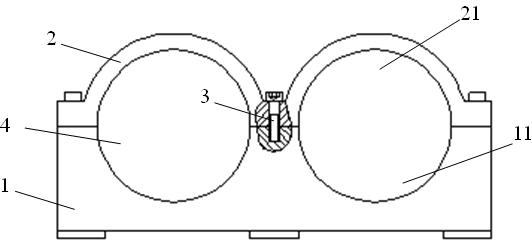

[0010] Such as figure 1 , 2 The main body processing tool of the auxiliary chamber of the crystal pulling furnace includes two bases 1, each base has two grooves 11 with a semicircular cross-section on the upper part, and the pressure plate 2 is detachably connected to the base through bolts 3. Each pressing plate 2 also has two grooves 21 with a semicircular cross section, and the grooves on the pressing plate and the grooves on the base form a through hole 4 with a circular cross section. When in use, place the two ends of the crystal pulling furnace auxiliary chamber body 5 in the through hole 4 of the tooling, press and fix the crystal pulling furnace auxiliary chamber body on the base through the pressing plate, and the two round flanges of the crystal pulling furnace auxiliary chamber body 51 outside the through hole 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com