Method and system for continuously preparing liquid crystal polymer with adjustable molecular structure

A liquid crystal polymer and molecular structure technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve problems such as difficulty in continuous production, small specific surface area, and high monomer concentration , to achieve the effects of inhibiting the formation of small molecule by-products and branched chains, enhancing the mass transfer and heat transfer effects, and reducing the acetylation reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

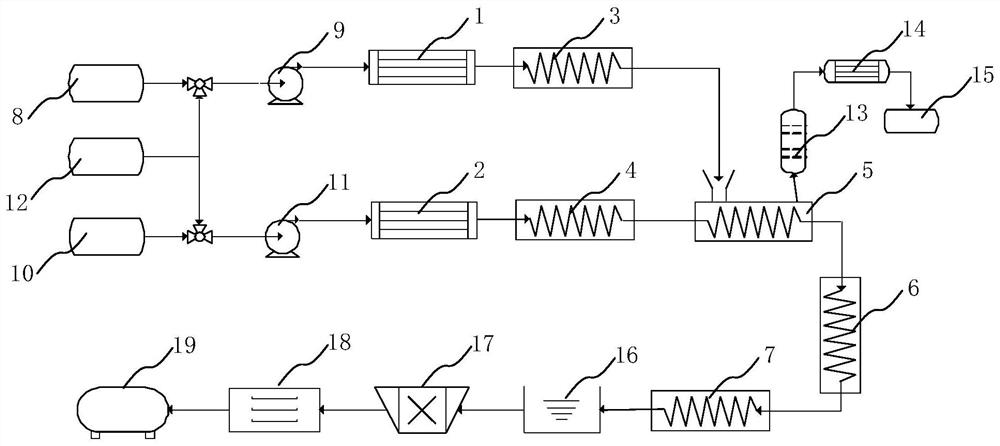

[0138] With p-hydroxybenzoic acid (A) and 2-hydroxy-6-naphthoic acid (B 1 ) as raw material, the continuous preparation of the structural unit is AB 1 AB 1 type liquid crystal polymers.

[0139] Such as figure 1 138.13g of p-hydroxybenzoic acid, 0.11g of potassium acetate and 204g of acetic anhydride are added to the first raw material dissolving device 8, and after the materials are dissolved, they are introduced into the first multi-stage micro-reaction device 1 through an advection pump for acetylation reaction. The stage micro-reaction device 1 includes a plurality of microreactors connected in series. The reaction time of materials in each stage of microchannels is gradually shortened, the heating temperature is gradually increased, and the propulsion rate of the advection pump is controlled at 100-120ml / min. The residence time in the micro-reaction device 1 is controlled to be 10-20s, and the reaction temperature is controlled to be 130-140°C; The heating temperature...

Embodiment 2

[0145] With p-hydroxybenzoic acid (A) and 2-hydroxy-6-naphthoic acid (B 1 ) as raw material, the continuous preparation of the structural unit is AAAB 1 AAAB 1 type liquid crystal polymers.

[0146] Such as figure 1 138.13g of p-hydroxybenzoic acid, 0.11g of potassium acetate and 204g of acetic anhydride are added to the first raw material dissolving device 8, and after the materials are dissolved, they are introduced into the first multi-stage micro-reaction device 1 through an advection pump for acetylation reaction. The stage micro-reaction device 1 includes a plurality of microreactors connected in series. The reaction time of materials in each stage of microchannels is gradually shortened, the heating temperature is gradually increased, and the propulsion rate of the advection pump is controlled at 100-120ml / min. The residence time in the micro-reaction device 1 is controlled to be 10-20s, and the reaction temperature is controlled to be 130-140°C; The heating tempera...

Embodiment 3

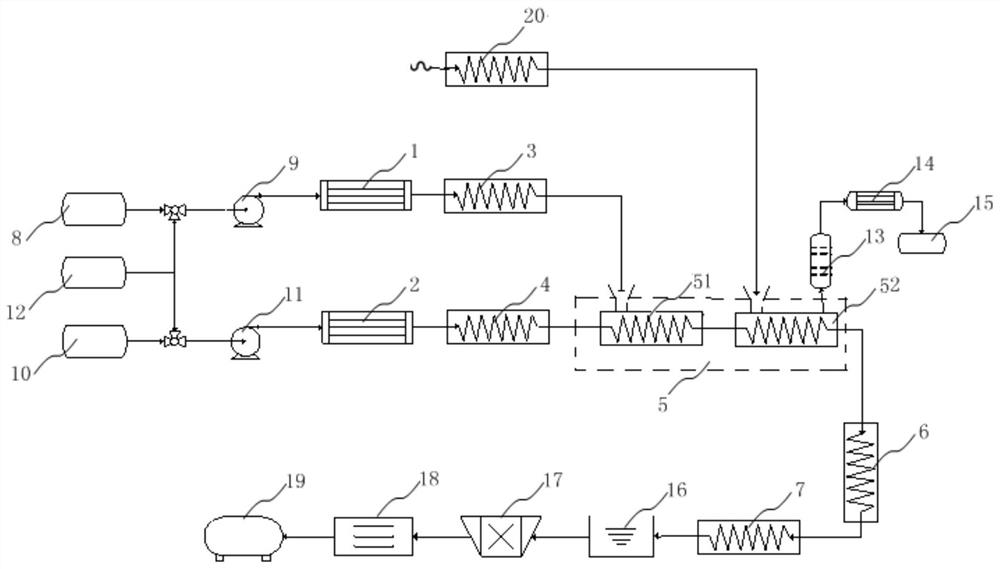

[0151] With p-hydroxybenzoic acid (A), hydroquinone (B 2 ) and terephthalic acid (C) as raw materials, the continuous preparation of the structural unit is AAB 2 C-type liquid crystal polymer.

[0152] Such as figure 2 138.13g of p-hydroxybenzoic acid, 0.11g of potassium acetate and 204g of acetic anhydride are added to the first raw material dissolving device 8, and after the materials are dissolved, they are introduced into the first multi-stage micro-reaction device 1 through an advection pump for acetylation reaction. The stage micro-reaction device 1 includes a plurality of micro-reactors connected in series. The reaction time of materials in each stage of micro-channel is gradually shortened, and the heating temperature is gradually increased. The residence time in the first-stage micro-reaction device 1 is controlled to be 10-20s, and the reaction temperature is controlled to be 130-140°C; The heating temperature of the screw extrusion device 3 is controlled at 200-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com