Drawing-out method for high-speed steel cold roll neck

A technology for cold rolling and high-speed steel, which is applied in the field of elongation of high-speed steel cold rolling roll necks, can solve the problems of large residual stress in the core of forgings, increase in temperature of the core of forgings, and large accumulated deformation, so as to improve the qualification of forgings. rate, changing stress state, and the effect of uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

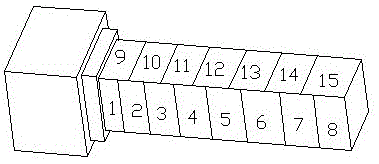

Image

Examples

Embodiment 1

[0029] The high-speed steel cold rolling roll blank, wherein the diameter of the roll neck part is φ900mm, and the length is 450mm, the roll neck part needs to be drawn now, and the specific process steps of the drawing method of the present invention are as follows:

[0030] a. After the billet is heated, it is transferred to the forging platform to press the shoulder;

[0031] b. Starting from the pressure shoulder, the lower anvil is drawn sequentially along the axial direction of the blank to the end. The width of the lower flat anvil is 500 mm, and the feeding amount is 0.5 to 0.7 times the width of the lower flat anvil. Therefore, the feeding amount of each time can be obtained It is 250-350mm, and the relative reduction is 8%-12%, so the reduction is controlled between 80-120mm;

[0032] c. Flip the blank by 90°, and lengthen the other side according to the parameters in step c. Similarly, the anvil is drawn from the shoulder along the axial direction of the blank, and ...

Embodiment 2

[0036] The high-speed steel cold rolling roll billet, wherein the diameter of the roll neck part is φ750mm, and the length is 400mm, the roll neck part needs to be drawn now, and the specific process steps of the drawing method of the present invention are as follows:

[0037] a. After the billet is heated, it is transferred to the forging platform to press the shoulder;

[0038] b. Starting from the pressure shoulder, the lower anvil is drawn sequentially along the axial direction of the blank to the end. The width of the lower flat anvil is 500 mm, and the feeding amount is 0.5 to 0.7 times the width of the lower flat anvil. Therefore, the feeding amount of each time can be obtained It is 250-350mm, and the relative reduction is 8%-12%, so the reduction is controlled between 60-90mm;

[0039] c. Flip the blank by 90°, and lengthen the other side according to the parameters in step c. Similarly, the anvil is drawn from the shoulder along the axial direction of the blank, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com