Pin pile leg for offshore lifting platform

A technology for lifting platforms and legs, which is applied in the field of pin legs, can solve the problems of increasing the weight and cost of pin legs, achieve the effects of reducing weight, increasing cross-sectional area and modulus, and improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

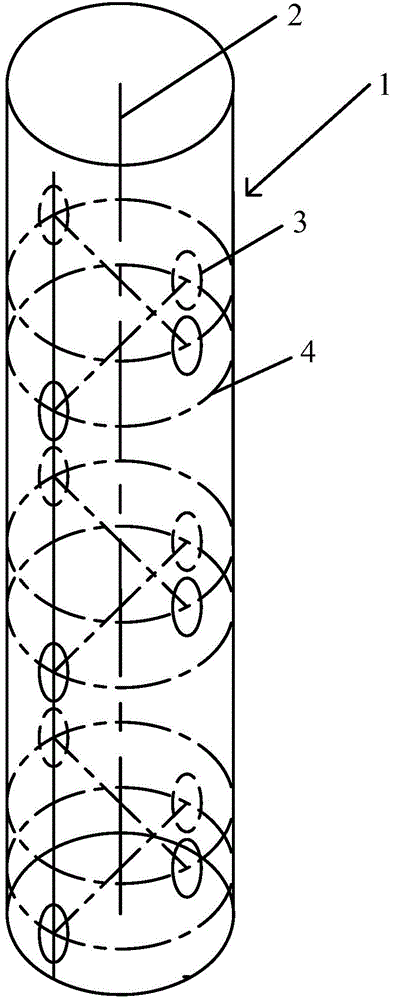

[0022] An embodiment of the present invention provides a latch leg for an offshore lifting platform, see figure 1 , the bolt leg 1 is provided with several stages of pin holes 3 along the axis 2 of the bolt leg, and the pin holes 3 of each stage include 4 pin holes 3, and the pin holes 3 of each stage are along the The direction of the outer contour line of the cross-section 4 is arranged at intervals, and the distance between the two pin holes on the same straight line along the axis 2 of the pin leg in the pin holes 3 of two adjacent stages is equal, and the pin holes 3 of each stage It is divided into two layers, and the cross-sections 4 of the bolt legs where the pin holes 3 of different layers are located are different. Among them, the pin hole 3 of each level corresponds to one rising or falling action of the marine lifting platform, and the pin hole 3 of two adjacent levels is located between the two pin holes 3 on the same straight line along the axis 2 of the pin leg....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com