Dual-mode fluorescent anti-counterfeiting material and preparation method thereof

A fluorescent nanomaterial and dual-mode technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of simple fluorescent anti-counterfeiting mode, single detection light source, cumbersome preparation steps, etc., to meet technical requirements, good repeatability, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

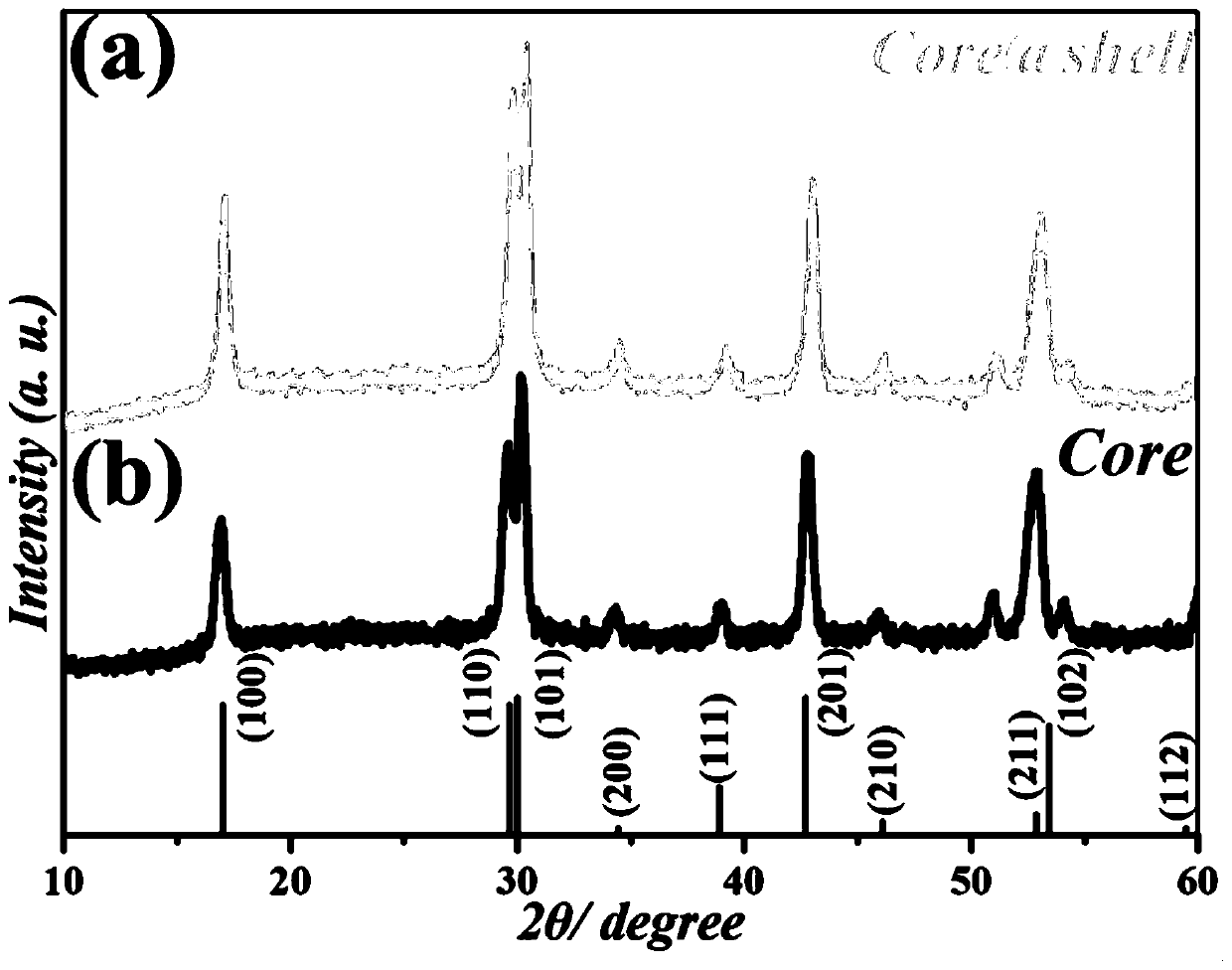

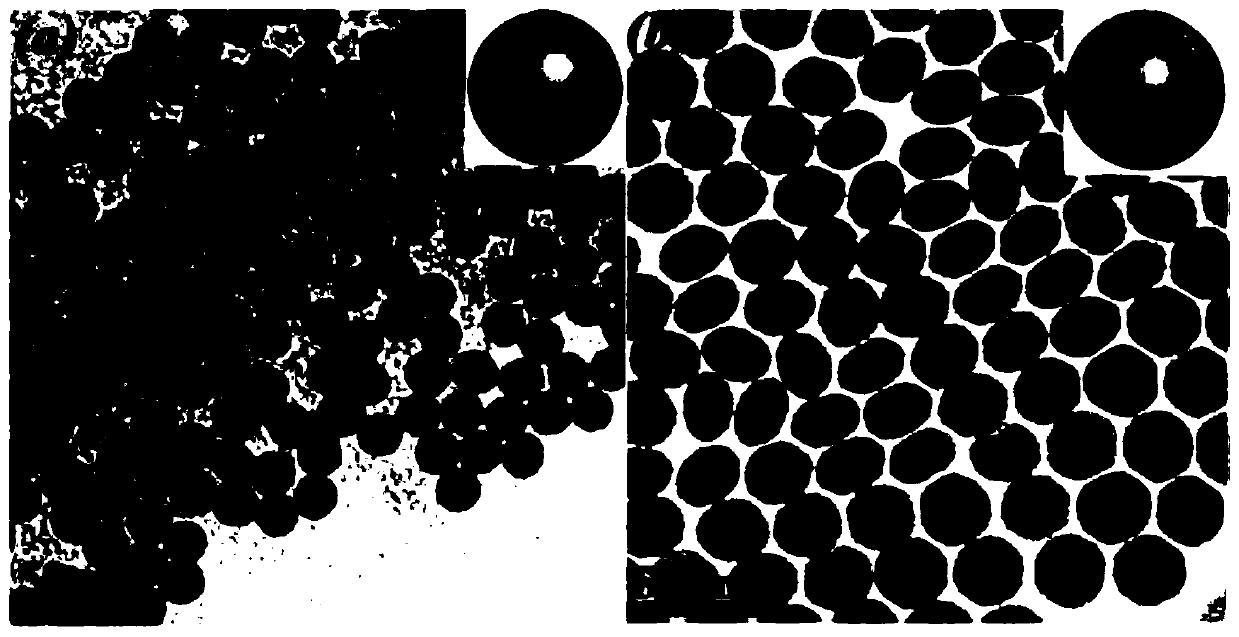

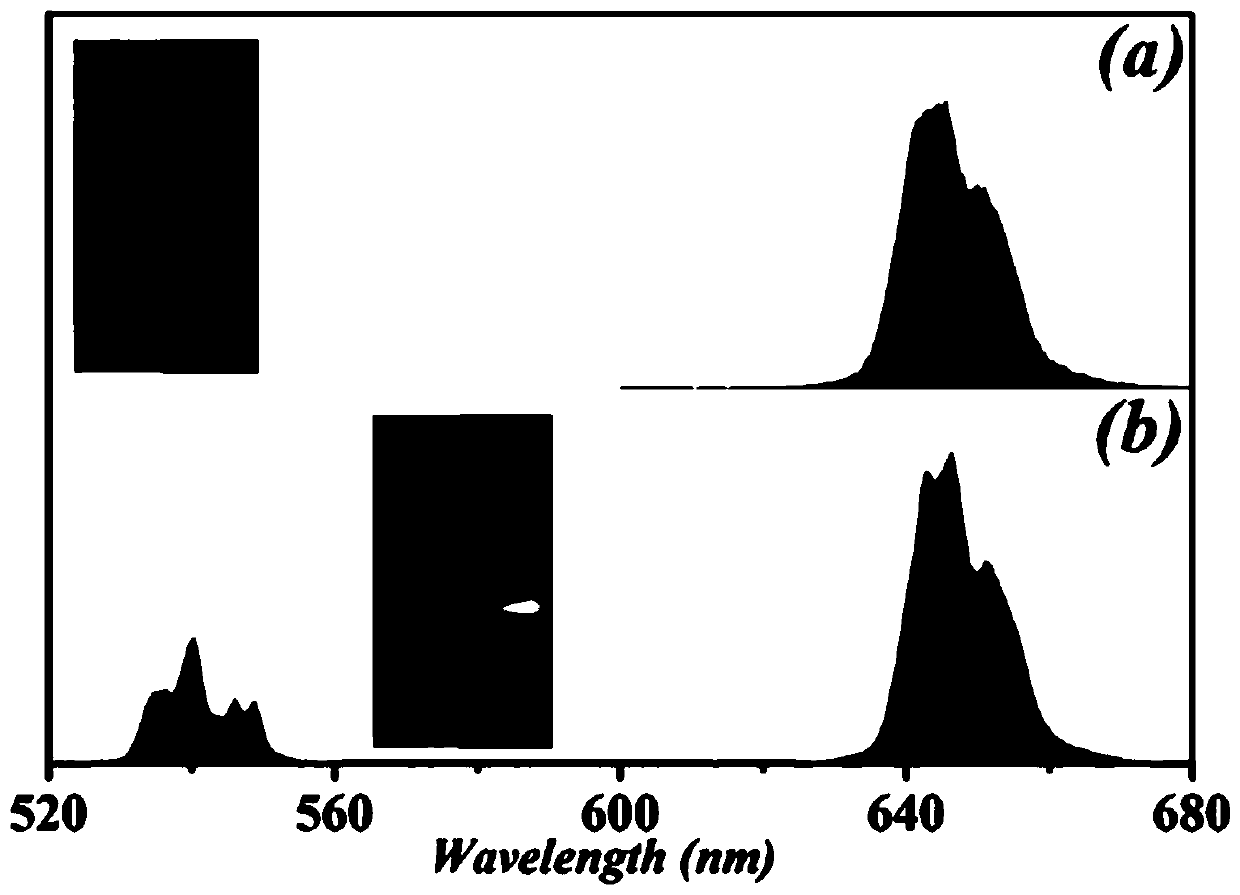

[0024] A dual-mode fluorescent material, the molecular formula is NaGdF4:20Yb / 2Ho / 8Ce@NaYF4:5Eu, the preparation method is as follows:

[0025] (1) Preparation of NaGdF4:20Yb / 2Ho / 8Ce nanocrystals. Weigh 0.56 mmol of gadolinium chloride, 0.16 mmol of ytterbium chloride, 0.016 mmol of holmium chloride and 0.064 mmol of cerium chloride into a three-necked flask, then add 8 ml of oleic acid and 12 ml of 1- Octadecene was stirred evenly under the action of a magnetic stirring bar. After feeding nitrogen gas, the mixed solution was rapidly heated to 150° C. and kept at this temperature for 1 hour to obtain an anhydrous yellow transparent solution. After the solution was naturally cooled to room temperature, 10 ml of methanol solution dissolved with 3 mmol of ammonium fluoride and 2 mmol of sodium hydroxide was gradually added dropwise, stirred evenly, and then heated to 80°C for 1 hour. Then the mixed solution was heated up to 110°C and kept for 30 minutes so that the formaldehyde...

Embodiment 2

[0029] A dual-mode fluorescent material, the molecular formula is NaGdF4:20Yb / 2Ho / 8Ce@NaYF4:5Tb, the preparation method is as follows:

[0030] (1) Preparation of NaGdF4:20Yb / 2Ho / 8Ce nanocrystals. Weigh 0.56 mmol of gadolinium chloride, 0.16 mmol of ytterbium chloride, 0.016 mmol of holmium chloride and 0.064 mmol of cerium chloride into a three-necked flask, then add 8 ml of oleic acid and 12 ml of 1- Octadecene was stirred evenly under the action of a magnetic stirring bar. After feeding nitrogen gas, the mixed solution was rapidly heated to 150° C. and kept at this temperature for 1 hour to obtain an anhydrous yellow transparent solution. After the solution was naturally cooled to room temperature, 10 ml of methanol solution dissolved with 3 mmol of ammonium fluoride and 2 mmol of sodium hydroxide was gradually added dropwise, stirred evenly, and then heated to 80°C for 1 hour. Then the mixed solution was heated up to 110°C and kept for 30 minutes so that the formaldehyde...

Embodiment 3

[0033] A dual-mode fluorescent material, the molecular formula is NaGdF4:20Yb / 2Ho / 16Ce@NaYF4:5Eu, the preparation method is as follows:

[0034] (1) Preparation of NaGdF4:20Yb / 2Ho / 16Ce nanocrystals. Weigh 0.496 mmol of gadolinium chloride, 0.16 mmol of ytterbium chloride, 0.016 mmol of holmium chloride and 0.128 mmol of cerium chloride into a three-necked flask, then add 8 ml of oleic acid and 12 ml of 1- Octadecene was stirred evenly under the action of a magnetic stirring bar. After feeding nitrogen gas, the mixed solution was rapidly heated to 150° C. and kept at this temperature for 1 hour to obtain an anhydrous yellow transparent solution. After the solution was naturally cooled to room temperature, 10 ml of methanol solution dissolved with 3 mmol of ammonium fluoride and 2 mmol of sodium hydroxide was gradually added dropwise, stirred evenly, and then heated to 80°C for 1 hour. Then the mixed solution was heated up to 110°C and kept for 30 minutes so that the formaldeh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com