Equipment for bend-forging crank axle toggle of large ship and method for forging the same

A bending and marine technology, which is applied in the bending forging device and forging forming field of large-scale marine crankshaft throws, can solve the problems that it is difficult to reflect the plastic flow and force of the metal, and the effect is limited, so as to reduce the research cost and achieve good forming quality. The effect of uniform machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

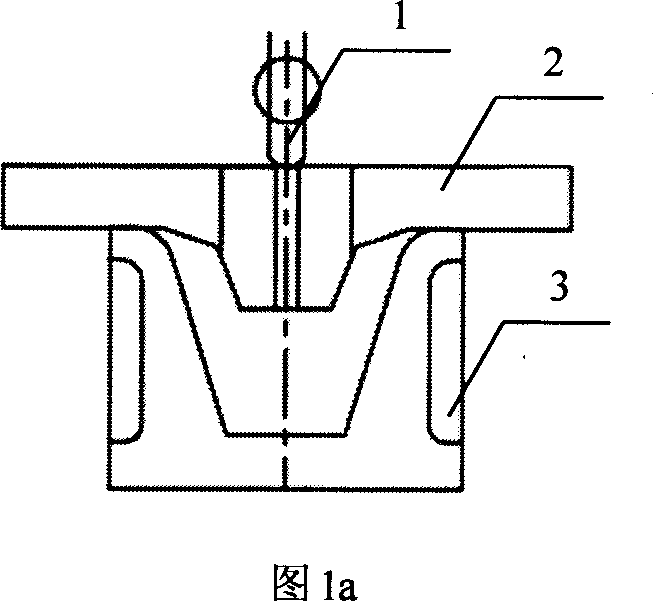

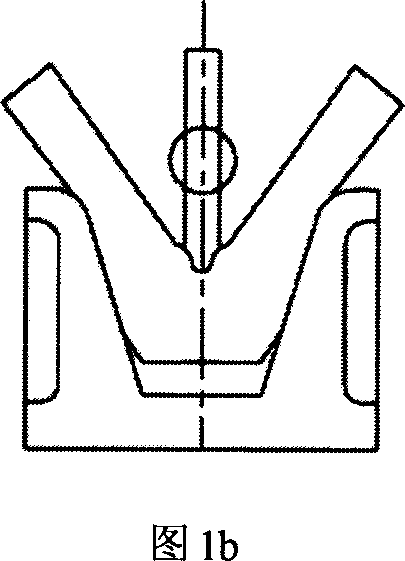

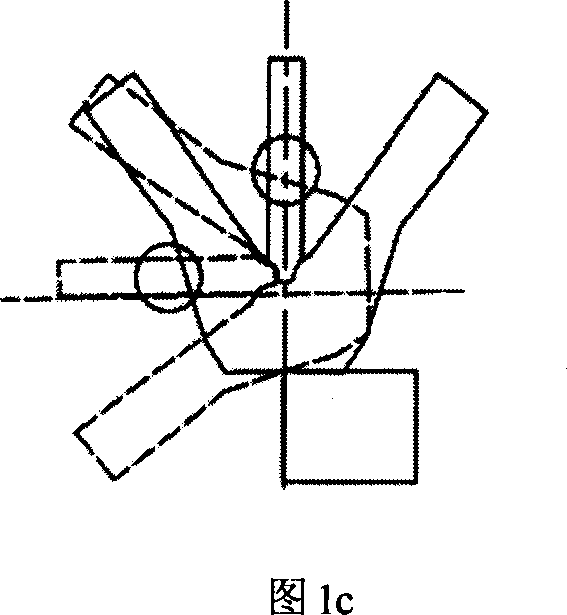

[0050] The forged part in this embodiment is the 6S60MC-C crankshaft throw of MAN B&W patent company. The material of the blank is S34MnV, the weight of the blank is 16t, the heating temperature of the blank is 1250°C, and the material of the mold is 35CrMo. The whole forging process is carried out on a 10,000-ton hydraulic press. , The pressing speed of the upper anvil of the hydraulic press is about 20mm / s when bending, and the whole bending and finishing process takes about 40min. The simulation results of the bending and finishing process are shown in Figure 2-4. Figure 5a-b shows the comparison between the formed blank 9 (grid line part) and the processed part 8 (contour line part). It can be seen from the figure that the machining allowance of the entire forging It is relatively uniform, and the bell mouth defect of the blank is eliminated. Fig. 6 is a photo of the crank throw blank after final forming. It can be seen from the figure that the crank throw blank manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com