Forging method of AP1000 nuclear-power main pipeline forging piece

A technology for main pipes and forgings, applied in the field of forging, can solve the problems of increased difficulty in forging, large deformation resistance, narrow forging temperature range, etc., and achieves the effects of improving the utilization rate, reducing the number of forging fires, and improving the qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

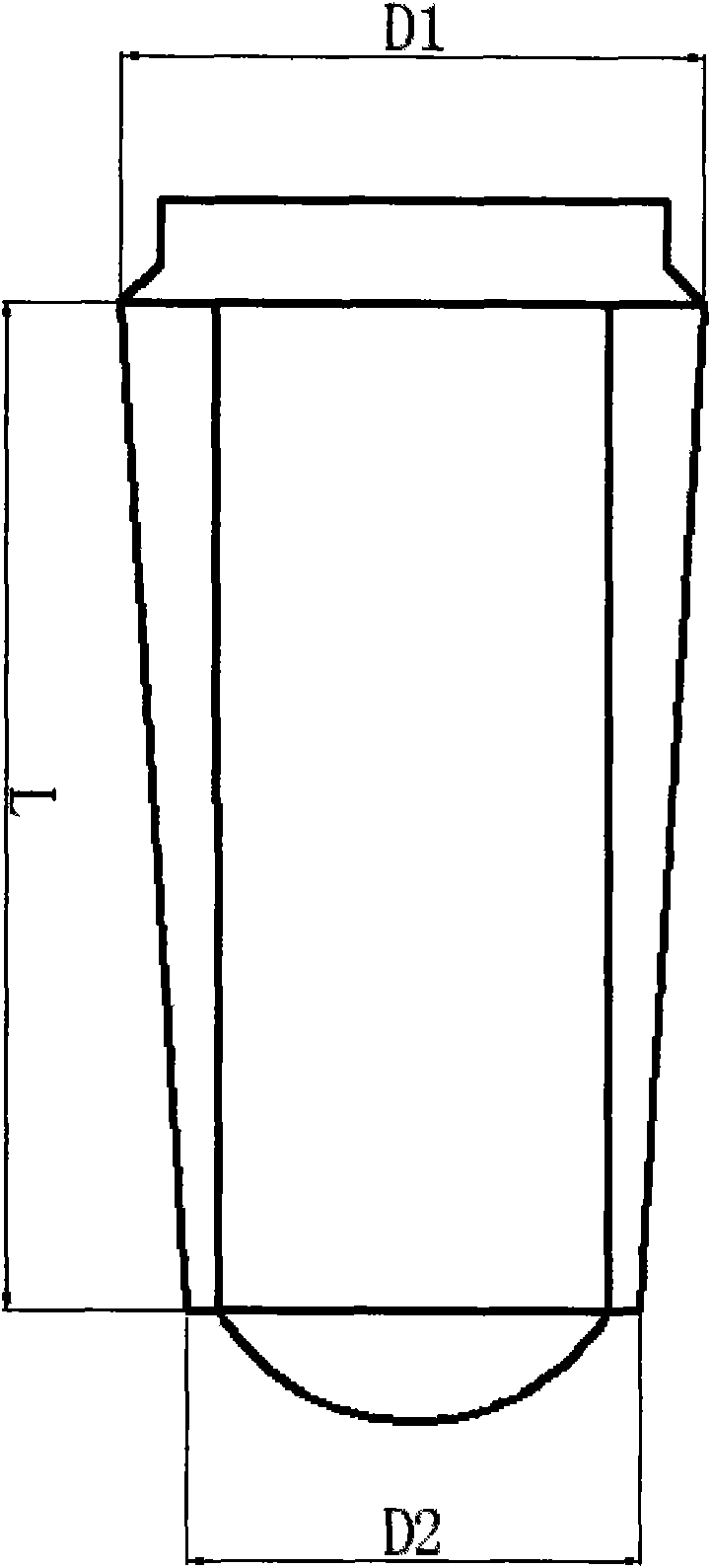

[0027] Prepare the steel ingot: the nominal weight is 56000kg, and the specifications are the diameter of the front end D1, the length L, and the diameter of the tail end D2 ( figure 1 shown), heating before forging. Then complete the forging process on the open die forging press with a tonnage of 8000t as follows:

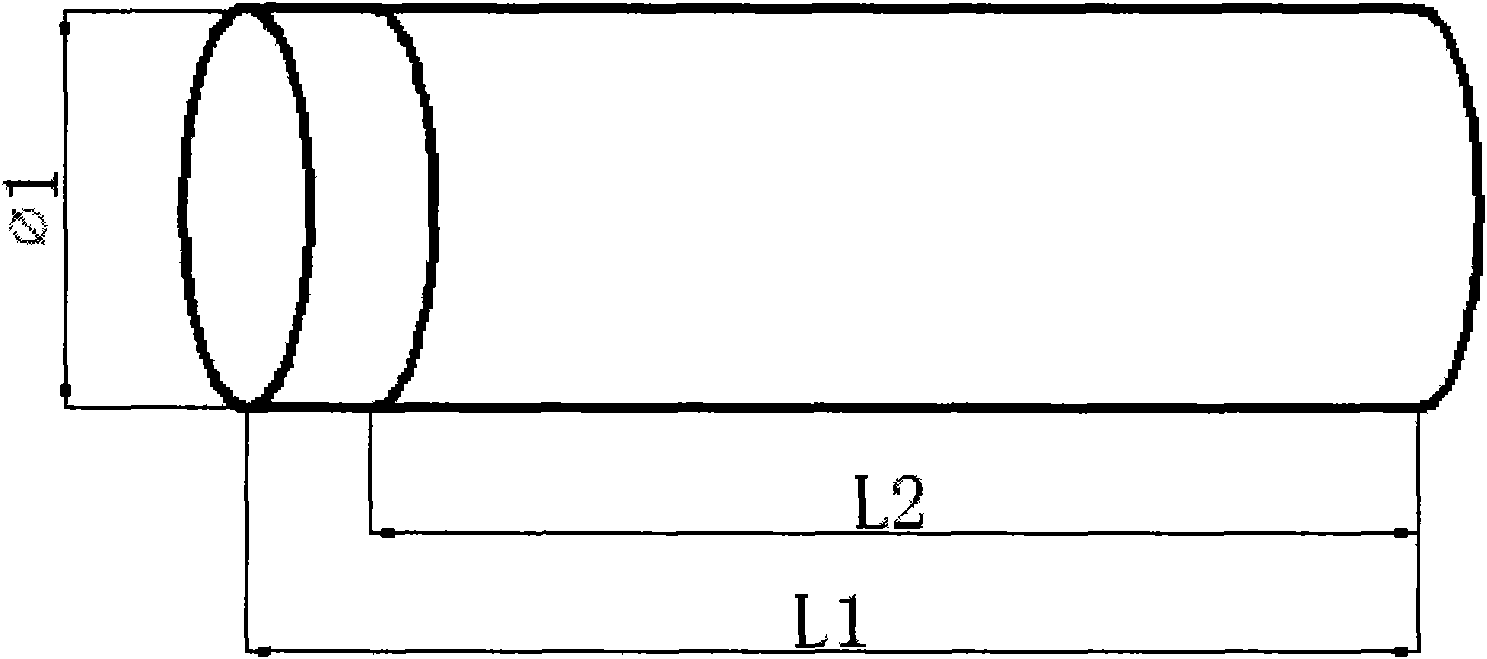

[0028] The first forging: heat the steel ingot to 1200~1220°C, keep it warm for 12 hours, and forge it into a cylinder according to the forging ratio of 1.5 ( figure 2 shown), use an anvil to cut off the head and tail, and then return to the oven to reheat and keep warm.

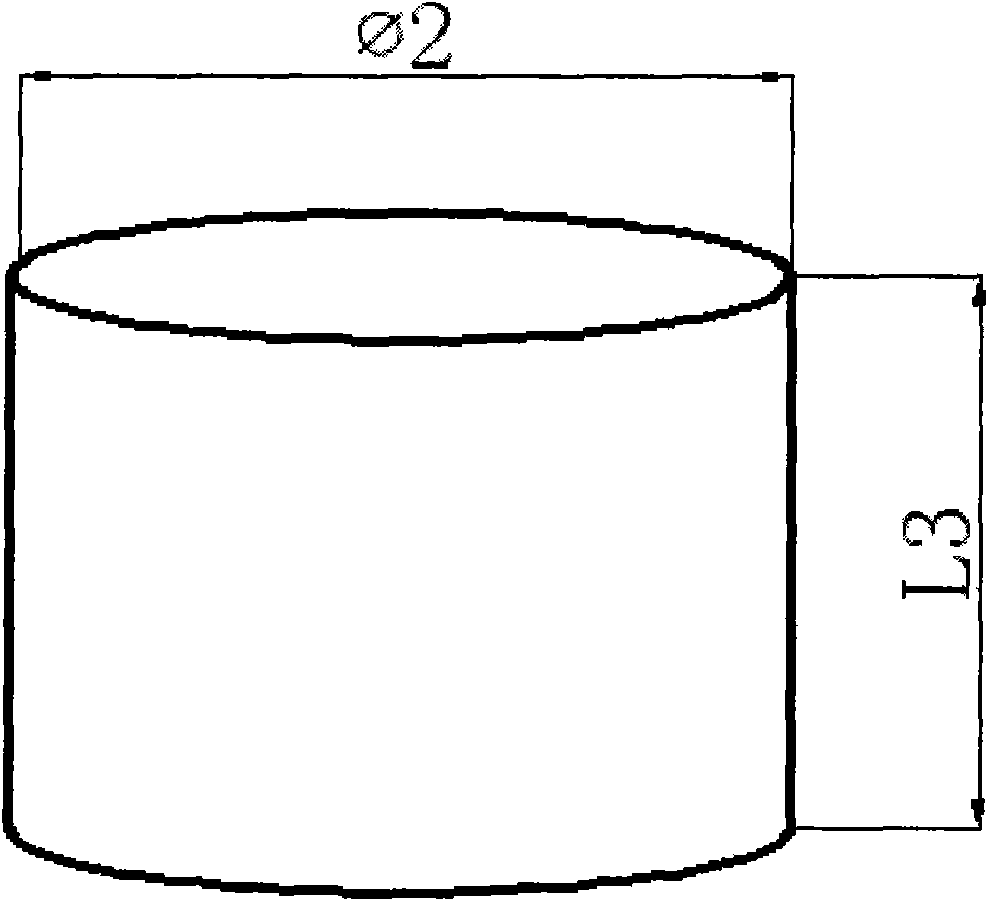

[0029] The second forging: heat the above steel ingot to 1200~1220℃, keep it warm for 3~4 hours, carry out overall upsetting according to the forging ratio of 2, and upsetting the diameter to ( image 3 shown), and then return to the furnace to reheat and keep warm.

[0030] The third forging: heat the above steel ingot to 1180~1200℃, keep it warm for 3~4 hours, carry out elongation and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com