Method for processing turbine of ORC expander generator

A technology of a power generation device and a processing method, which is applied to machines/engines, mechanical equipment, engine components, etc., can solve the problems of high technical difficulty, serious tool wear, and processing difficulty, and achieves high positioning accuracy, high processing efficiency, and high processing efficiency. Easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings.

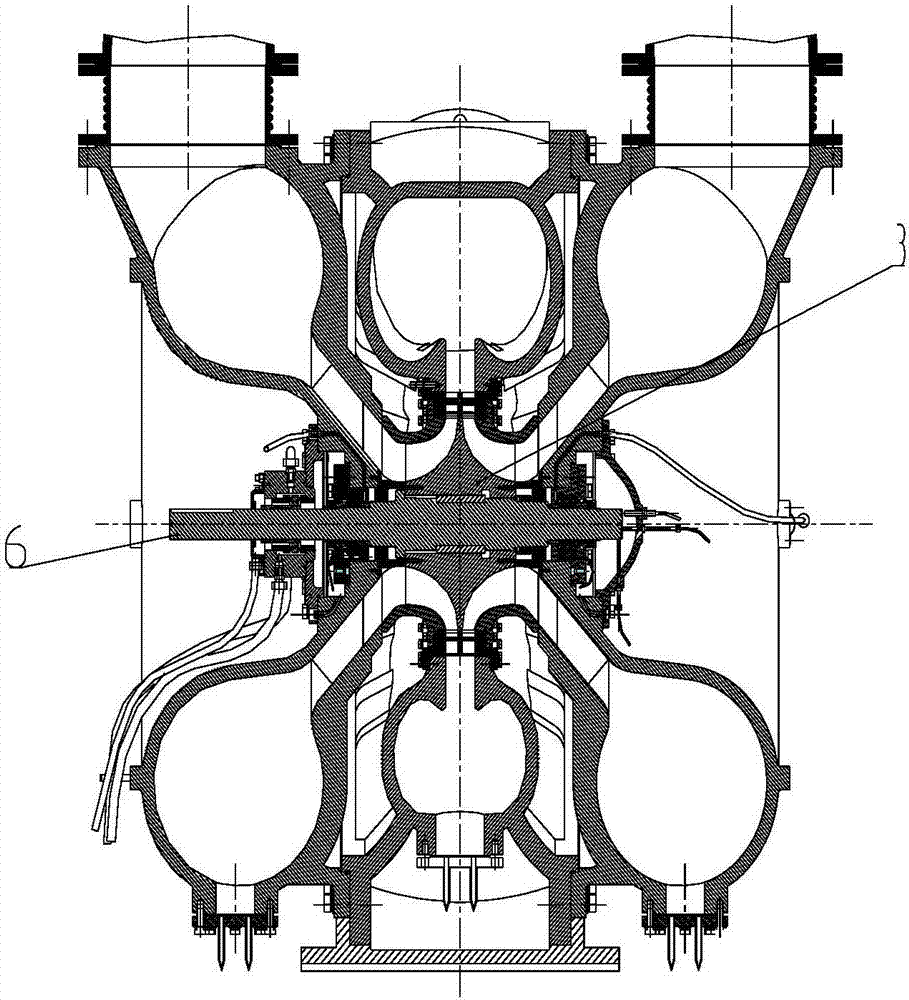

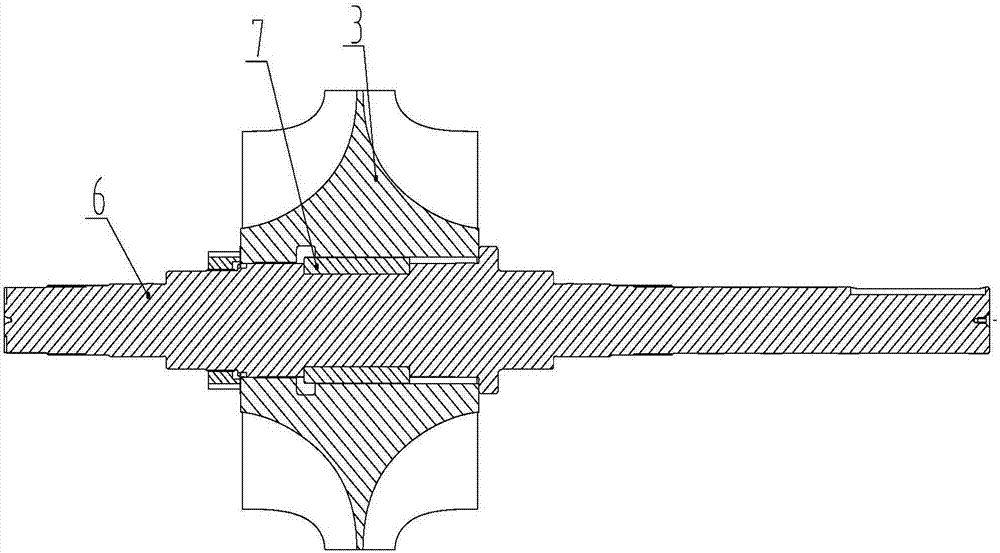

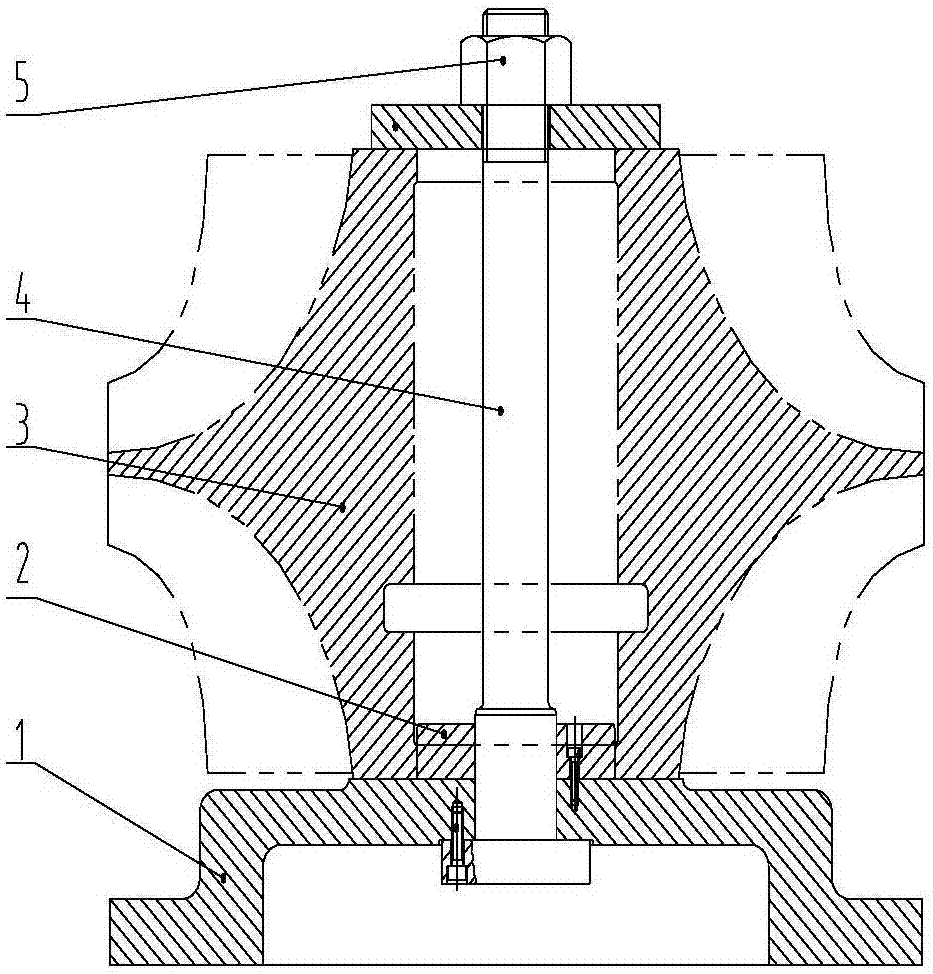

[0049] During specific implementation: if Figure 1 ~ Figure 3 Shown, a kind of processing method of ORC expander power plant turbine, comprises the following steps:

[0050] (1) Perform rough turning on the end face of the blank to obtain part 3 and perform flaw detection on part 3;

[0051] (2), rough car part 3, remove the large margin of part 3;

[0052] (3) Check the mechanical properties of the material of part 3;

[0053] (4) The end surface and the outer meridian surface of the semi-finishing part 3, and the inner hole is turned through the inner part of the part 3 at one time;

[0054] (5) Draw the milling datum line of the runners on both sides;

[0055] (6), milling flow channel;

[0056] (7), semi-finishing the outer meridian surface and inner hole, adjust the runout tolerance of the outer meridian surface and the inner hole;

[0057] (8) Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com