Forging method of large medium-thickness cake-like forging

A technology for forging and thick cakes, which is applied in the field of forging and pressing manufacturing, and can solve the problems of multiple forging fires, large fire consumption, and high energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

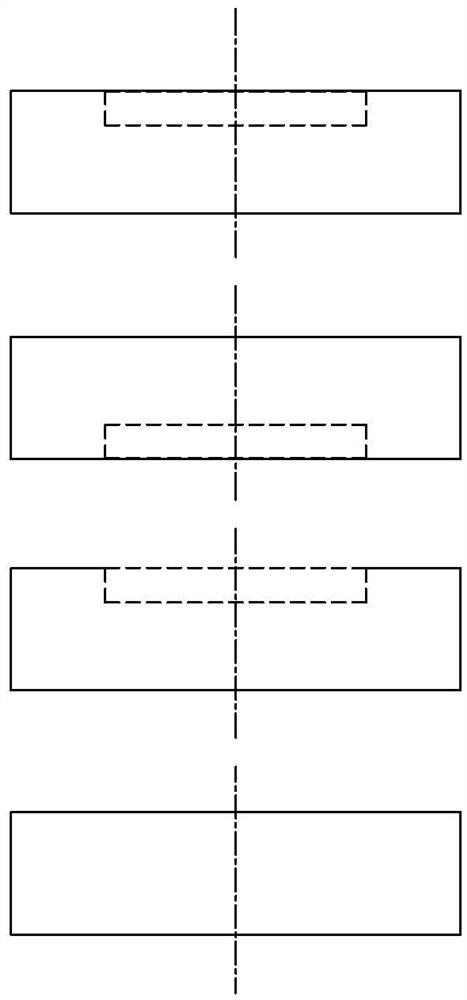

[0031] The first fire: heat the steel ingot to 1250°C, perform pre-deformation and chamfering, press the square, cut off the bottom of the riser, and cut the square 1500×2760.

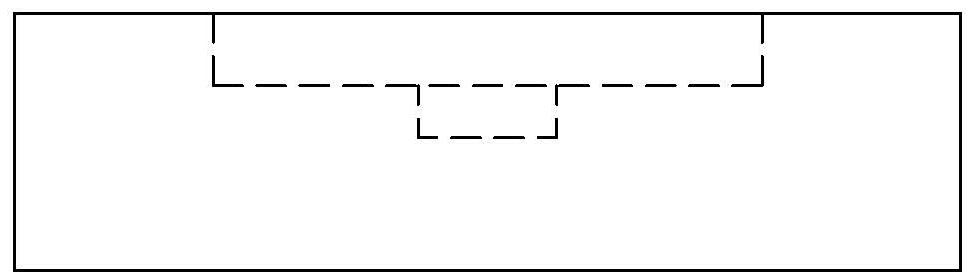

[0032] The second fire: heat the Bafang forging to 1270°C, carry out large deformation upsetting, rounding, and rotary flattening to 480, and use the upper flat anvil with a length of 3200×width of 600 to rotate and press the first dimple within the range of about Φ3200 in the center of the forging. The depth of the recess is 40, and then cover the first recess with a dense punch of Φ700. The depth of the second punch is 30, and the total depth of the two impressions is 70mm.

[0033] The third fire: Turn the forging 180 degrees, that is, the concave gear is facing down. Reheat to 1270°C, and then use a 3200×600 upper flat anvil to rotate the dimple within the range of about Φ3200 in the center of the forging to create the first recess with a depth of 40, then use a Φ700 punch to cover the recess and p...

Embodiment 2

[0035] In the first fire, the steel ingot is heated to 1250°C, the surface is pre-deformed and chamfered, pressed in all directions, the bottom of the riser is cut off, and the ingot is cut to a size of 1500×2760.

[0036] In the second fire, heat Bafang to 1270°C, carry out large-scale upsetting, rounding, and rotary flattening to a height of 480, and then use an upper flat anvil with a length of 3000×width of 300 to directly rotate and press the dimple within a range of about Φ3000 in the center of the forging to make a concave The file depth is 70. (The upper flat anvil with a length of 3000×width 300 has enough power to press down 70mm at one time. However, with a flat anvil of 3200×600, due to the large pressing area, the force of the press can only press down about 40mm. So in the last application example, it is necessary to use the punch to cover and press down 30.)

[0037] In the third fire, turn the forging 180 degrees, with the recess facing down, heat it again to ...

Embodiment 3

[0041] First fire: heat the steel ingot to 1250°C, and heat and keep warm according to the process specification. After being out of the furnace, pre-deform and chamfer the edges to improve the plasticity of the steel ingot surface and prevent cracking. Then press Bafang, cut off the riser and bottom, and cut Bafang 1480×2840.

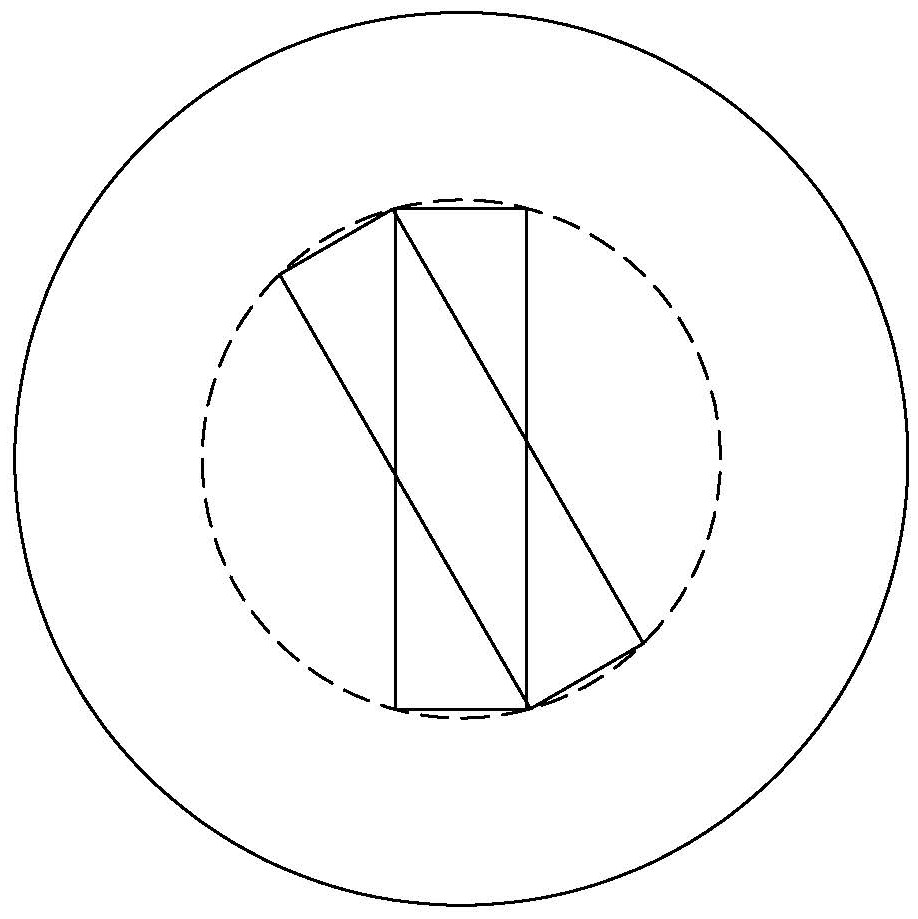

[0042] The second fire: heat Bafang to 1270°C, then upsetting, rotating and flattening to a height of 670, and then use a punch. The diameter of the punch is 1.2 to 1.8 times the final thickness of the forging. In this embodiment, the diameter of the punch is Φ800 , with the center of the forging as the center, extrude a multi-layered petal-shaped concavity in the shape of outward expansion; the depth of the concavity is 10% to 15% of the thickness of the forging at that time, and the range of the concavity is 50% to 60% of the diameter of the forging at that time %, the depth of the recess in this example is 70, and the diameter of the recess is Φ150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com