Forging method for refining grain size of long-bar-type steel forge piece

A technology for steel forgings and grain size, which is applied in the forging of refining the grain size of long rod steel forgings, and in the field of long rod steel forgings, which can solve the problem of coarse grain size and the inability to effectively control forging reduction and reprocessing. Crystallization temperature and other issues, to achieve the effect of reducing the number of forging fires, improving the surface quality and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: steel type: 022Cr22Ni5Mo3N; bad forging material: Φ660mm electroslag ingot, weighing 3.95 tons; finished forging size: Φ230mm*9500mm.

[0014] The present invention utilizes the frequency conversion forging of radial precision forging machine The specific implementation steps are:

[0015] Step 1), heating in a heating furnace, the temperature of the furnace is 1180°C, and the temperature is kept for 8 hours;

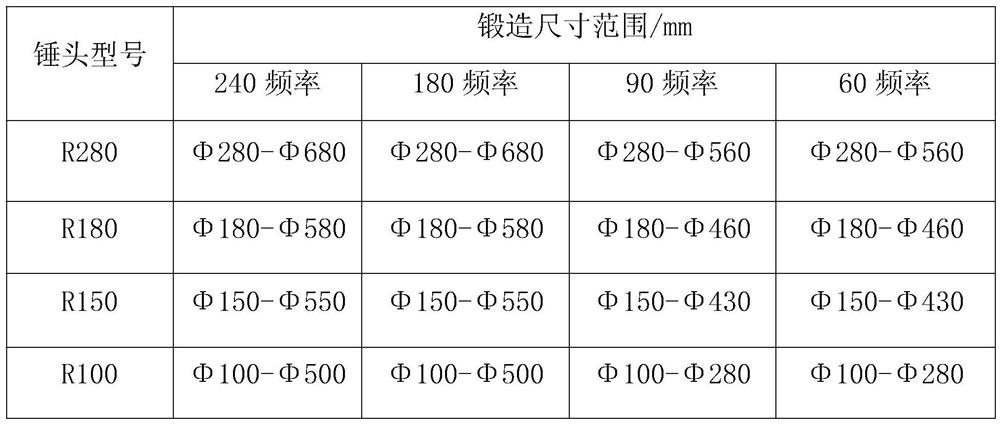

[0016] Step 2), precision forging machine to Φ560mm: use R280 hammer head, 180 frequency forging, forging deformation process: Φ660mm-Φ640mm-Φ600mm-Φ560mm;

[0017] Step 3), precision forging machine to Φ340mm: use R280 hammer, 60 frequency forging, forging deformation process: Φ560mm-Φ490mm-Φ410mm-Φ340mm, use 60 frequency forging.

[0018] Step 4), heating in a heating furnace, the temperature of the furnace is 1180°C, and the temperature is kept for 1.5 hours;

[0019] Step 5), replace the R280 hammer head with the R150 hammer head;

[0020] Step ...

Embodiment 2

[0024] Example 2: steel type: 1Cr18Ni9Ti; forging billet: large head diameter Φ666mm, small head diameter Φ618mm, ingot weight 3.6 tons; finished forging size: Φ260mm*6540mm.

[0025] The present invention utilizes the frequency conversion forging of radial precision forging machine The specific implementation steps are:

[0026] Step 1), heating in a heating furnace, the temperature of the furnace is 1150°C, and the temperature is kept for 8 hours;

[0027] Step 2), precision forging machine to Φ520mm; use R280 hammer, 180 frequency forging, forging deformation process: Φ666mm-Φ620mm-Φ570mm-Φ520mm;

[0028] Step 3), precision forging machine to Φ360mm; use R280 hammer, 60 frequency forging, forging deformation process: Φ520mm-Φ440mm-Φ360mm;

[0029] Step 4), heating in a heating furnace, the temperature of the furnace is 1100°C, and the temperature is kept for 1.0 hour;

[0030] Step 5), replace the R280 hammer head with the R180 hammer head;

[0031] Step 6), precision fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com