Ceramic particle reinforced aluminum-based gradient composite material and preparation method thereof and jetting precipitation device for preparing material

A composite material and ceramic particle technology, applied in the field of aluminum matrix composite material and its preparation, can solve the problems of unsatisfactory heat resistance, insufficient fatigue resistance and low overall plasticity of the aluminum alloy matrix, so as to meet the requirements of lightweight and operation. The effect of convenient and refined grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

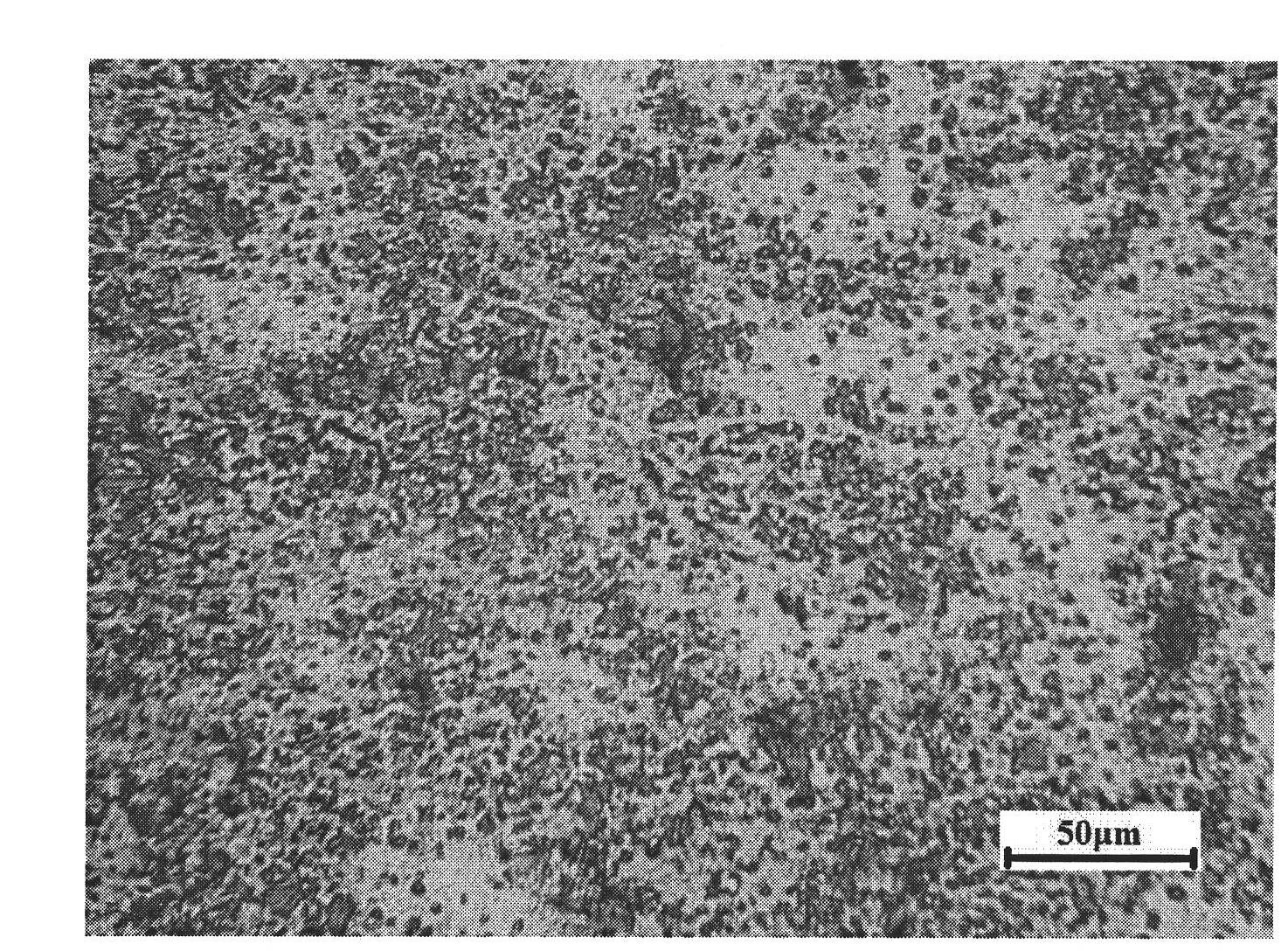

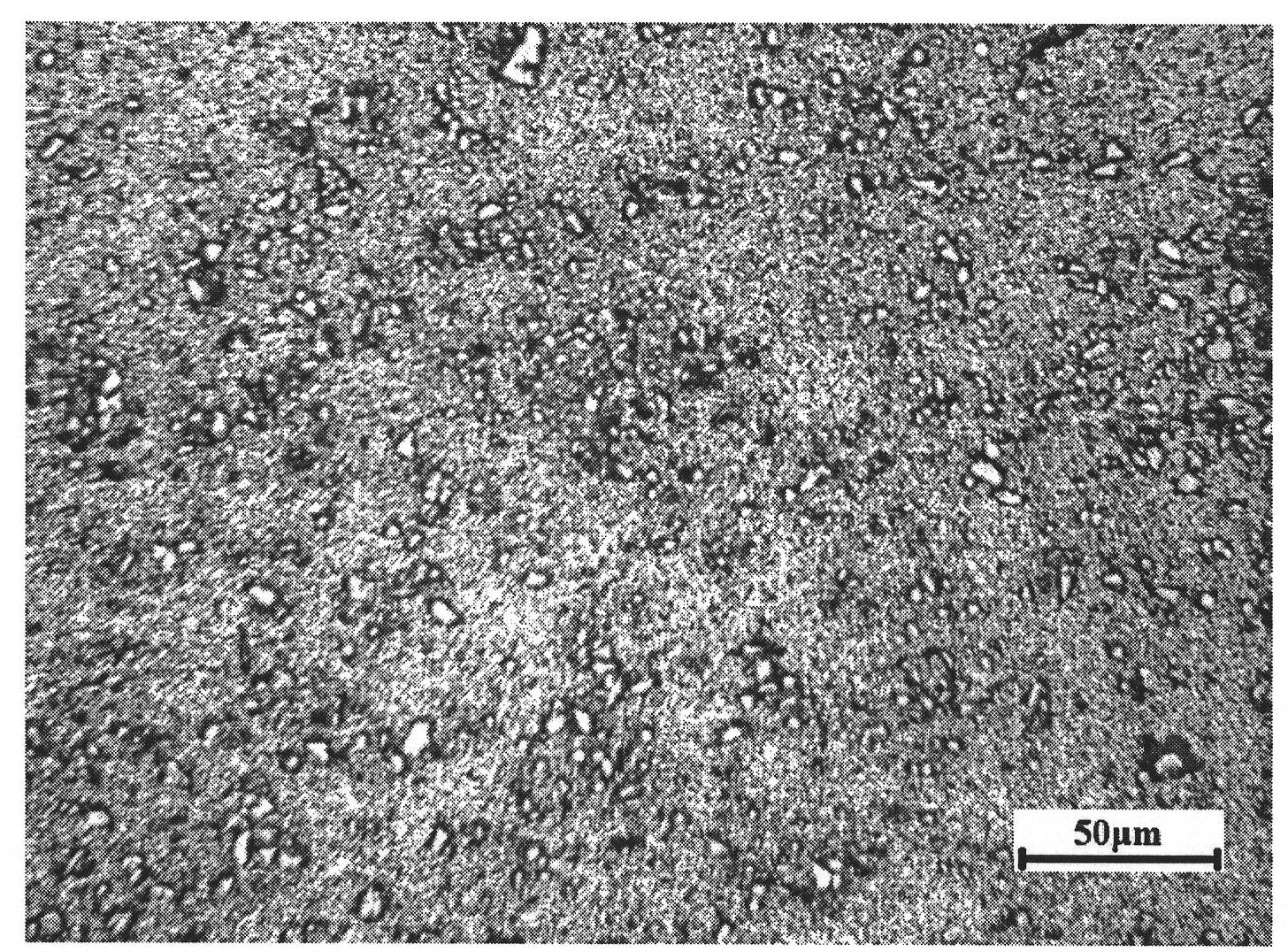

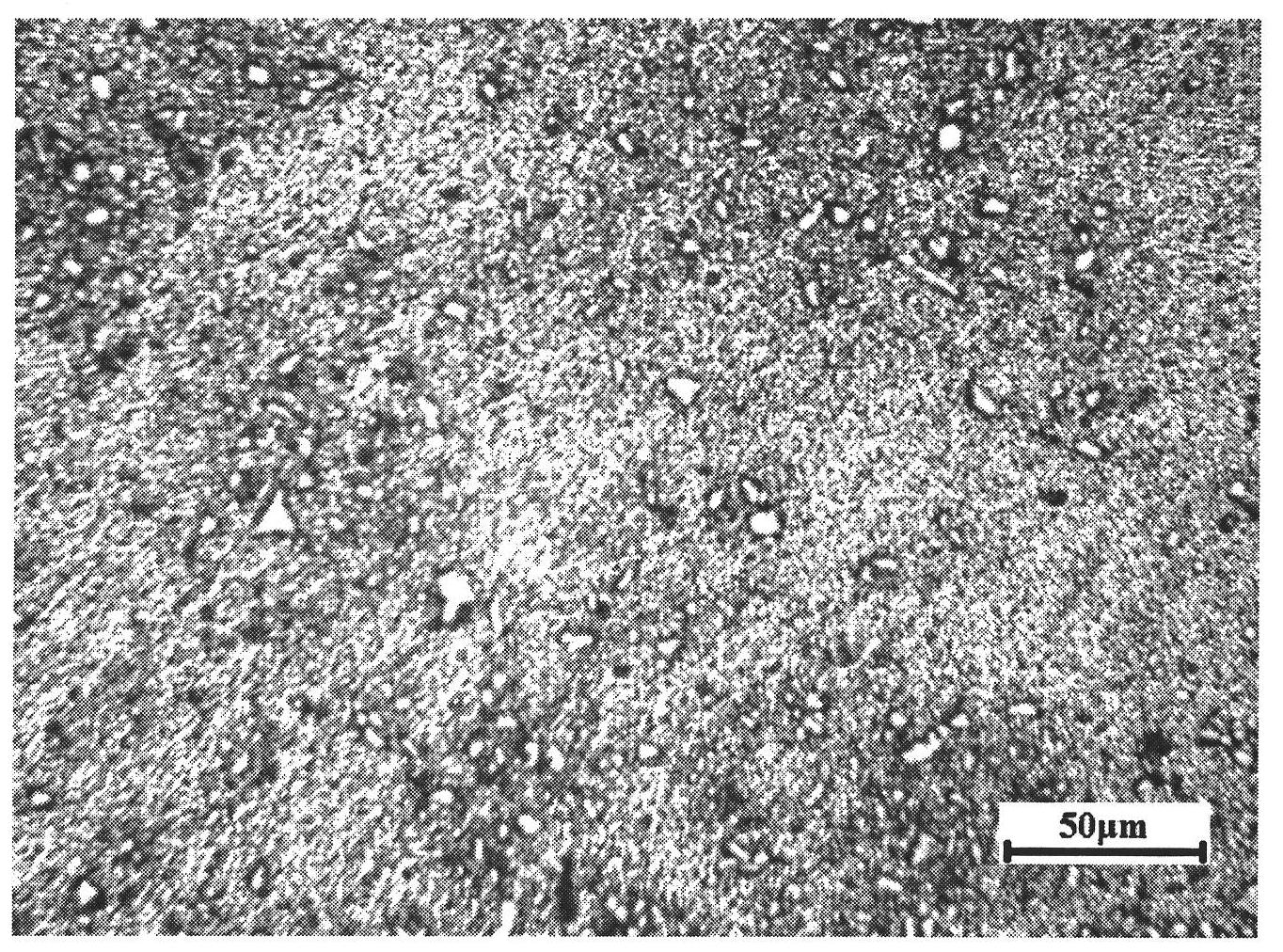

[0039] a kind of like Figure 1 to Figure 5 The shown ceramic particle reinforced aluminum-based gradient composite ingot of the present invention has a diameter of 250 mm and a thickness of 300 mm ( 250mm×300mm), the composite material is based on 6066 aluminum alloy, the average grain size of the aluminum alloy matrix is 10 μm, and SiCp ceramic particles are used as reinforcing materials, and the average particle size of the ceramic particles is 5 μm. Such as figure 1 As shown, in the surface layer of the ingot, the volume fraction of SiCp ceramic particles is 30%; as figure 2 As shown, in the upper part of the ingot (h=180mm height), the volume fraction of SiCp ceramic particles is about 20%; as image 3 As shown, in the lower part of the ingot (h=100mm height), the volume fraction of SiCp ceramic particles is about 10%; as Figure 4 As shown, at the height of the ingot h=5mm, the volume fraction of SiCp ceramic particles is about 5%; as Figure 5 As shown, the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com