High-strength hot rolled steel plate and manufacturing method thereof

A technology of structural steel plate and manufacturing method, which is applied to the manufacturing field of high-strength hot-rolled structural steel plate, continuous hot-rolled metal plate and strip, and high-strength hot-rolled structural steel plate, can solve the problem of difficult to meet the comprehensive requirements of automobile structure, unsatisfactory welding performance, etc. The problem of large springback of stamping parts can achieve the effect of promoting the formation of spherical carbides, reducing the amount of pearlite and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] During specific implementation, the weight percent of the chemical composition of the high-strength hot-rolled structural steel plate is controlled as follows: C: 0.08% to 0.10%; Si: 0.10% to 0.25%; Mn: 1.30% to 1.50%; P: ≤ 0.015%; S: ≤0.008%; Nb: 0.020% ~ 0.030%; Ca: 0.0010% ~ 0.0030%, the rest is iron and residual trace impurities.

[0044] The effects of the above-mentioned alloying elements and their effects on material properties are:

[0045] C: The increase of C content can increase the strength of the material, but the plasticity and formability of the steel decrease; Mn has a certain influence on the strength and toughness of the steel.

[0046] Mn: If the Mn content is low, the strength will decrease; if the Mn content is too high, the steel plate will easily form a banded structure, thereby affecting the cold forming and welding properties of the steel, and reducing the low temperature impact performance.

[0047] Si: Adding an appropriate amount of Si to th...

Embodiment 2

[0054] In order to improve the toughness of the high-strength hot-rolled structural steel plate, an appropriate amount of Alt can also be added. When the material is smelted, Al is added so that the weight percentage of the total amount in the base material is 0.015-0.050. Alt refers to the total content of aluminum in steel, including aluminum in solid solution in steel and aluminum in non-metallic inclusions in steel.

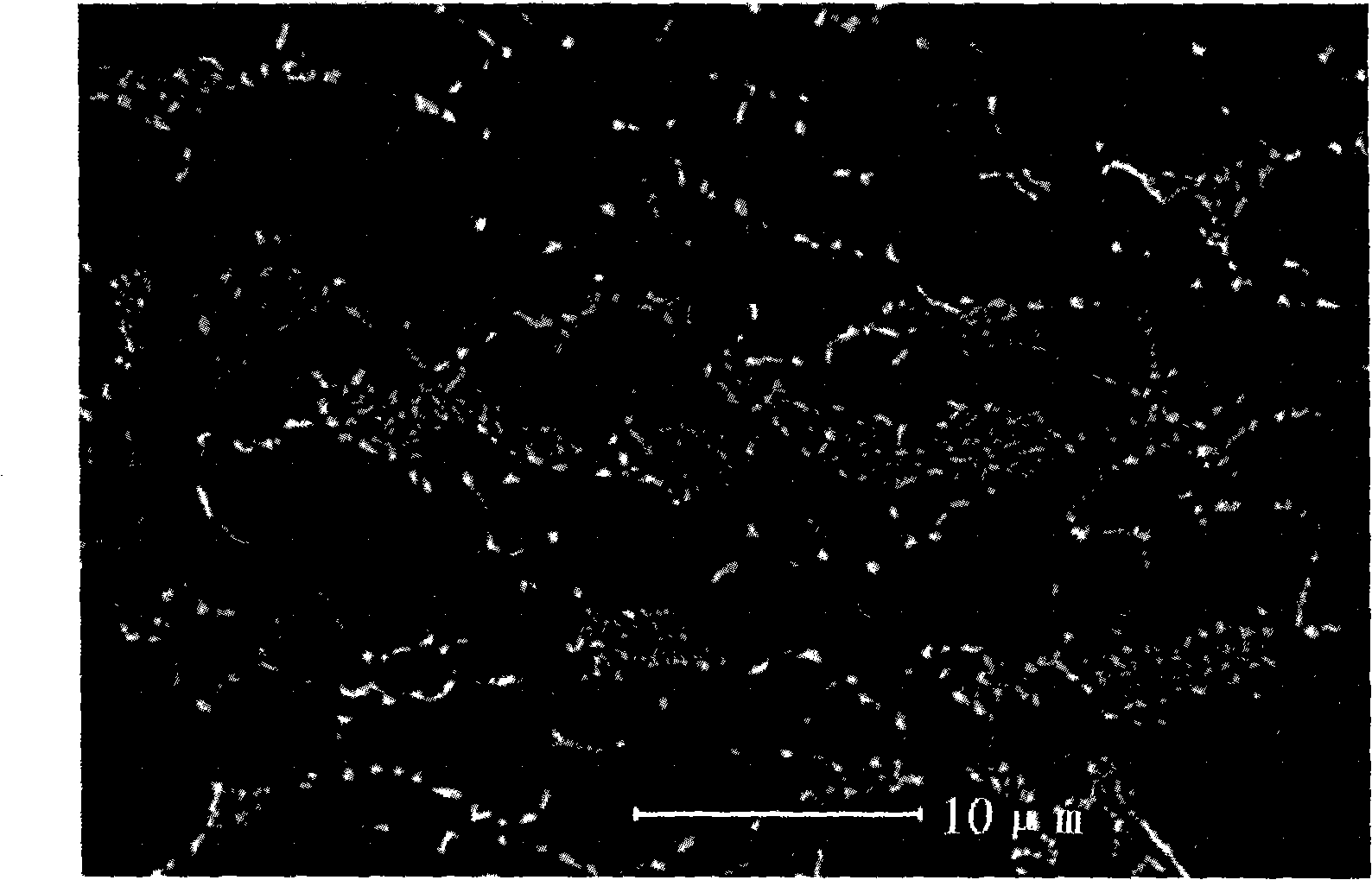

[0055] Such as figure 2 As shown, this figure is a micrograph of the microstructure of the high-strength hot-rolled structural steel plate involved in the present invention. The microstructure shown is a fine, uniform and strengthened ferrite + pearlite structure with reasonable chemical composition and obtained through appropriate process methods, which is conducive to obtaining high strength, high cold forming performance and good low temperature impact performance.

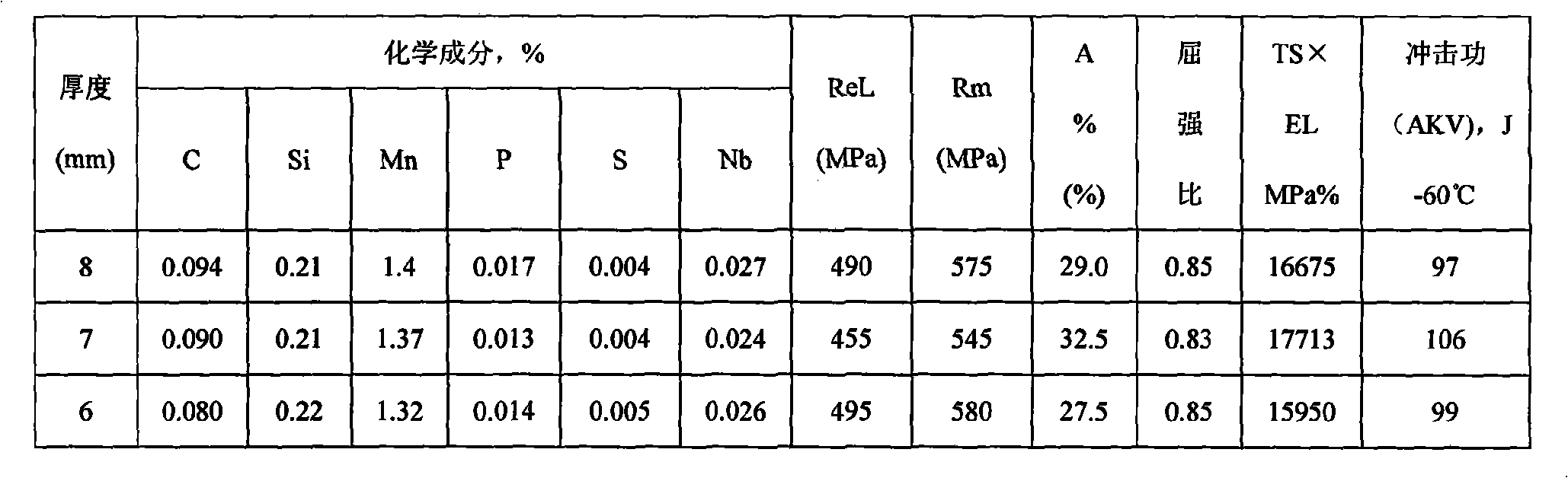

[0056] Through reasonable chemical composition design, converter smelting, refining, c...

Embodiment 3

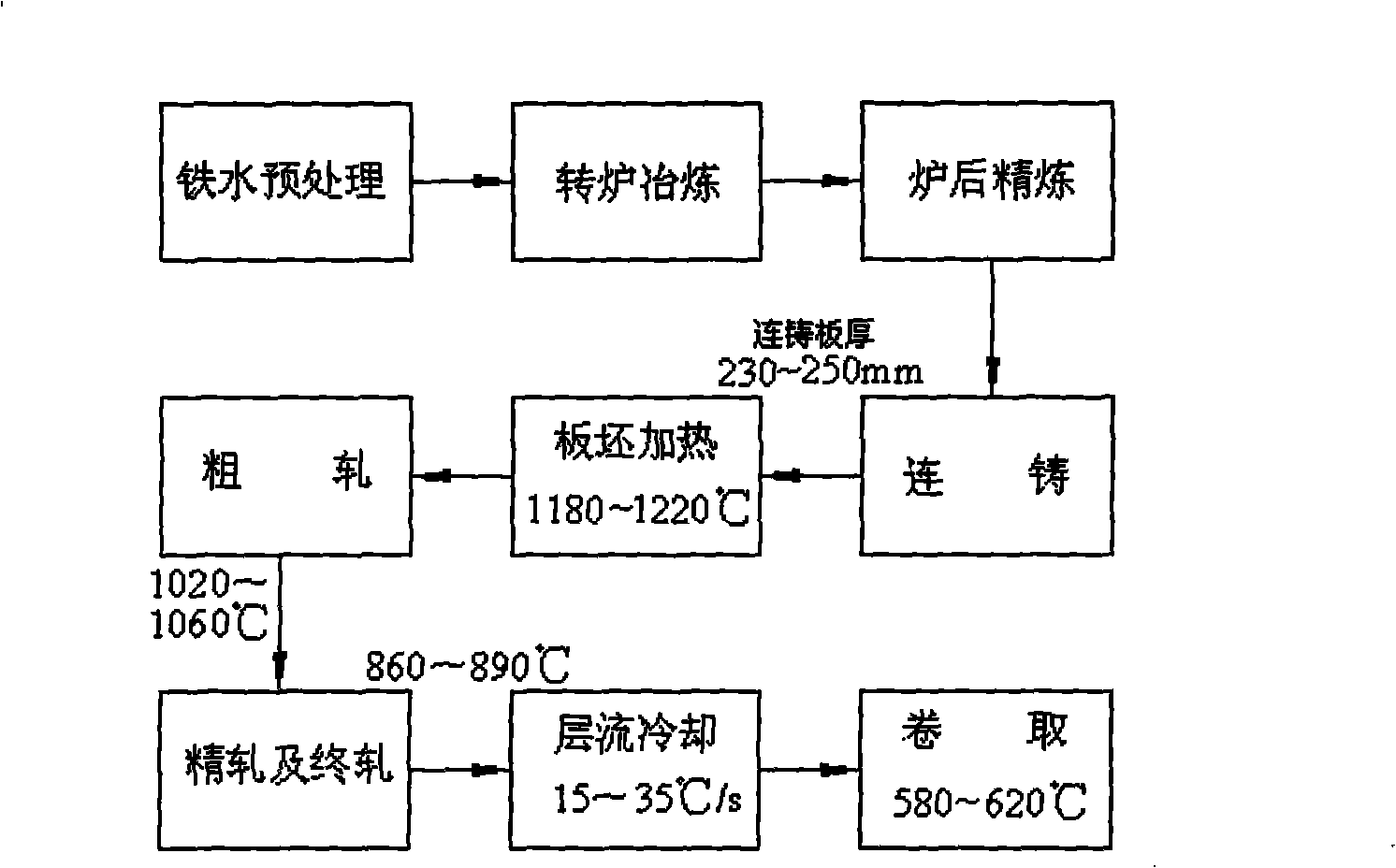

[0065] Such as figure 1 Shown, described manufacturing method is to adopt the manufacturing process of controlled rolling and controlled cooling on continuous rolling process, and its rolling is to produce in 2250mm hot rolling production line, and its technological process and technological content are:

[0066] (a), molten iron pretreatment: carry out desulfurization treatment to molten iron;

[0067] (b) Converter smelting: removing P, Si, C and alloying the molten iron;

[0068] (c) After refining, the LF furnace adopts deep desulfurization process and molten steel alloying treatment, and adds iron-calcium wire for inclusion denaturation treatment;

[0069] (d), continuous casting: the refined molten steel is protected and cast by a continuous casting machine to become a slab;

[0070] (e), slab heating: the cast slab is cold loaded into the furnace and heated, and then sent to the hot continuous rolling mill;

[0071] (f) Rough rolling: After descaling with high-pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com