Low-temperature rolling production method of high-performance 20CrMnTi gear steel

A production method and low-temperature rolling technology, applied in metal rolling, metal rolling, temperature control and other directions, can solve the problems of high requirements on deformation resistance, incompetence, increase production costs, etc., and achieve optimized heating process system, crystal The particle size is fine and uniform, and the effect of reducing heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

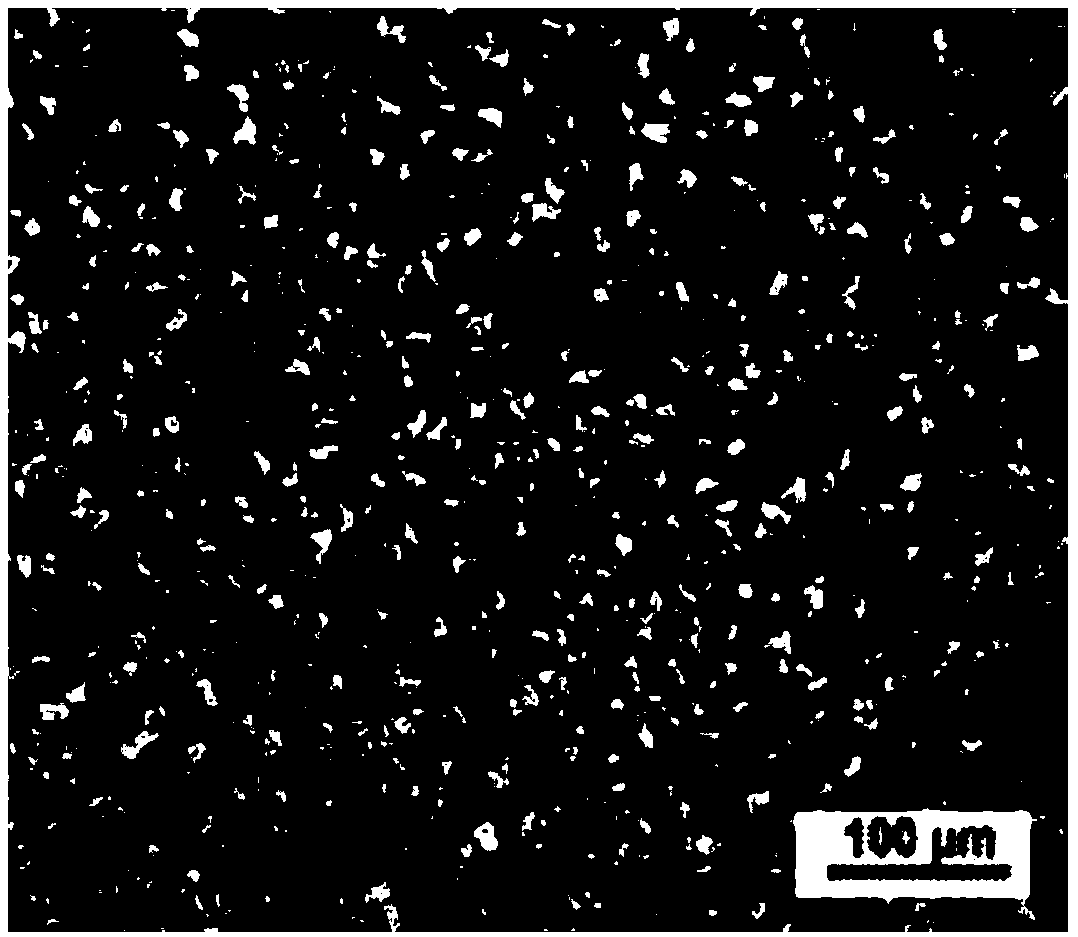

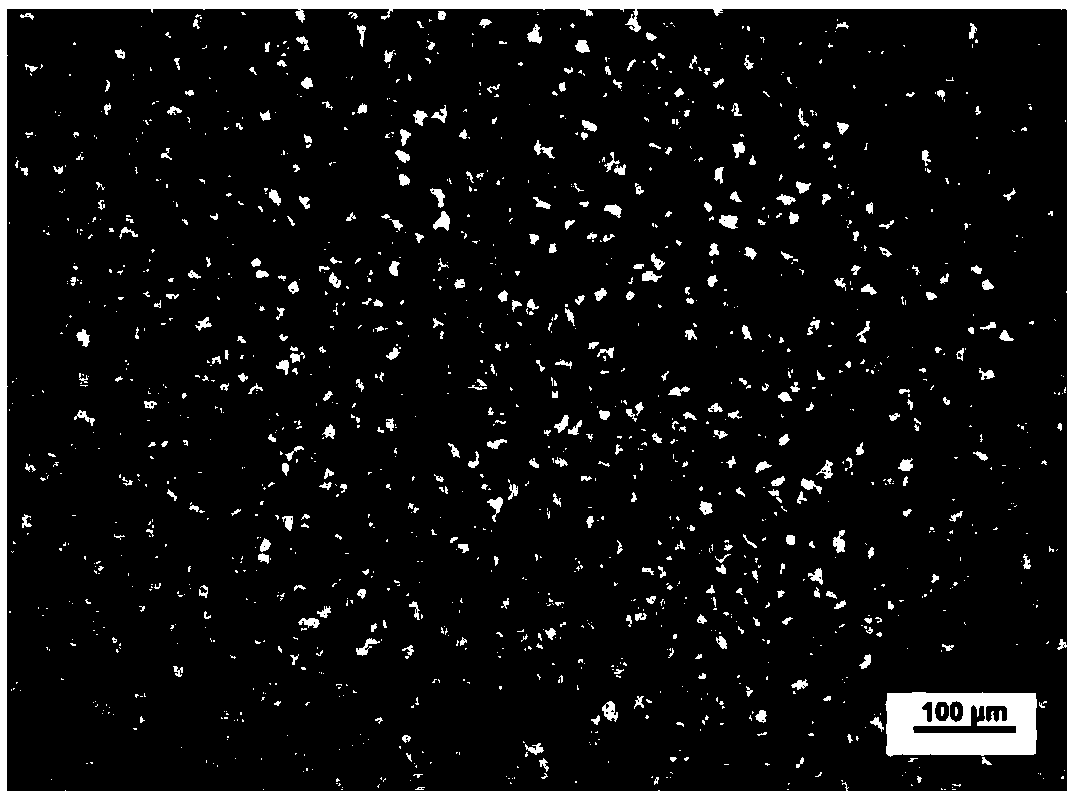

Image

Examples

Embodiment 1

[0045] The low-temperature rolling production method of the high-performance 20CrMnTi gear steel provided by the present embodiment requires a specification of 50mm for the finished product 20CrMnTi steel, including the following steps:

[0046] (1) Steel slab heating: Cut the 300×400×9000mm continuous casting slab and put it into a four-stage walking heating furnace for reheating by cold delivery, wherein the mass percentage of each component in the continuous casting slab is: C: 0.191 ; Si: 0.184; Mn: 1.005; Cr: 1.024; Ti: 0.057; P: 0.015; S: 0.012; Al: 0.023; N: 0.0055;

[0047] The temperature of the preheating section is 660°C, the temperature of the heating section is 1025°C, the temperature of the second heating section is 1080°C, and the temperature of the soaking section is 1128°C; the total heating time in this heating process is 3.5h, and the soaking time of the soaking section 55min;

[0048] (2) billet descaling: the heated billet is descaled with high-pressure w...

Embodiment 2

[0058] The low-temperature rolling production method of the high-performance 20CrMnTi gear steel provided by the present embodiment requires the specification of the finished product 20CrMnTi steel grade to be 80mm, including the following steps:

[0059] (1) Steel slab heating: cut the 300×400×9000mm continuous casting slab and put it into the heating furnace for reheating by red feeding method, wherein, the mass percentage of each content component in the continuous casting slab is: C: 0.195; Si: 0.219; Mn: 1.041; Cr: 1.103; Ti: 0.049; P: 0.012; S: 0.008; Al: 0.034; N: 0.0050;

[0060] The temperature of the preheating section is 620°C; the temperature of the heating section is 1030°C; the temperature of the second heating section is 1065°C; the temperature of the soaking section is 1135°C; the total heating time in the heating process is 4.0h, and the soaking time of the soaking section is 62min;

[0061] (2) Billet descaling: the heated billet is descaled with high-pressu...

Embodiment 3

[0071] The low-temperature rolling production method of the high-performance 20CrMnTi gear steel provided by the present embodiment requires a specification of 100 mm for the finished product 20CrMnTi steel, including the following steps:

[0072] (1) Steel slab heating: cut the 300×400×9000mm continuous casting slab and put it into the heating furnace for reheating by cold delivery method, wherein, the mass percentage of each content component in the continuous casting slab is: C: 0.201; Si: 0.196; Mn: 1.025; Cr: 1.054; Ti: 0.068; P: 0.020; S: 0.006; Al: 0.033; N: 0.0048;

[0073] The temperature of the preheating section is 680°C; the temperature of the heating section is 1040°C; the temperature of the second heating section is 1085°C; the temperature of the soaking section is 1125°C; the total heating time in the heating process is 4.2h, and the soaking time of the soaking section is 60min;

[0074] (2) Billet descaling: the heated billet is descaled with high-pressure wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com