Gamma'phase pre-adjusting plasticizing production process of high-performance high-temperature alloy

A high-temperature alloy and production process technology, applied in the field of material processing, can solve problems such as reducing high-temperature plasticity, and achieve the effects of reducing forging times, increasing high-temperature plasticity, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

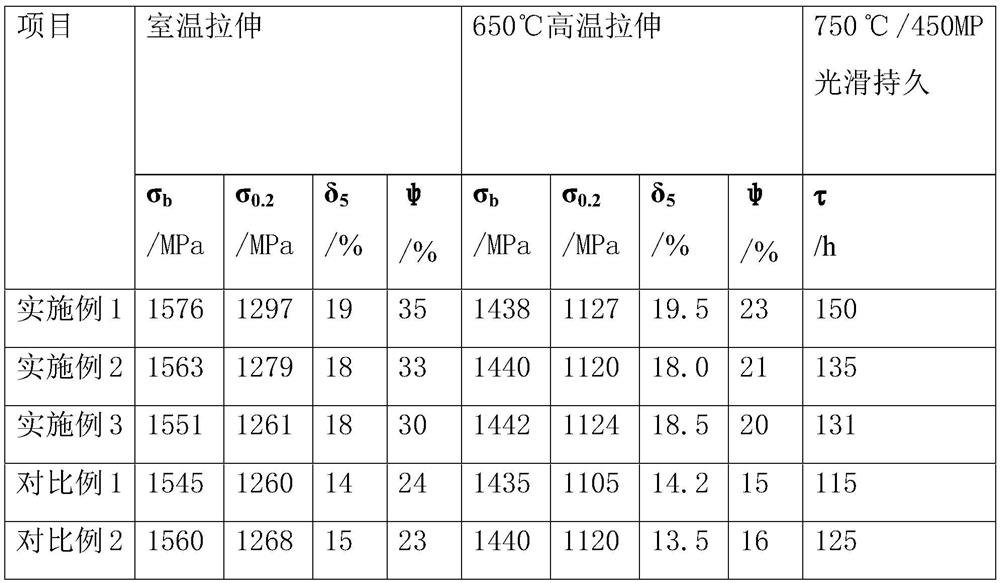

Embodiment 1

[0037] GH4730 alloy is a wrought superalloy with a mass fraction of γ' phase as high as 42%, and the complete melting temperature of γ' phase is 1090°C.

[0038] Step 1. The GH4730 alloy consumable ingot smelted by vacuum induction melting, electroslag remelting and vacuum consumable remelting process is subjected to two times of upsetting and two times of elongating forging in the single-phase region (1110°C) to obtain Φ480mm bar;

[0039] Step 2. Lower the temperature of the forging heat treatment furnace to 1070°C, and return the Φ480mm bar forged in step 1 to the forging heat treatment furnace. After holding it for 2 hours, cool it down to 900°C at a cooling rate of 20°C / h and keep it for 3 hours;

[0040] Step 3. The bar processed in step 2 is heated up to 1070°C at 10°C / min. After holding for 2 hours, it is taken out of the furnace and enters the forging heat treatment furnace for forging. After forging, return to the forging heat treatment furnace for 2 hours of heat pr...

Embodiment 2

[0043] GH4730 alloy is a wrought superalloy with a mass fraction of γ' phase as high as 42%, and the complete melting temperature of γ' phase is 1090°C.

[0044] Step 1. The GH4730 alloy consumable ingot smelted by vacuum induction melting, electroslag remelting and vacuum consumable remelting is subjected to two upsetting and elongating forging treatments in the single-phase region (1110°C) to obtain a Φ480mm rod material;

[0045] Step 2. Lower the temperature of the forging heat treatment furnace to 1050°C, and return the Φ480mm bar forged in step 1 to the forging heat treatment furnace. After holding it for 2 hours, cool it down to 800°C at a cooling rate of 50°C / h and keep it for 6 hours;

[0046] Step 3. The bar processed in step 2 is heated up to 1050°C at 5°C / min. After holding for 3 hours, it is taken out of the furnace and enters the forging heat treatment furnace for forging. After forging, return to the forging heat treatment furnace for 2 hours of heat preservatio...

Embodiment 3

[0049] GH4730 alloy is a wrought superalloy with a mass fraction of γ' phase as high as 42%, and the complete melting temperature of γ' phase is 1090°C.

[0050] Step 1. The GH4730 alloy consumable ingot smelted by vacuum induction melting, electroslag remelting and vacuum consumable remelting is subjected to two upsetting and elongating forging treatments in the single-phase region (1110°C) to obtain a Φ480mm rod material;

[0051] Step 2. Lower the temperature of the forging heat treatment furnace to 1060°C, and return the Φ480mm bar forged in step 1 to the forging heat treatment furnace. After holding it for 2 hours, cool it down to 1000°C at a cooling rate of 50°C / h and keep it for 5 hours;

[0052] Step 3. The bar processed in step 2 is heated up to 1050°C at 2°C / min. After holding for 4 hours, it is taken out of the furnace and enters the forging heat treatment furnace for forging. After forging, return to the forging heat treatment furnace for 2 hours of heat preservati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com