Patents

Literature

37results about How to "Homogenization of ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

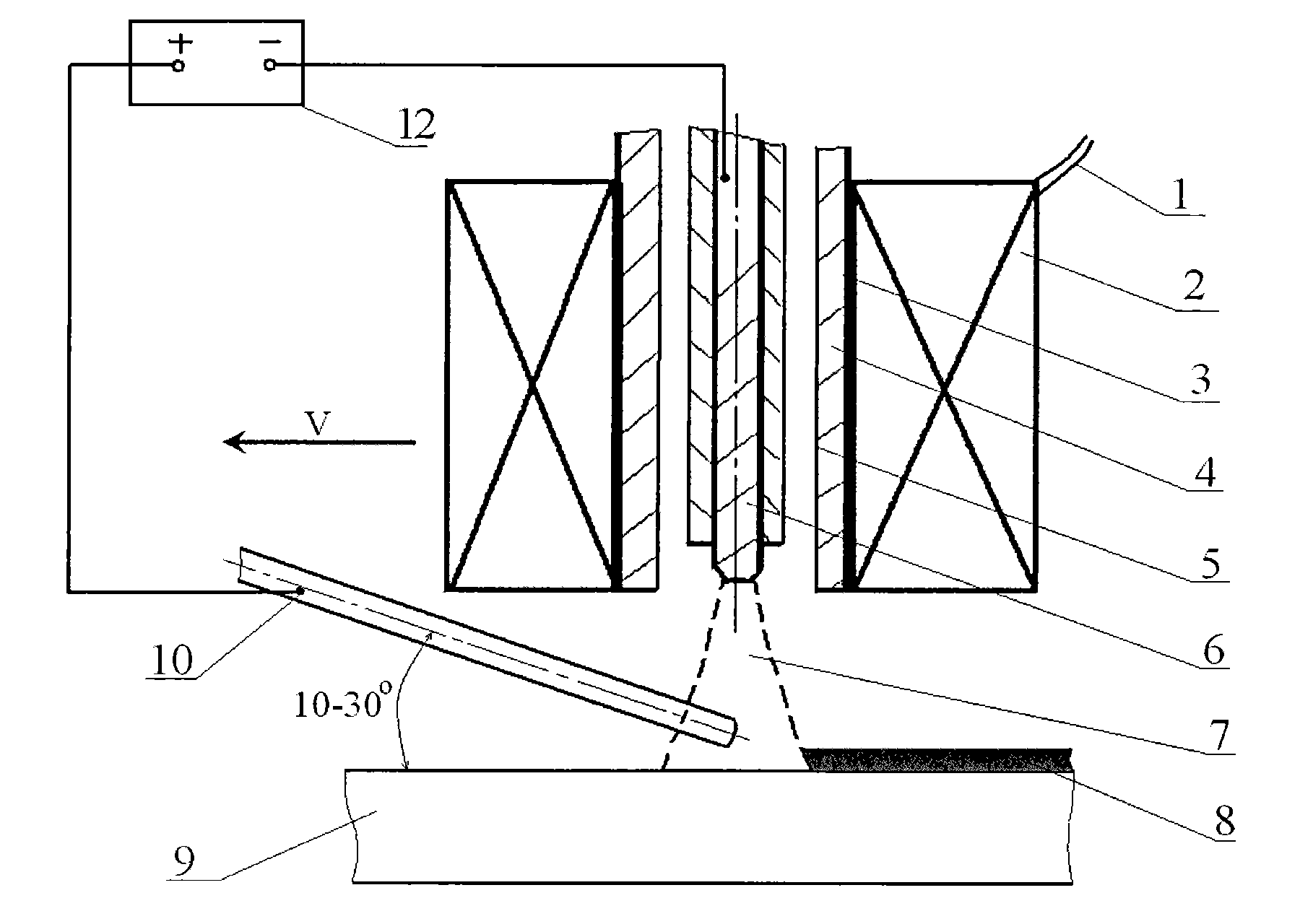

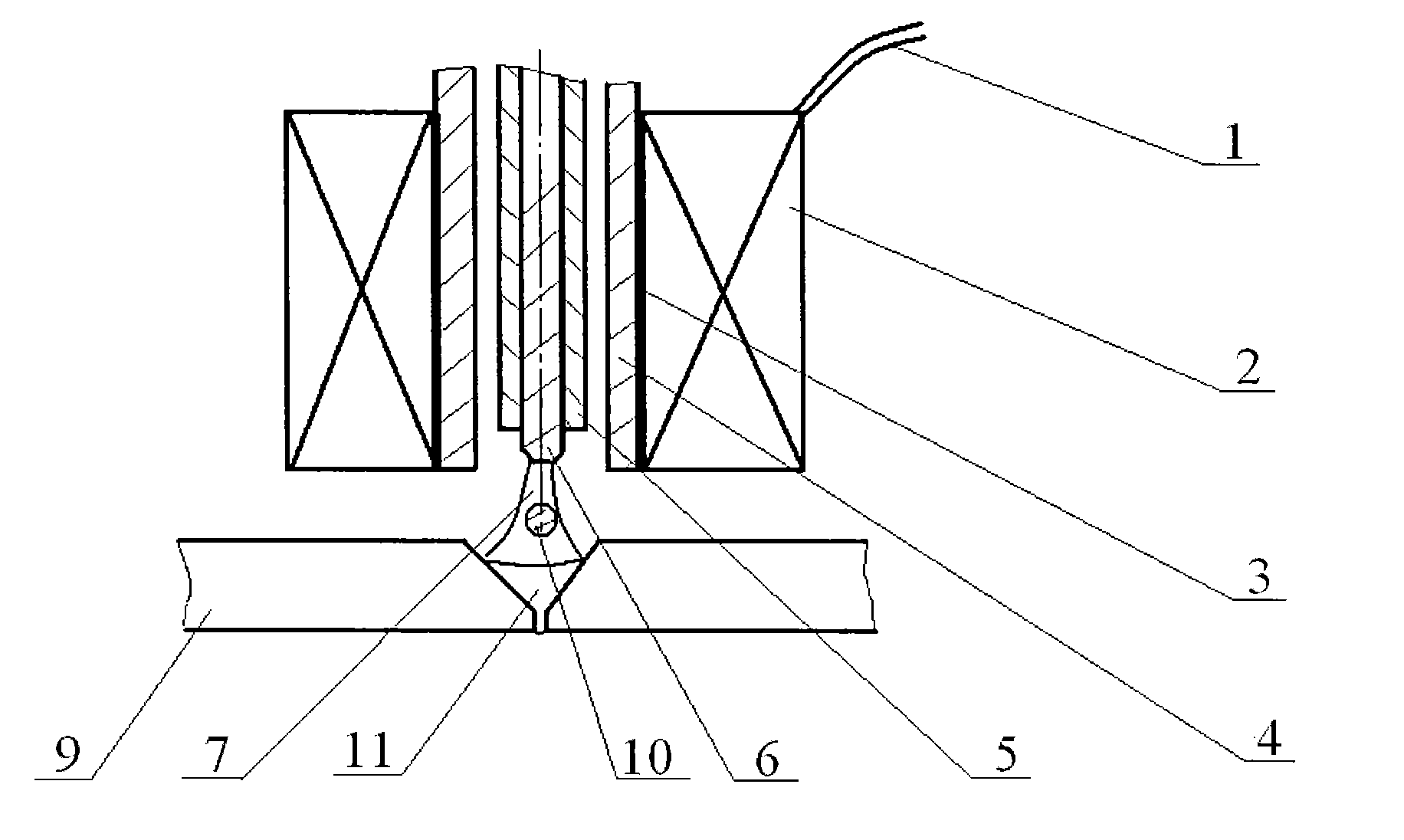

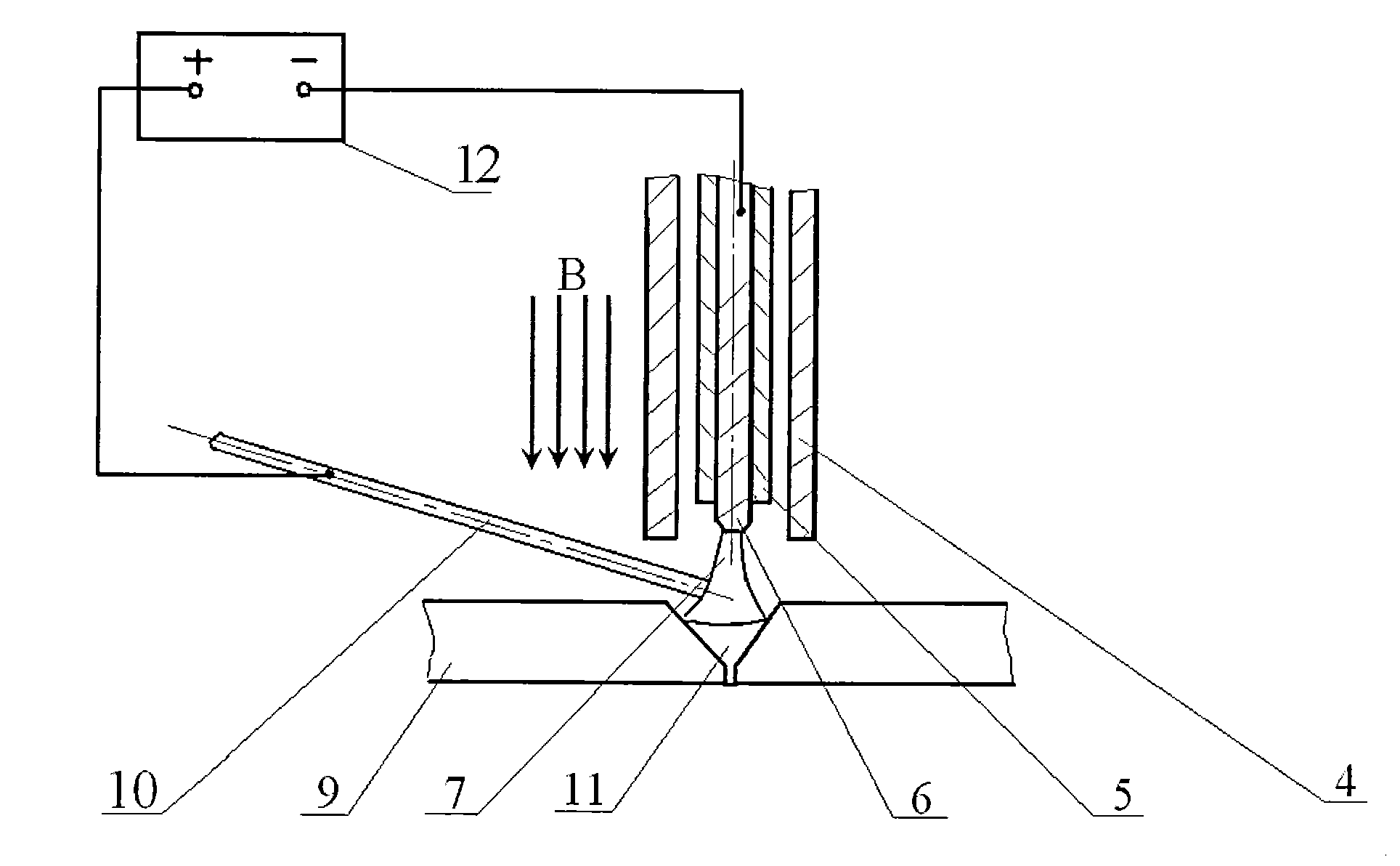

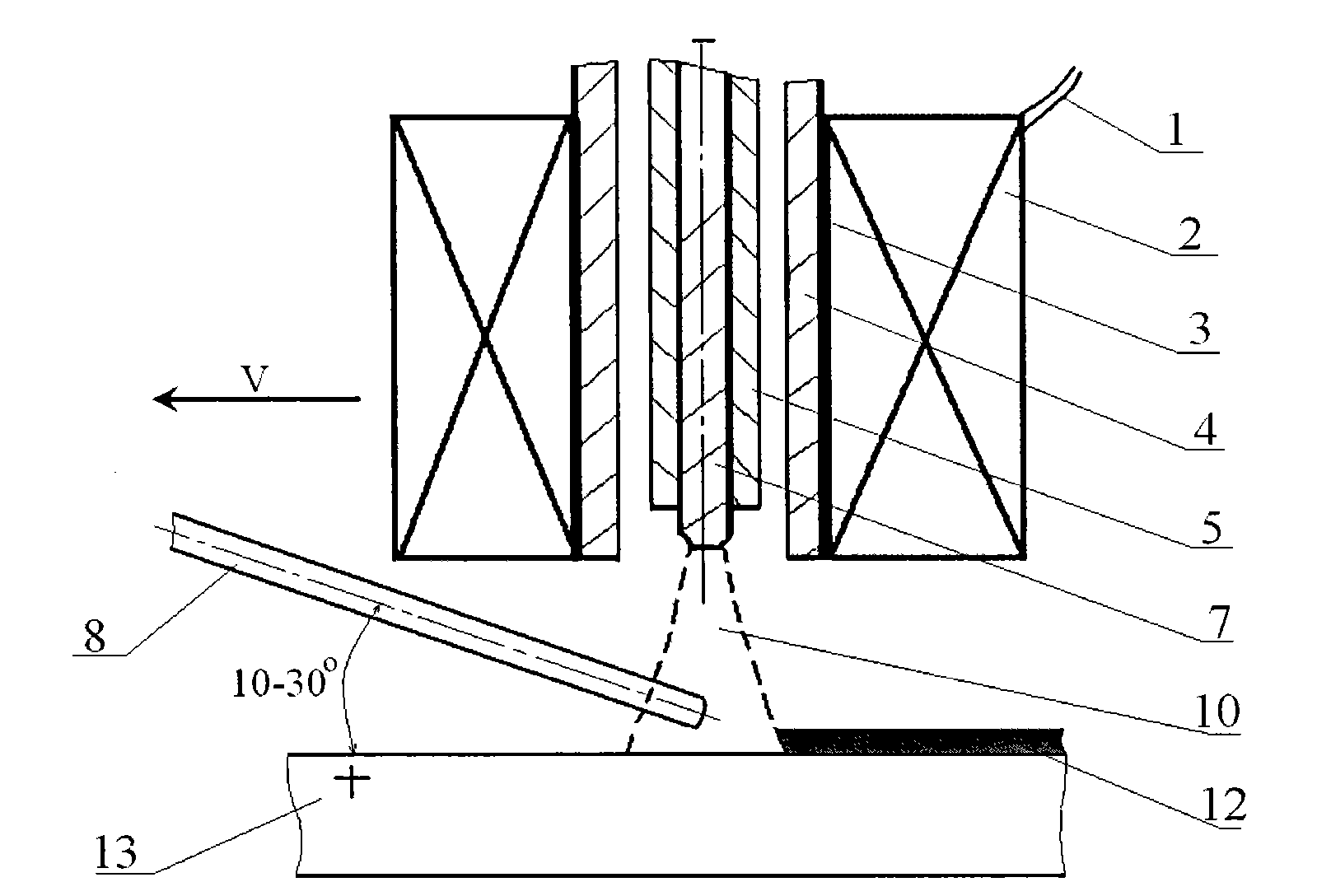

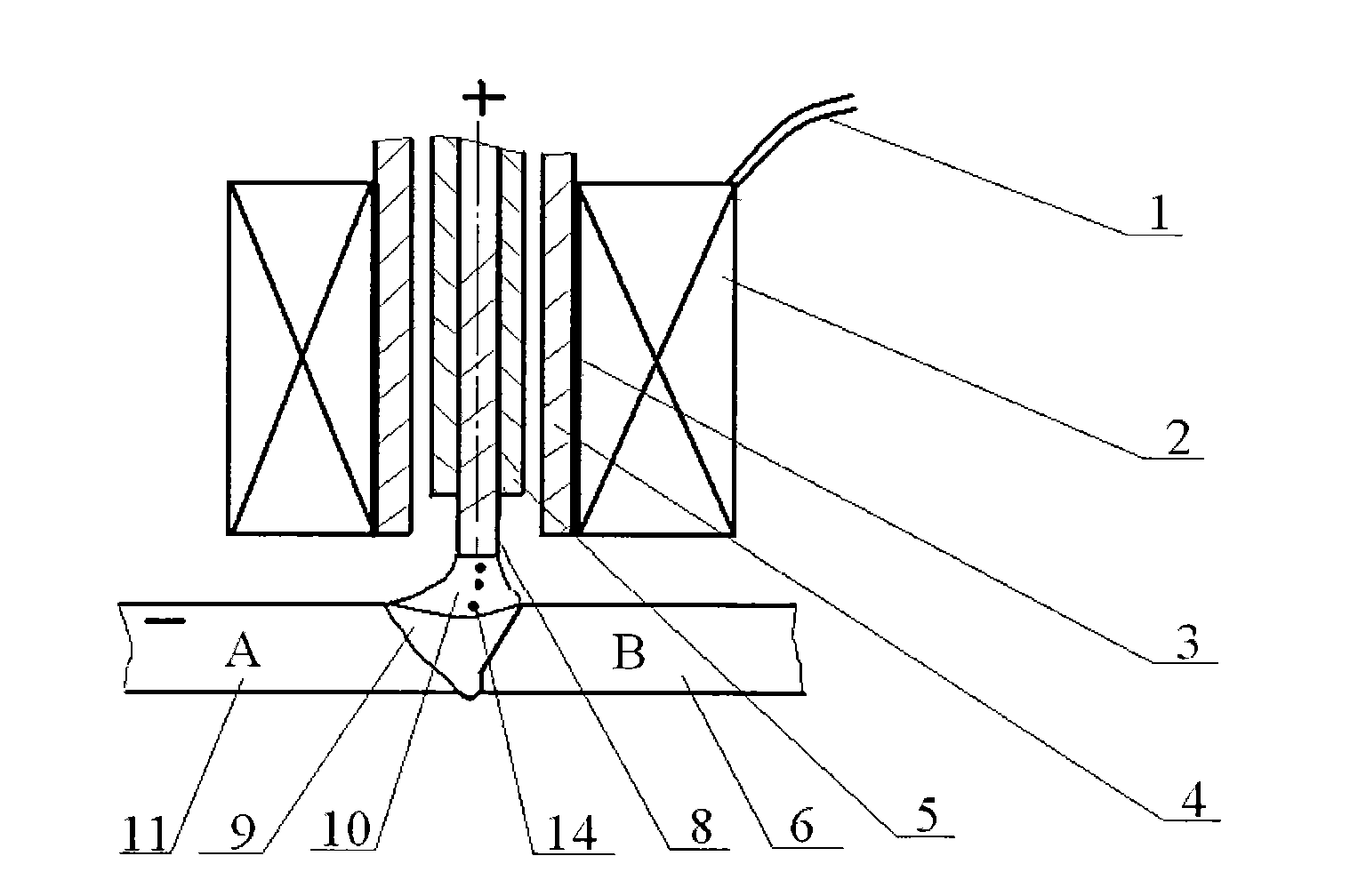

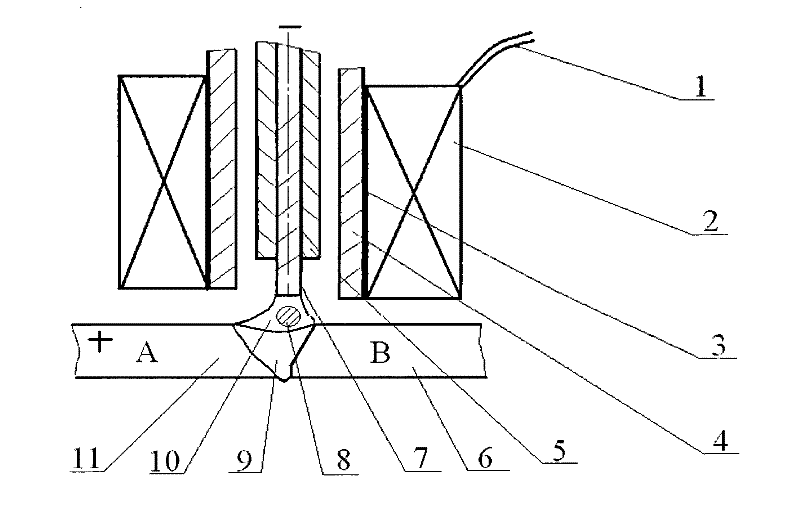

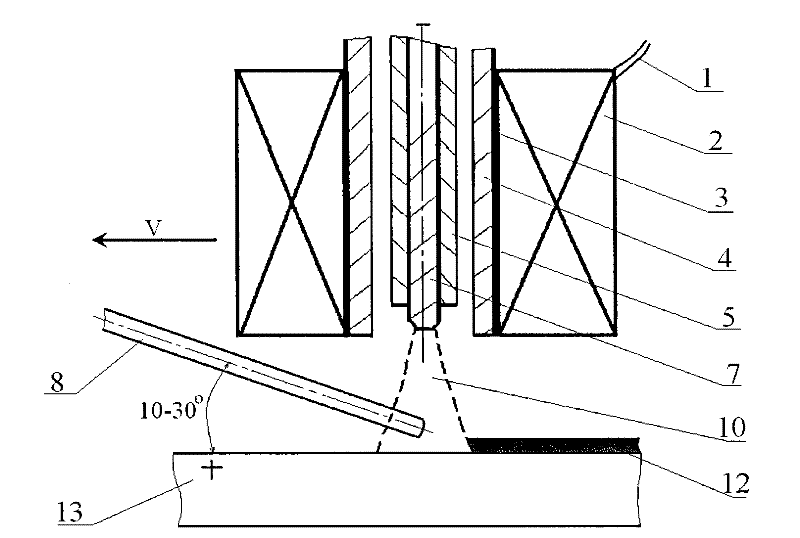

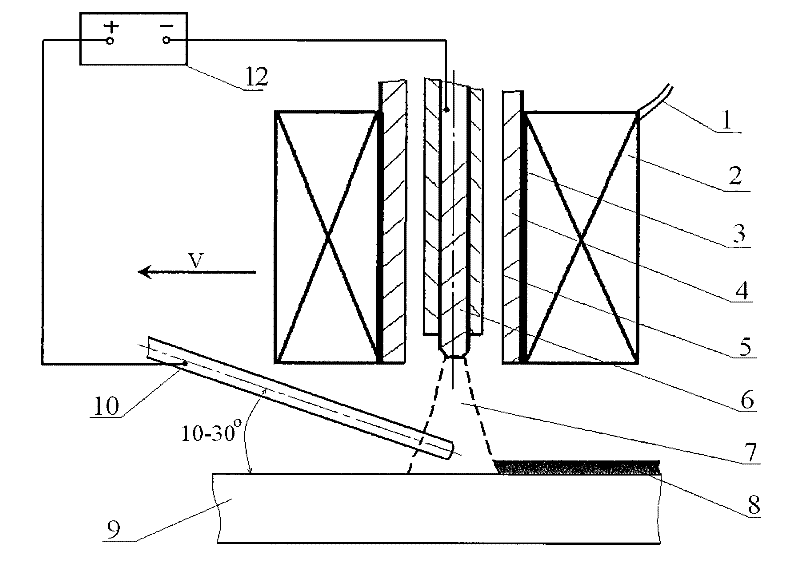

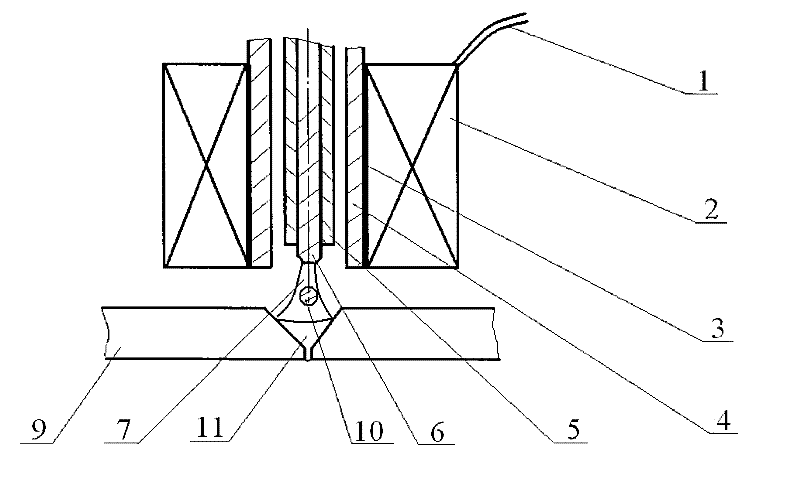

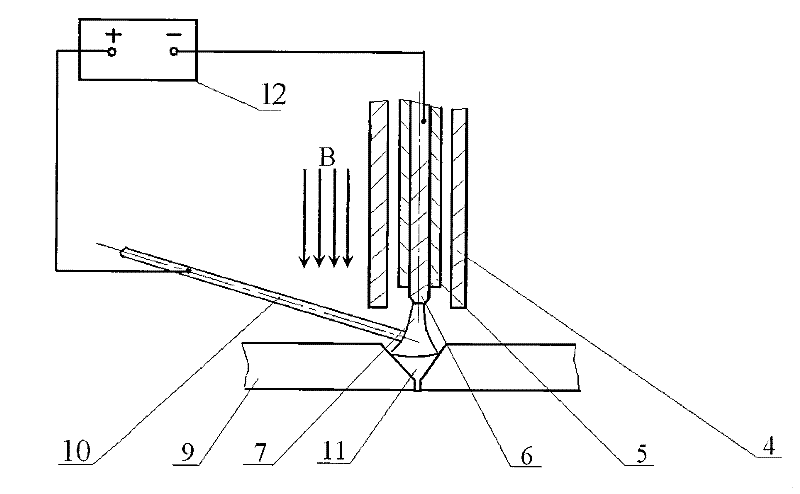

Electromagnetic excited TIG arc melting-brazing hybrid welding method and equipment

InactiveCN101862873AAvoid severe burnsLow heat inputSoldering apparatusMetal working apparatusMetallic materialsWelding defect

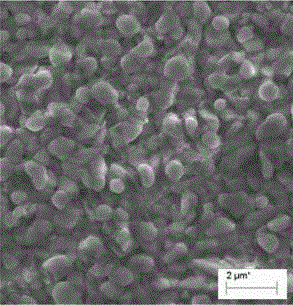

The invention discloses an electromagnetic excited TIG arc melting-brazing hybrid welding method and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of a welding arc, and the assistant effect on the melting bath of the liquid-state brazing filler metal for arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

Laser cladding alloy powder for repairing and remanufacturing hot-working die

ActiveCN105132913AHigh temperature hardnessGood toughness, crack resistanceMetallic material coating processesRare-earth elementYttrium

The invention provides laser cladding alloy powder for repairing and remanufacturing a hot-working die. In order to solve the problem that nickel-based or cobalt-based thermal spraying powder is expensive, iron-based alloy powder is adopted in the invention. While the iron-based alloy is formed through replacing pure iron with waste steel, the reutilization of the waste is realized. However, as the impurity content in the waste steel is high, the removal of phosphorous, carbon and sulphur is required in the refining process so as to obtain molten steel of which the components and temperature are qualified. The traditional method usually removes the impurities through slagging in the form of furnace slag, but has the problems of high heat energy requirement, large metal losses and serious splashing. In order to solve the problems, a traditional slag former is replaced by yttrium oxide, and waste steel impurities and glomeration inclusions are removed through the purifying functions of rare-earth elements. Meanwhile, deposited metal is endowed with excellent anti-fatigue performance.

Owner:SHANDONG UNIV

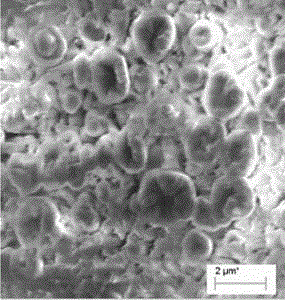

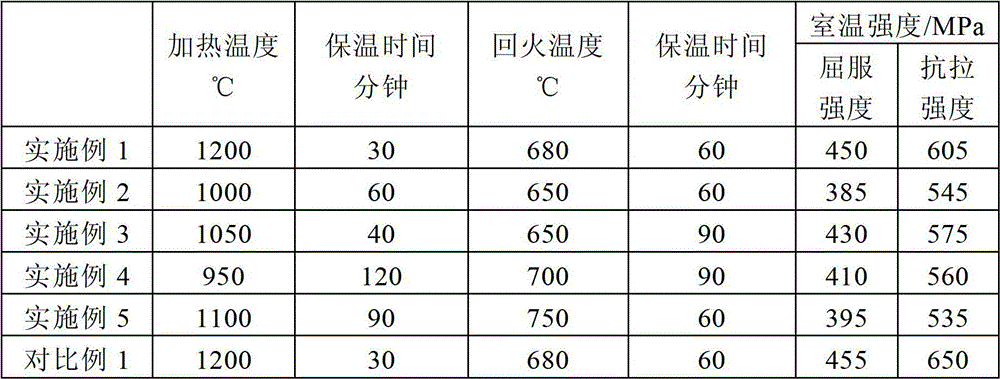

Sulfate reducing bacteria corrosion-resistant oil well pipe and production method thereof

InactiveCN102719747AEliminate segregated tissueHomogenization of ingredientsDrilling rodsRigid pipesCorrosion resistantChemical composition

The invention relates to a sulfate reducing bacteria corrosion-resistant oil well pipe and a production method thereof. The sulfate reducing bacteria corrosion-resistant oil well pipe consists of the following chemical components in percentage by weight: 0.12 percent or less of C; 0.15 to 0.45 percent of Si; 0.7 percent or less of Mn; 8.5 to 25 percent of Cr; 0.15 to 2.5 percent of Cu; 0.5 to 3.5 percent of Al; and the balance of Fe and inevitable impurities. The production method for the sulfate reducing bacteria corrosion-resistant oil well pipe includes the following steps: the chemical components are smelted and continuously cast into a round billet or cast into a square billet which is then rolled into a round billet; after hot rolling, a seamless steel pipe is produced; high-temperature solution heat treatment is carried out, the heating temperature is 950 DEG C to 1200 DEG C, and the temperature-keeping time is 30 to 120 minutes; the tempering temperature is 650 DEG C to 750 DEG C, and the tempering temperature-keeping time is 60 to 90 minutes; sizing and straightening are carried out, the hot straightening temperature is higher than 450 DEG C, and therefore the oil well pipe is produced. The oil well pipe produced by the method can effectively resist SRB (sulfate reducing bacteria) corrosion in external environment, moreover, the yield strength of the oil well pipe is greater than 380MPa, thus meeting the requirement of J55 steel grade, and better meeting the requirements of production strings for water injection wells under harsh environment.

Owner:BAOSHAN IRON & STEEL CO LTD

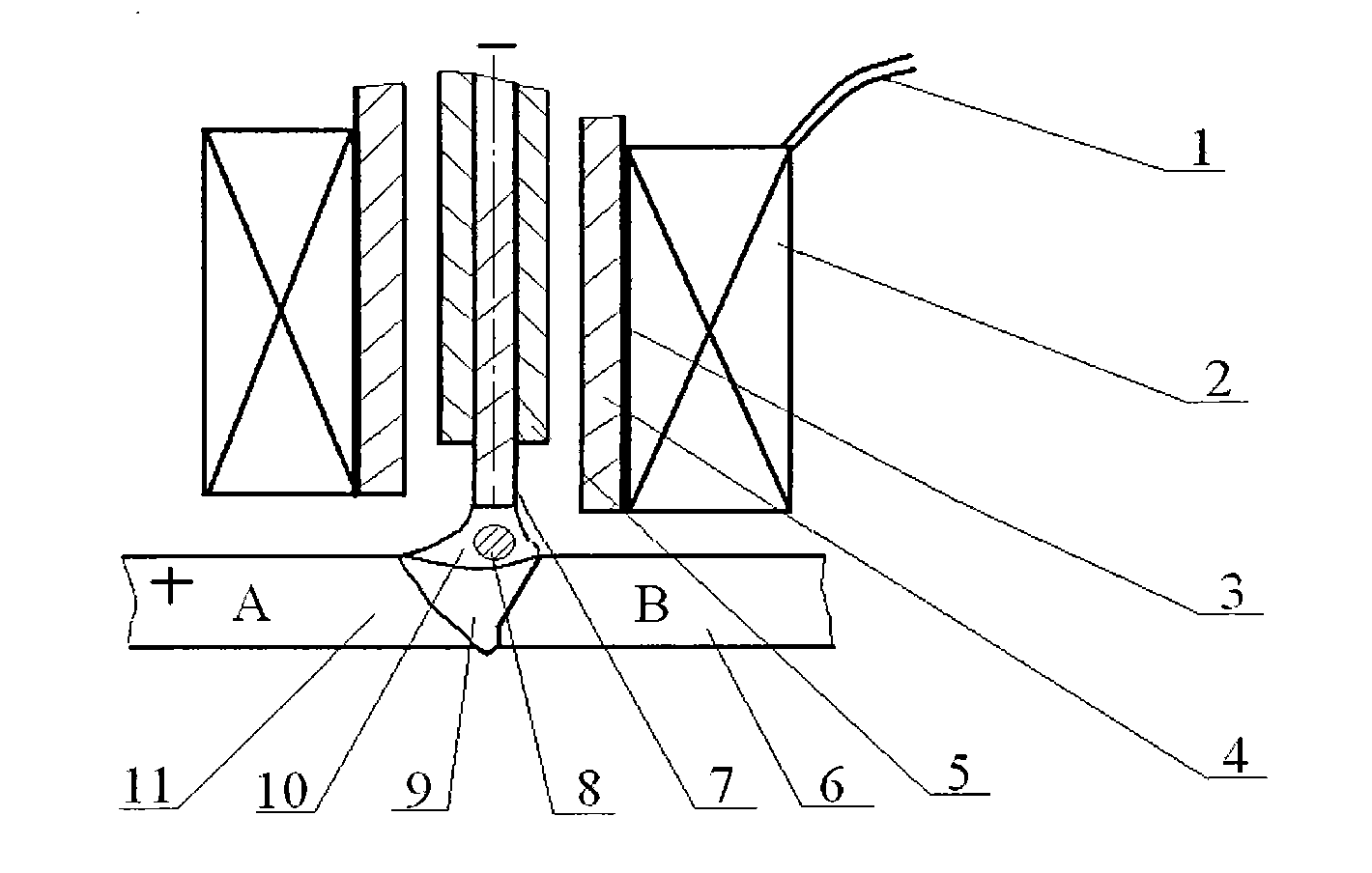

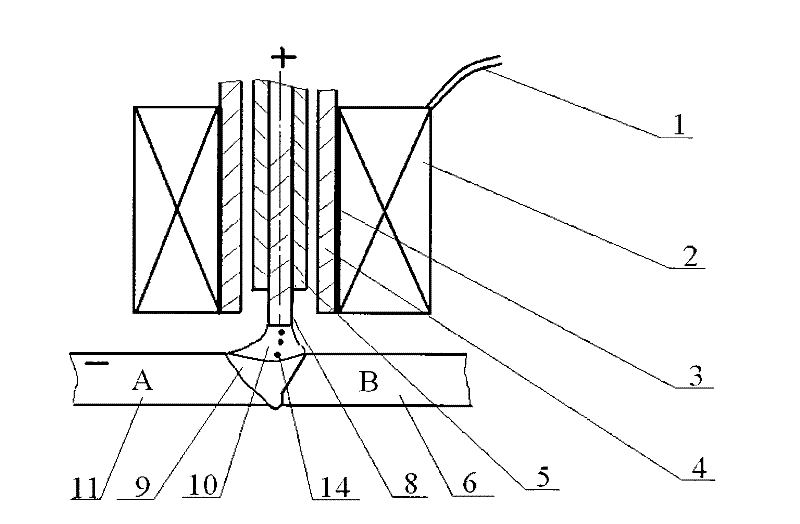

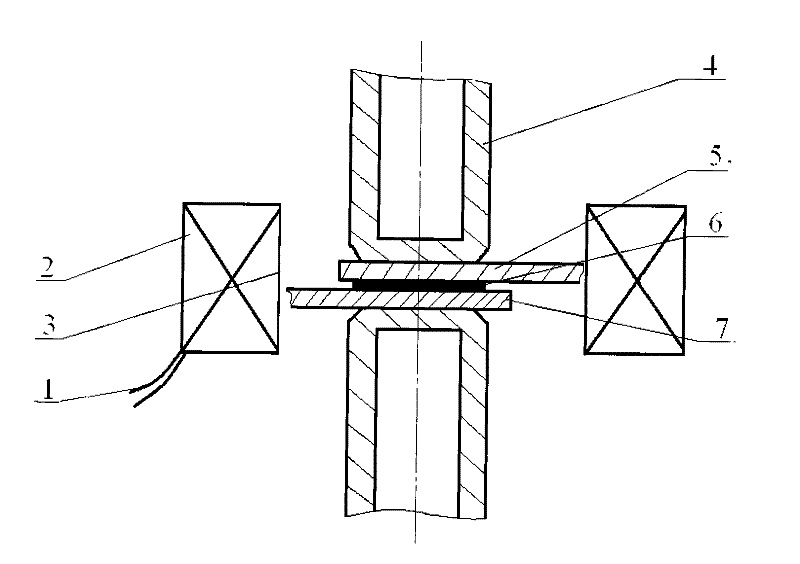

Method and device for performing electric magnetization arc welding-braze welding compounding on dissimilar materials

InactiveCN101844259AImprove connection qualityInhibition formationSoldering apparatusMetal working apparatusMetallic materialsMagnetization

The invention discloses a method and a device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials. In the process of performing arc welding-braze welding on the dissimilar metal material, a brazed liquid solder molten pool is subjected to the reinforced booster action of electromagnetic stirring and electric magnetization by using the characteristic that a magnet exciting coil generates an external applied alternating magnetic field in a welding area to control a welding arc so as to promote ordered flow of the liquid solder, and rupture of membranes, wetting, spreading and diffusion of the liquid solder on the surface of the metal material with a higher melting point, promote the liquid solder and a base metal which is molten by the metal material with a lower melting point to be mixed fully, improve uniformity of compositions of a soldered seam, reduce the weld defects, optimize the compositions and the performance of the soldered seam, and improve the soldered joint; and the device has the advantages of simple structure, flexible application, lower cost, good effect, and easy implementation.

Owner:CHONGQING UNIV

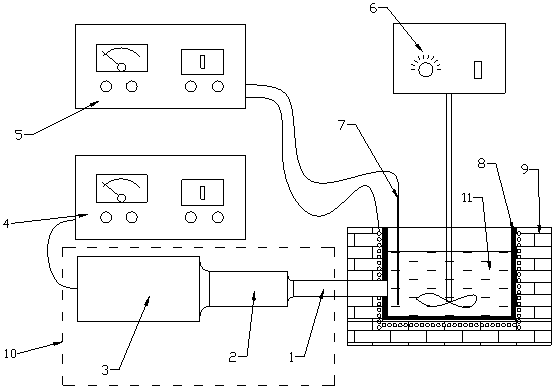

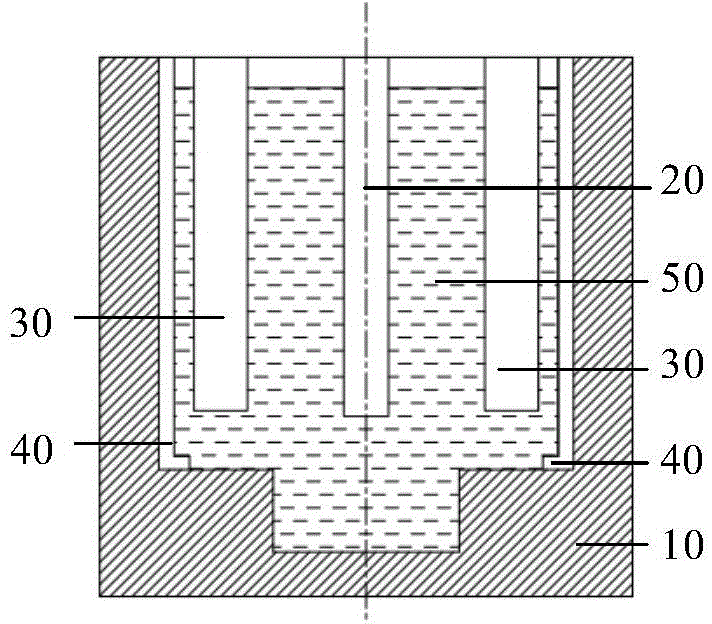

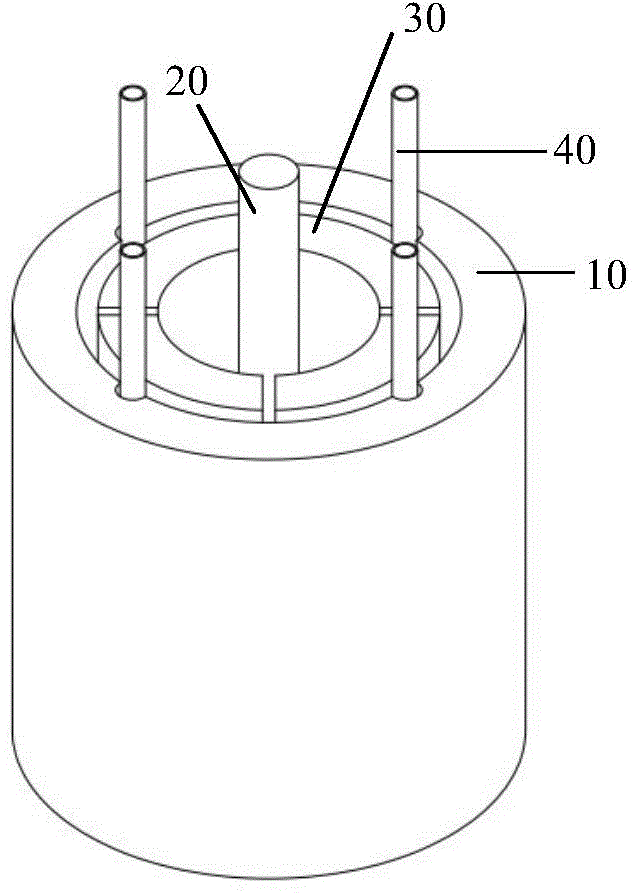

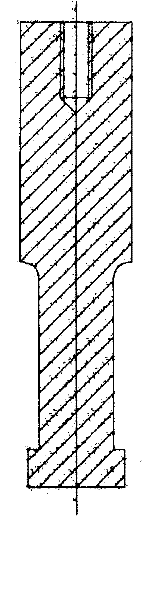

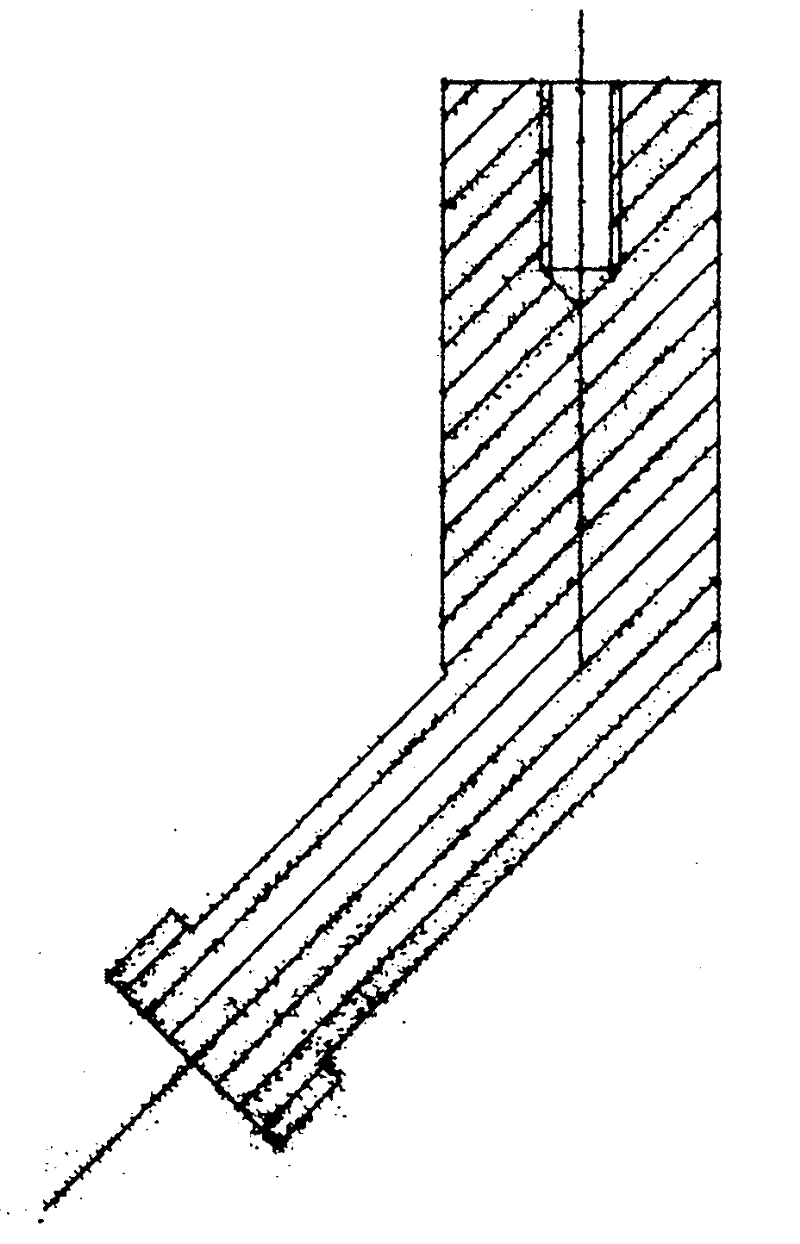

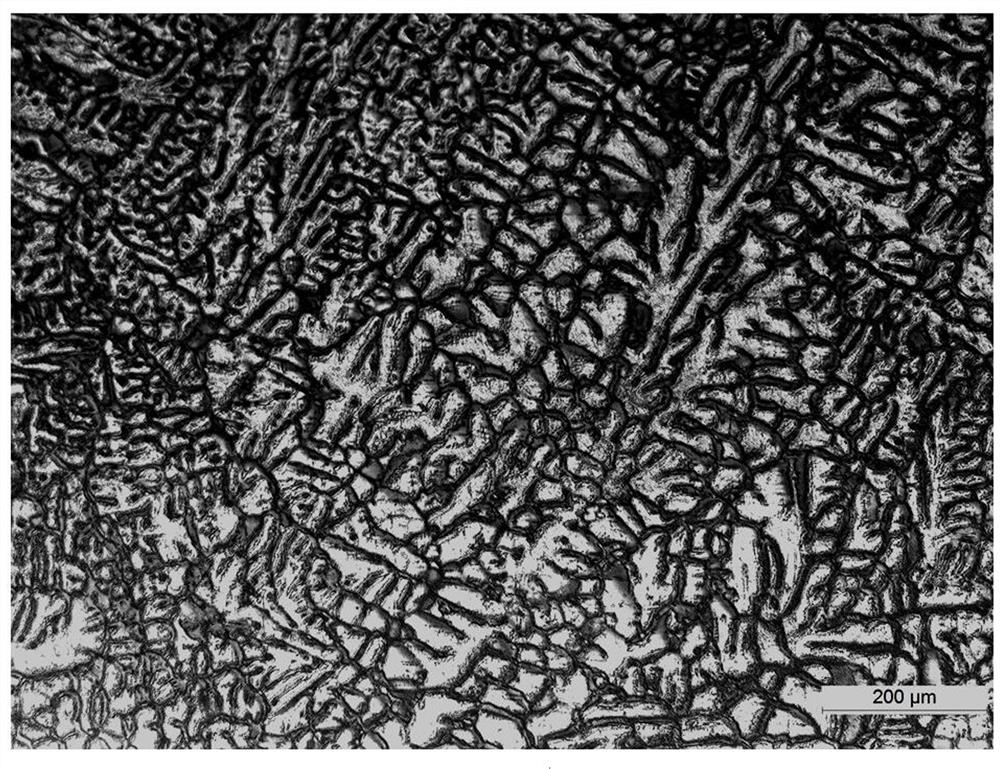

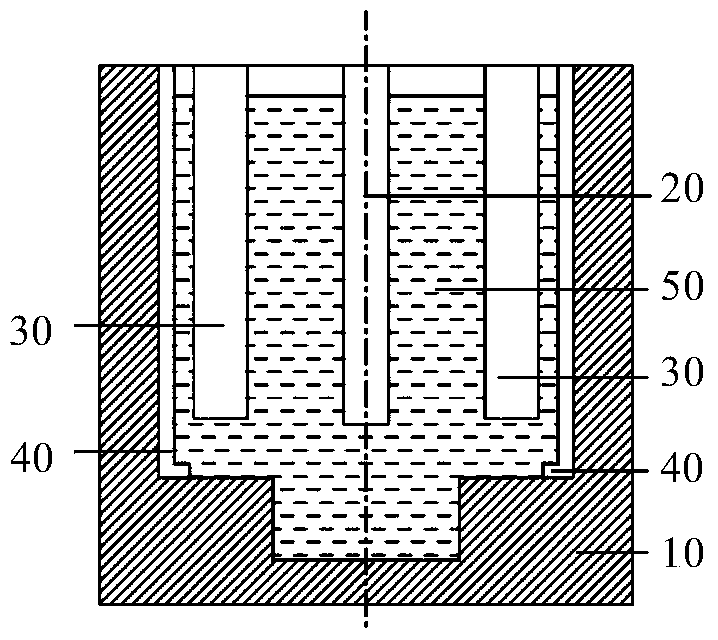

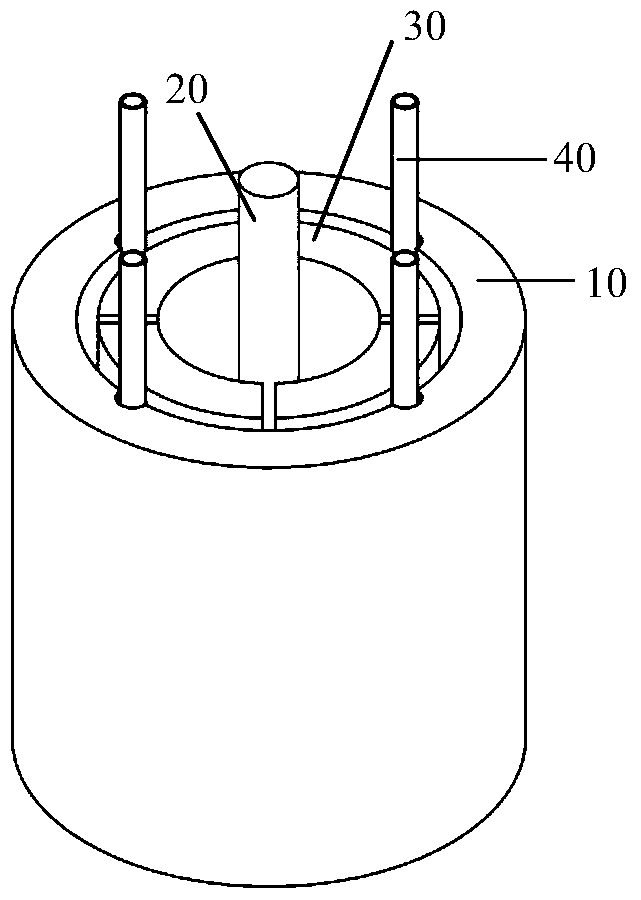

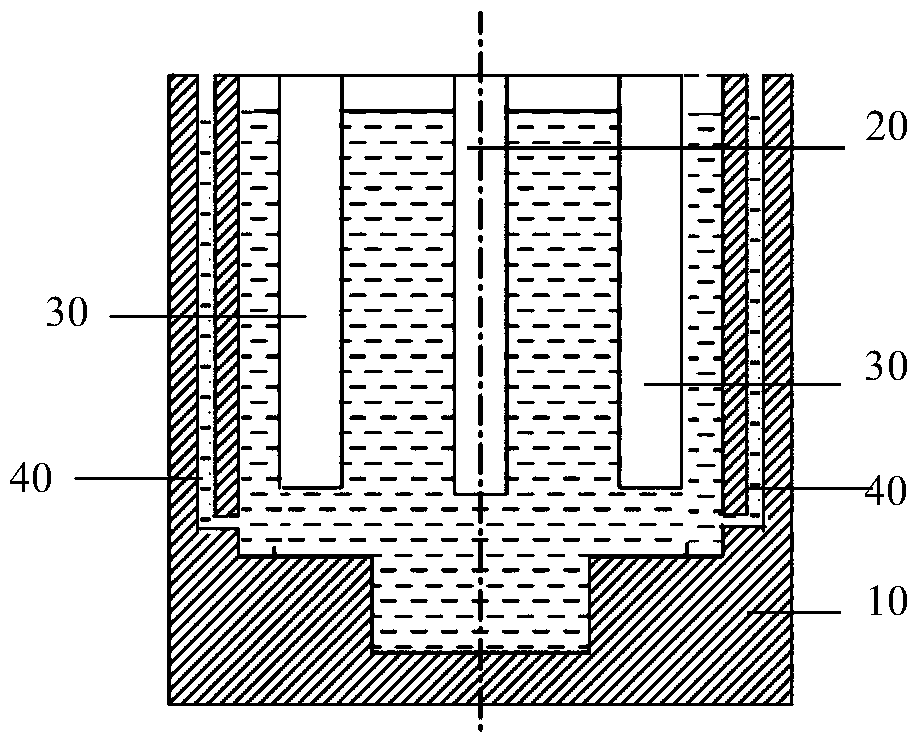

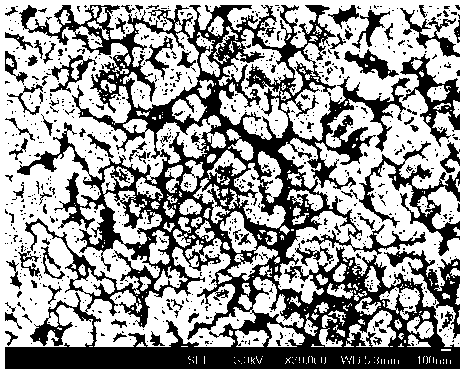

Compound smelting equipment ultrasonically stirring low-melting-point alloy

The invention discloses compound smelting equipment ultrasonically stirring low-melting-point alloy, which is applicable for the smelting and preparation of the low-melting-point alloy, in particular to various tin-bismuth series alloy at the low melting point of below 300 DEG C. The equipment comprises a crucible, a heat-preservation and heating device, a temperature control device, an ultrasonic stirring device, an ultrasonic wave generation and control device and a mechanical stirring device, wherein molten metal is put in the crucible. The equipment is simple in structure and practical; the mechanical stirring device and the ultrasonic stirring device are mutually perpendicular without intervention; ultrasonic waves are imported to the molten metal from the side of the crucible; the efficiency is high, the ultrasonic energy loss is low, and moreover, the solid rate of the molten metal is higher; even when metal stirring fails, the ultrasonic waves still can be applied till metal solidification; through the compound ultrasonic and mechanical stirring, grains can be refined, so that a non-dendritic structure is obtained; homogenizing of the ingredients and the temperature of the fused molten metal is sped up; the plasticity of prepared alloy is improved greatly in comparison with the plasticity of alloy prepared by a traditional method.

Owner:GUANGDONG UNIV OF TECH

Method for controlling blank casting quality of phi-280mm 37Mn circular tube blank

ActiveCN105695659AImprove purityHomogenization of ingredientsManufacturing convertersMolten steelParameter control

The invention discloses a method for controlling the internal quality of a 37Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, RH vacuum treatment and continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Preparation method of high-toughness wear-resistant steel casting

InactiveCN106119728AReasonable organizational changesHomogenization of ingredientsMagnesiumBoron nitride

The invention discloses a preparation method of a high-toughness wear-resistant steel casting. The preparation method comprises the following steps: raw materials are added to a smelting furnace, a smelting additive, which comprises sodium borate, sodium fluosilicate, sodium carbonate, sodium chloride, rare earth carbonate, lithium oxide and titanium dioxide, is added, an inert gas mixture of an argon gas and a helium gas is supplied, and matrix alloy liquid is obtained; the component contents of the matrix alloy liquid are detected, and the components comprise C, Si, Cr, Mn, Mo, B, Al, V, Zr, Nb, S, P, the balance Fe and unavoidable impurities; a modificator, which comprises silicon carbide, boron nitride, tungsten oxide, silicon dioxide, molybdenum metal and magnesium metal, is added to the matrix alloy liquid, and a cast steel blank is obtained by casting; and the cast steel blank is subjected to heat treatment, and the high-toughness wear-resistant steel casting is obtained. The steel casting obtained by the preparation method has good wear resistance, the hardness can reach above 70HRC, and the impact toughness can reach 15J / cm<2>.

Owner:蚌埠市北晨微型机床厂

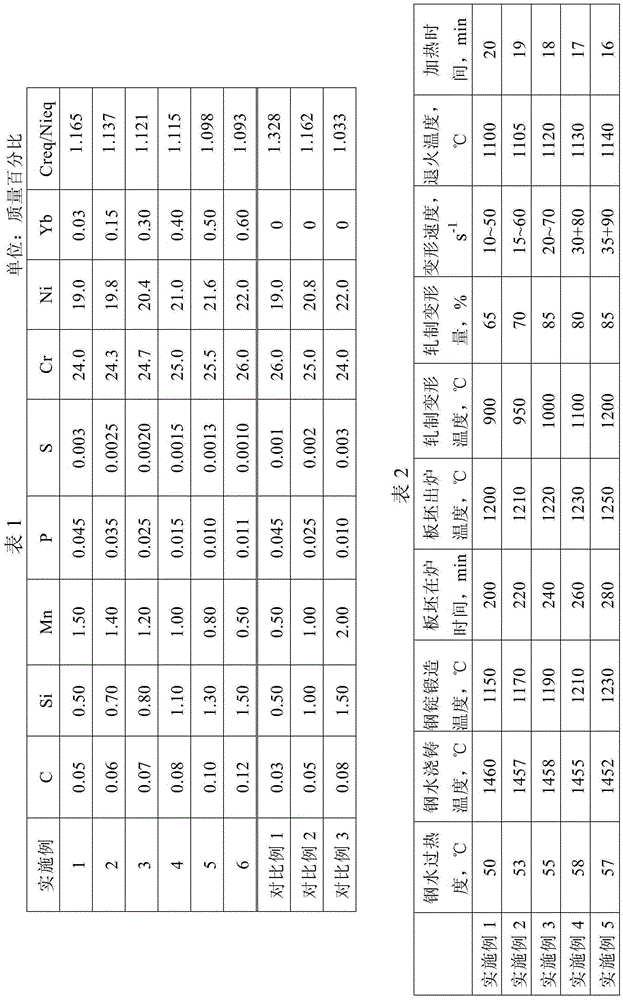

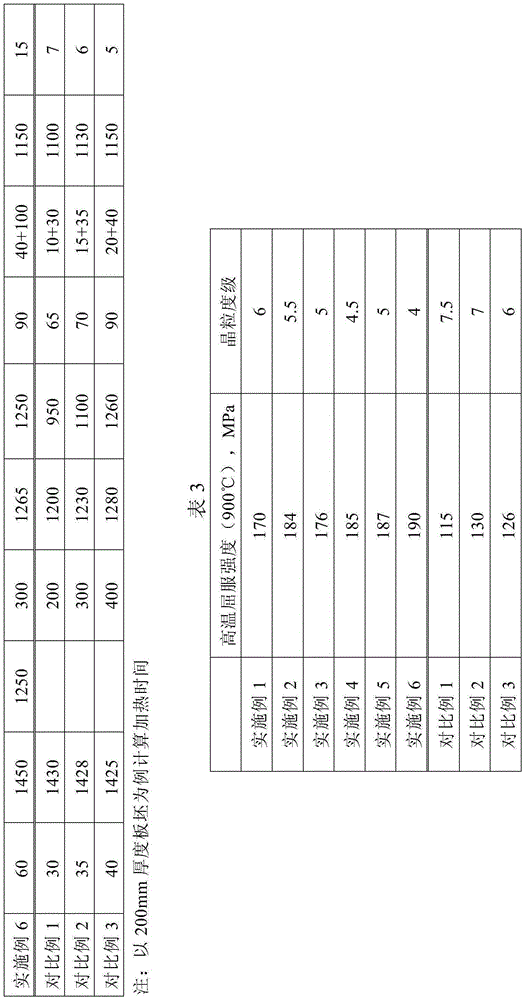

High-strength rare earth ytterbium heat-resistant steel and manufacture method thereof

ActiveCN106256921AImprove high temperature strengthReduce the content of harmful inclusionsChemical compositionRare earth

The invention relates to high-strength rare earth ytterbium heat-resistant steel and a manufacture method thereof. The heat-resistant steel comprises the following chemical components by mass percentage: 0.05-0.12% of C, 0.2-1.5% of Si, 0.5-1.7% of Mn, less than or equal to 0.045% of P, less than or equal to 0.030% of S, 24.0-26.0% of Cr, 19.0-22.0% of Ni, 0.03-0.6% of Yb, and the balance of Fe and the unavoidable impurity element; and the following condition should be simultaneously satisfied: Creq / Nieq is less than or equal to 1.165, Creq is Cr+1.5Si, and Nieq is Ni+30C+0.5Mn. By adding rare earth ytterbium, crystal boundary intensity is increased, the method provides favorable condition for increasing carbon content in the heat resistant steel, so that the high temperature intensity and service life of the steel are increased, the reasonable manufacturing process condition is cooperated, under guarantee of mechanical properties, the grain size of the heat-resistant steel can reach 4-6 grade, and the steel antioxidation performance is increased.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

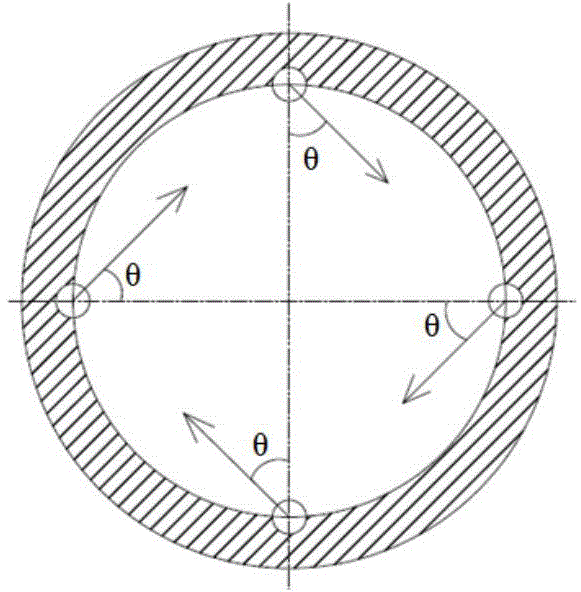

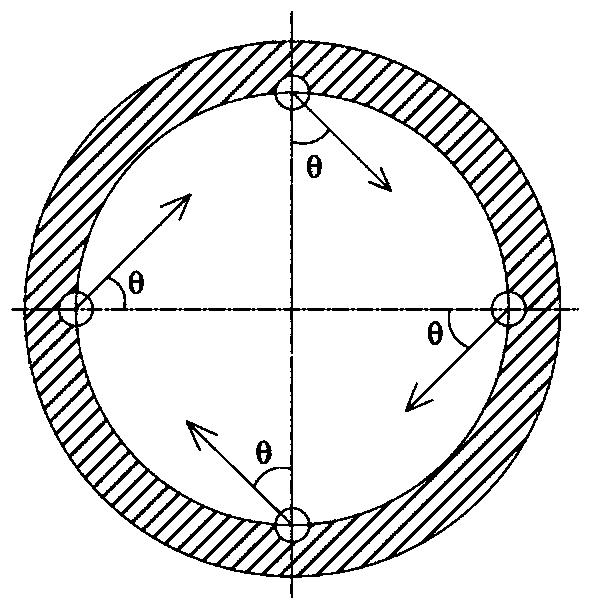

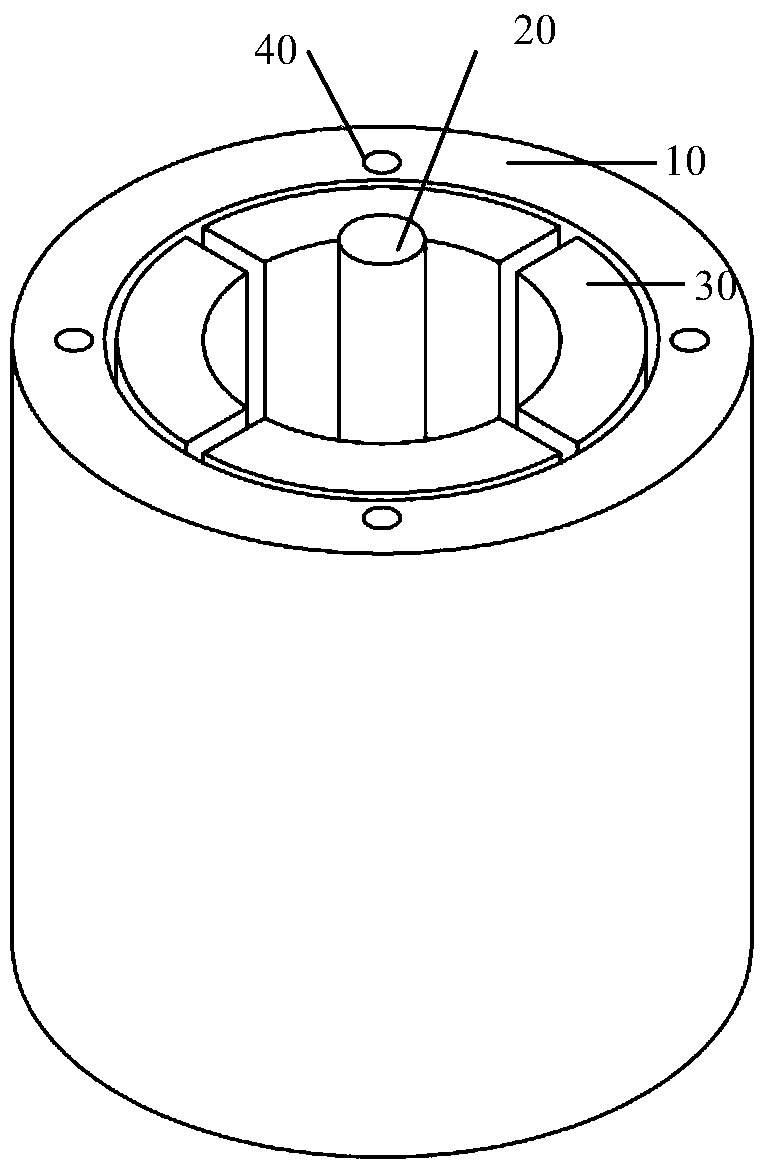

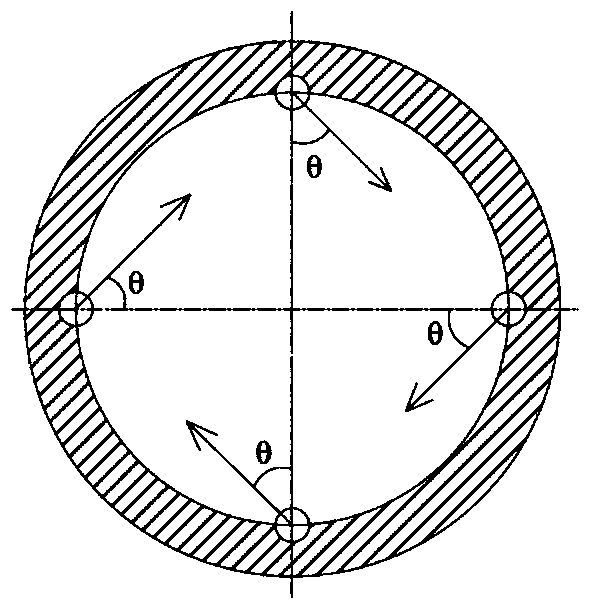

Electrolysis device and method

ActiveCN106337193AImprove liquidityImprove heat transfer performanceElectrolysis componentsElectrolysisEddy current

The invention provides an electrolysis device and method. The electrolysis device comprises an electrolysis tank, at least one cathode in the electrolysis tank, multiple anodes arranged around the cathode in intervals and multiple air blowing pipes symmetrically arranged on the inner wall of the electrolysis tank, wherein bottom outlets of the air blowing pipes stretch out of the bottom surface of the electrolysis tank and are arranged along a horizontal direction. An electrolyte at the bottom of the electrolysis tank is stirred through gas and a gas outlet direction and a cathode center direction form an a certain angle in air blowing so that the electrolyte on the bottom produces eddy currents along a horizontal direction and the electrolyte in all zones in the electrolysis tank can circularly flow and thus heat transfer and mass transfer in the electrolysis tank are improved, inner temperatures and components are uniformed, product quality is improved and furnace conditions are improved.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

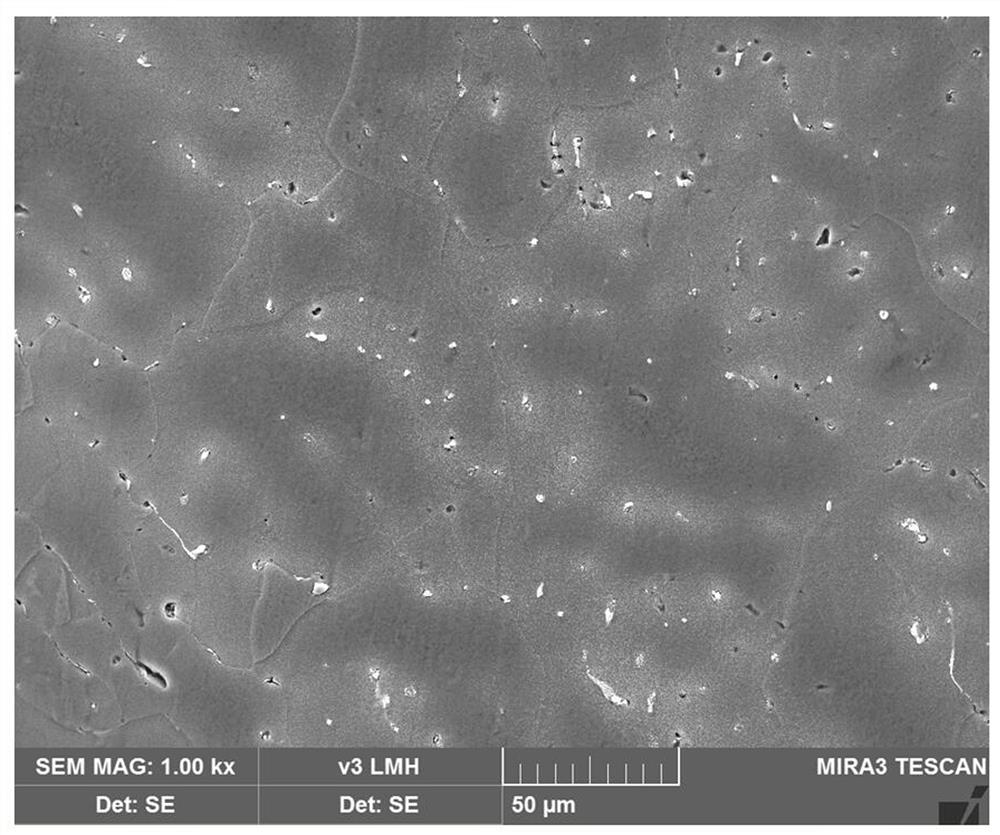

Preparation method for palladium alloy small-diameter thin-walled capillary tube

The invention discloses a preparation method for a palladium alloy small-diameter thin-walled capillary tube. The method comprises the following steps that 1, a palladium alloy raw material is subjected to vacuum induction melting and then poured to obtain an electrode; 2, the electrode is subjected to vacuum electric arc melting and diffusion annealing to obtain a cast ingot; 3, the cast ingot ismade into a pierced billet to obtain the pierced billet; 4, the pierced billet is extruded and straightened to obtain a tube blank; 5, the tube blank is rolled to obtain a semi-finished tube material; and 6, the semi-finished tube material is subjected to drawing to obtain the palladium alloy small-diameter thin-walled capillary tube. According to the preparation method, by controlling technologyparameters of duplex melting and diffusion annealing, atoms in the cast ingot are diffused, and it is ensured that the palladium alloy small-diameter thin-walled capillary tube is uniform in component and compact in structure; by controlling the size of the semi-finished tube material and collaborative optimization between the steps, the outer diameter and the wall thickness of the palladium alloy small-diameter thin-walled capillary tube are decreased, and production of the palladium alloy small-diameter thin-walled capillary tube which is high in precision, compactness and gas tightness isachieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

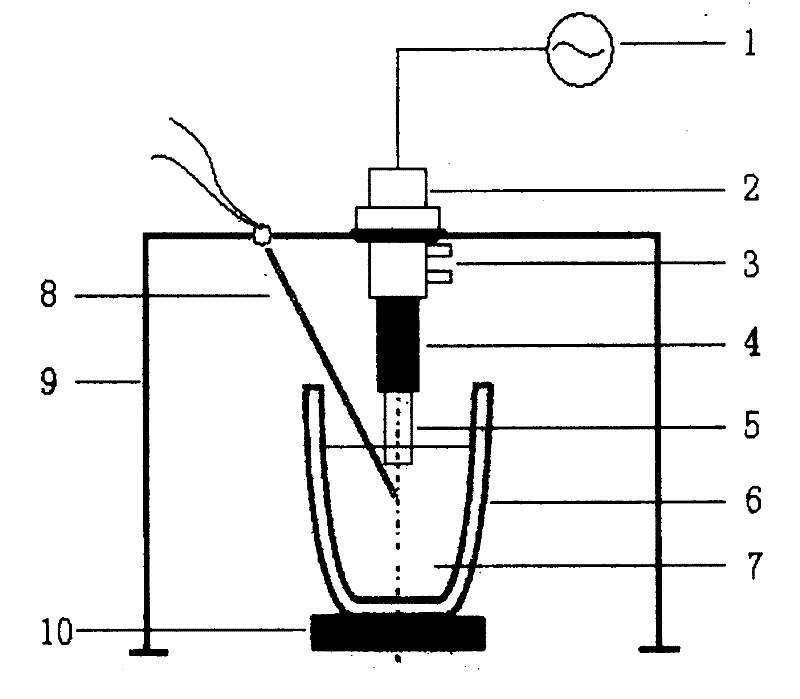

High sound intensity ultrasonic processing apparatus for metal and alloy solidification and processing method thereof

The invention provides an ultrasonic processing device with high sound intensity, which is used for grain refining, degassing and ingredient homogenization when the metal and the alloy are solidified in a high temperature and comprises an ultrasonic generator, a transducer, an amplitude variable rod and a coupling head; wherein, the ultrasonic generator comprises a frequency phase locking tracking module, which is used for automatically carrying out tracking and detection to working frequency of the ultrasonic generator and adjusting matching frequency, thereby the high frequency resonance of the ultrasonic generator and the transducer is achieved. By adopting the frequency phase locking tracking module, the decrease and drift problems of frequency are solved and even in different high-temperature melts, the ultrasonic effect same as that of starting at rated frequency can also be obtained, thus realizing grain refining, degassing and ingredient homogenization when the metal and the alloy are solidified.

Owner:TSINGHUA UNIV

Dispersion strengthened material used for platinum-based vessel and preparation method and application of material

ActiveCN108165812AGood erosion resistanceGuaranteed Alloy PropertiesMolten spray coatingCorrosionOxide

The invention provides a dispersion strengthened material used for a platinum-based vessel. The dispersion strengthened material comprises a substrate and a strengthening phase dispersed in the substrate, wherein the substrate is platinum and the strengthening phase element is any one or more of zirconium, scandium and cerium. The zirconium content is more than 0 and no more than 0.4 wt%, the scandium content is in a range of 0-0.4 wt%, and the cerium content is in a range of 0-0.4 wt%, with the balance being platinum, wherein the total content of zirconium and scandium and cerium is less than0.6 wt%. The strengthening phase element is dispersed in the substrate in an oxide form to form a dispersion strengthened material. The dispersion strengthened material is good in scouring resistance, corrosion resistance and high-temperature creep resistance. A vessel prepared from the material is long in service life. The production cost in the technical fields, such as optical glass and glassfiber, can be efficiently reduced.

Owner:CHONGQING MATERIALS RES INST +1

Quality Control Method of 37mn Round Tube Billet with φ280mm

ActiveCN105695659BImprove purityHomogenization of ingredientsManufacturing convertersMolten steelParameter control

The invention discloses a method for controlling the internal quality of a 37Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, RH vacuum treatment and continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

A kind of dispersion strengthened material for platinum-rhodium-based vessel and its preparation method and application

ActiveCN108149055BExtended service lifeImprove compactnessTransportation and packagingMetal-working apparatusPlatinumGlass fiber

The invention provides a dispersion-strengthened material for platinum-rhodium-based vessels, which includes a base material and a strengthening phase dispersed in the base material, the base material is a platinum-rhodium alloy, and the strengthening phase elements are zirconium and scandium Any one or several of cerium and cerium, the content of rhodium in each component is > 0 ~ ≤ 20wt%; the content of zirconium is > 0 ~ ≤ 0.4wt%; the content of scandium is 0 ~ 0.4wt%; the content of cerium is 0 ~0.4wt%; platinum is the balance; zirconium+scandium+cerium<0.6wt%, the strengthening phase elements are dispersed in the base material in the form of oxides, forming a dispersion-strengthened material. The dispersion-strengthened material used for platinum-rhodium-based vessels provided by the invention has good erosion resistance, corrosion resistance and high-temperature creep resistance, and the vessels prepared by using this material have a long service life and can effectively reduce such as optical glass and glass fiber. production costs in industrial fields.

Owner:CHONGQING MATERIALS RES INST

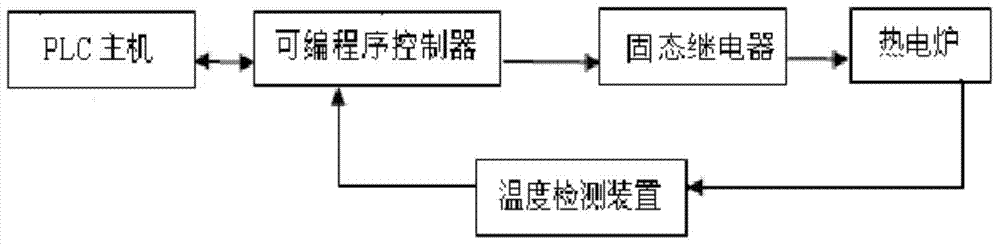

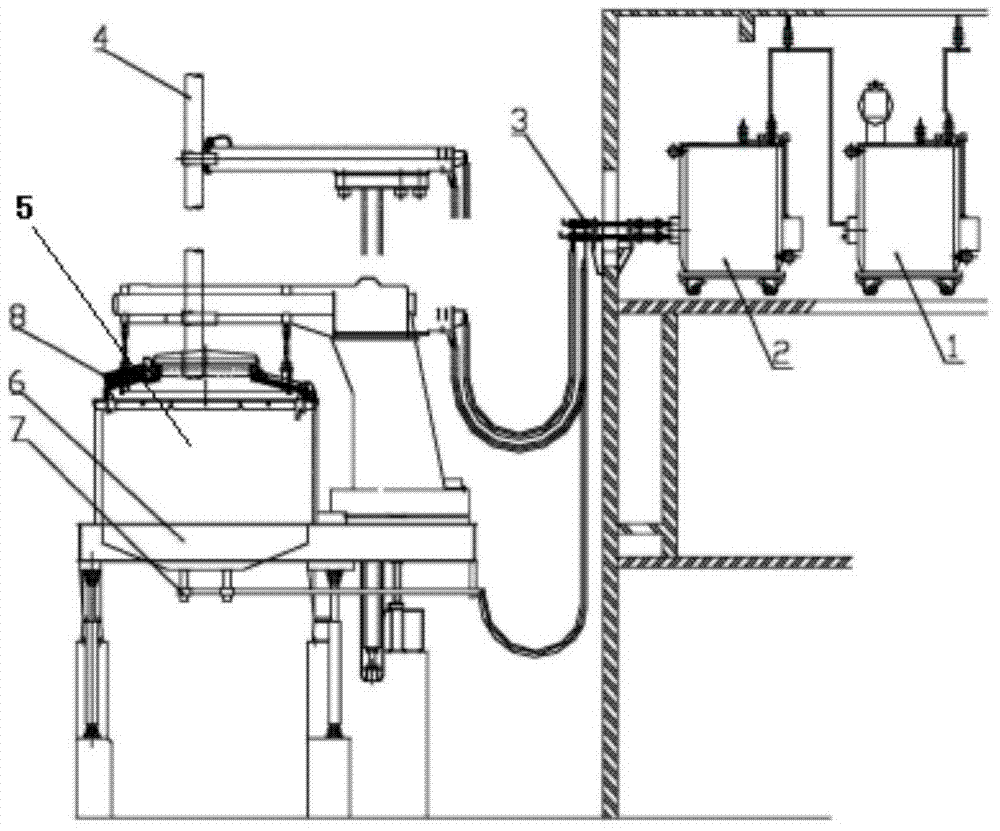

Thermoelectric furnace provided with temperature control system

InactiveCN103575091ARealize automatic controlTemperature homogenizationLighting and heating apparatusAutomatic controlCombustion chamber

The invention discloses a thermoelectric furnace provided with a temperature control system. The thermoelectric furnace comprises a furnace body, a power unit and the temperature control system, wherein the furnace body consists of a combustion chamber, a furnace bottom and a furnace cover; and the power unit comprises a transformer, a rectifier, a short net system and power supply electrodes, the power supply electrodes consist of the negative electrode and the positive electrode, the negative electrode is arranged on the furnace cover, and the positive electrode is arranged at the furnace bottom. According to the thermoelectric furnace, smelted metal is located inside the combustion chamber between the negative electrode and the positive electrode, the metal is smelted by direct-current arcs produced between the negative electrode and the positive electrode, and strong electromagnetic stirring is formed in the molten liquid metal, so that the temperature and the composition of a metal solution are uniform. According to the thermoelectric furnace, a programmable controller is used, so that automatic control of the temperature of the thermoelectric furnace can be realized, the temperature control is accurate, and the operation cost of the whole system is low.

Owner:ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

Center porosity control method for 35CrMo round blooms with cross section diameter being 280 mm

ActiveCN105803151AImprove purityGood exit conditionsManufacturing convertersPorosityCrystal structure

The invention discloses a center porosity control method for 35CrMo round steel casting blooms with cross section diameter being 280 mm. The method comprises the following steps: converter smelting, LF molten steel refining, RH refining and continuous casting of molten steel, and is characterized in that crystallizer electromagnetic stirring and solidification end electromagnetic stirring are combined in the continuous casting step. The method has the benefits that first, in the molten steel smelting step, control is carried out according to reasonable parameters, so as to improve the impurity of molten steel and ensure that the discharging conditions of the molten steel are optimal; and then, in the molten steel casting step, crystallizer electromagnetic stirring and solidification end electromagnetic stirring are combined to ensure that molten steel ingredients and temperature are homogenized, a blank shell grows uniformly, and columnar crystal structures are consistently scoured and fused in the stirring process, so that the areas of center porosity in the casting blooms are reduced, and the density is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for controlling blank casting quality of phi-280mm 30Mn circular tube blank

ActiveCN105695657AImprove purityHomogenization of ingredientsManufacturing convertersMolten steelSteel casting

The invention discloses a method for controlling the internal quality of a 30Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

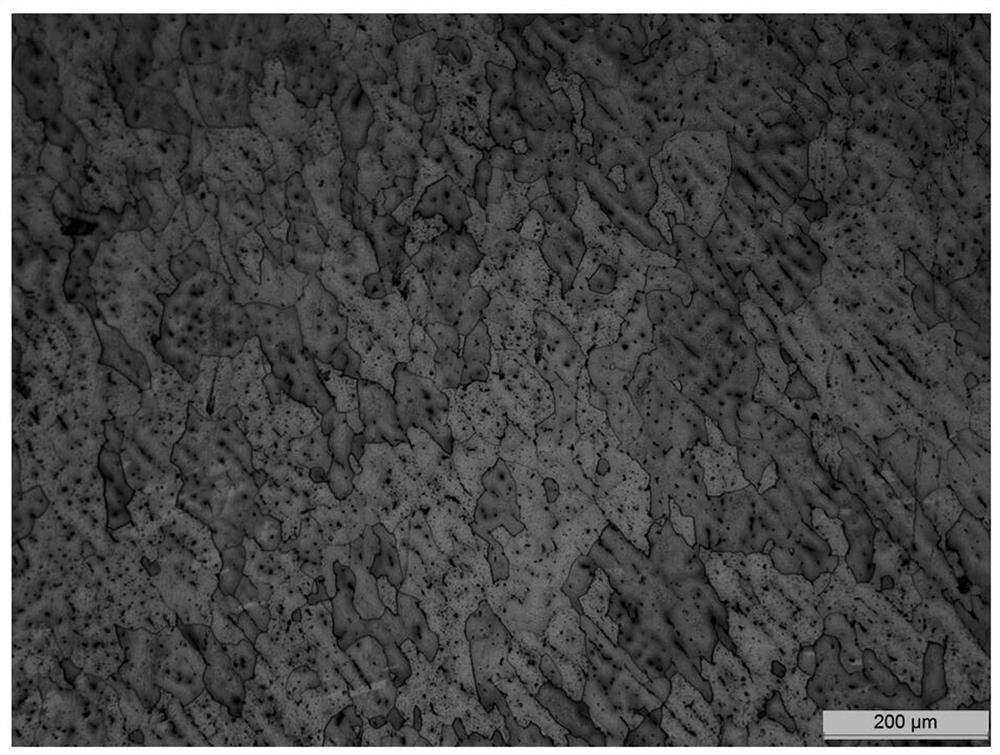

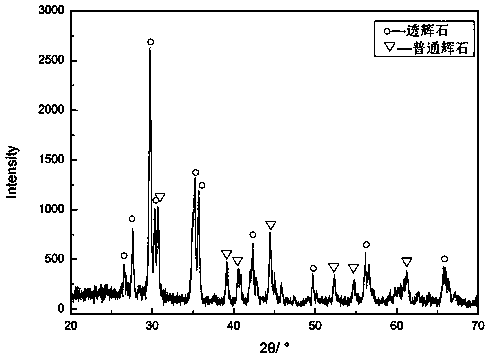

Homogenizing deformation heat treatment method for rapidly refining and homogenizing as-cast aluminum-lithium alloy

ActiveCN113897567AHomogenization of ingredientsGrain refinementProcess efficiency improvementIngotAluminium-lithium alloy

The invention discloses a homogenizing deformation heat treatment method for rapidly refining and homogenizing an as-cast aluminum-lithium alloy. The homogenizing deformation heat treatment method for rapidly refining and homogenizing the as-cast aluminum-lithium alloy comprises the following steps of 1, preparing an aluminum-lithium alloy cast ingot: preparing the aluminum-lithium alloy cast ingot through common gravity casting smelting, and cutting the aluminum-lithium alloy cast ingot into a plate; 2, carrying out primary homogenization treatment: carrying out heat preservation at the primary homogenization treatment temperature; 3, carrying out rolling deformation: after primary homogenization is finished, carrying out rolling deformation on the plate rapidly; and 4, carrying out secondary homogenization treatment: raising the temperature of the deformed sample from the primary temperature to a secondary temperature, and carrying out heat preservation. According to the homogenizing deformation heat treatment method for rapidly refining and homogenizing the as-cast aluminum-lithium alloy provided by the invention, the aluminum-lithium alloy is short in homogenization treatment time, low in temperature, uniform in component and fine in grain; the technical problems that a conventional homogenization treatment process needs high-temperature and long-time heat preservation, grain growth and coarsening are serious after homogenization treatment, and component particles are difficult to regulate and control are solved; and the method has an engineering practical value for preparation and industrial production of the high-performance aluminum-lithium alloy.

Owner:TAIYUAN UNIV OF TECH

Method and device for performing electric magnetization arc welding-braze welding compounding on dissimilar materials

InactiveCN101844259BSpeed up the flowReduce temperature gradientSoldering apparatusMetal working apparatusMetallic materialsMagnetization

The invention discloses a method and a device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials. In the process of performing arc welding-braze welding on the dissimilar metal material, a brazed liquid solder molten pool is subjected to the reinforced booster action of electromagnetic stirring and electric magnetization by using the characteristic that a magnet exciting coil generates an external applied alternating magnetic field in a welding area to control a welding arc so as to promote ordered flow of the liquid solder, and rupture of membranes, wetting, spreading and diffusion of the liquid solder on the surface of the metal material with a higher melting point, promote the liquid solder and a base metal which is molten by the metal material with a lower melting point to be mixed fully, improve uniformity of compositions of a soldered seam, reduce the weld defects, optimize the compositions and the performance of the soldered seam, and improve the soldered joint; and the device has the advantages of simple structure, flexible application, lower cost, good effect, and easy implementation.

Owner:CHONGQING UNIV

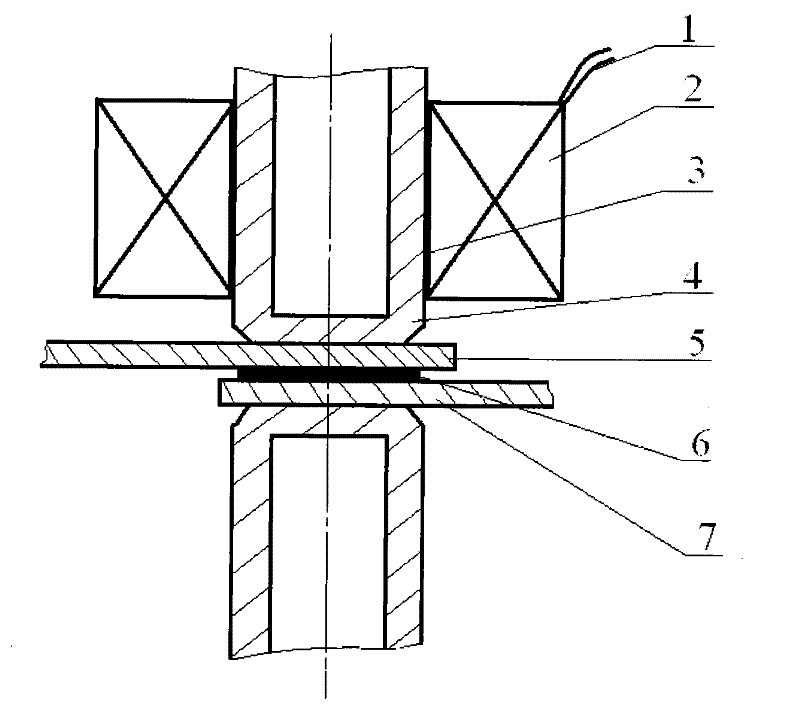

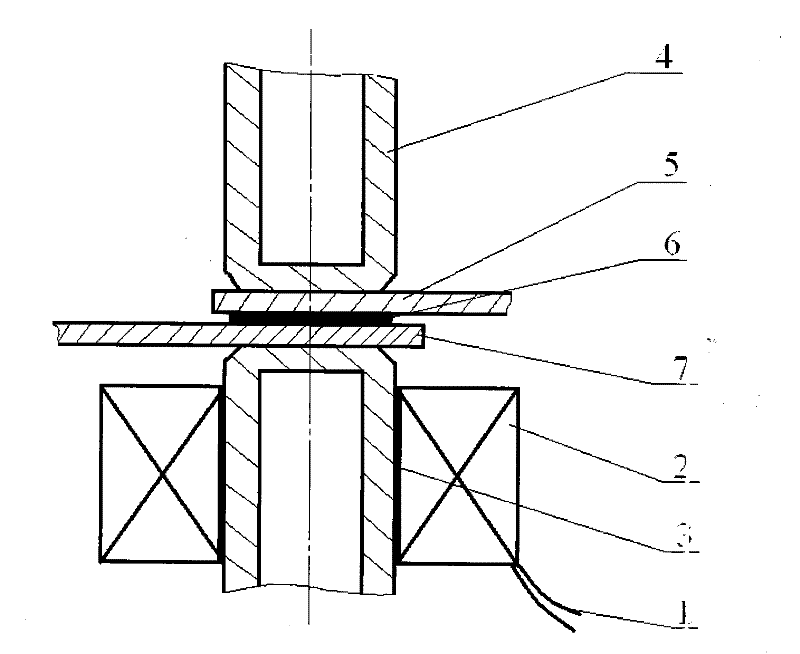

Method and device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials

InactiveCN101844260BSpeed up the flowReduce temperature gradientSoldering apparatusMetal working apparatusMagnetizationMetallic materials

The invention discloses a method and a device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials by assistance of an applied magnetic field. In the process of performing resistance welding-braze welding on the dissimilar metal material, a liquid solder is subjected to auxiliary electromagnetic stirring and ordered control, and the molten liquid solder is subjected to the reinforced booster action of electromagnetic stirring and electric magnetization by using an external applied alternating magnetic field which is generated by a magnet exciting coil in a welding area so as to promote directional flow of the liquid solder, and rupture of membranes, wetting, spreading and diffusion of the liquid solder on the surface of the metal material with a higher melting point, promote the liquid solder and a base metal which is molten by the metal material with a lower melting point to be mixed fully, promote interdiffusion of elements and compositions between the solder and the base metal and alloying between the two, improve uniformity of compositions of a soldered seam, reduce the weld defects, optimize the texture and the performanceof the soldered seam, and improve the resistance soldered joint; and the device has the advantages of simple structure, flexible application, lower cost, good effect, and easy implementation.

Owner:CHONGQING UNIV

Control method of center loosening of φ280mm 30crmo round tube billet

The invention discloses a center porosity control method for producing a 30CrMo circular tube blank with the diameter of the section being phi 280 mm and belongs to the field of metallurgy. The method comprises the steps of converter steel making, LF furnace molten steel refining, RH refining, molten steel continuous casting and the like, and the method is characterized in that a technology combining crystallizer electromagnetic stirring and solidification final stage electromagnetic stirring is adopted in the continuous casting stage. The center porosity control method has the beneficial effects that firstly, the purity degree of molten steel is increased and the optimal tapping condition of the molten steel is reached according to reasonable parameter control in the molten steel smelting stage; and afterwards, in the molten steel pouring process, the mode combining crystallizer electromagnetic stirring and solidification final stage electromagnetic stirring is adopted, so that ingredients and temperature of the molten steel are uniformized, a blank shell grows uniformly, and columnar crystal structures are continuously eroded and fused in the stirring process. Accordingly, the area of a center porosity zone of the casting blank is reduced, and the compactness is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A laser cladding alloy powder for hot work mold repair and remanufacturing

ActiveCN105132913BOvercoming the disadvantages of uneven compositionHomogenization of ingredientsMetallic material coating processesRare-earth elementSlag

The invention provides laser cladding alloy powder for repairing and remanufacturing a hot-working die. In order to solve the problem that nickel-based or cobalt-based thermal spraying powder is expensive, iron-based alloy powder is adopted in the invention. While the iron-based alloy is formed through replacing pure iron with waste steel, the reutilization of the waste is realized. However, as the impurity content in the waste steel is high, the removal of phosphorous, carbon and sulphur is required in the refining process so as to obtain molten steel of which the components and temperature are qualified. The traditional method usually removes the impurities through slagging in the form of furnace slag, but has the problems of high heat energy requirement, large metal losses and serious splashing. In order to solve the problems, a traditional slag former is replaced by yttrium oxide, and waste steel impurities and glomeration inclusions are removed through the purifying functions of rare-earth elements. Meanwhile, deposited metal is endowed with excellent anti-fatigue performance.

Owner:SHANDONG UNIV

Electrolysis device and electrolysis method

ActiveCN106337193BImprove liquidityImprove heat transfer performanceElectrolysis componentsElectrolysisEddy current

The invention provides an electrolysis device and method. The electrolysis device comprises an electrolysis tank, at least one cathode in the electrolysis tank, multiple anodes arranged around the cathode in intervals and multiple air blowing pipes symmetrically arranged on the inner wall of the electrolysis tank, wherein bottom outlets of the air blowing pipes stretch out of the bottom surface of the electrolysis tank and are arranged along a horizontal direction. An electrolyte at the bottom of the electrolysis tank is stirred through gas and a gas outlet direction and a cathode center direction form an a certain angle in air blowing so that the electrolyte on the bottom produces eddy currents along a horizontal direction and the electrolyte in all zones in the electrolysis tank can circularly flow and thus heat transfer and mass transfer in the electrolysis tank are improved, inner temperatures and components are uniformed, product quality is improved and furnace conditions are improved.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Electrolysis device and electrolysis method

ActiveCN106702434BSolve the problem of the existence of flow dead zoneImprove heat transfer performanceCellsCell cavityEngineering

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

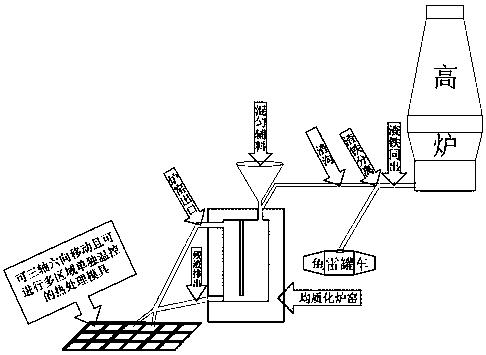

One-step forming method of glass-ceramic plate by using molten blast furnace slag

ActiveCN105601117BAvoid wastingSimple preparation stepsGlass shaping apparatusMolten stateChemical composition

The invention relates to a method for one-step forming of a microcrystal glass plate through molten-state blast furnace slag. According to the method, the molten-state blast furnace slag and a commercial chemical reagent serve as raw materials, wherein the dosage of the blast furnace slag is 35-70%, and blast furnace slag microcrystal glass is prepared from, by weight, 10-30% of CaO, 35-60% of SiO2, 10-15% of Al2O3, 8-12% of MgO, 2-5% of K2O, 3-4% of ZnO and 3-6% of TiO2; component homogenization of all the materials is completed in a constant-temperature kiln, then the materials are poured into a die, solidification, nucleation, growing and cooling are completed in the die at one step, and finally the microcrystal glass plate is obtained through die release. According to the method, primary sensible heat of the molten-state blast furnace slag is sufficiently and efficiently used, energy waste is avoided, a proper preparing technological process and proper microcrystal glass chemical components are proposed, the preparing steps are simple, cost is low, and a cycle is short.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

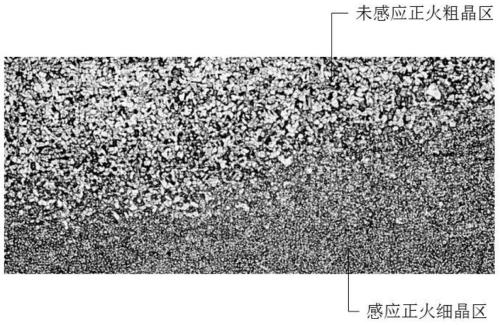

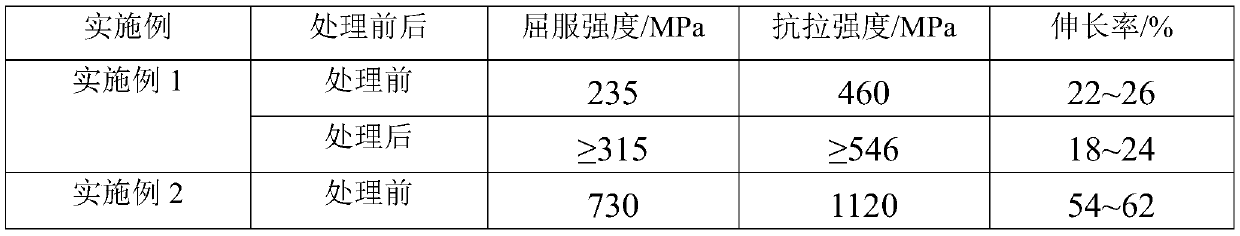

A method of applying induction normalizing to prepare laminated materials with grain gradient

ActiveCN110512064BAchieve the purpose of regulationConvenient local normalizing heat treatmentIncreasing energy efficiencyRoom temperatureHeat conservation

The invention provides a method for preparing a laminated material with a grain gradient by using induction normalizing, comprising the following steps: using induction heating to partially normalize the surface of the steel plate, keeping it warm, and air cooling to room temperature to obtain a steel plate; Heating to the recrystallization zone, and then rolling the steel plate, each time the rolling pressure is 0.7-1.2mm, and the total pressure is 60-90%, to obtain the final rolled steel plate; the final rolled steel plate is recrystallized as a whole Annealing heat treatment, the temperature is 30-50°C above Ac3 or Acm, heat preservation, cooling with the furnace, to obtain laminated materials. The invention utilizes the method of induction heating, adopts appropriate heating process parameters, and sequentially induces normalizing treatment on the front and back sides of the steel plate, and then undergoes rolling treatment and recrystallization annealing, and realizes the high-strength plastic product without relying on alloying. The laminated material with grain gradient solves the problems of high cost, complicated equipment and difficult organization regulation in the prior art.

Owner:SOUTHWEST JIAOTONG UNIV

A homogenization deformation heat treatment method for rapid refinement and homogenization of as-cast aluminum-lithium alloy

ActiveCN113897567BHomogenization of ingredientsGrain refinementProcess efficiency improvementIngotAluminium-lithium alloy

Owner:TAIYUAN UNIV OF TECH

A kind of dispersion strengthened material for platinum-based vessel and its preparation method and application

The invention provides a dispersion strengthened material used for a platinum-based vessel. The dispersion strengthened material comprises a substrate and a strengthening phase dispersed in the substrate, wherein the substrate is platinum and the strengthening phase element is any one or more of zirconium, scandium and cerium. The zirconium content is more than 0 and no more than 0.4 wt%, the scandium content is in a range of 0-0.4 wt%, and the cerium content is in a range of 0-0.4 wt%, with the balance being platinum, wherein the total content of zirconium and scandium and cerium is less than0.6 wt%. The strengthening phase element is dispersed in the substrate in an oxide form to form a dispersion strengthened material. The dispersion strengthened material is good in scouring resistance, corrosion resistance and high-temperature creep resistance. A vessel prepared from the material is long in service life. The production cost in the technical fields, such as optical glass and glassfiber, can be efficiently reduced.

Owner:CHONGQING MATERIALS RES INST

The quality control method of chrome-molybdenum series round tube billets with a diameter of φ280mm

ActiveCN105803150BImprove purityHomogenization of ingredientsManufacturing convertersSteel castingMaterials science

The invention discloses a method for controlling the internal quality of a Cr-Mo series circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, RH refining, and continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium micro-alloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com