A method of applying induction normalizing to prepare laminated materials with grain gradient

A technology of laminated material and normalizing temperature, applied in the field of laminated material preparation, can solve the problems of complex organization control and high cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

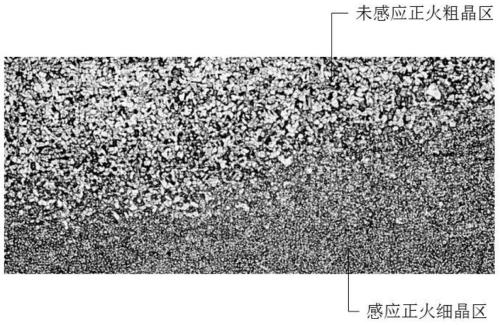

Image

Examples

Embodiment 1

[0024] A method for applying induction normalizing to prepare laminated materials with grain gradients, comprising the following steps:

[0025] (1) Partially normalize the surface of Q235 steel plate at a depth of 1mm by induction heating, the heating frequency is 200KHz, the heating power is 40KW, the normalizing temperature is 30°C above Ac3 or Acm, the heat preservation is 2min / mm, and the steel plate is obtained by air cooling to room temperature. ;

[0026] (2) Heating the steel plate piece obtained in step (1) to the recrystallization zone, then rolling the steel plate piece 4 times, each rolling downfall is 0.7mm, and the total downstroke is 60%, to obtain the final rolled steel piece ;

[0027] (3) The final-rolled steel plate obtained in step (2) is subjected to an overall recrystallization annealing heat treatment at a temperature of 30° C. above Ac3 or Acm, and a holding time of 20 min / mm, and is cooled in a furnace to obtain a laminated material.

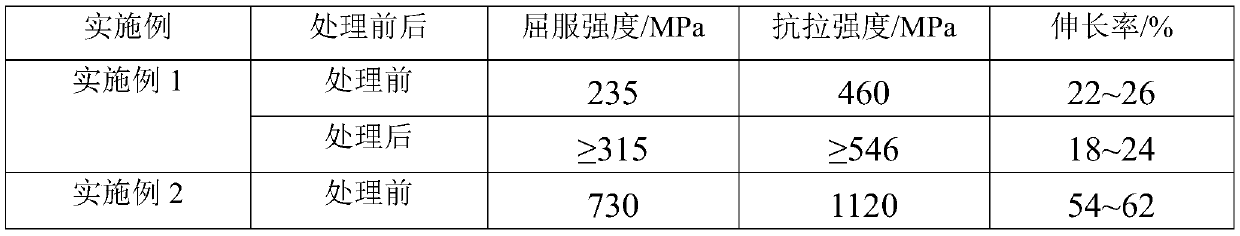

[0028] The Q2...

Embodiment 2

[0030] A method for applying induction normalizing to prepare laminated materials with grain gradients, comprising the following steps:

[0031] (1) Induction heating is used to locally normalize the surface of the medium manganese steel plate at a depth of 2mm, the alloy composition is 0.25C-9Mn-0.02Cr-0.03Cu-0.03W-0.02Co, the heating frequency is 100KHz, and the heating power is 70KW. The normalizing temperature is 40°C above Ac3 or Acm, heat preservation for 1.5min / mm, and air-cooled to room temperature to obtain a steel plate;

[0032] (2) Heating the steel plate obtained in step (1) to the recrystallization zone, then rolling the steel plate 6 times, each time the rolling reduction is 0.9 mm, and the total reduction is 80%, to obtain the final rolled steel plate ;

[0033] (3) The final-rolled steel plate obtained in step (2) is subjected to an overall recrystallization annealing heat treatment at a temperature of 40° C. above Ac3 or Acm, and a holding time of 30 min / mm,...

Embodiment 3

[0036] A kind of application induction normalizing prepares the method for laminated material with grain gradient, comprises the following steps:

[0037] (1) Locally normalize the surface of 304 stainless steel plate at a depth of 3mm by induction heating, the heating frequency is 40KHz, the heating power is 100KW, the normalizing temperature is 50°C above Ac3 or Acm, heat preservation 1min / mm, and air-cooled to room temperature to obtain a steel plate pieces;

[0038] (2) Heating the steel plate obtained in step (1) to the recrystallization zone, then rolling the steel plate 6 times, each time the rolling reduction is 1.2 mm, and the total reduction is 90%, to obtain the final rolled steel plate ;

[0039] (3) The final-rolled steel plate obtained in step (2) is subjected to an overall recrystallization annealing heat treatment at a temperature of 50° C. above Ac3 or Acm, and a holding time of 40 min / mm, and is cooled in a furnace to obtain a laminated material.

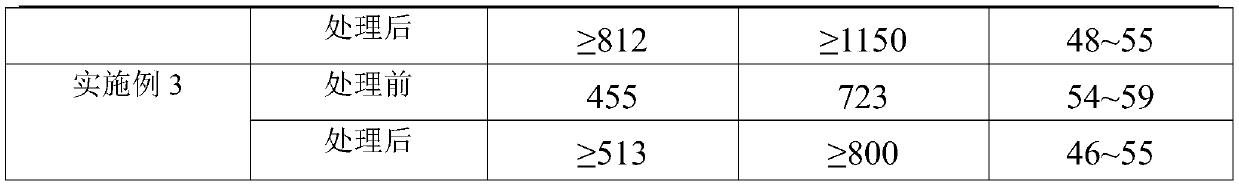

[0040] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com