Thermoelectric furnace provided with temperature control system

A temperature control system and thermoelectric technology, applied in lighting and heating equipment, etc., can solve the problems of short life of AC contactors, low control accuracy, poor measurement accuracy, etc., and achieve low operating costs, accurate temperature control, and uniform temperature and composition. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

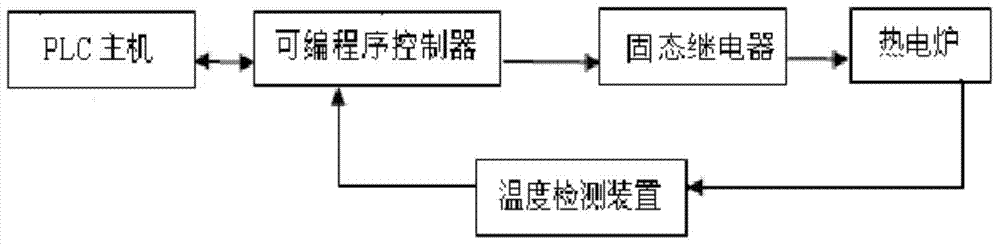

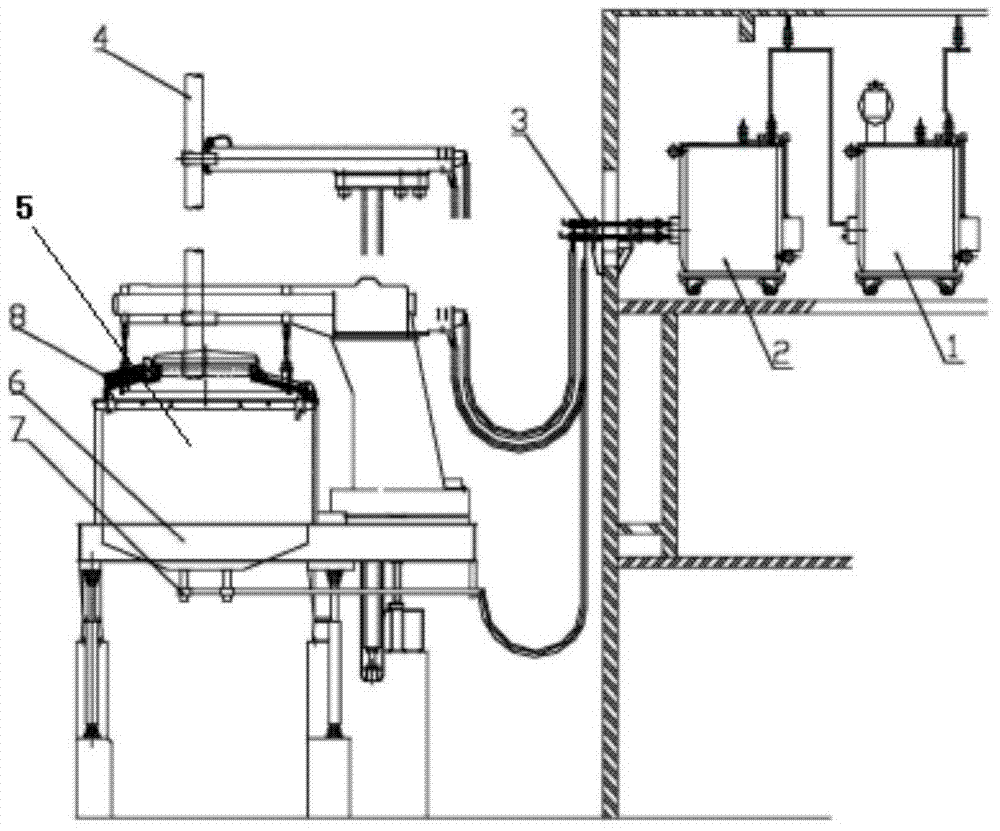

[0016] Such as figure 1 and figure 2 As shown, a thermoelectric furnace with a temperature control system includes a furnace body and a power supply device. The furnace body is composed of a furnace hearth 5, a furnace bottom 6 and a furnace cover 8. The power supply device includes a transformer 1, a rectifier 2, and a short network System 3 and a power supply electrode, the power supply electrode is composed of a cathode 4 and an anode 7, the cathode 4 is arranged on the furnace cover 8, the anode 7 is arranged on the furnace bottom 6, and the thermoelectric furnace is also provided with a temperature control system , the temperature control system includes a PLC host and a programmable controller connected to it, the signal output of the programmable controller is connected to the signal input of the solid state relay, and the signal output of the solid state relay is connected to the thermal The hearth 5 of the electric furnace is connected, the temperature sensing line ...

Embodiment 2

[0020] On the basis of Embodiment 1, in order to realize remote monitoring, a communication module is added, that is, the signal output end of the PLC host is connected to the signal input end of the communication module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com