Patents

Literature

48results about How to "Temperature homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

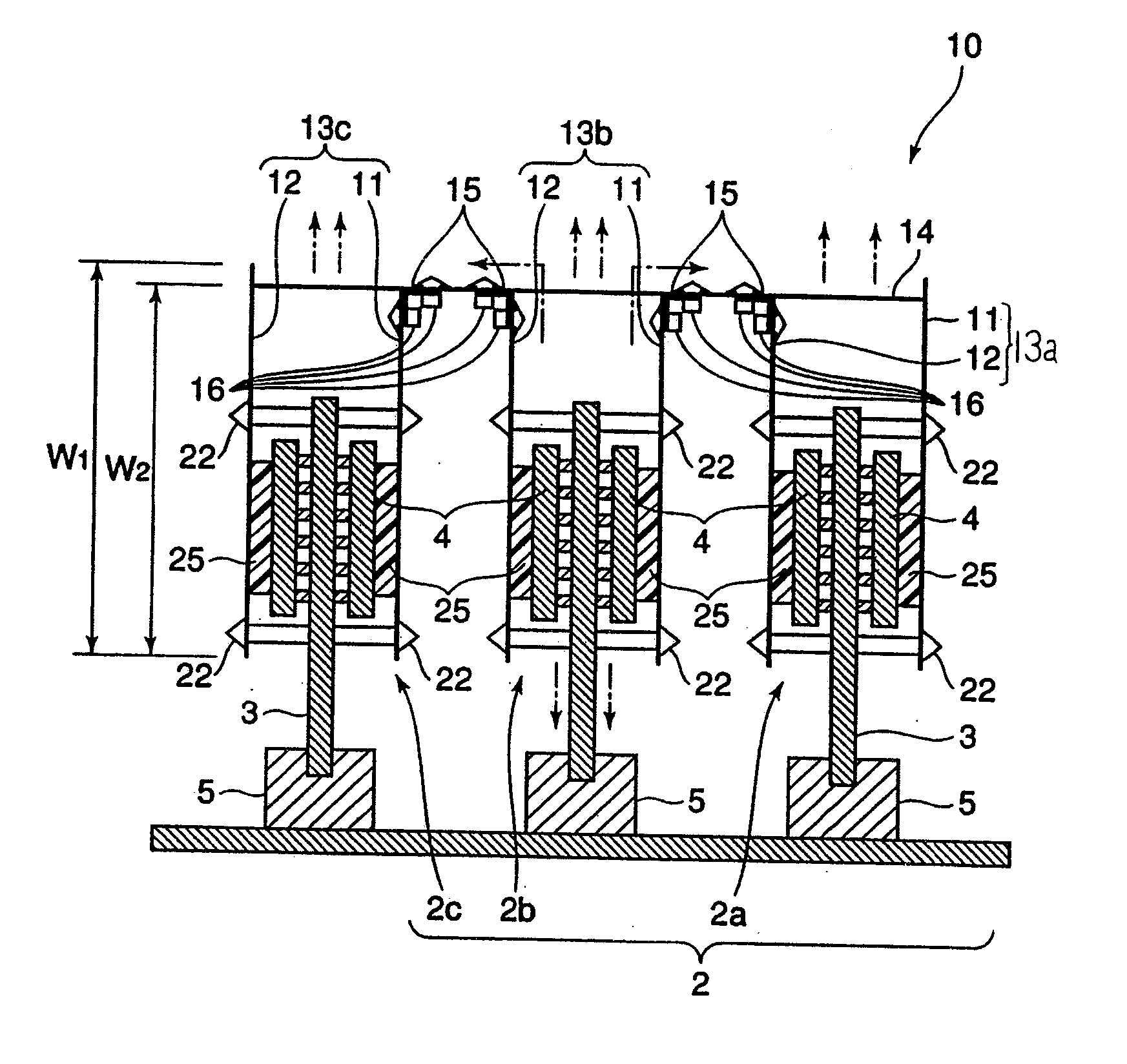

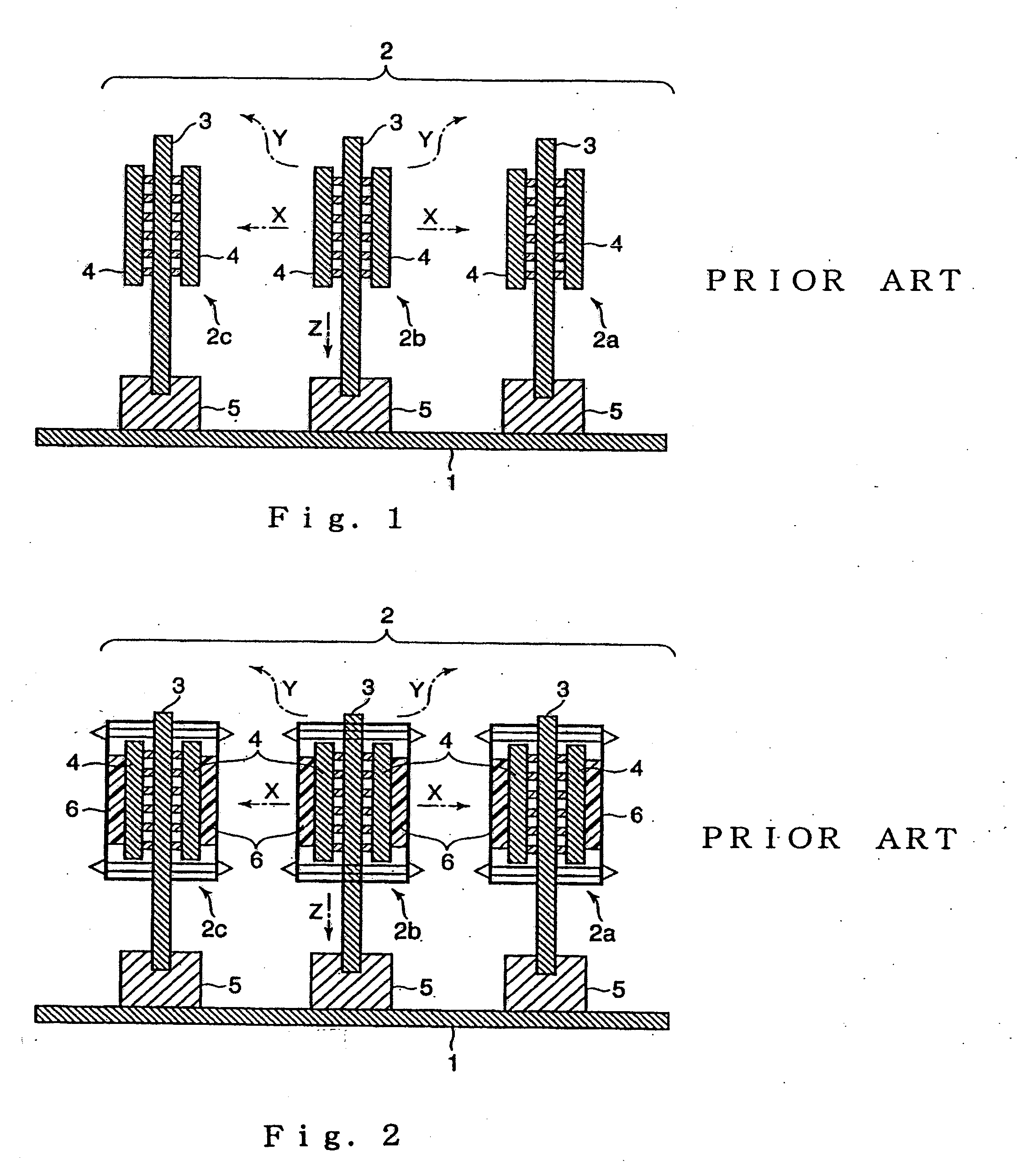

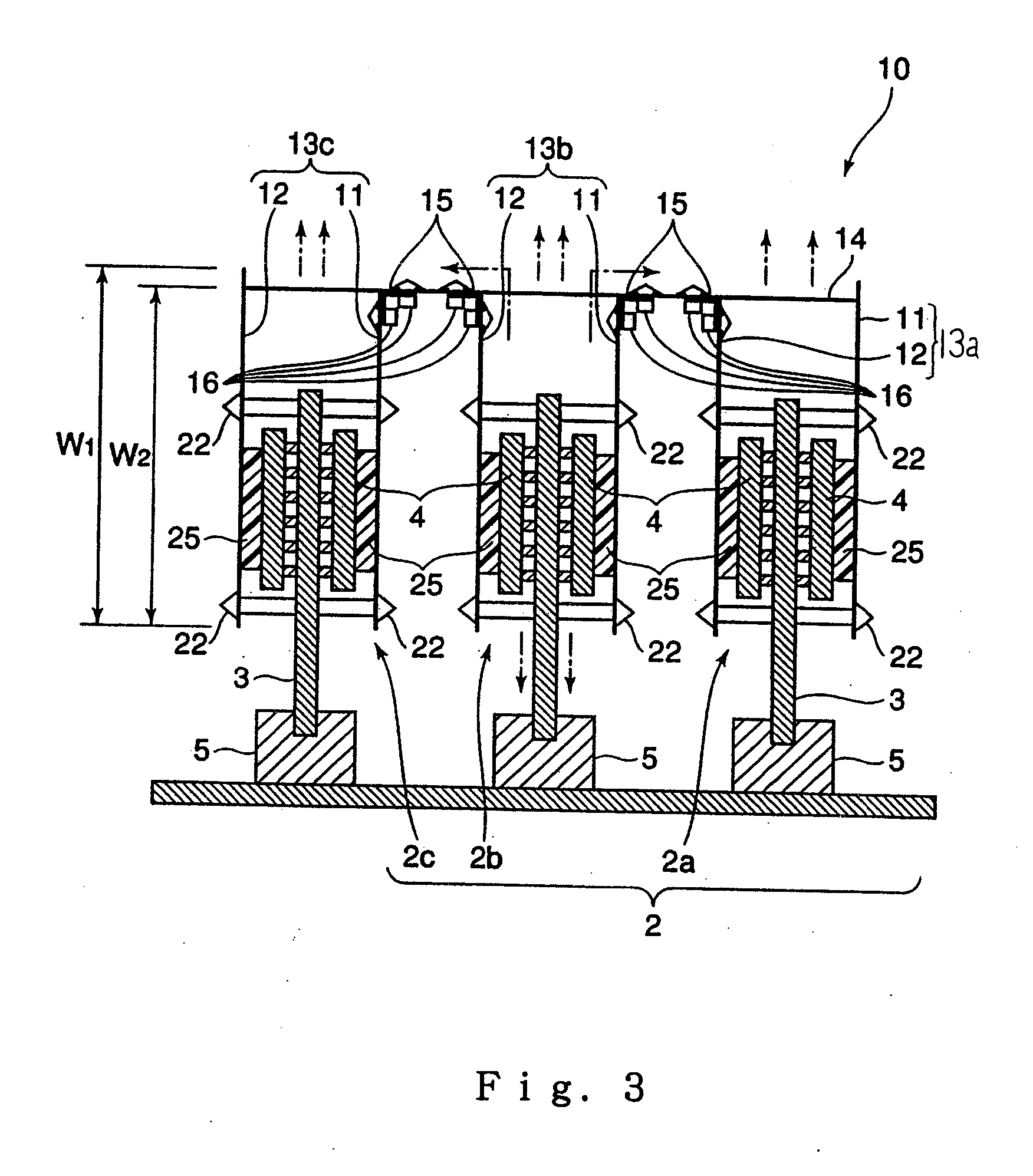

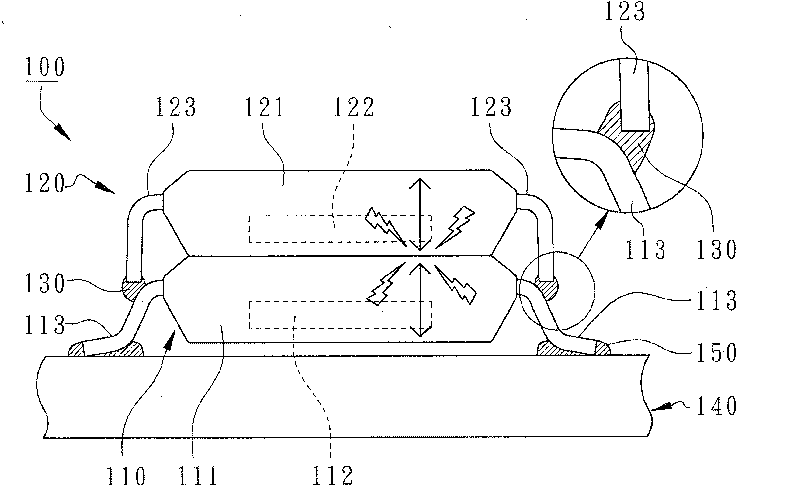

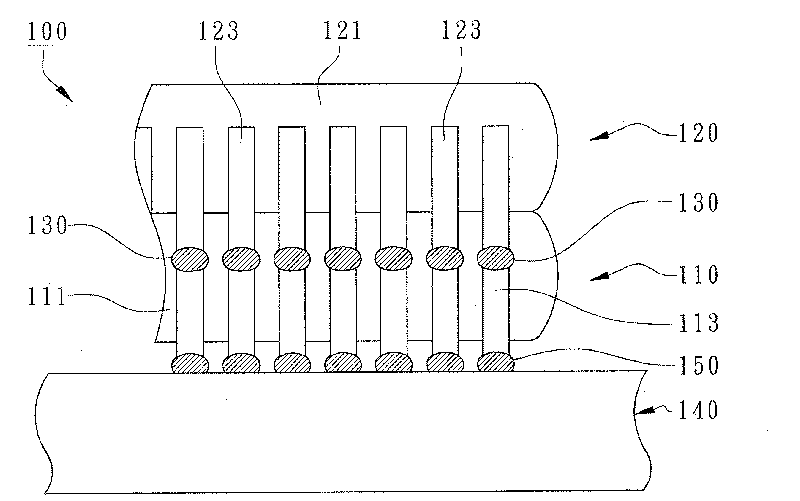

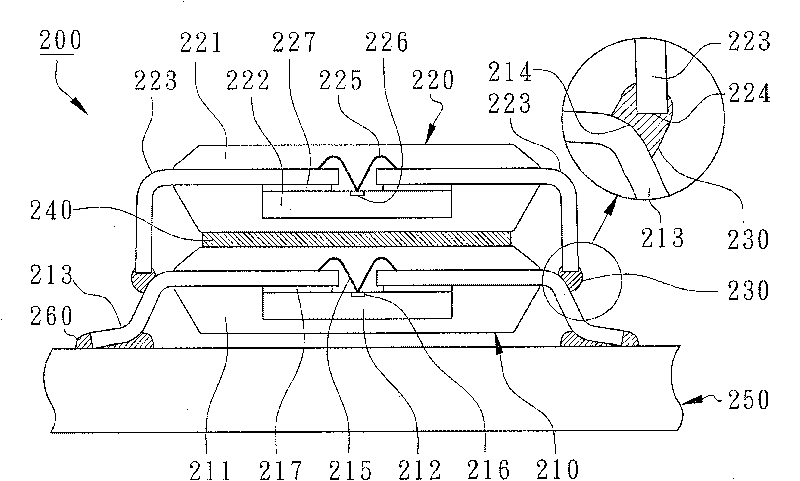

Heat radiation device for memory module

InactiveUS20080013284A1Effective coolingTemperature homogenizationSemiconductor/solid-state device detailsSolid-state devicesThermal radiationEuhedral and anhedral

There is disclosed a heat radiation device for memory modules intended for radiating heat that is generated from a memory module group wherein a plurality of memory modules equipped with memory elements on both the front and rear face sides of a substrate are placed in parallel. The device comprises heat radiation plates in pairs composed of front face side heat radiation plates in contact with memory elements that are installed on the front face side of the substrate for each of the memory modules, and of rear face side heat radiation plates in contact with memory elements that are installed on the rear face side of the substrate; and connecting members for heat radiation plates in pairs which connect the heat radiation plates in pairs so that heat is conducted among a plurality of the heat radiation plates in pairs.

Owner:PS4 LUXCO SARL

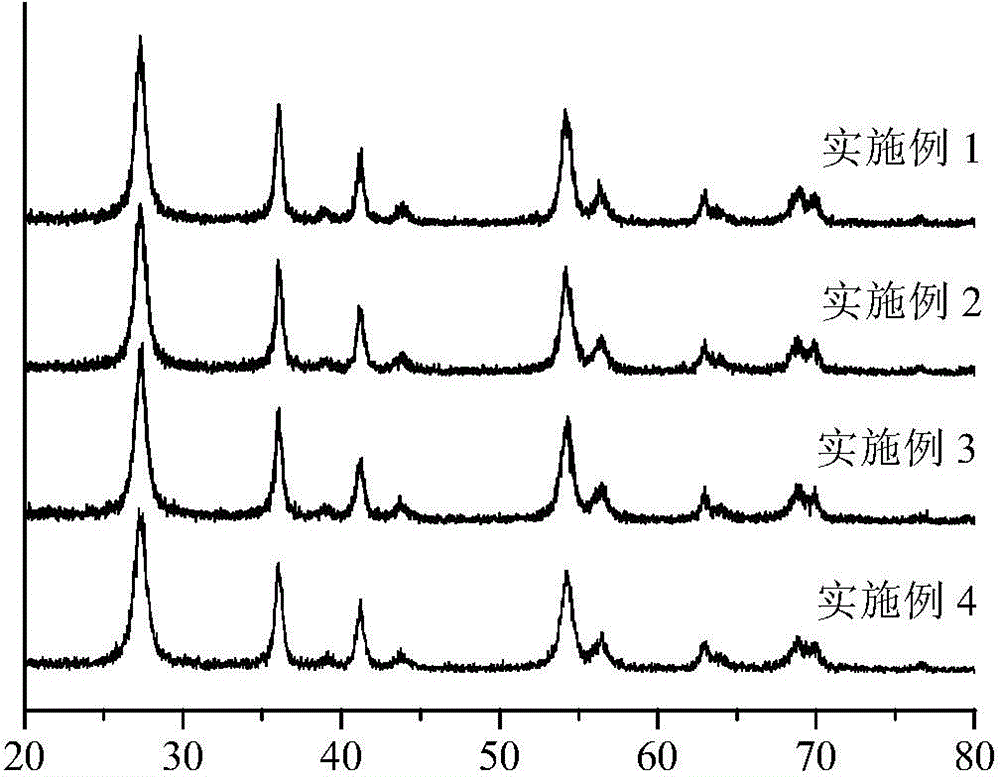

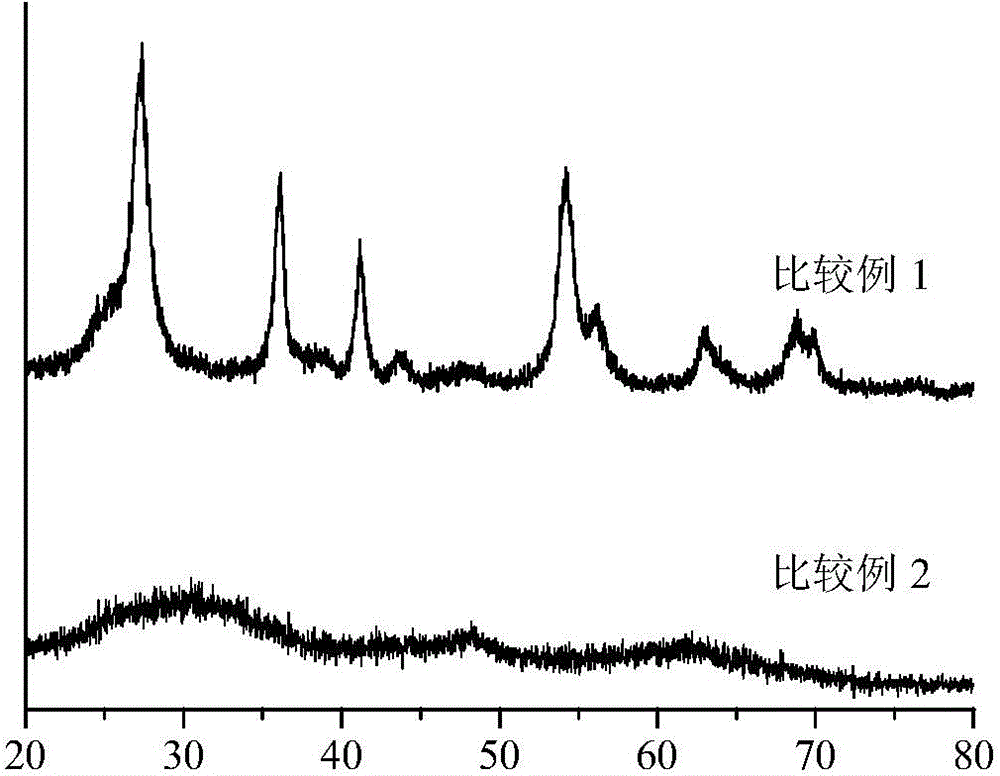

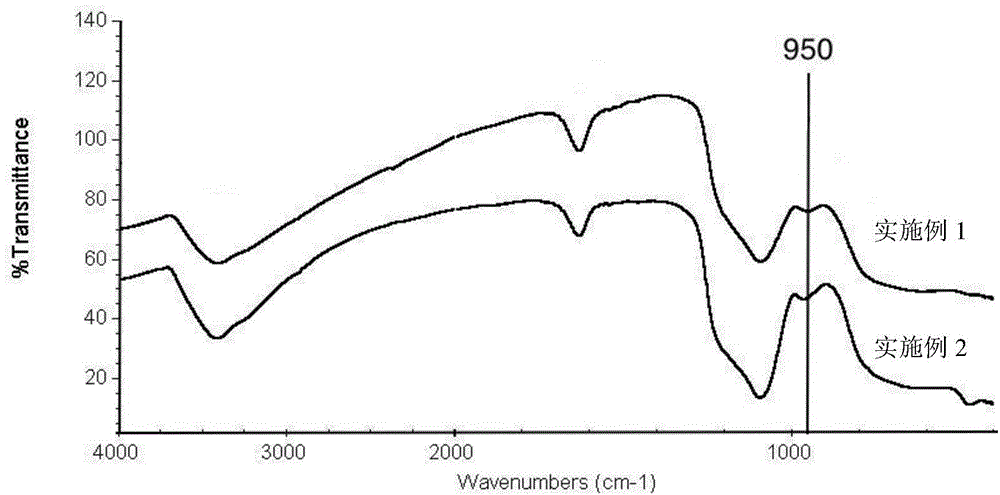

Preparation method of hollow sphere made of titanium dioxide composite

ActiveCN104671282AGood suspensionDoes not cause dissolutionMaterial nanotechnologyTitanium dioxideMetallic materialsAmorphous silicon

The invention belongs to the technical field of inorganic nonmetallic materials, particularly relates to a preparation method of a hollow sphere made of titanium dioxide composite, and specifically relates to a method for preparing a rutile type titanium dioxide hollow sphere with calcium carbonate serving as a template. The specific idea of the method is as follows: firstly, the surface of calcium carbonate is coated with amorphous silica, then, titanium dioxide nanocrystalline is deposited or grown on the surface of silica, meanwhile, calcium carbonate is removed, and the rutile type titanium dioxide hollow sphere is prepared.

Owner:常州纳欧新材料科技有限公司

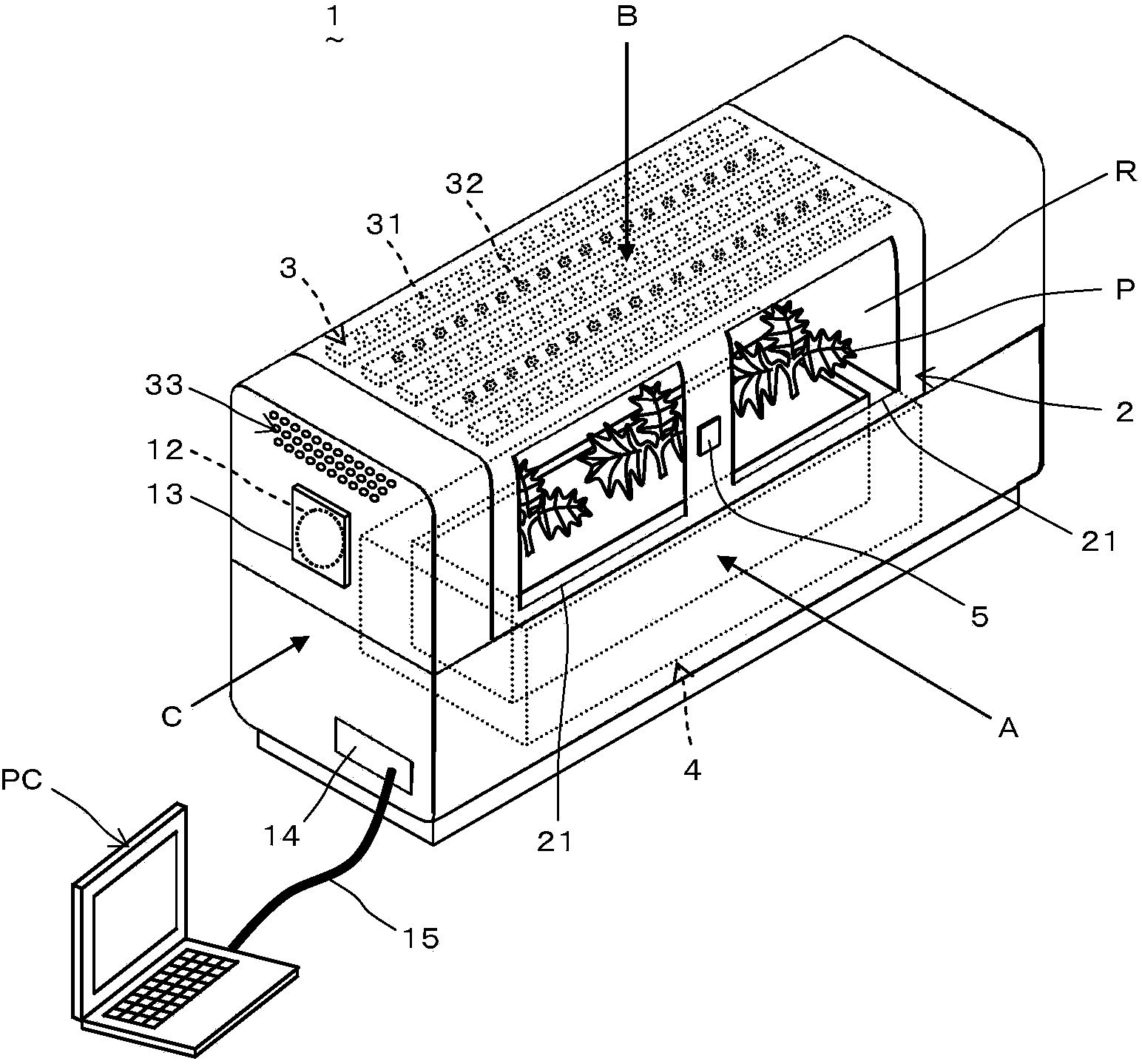

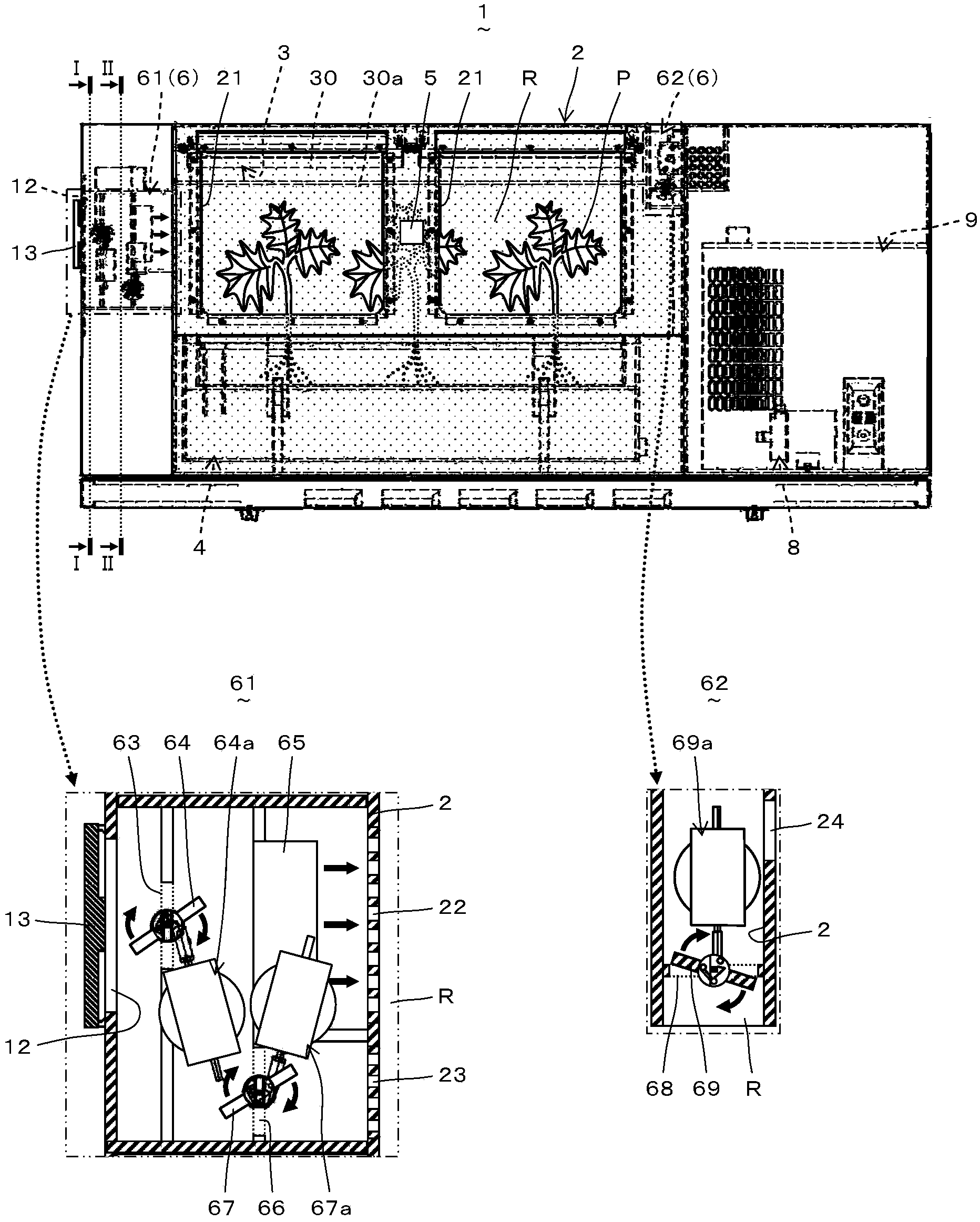

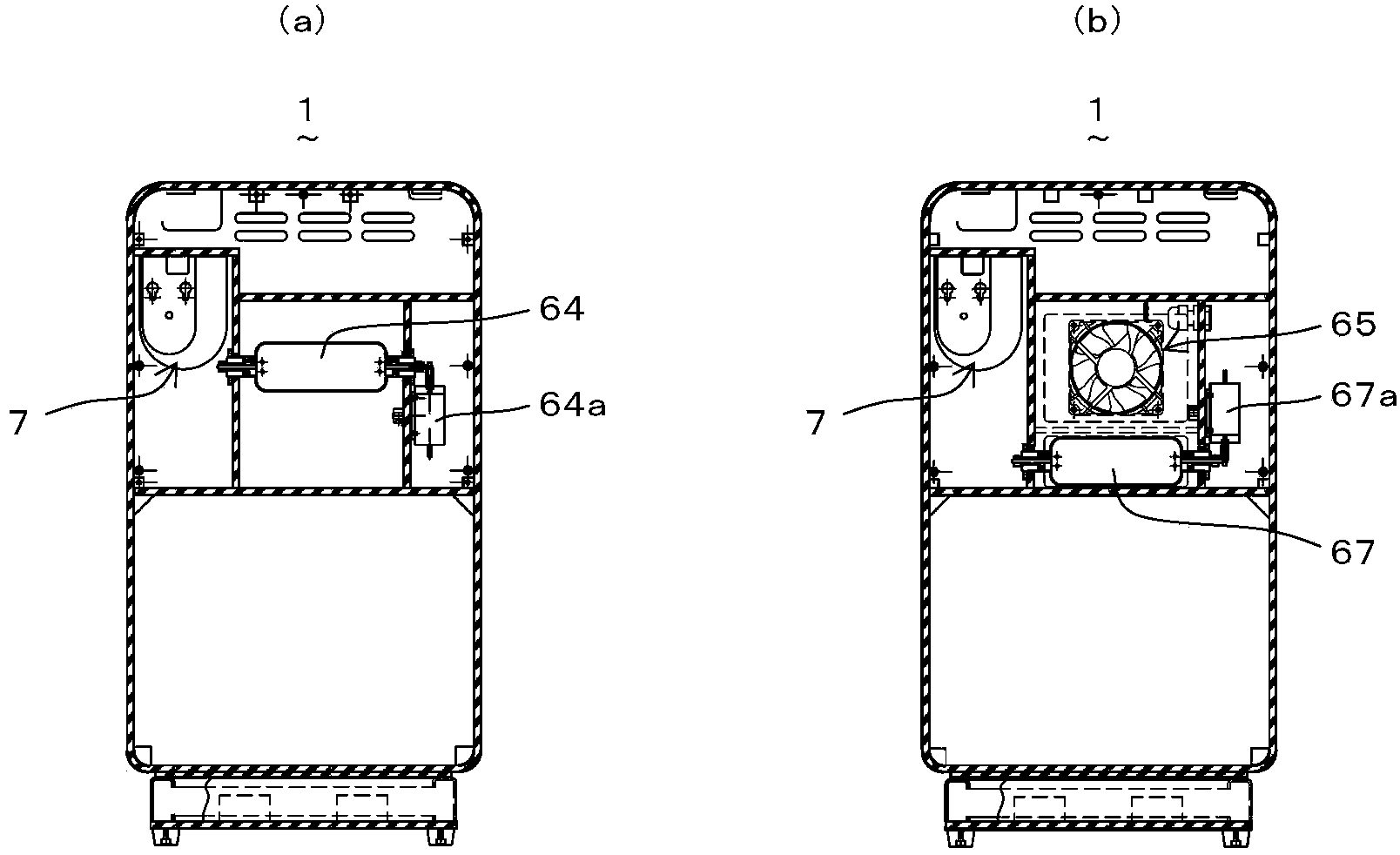

Plant growing device

InactiveCN104053355AConcentration homogenizationTemperature homogenizationMechanical apparatusLighting and heating apparatusVolumetric Mass DensityEngineering

A plant growing device (1) is provided with a ventilation unit (6) comprising an intake unit (61) for taking air into a growing chamber (R) and an exhaust unit (62) for exhausting air from the growing chamber (R). The intake unit (61) has an intake port (63), an intake damper (64) for opening and closing the intake port (63), a blower (65) for sending air in the direction of the growing chamber (R), a passage (66) for guiding air to the upstream side of the blower (65), and a circulation damper (67) for opening and closing the passage (66). The exhaust unit (62) has an exhaust port (68) and an exhaust damper (69) for opening and closing the exhaust port (68). The ventilation unit (6) operates under either an intake and exhaust mode for taking air into and exhausting air from the growing chamber (R) or a circulation mode in which air is caused to circulate in the growing chamber (R). By switching between these modes, CO2 is taken into the growing chamber (R) and gas density, temperature, and humidity within the growing chamber (R) can be made uniform, and as a result, the growing efficiency of a plant (P) can be improved.

Owner:PANASONIC CORP

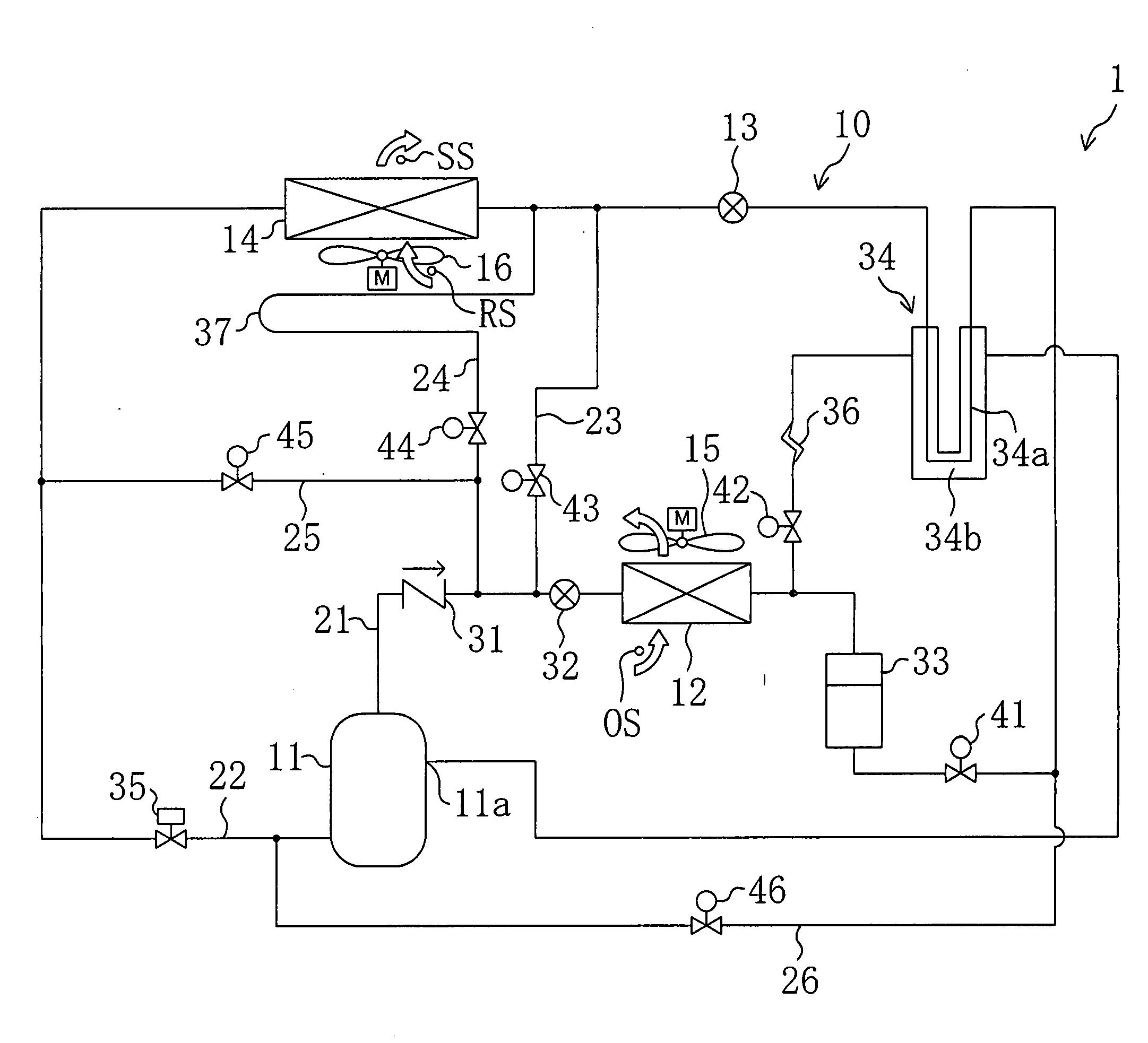

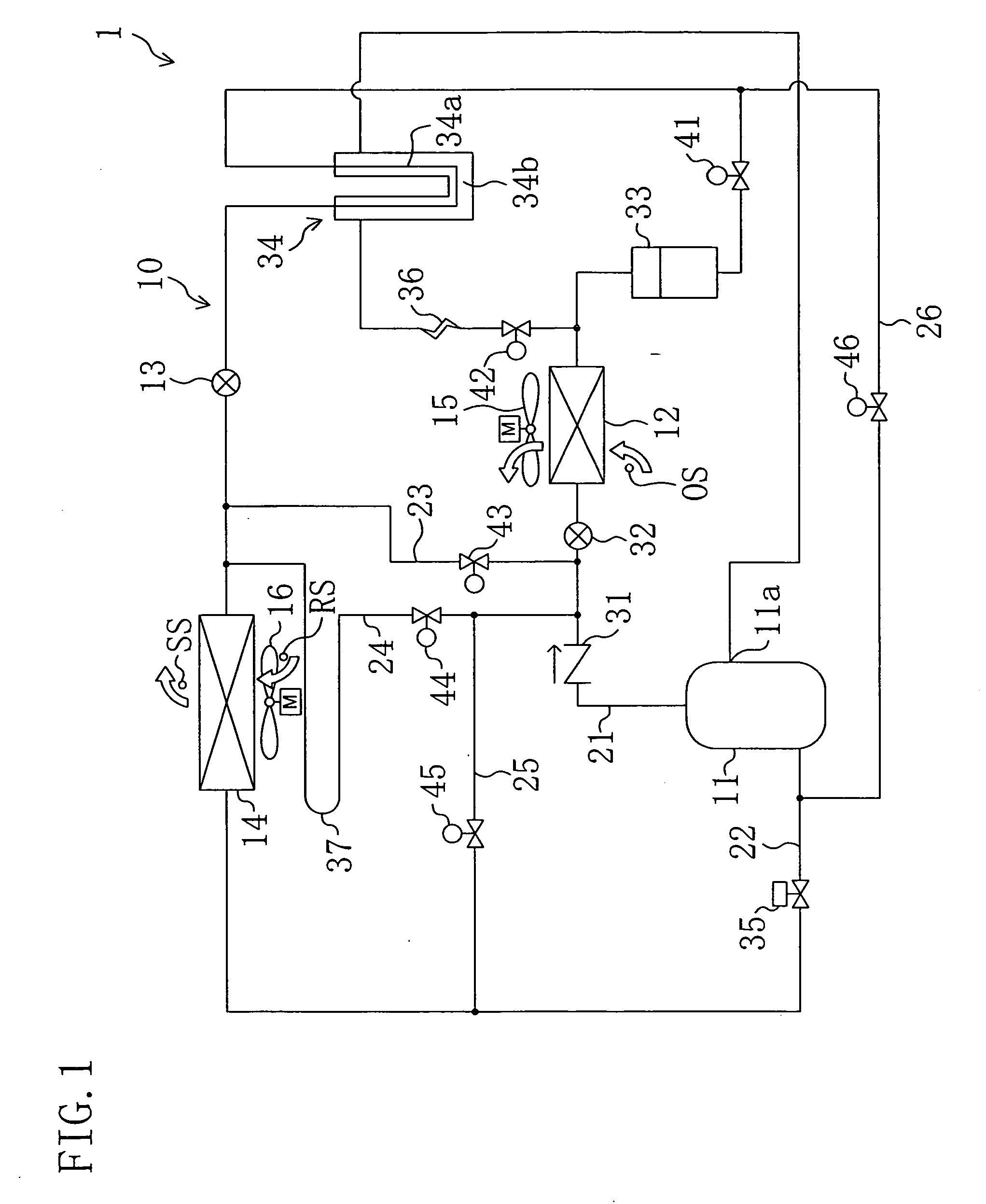

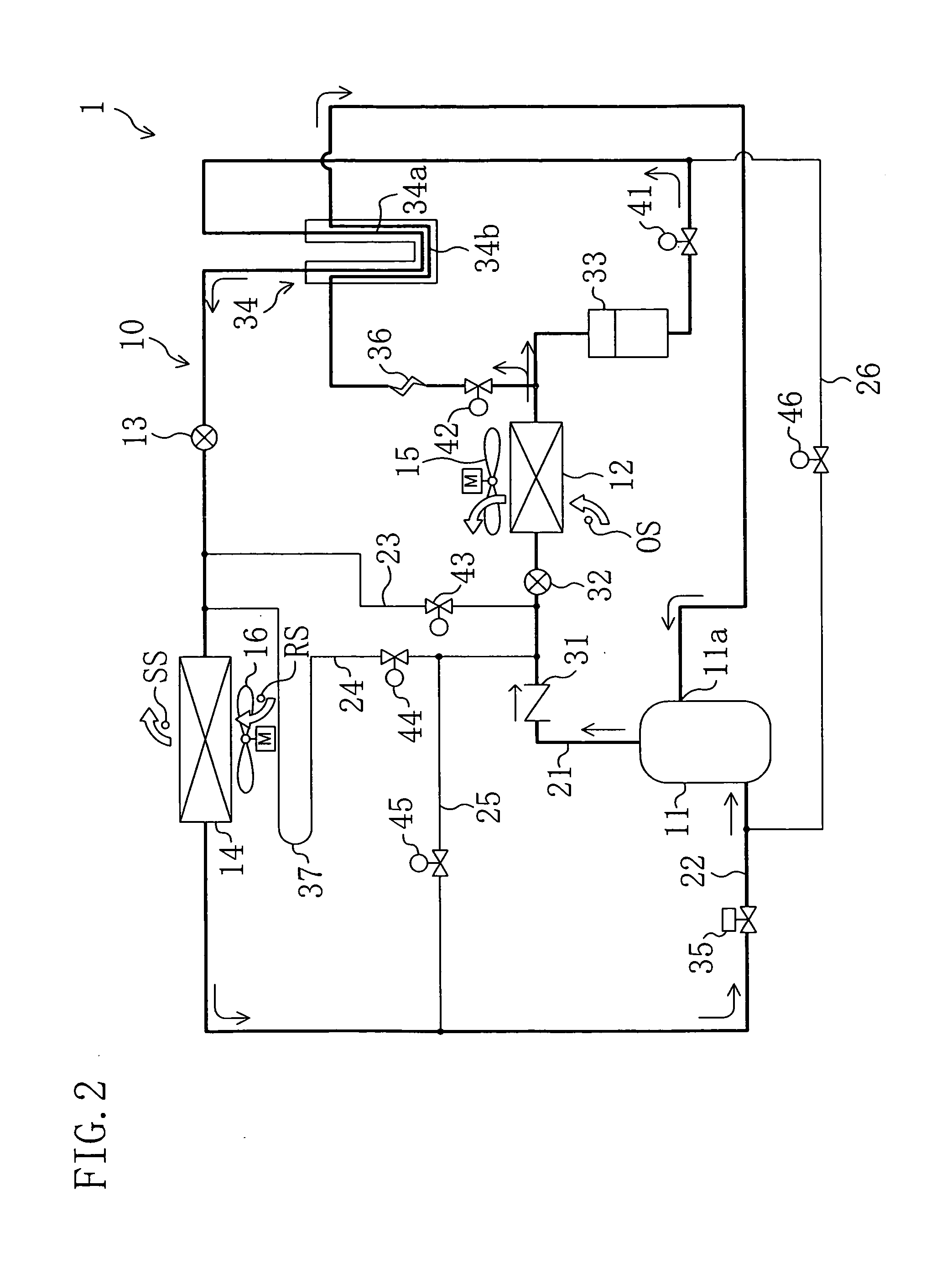

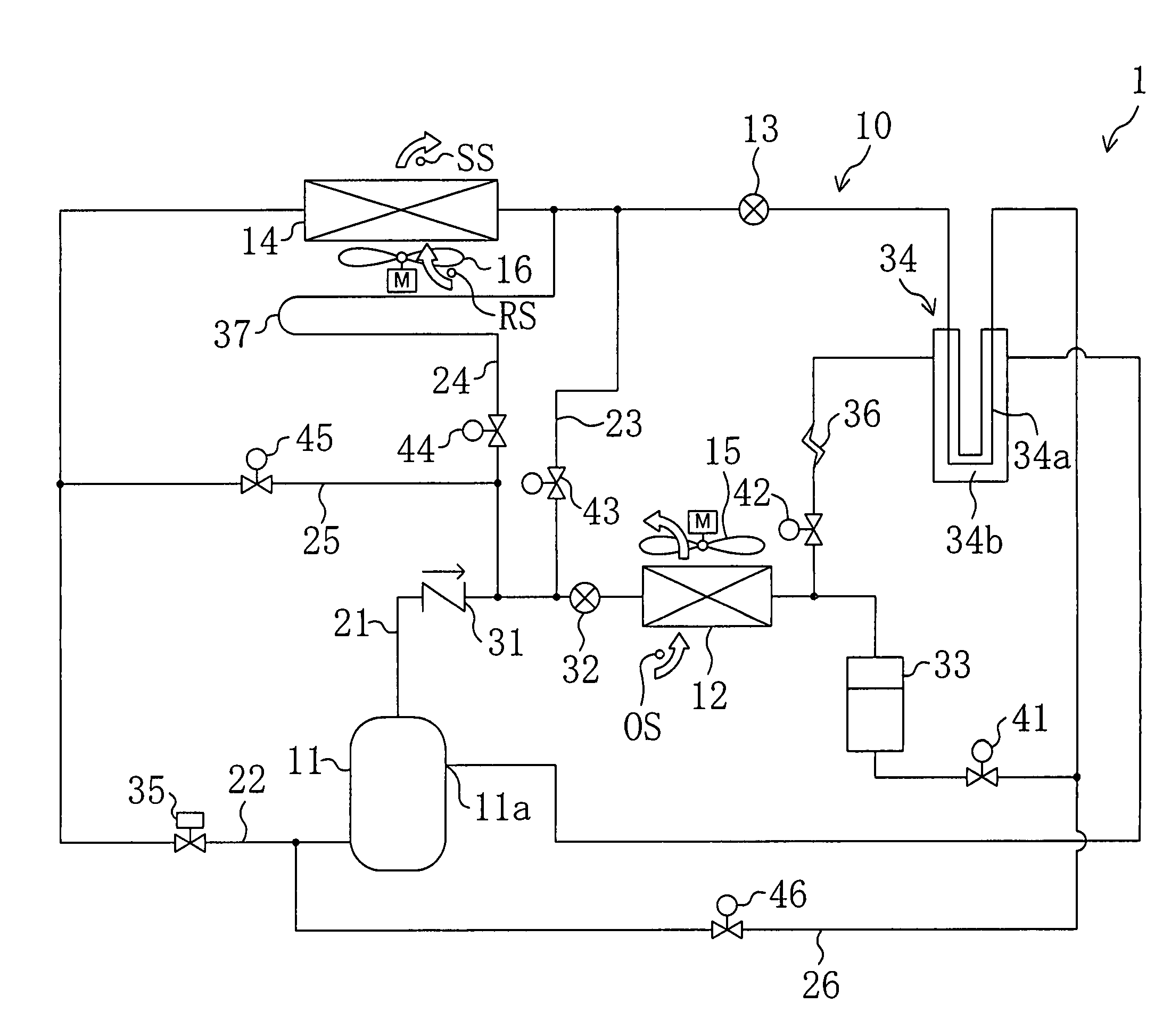

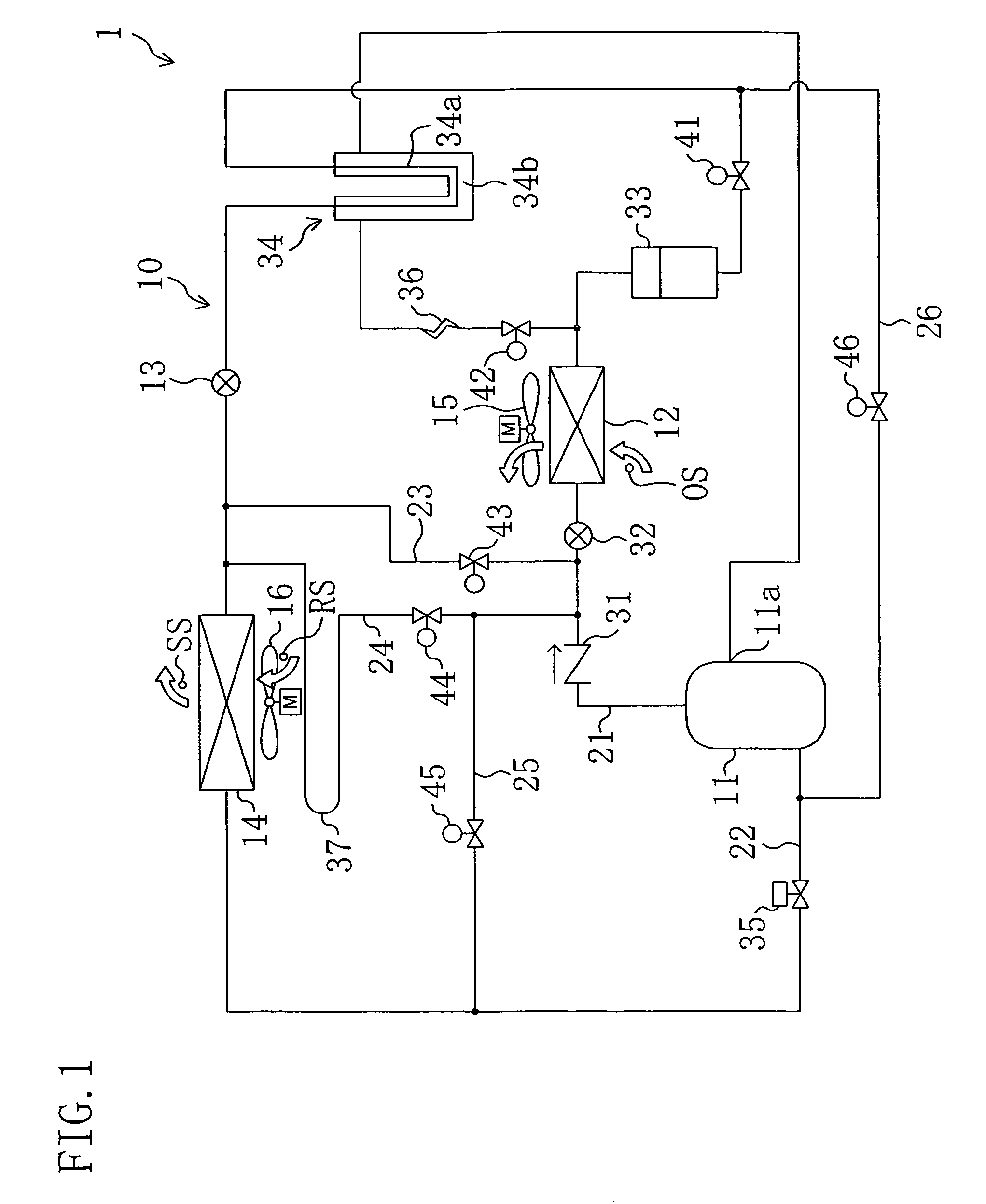

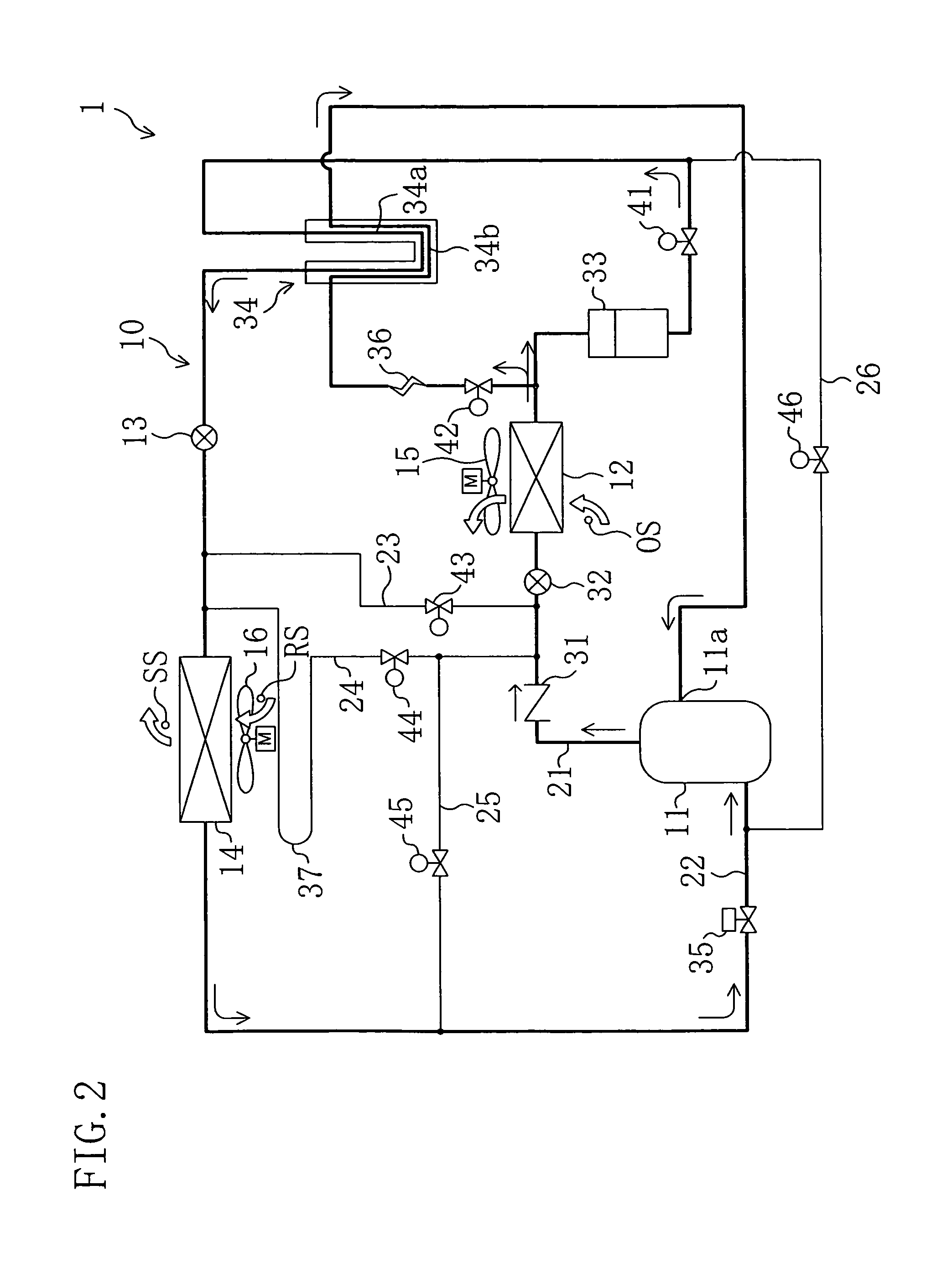

Refrigeration System

ActiveUS20090025410A1Reduce compressor powerGood energy saving effectMechanical apparatusCompression machines with non-reversible cycleEngineeringCooling capacity

When during a first action of a refrigeration system the internal cold storage temperature is held at a desired temperature by an evaporator, the refrigeration system performs a second action of increasing the cooling capacity of the evaporator to decrease the internal cold storage temperature. When during the second action the internal cold storage temperature reaches a minimum temperature Tmin, the refrigeration system stops a compressor and performs a third action. When during the third action the internal cold storage temperature reaches a maximum temperature Tmin, the refrigeration system drives the compressor and performs the first action.

Owner:DAIKIN IND LTD

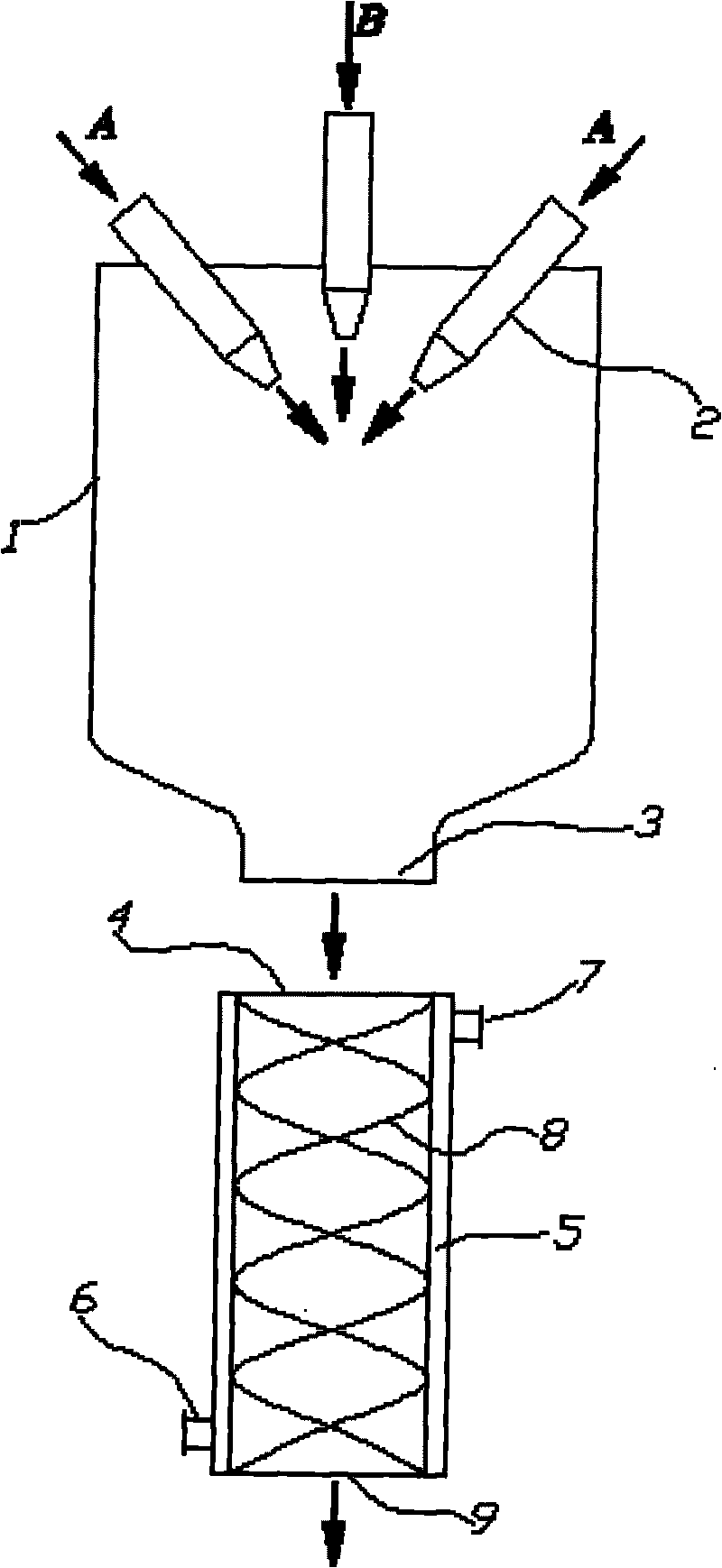

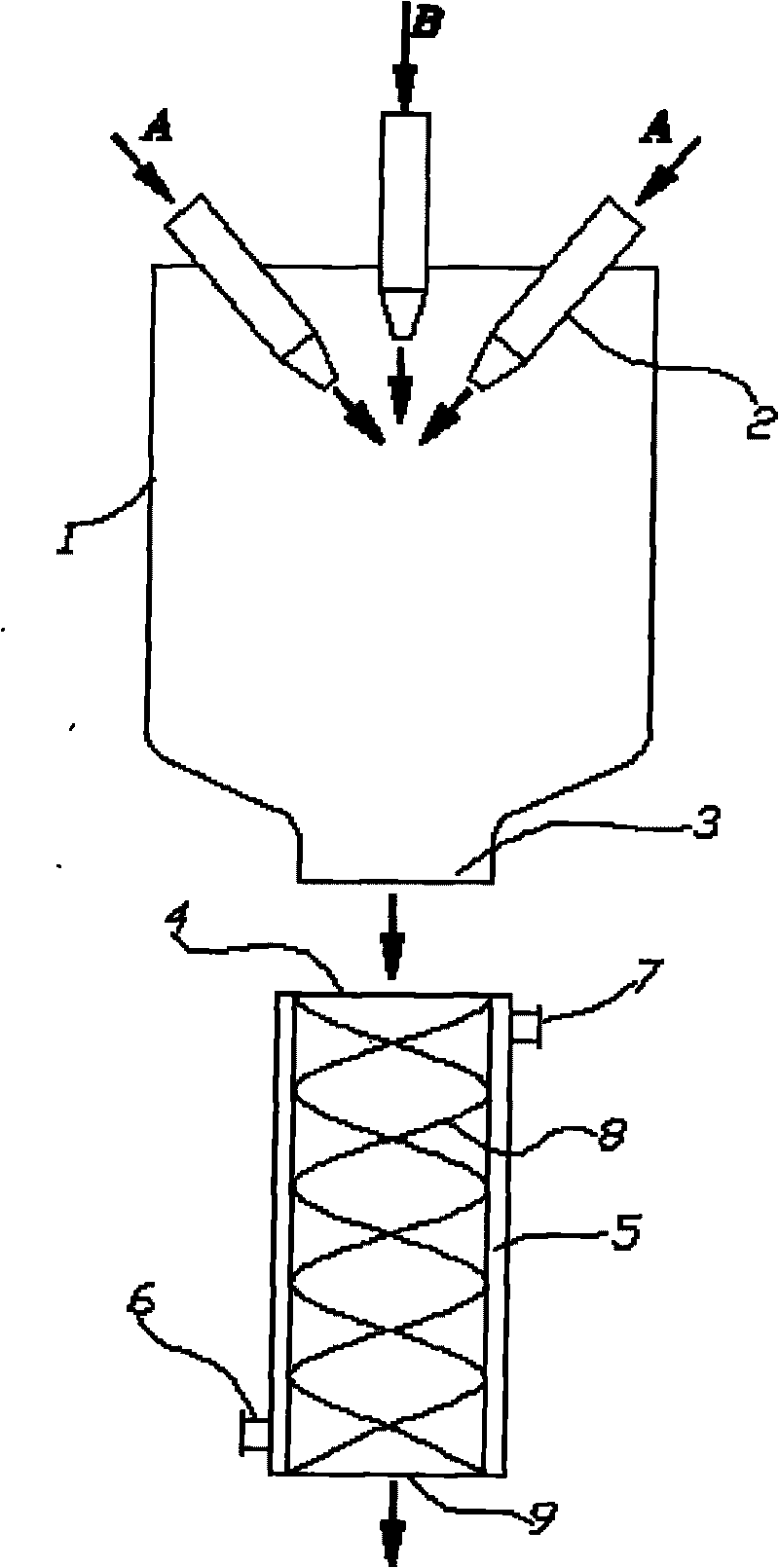

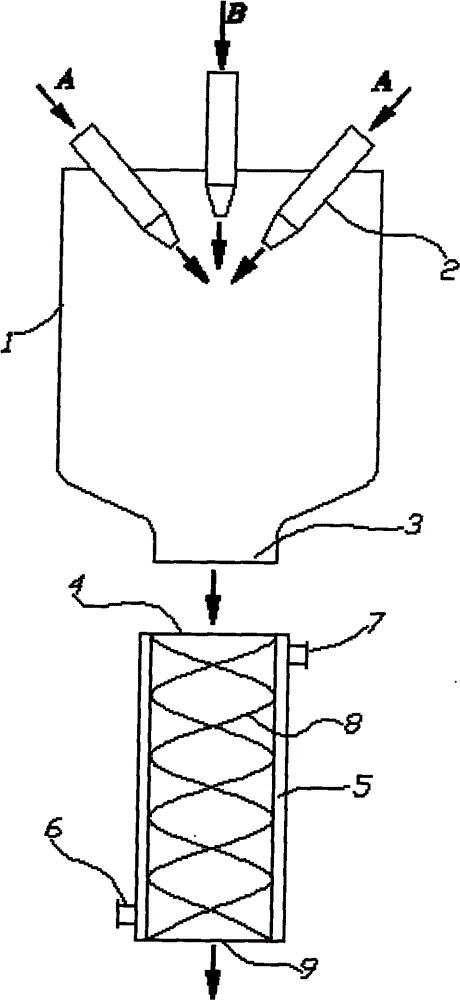

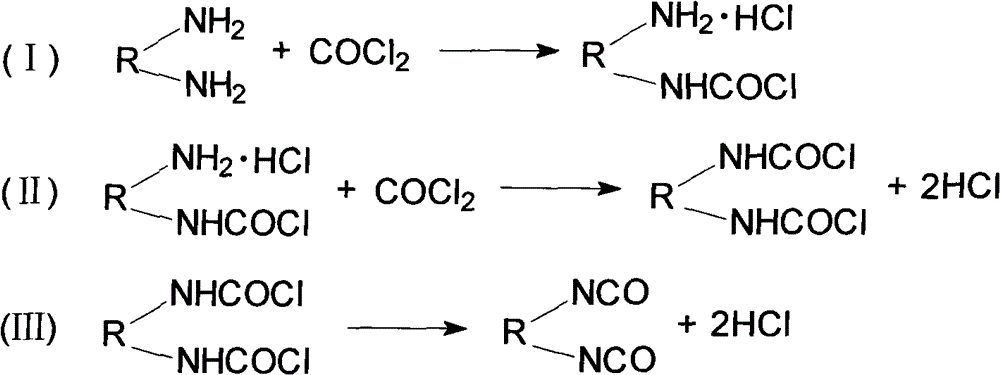

Method for continuously producing organic isocyanate

ActiveCN101735109AReduce manufacturing costIncrease production capacityIsocyanic acid derivatives preparationOrganic compound preparationOrganic solventRetention time

The invention discloses a method for continuously preparing organic isocyanate. The method comprises the steps of: preparing an impinging stream reactor and a static mixer, wherein the impinging stream reactor comprises an outer cylinder, feed nozzles are arranged on the upper part of the outer cylinder, and a discharge outlet is arranged on the bottom of the outer cylinder; dissolving organic primary amine and phosgene into the same inert organic solvent respectively, adding the obtained solution into the outer cylinder through the feed nozzles for a phosgenation reaction, and ensuring that the average retention time of materials does not exceed 30s; and introducing the material discharged from the discharge outlet of the impinging stream reactor from a feed inlet of the static mixer provided with a heat exchange device for a reaction to generate a crude product of the organic isocyanate, wherein the average retention time of the material is less than 30min. The method of the invention utilizes good micromixing property of the impinging stream reactor to improve the mixing efficiency of raw materials, reduce the production cost of isocyanate and improve the production capacity ofthe isocyanate. The reactor of the invention has a simple structure, reduces the danger of solid blockage, is easy to seal, and reduces the danger of phosgene leakage.

Owner:SEDIN ENG +1

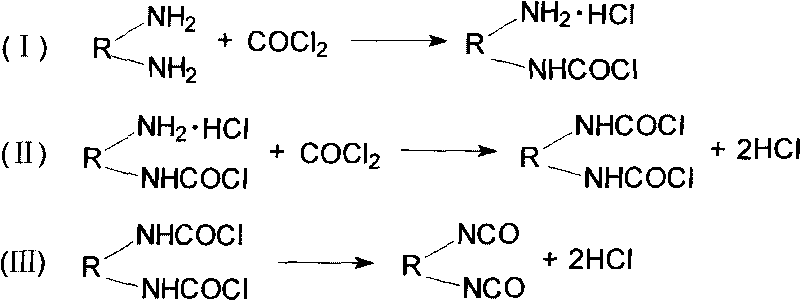

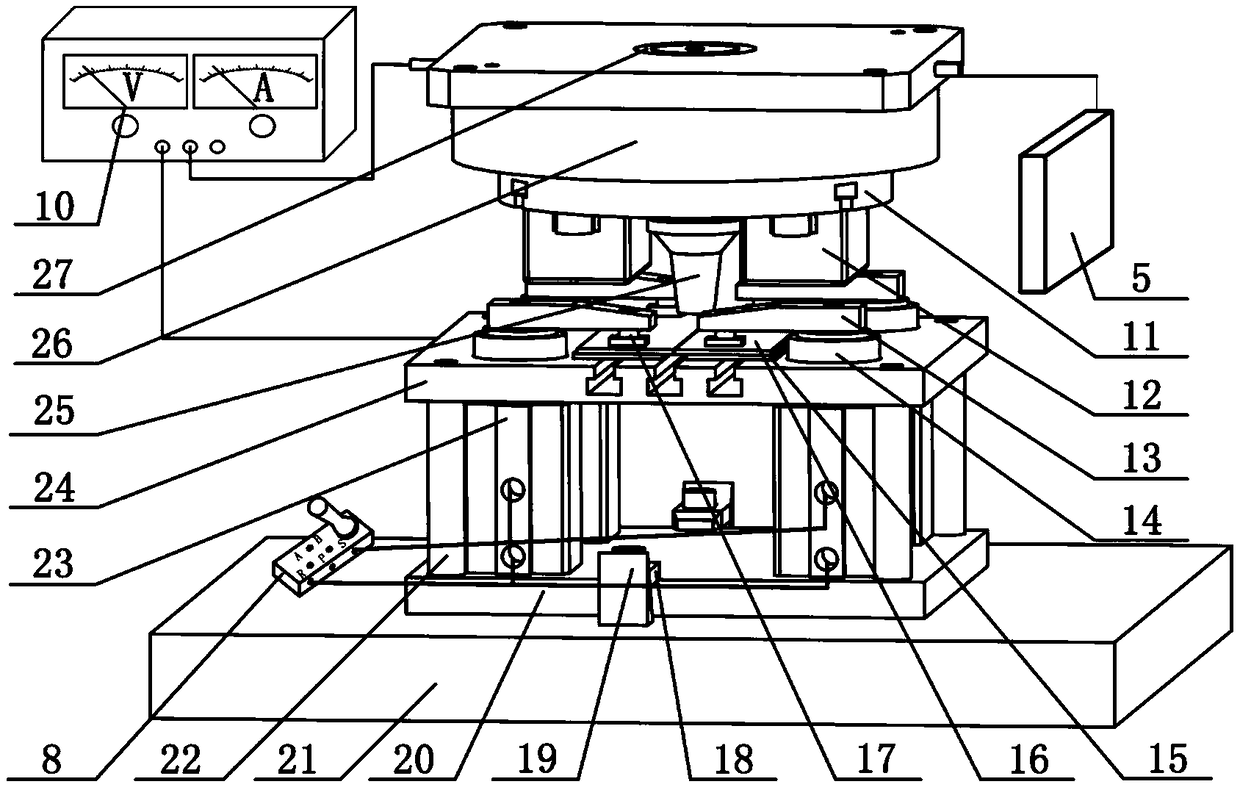

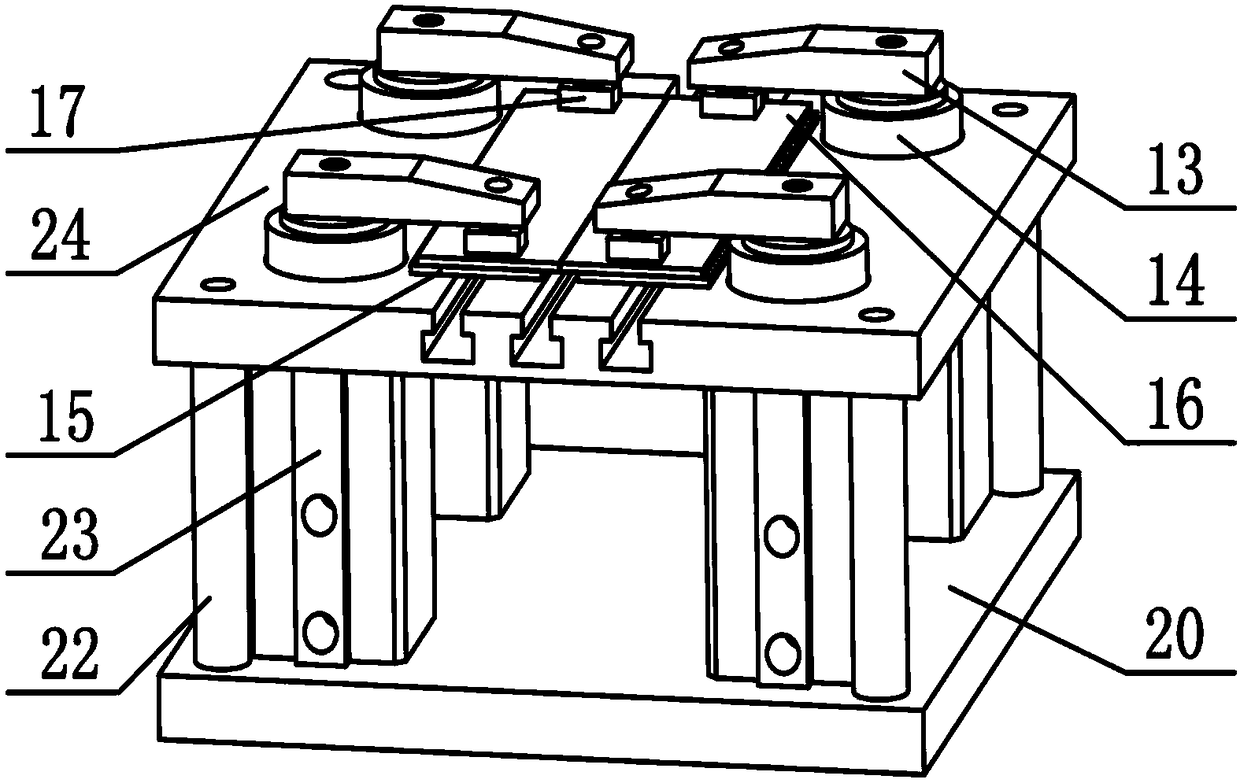

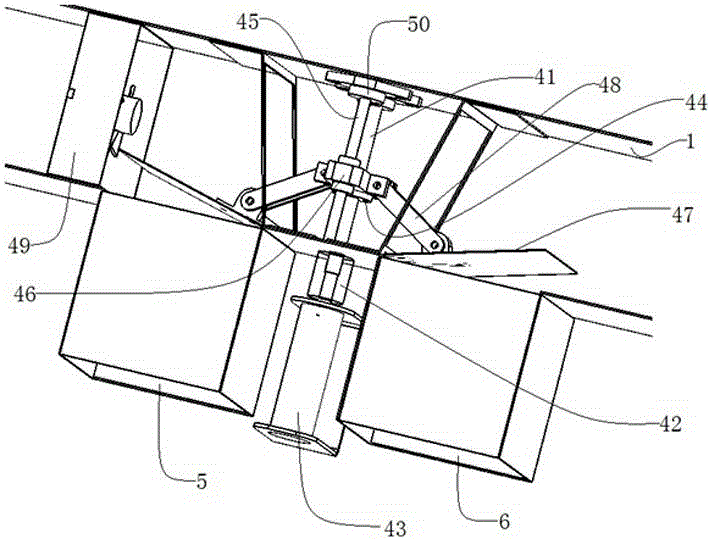

Rotary electric field and magnetic field synchronously assisted laser welding device and method

ActiveCN109128502AAchieve overlapEasy to adjustLaser beam welding apparatusElectric machineryDrive motor

The invention discloses a rotary electric field and magnetic field synchronously assisted laser welding device and method and belongs to the field of laser welding. The welding device comprises an electricity and magnet regulating device and a positioning and clamping tooling. Supporting columns and rotary air cylinders in the positioning and clamping tooling are mounted on a bottom plate. An electric field generation bottom plate is mounted on the supporting columns. Press blocks are mounted on the rotary air cylinders correspondingly. Neodymium iron boron permanent magnets in the electricityand magnet regulating device are fastened to a magnetic field regulating disc. Insulation sleeves, a welding laser head and the magnetic field regulating disc are mounted on a direct drive motor. Thedirect drive motor is mounted on a main shaft. The two poles of an electric field power source are connected to the electric field generation bottom plate and the welding laser head correspondingly.By means of the device and method provided by the invention, easy, convenient and fast regulation of a rotary magnetic field and a steady electric field can be achieved, continuous regulation of the intensity can be achieved, synchronous movement of the electric field and the magnetic field along with welding laser beams is guaranteed, and therefore, the forming quality of laser welding joints isimproved by setting the reasonable laser technological parameters including the power, the focal length, the defocusing amount, the helium protective gas flow rate and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH

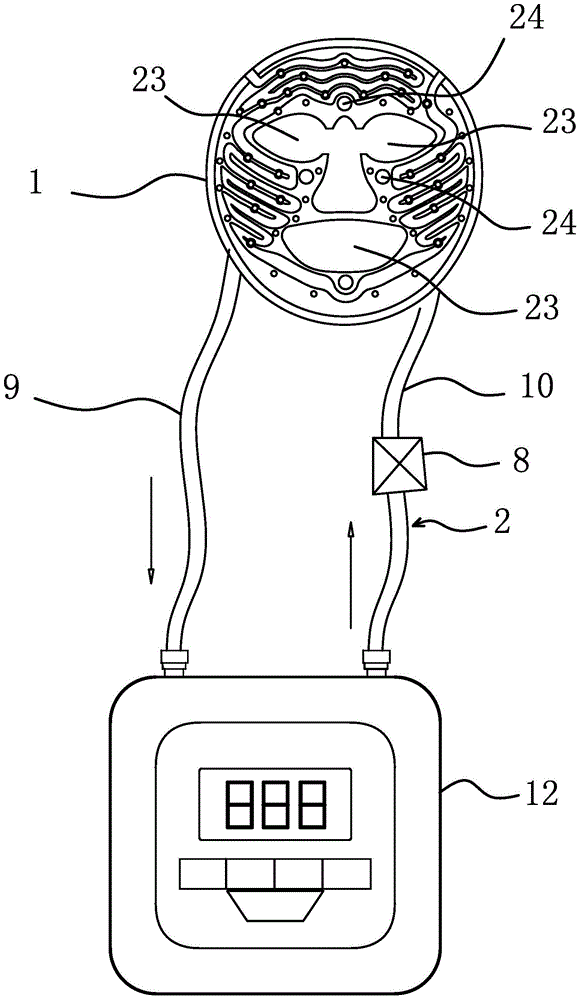

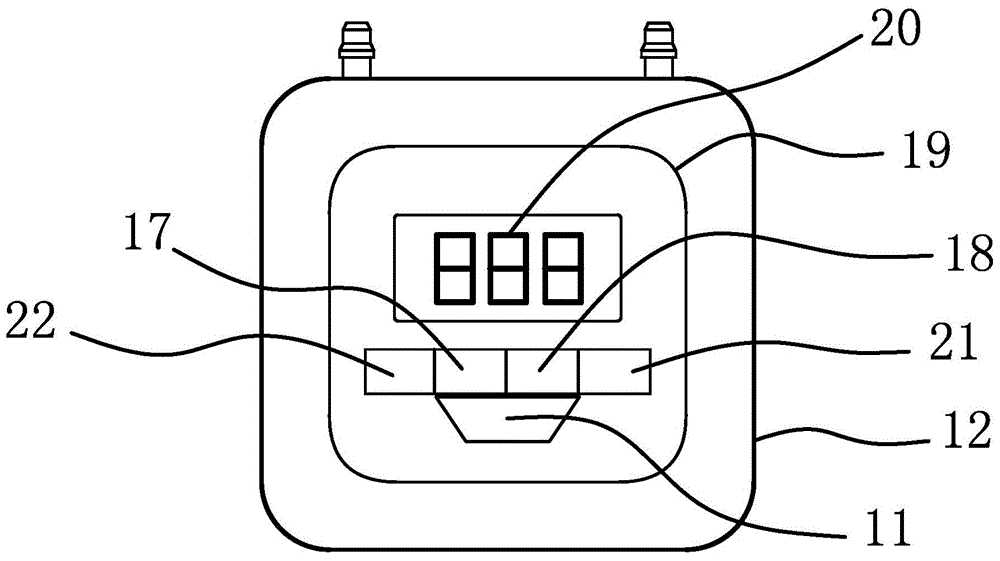

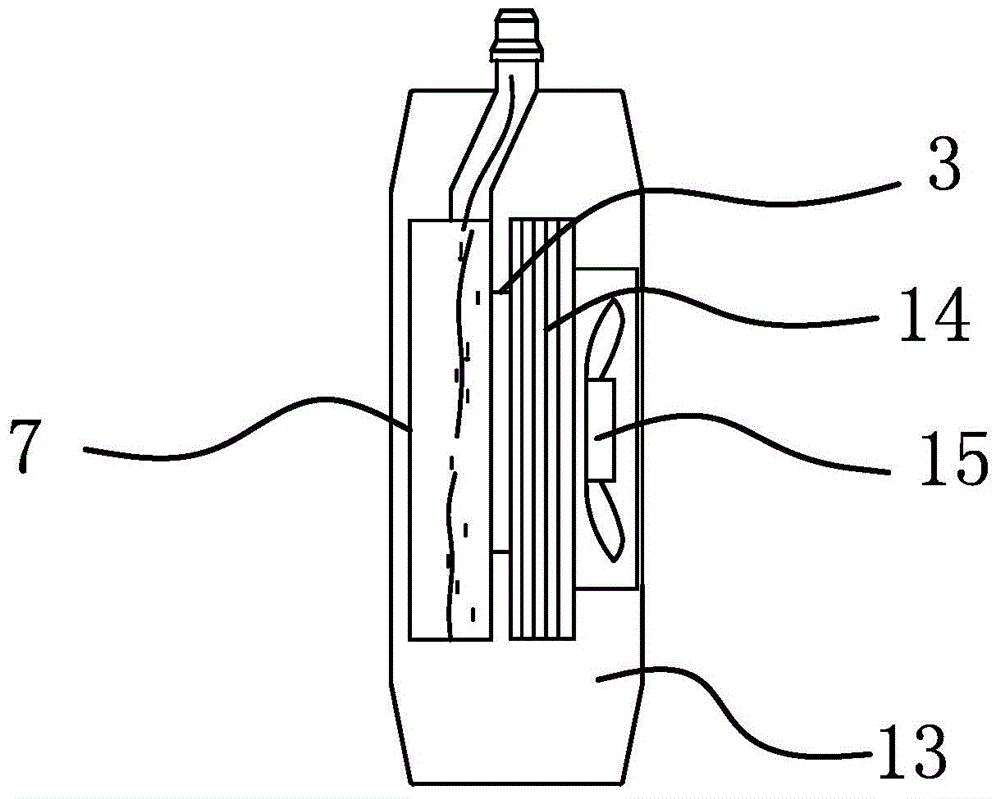

Cold and hot mask applying device with ventilation structure

ActiveCN104644313AEnsure consistencyTemperature homogenizationVibration massageTherapeutic coolingExcess heatEngineering

The invention provides a cold and hot mask applying device with a ventilation structure, belongs to the technical field of articles for daily life, and aims at solving the technical problems of an existing cold and hot applied mask that the surface temperature is not uniform and the like. The mask applying device comprises a mask patch and an outer mask piece which are overlapped; the mask patch and the outer mask piece are provided with through holes for exposing eyes, nose and mouth of a user; the mask patch is provided with a temperature adjusting mechanism for heating or cooling the mask patch; a plurality of inner air vents which penetrate through the mask patch are formed in the mask patch; a plurality of outer air vents which penetrate through the outer mask piece are formed in the outer mask piece. According to the mask device, the inner air vents penetrate through the mask patch and the outer air vents penetrate through the outer mask piece, so that air between the mask patch and the outer mask piece can be exchanged with the outside air for uniformly dispersing surplus heat, and furthermore, the consistency of the temperatures of all parts of the mask patch is guaranteed, and the surface temperature of the cold and hot applied mask is uniformed.

Owner:TAIZHOU TAI CHENG ELECTRONICS TECH

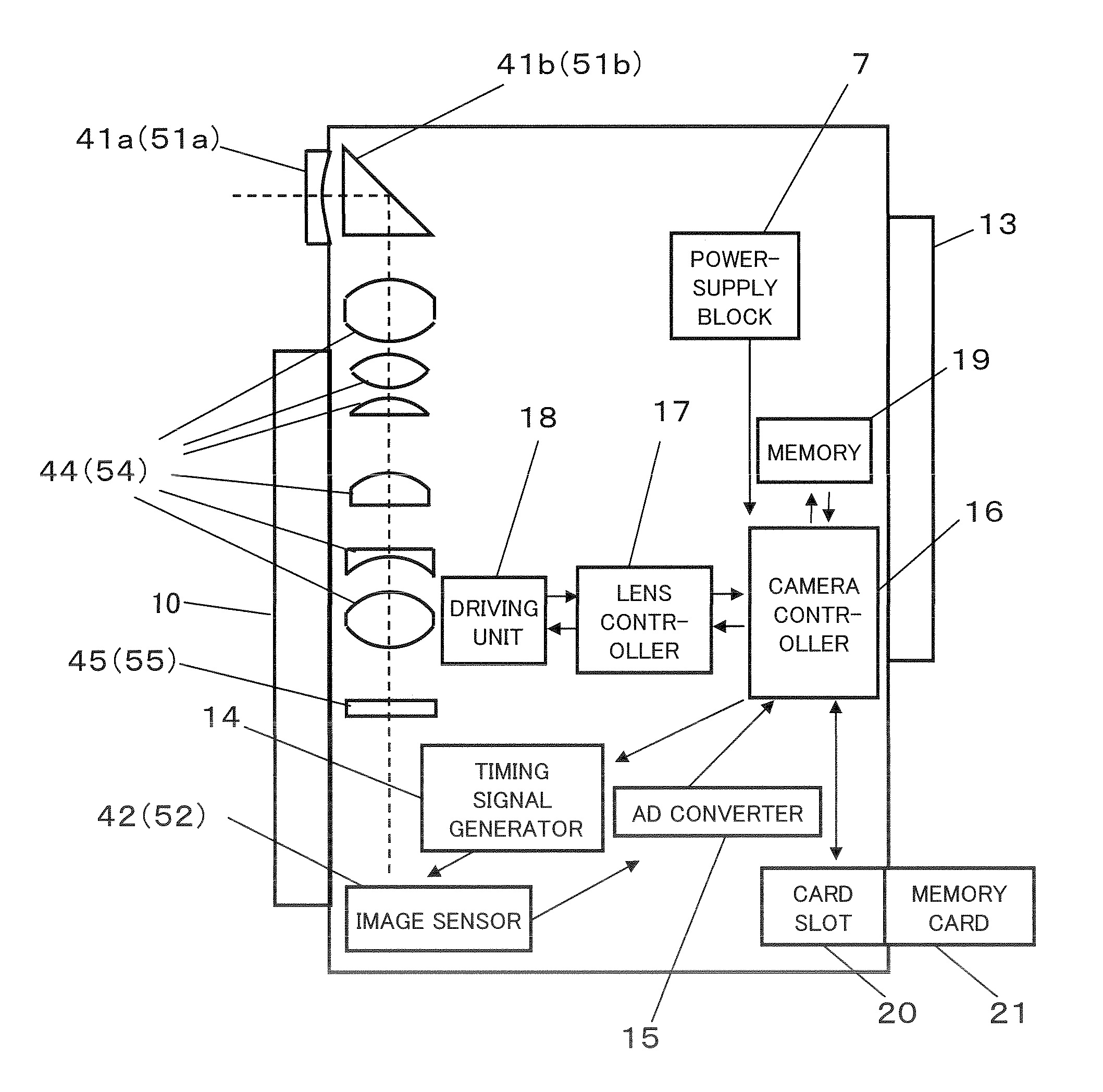

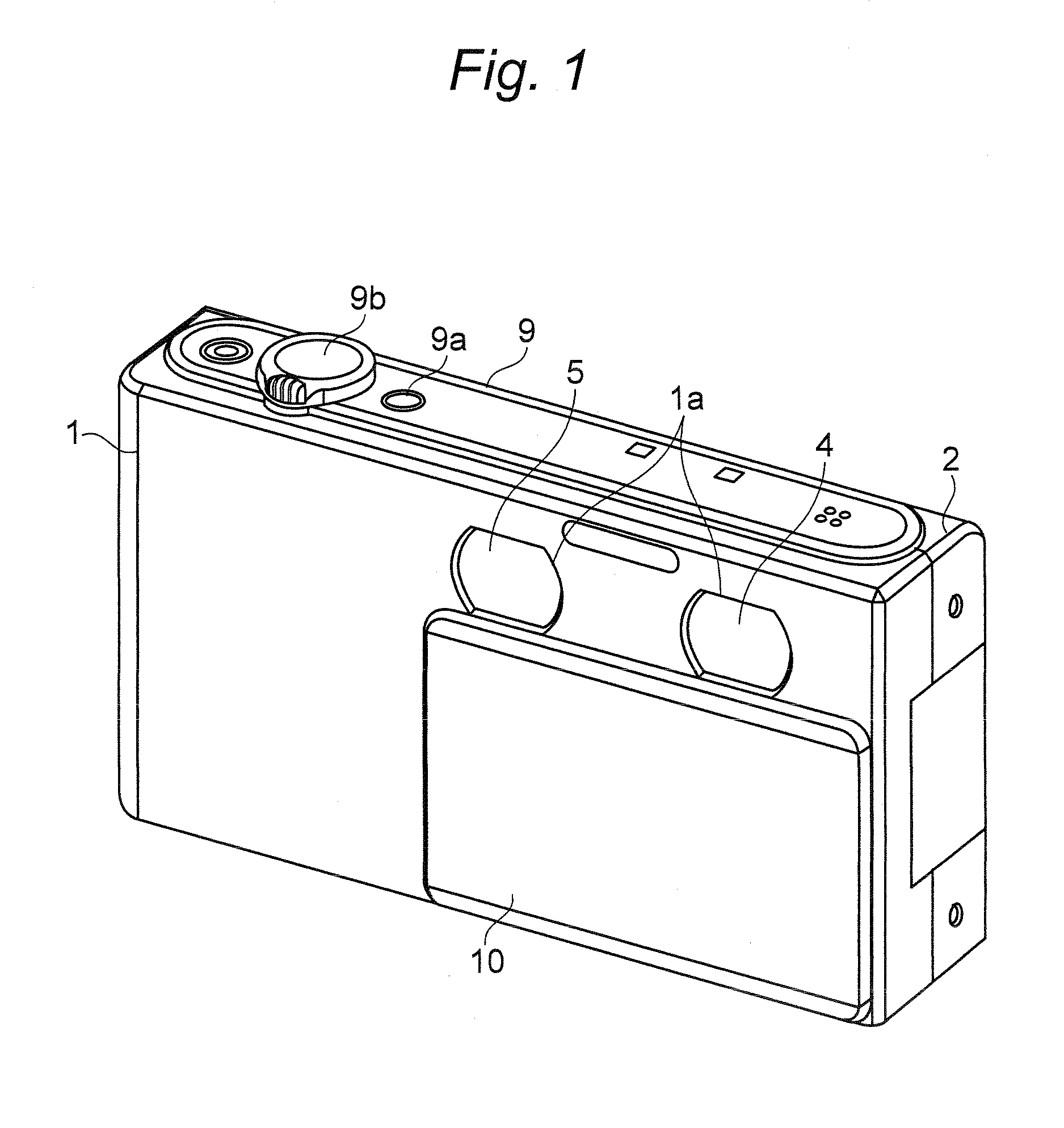

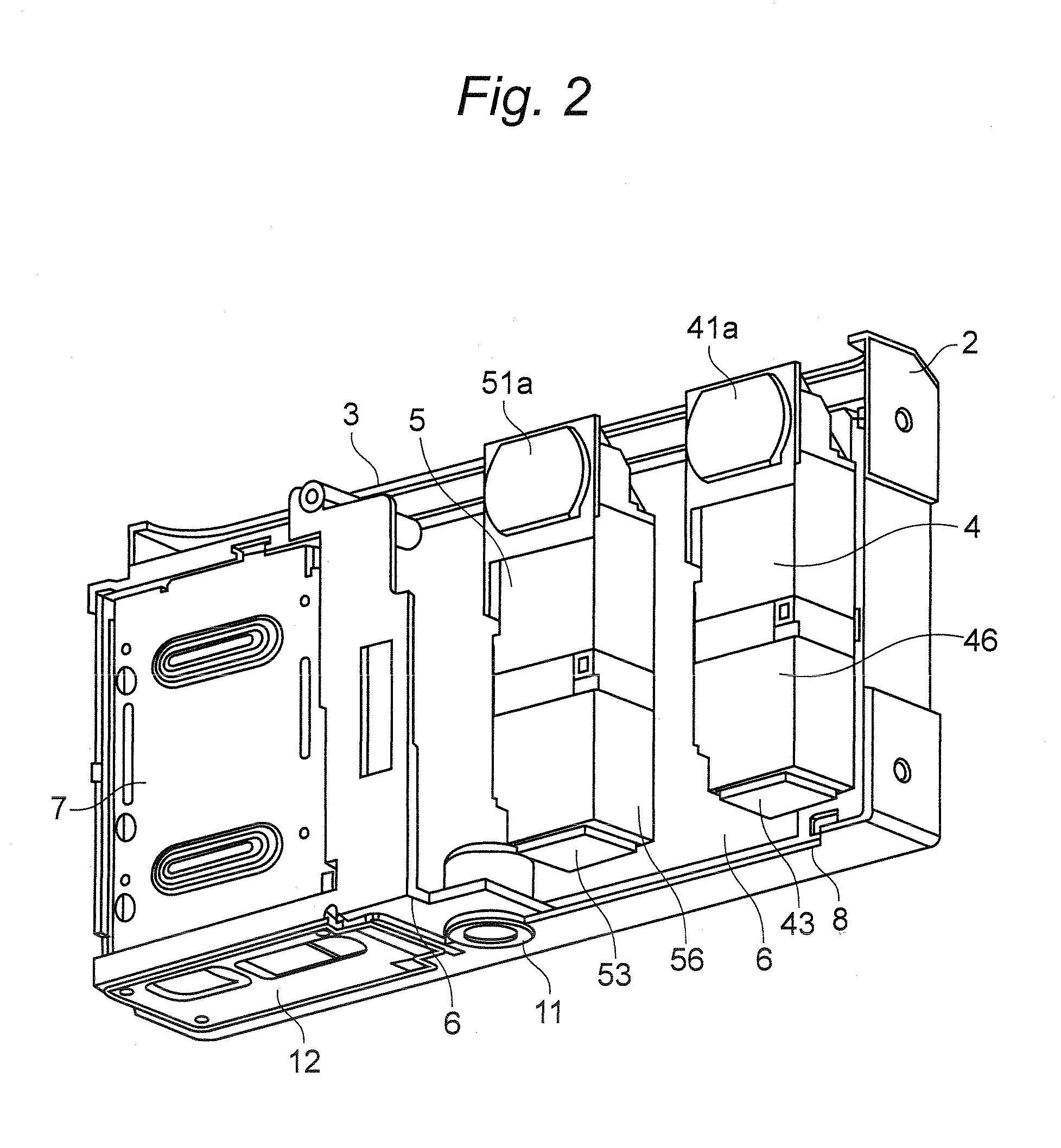

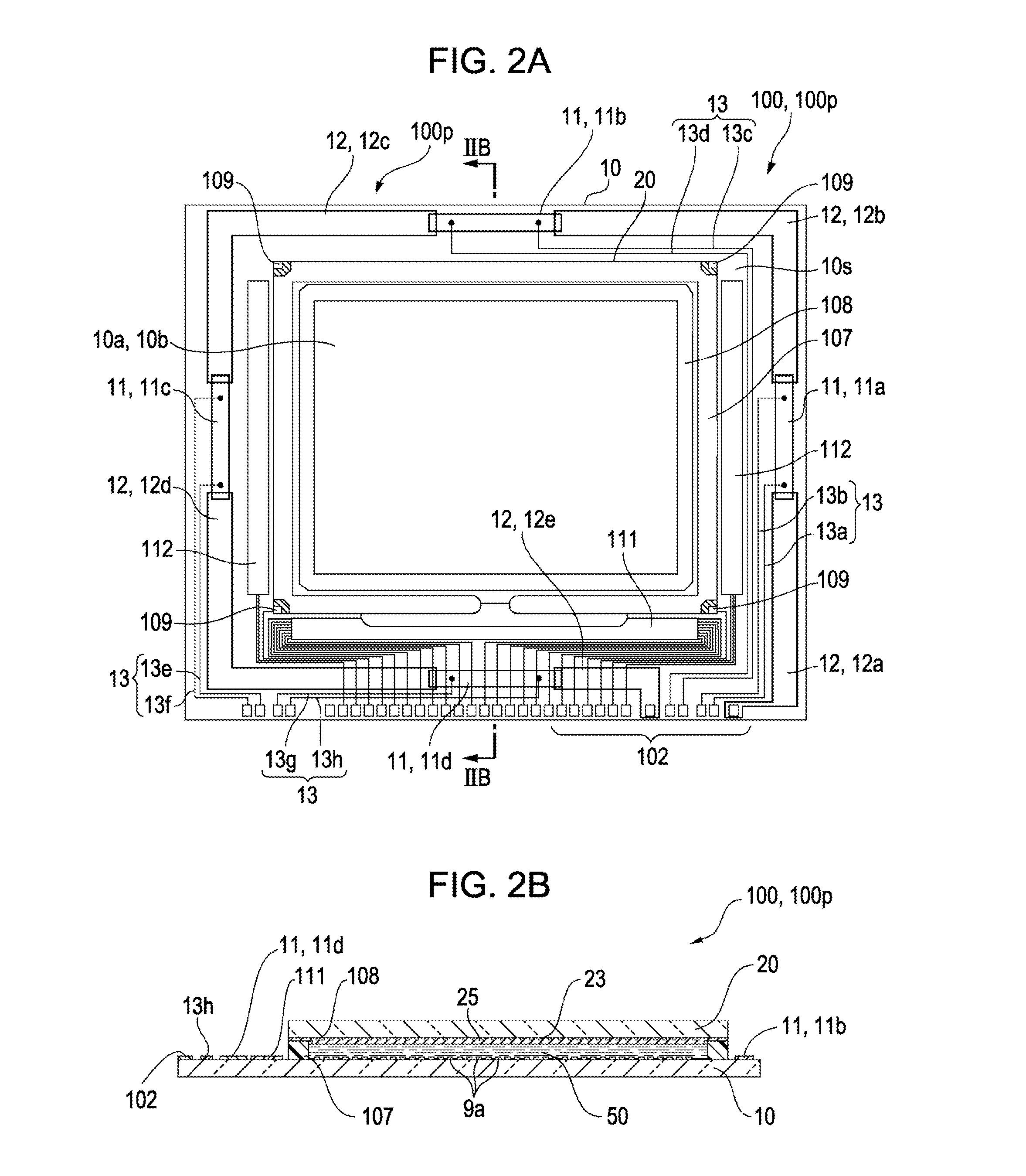

Imaging apparatus

InactiveUS20130044189A1Quality improvementTemperature homogenizationTelevision system detailsStereoscopic photographyImaging equipmentPhysics

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

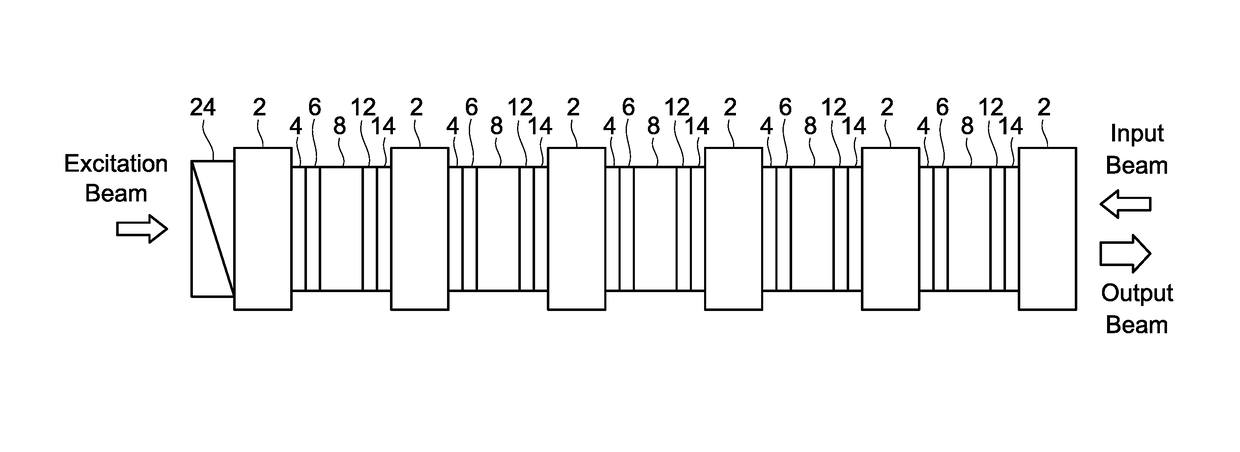

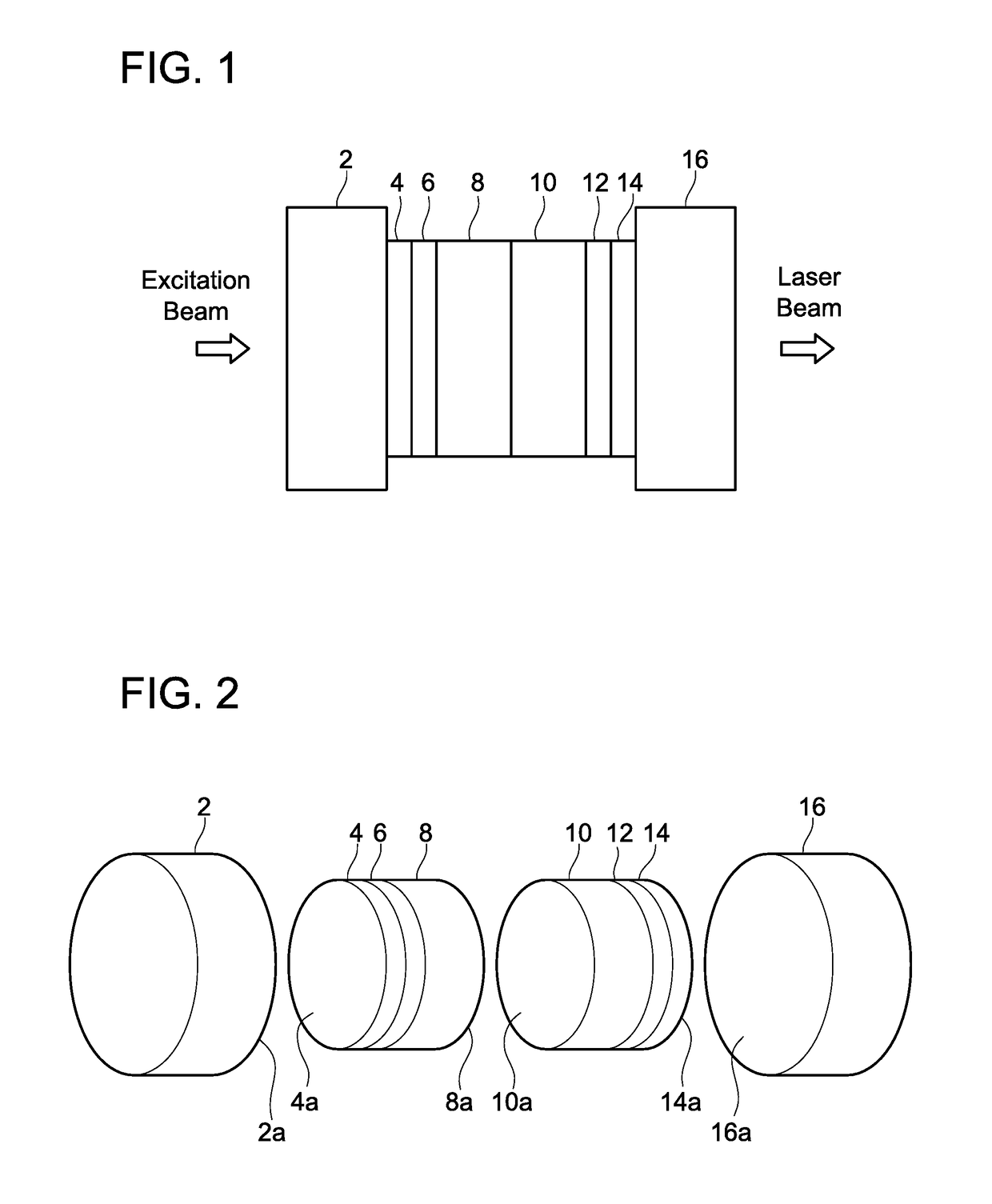

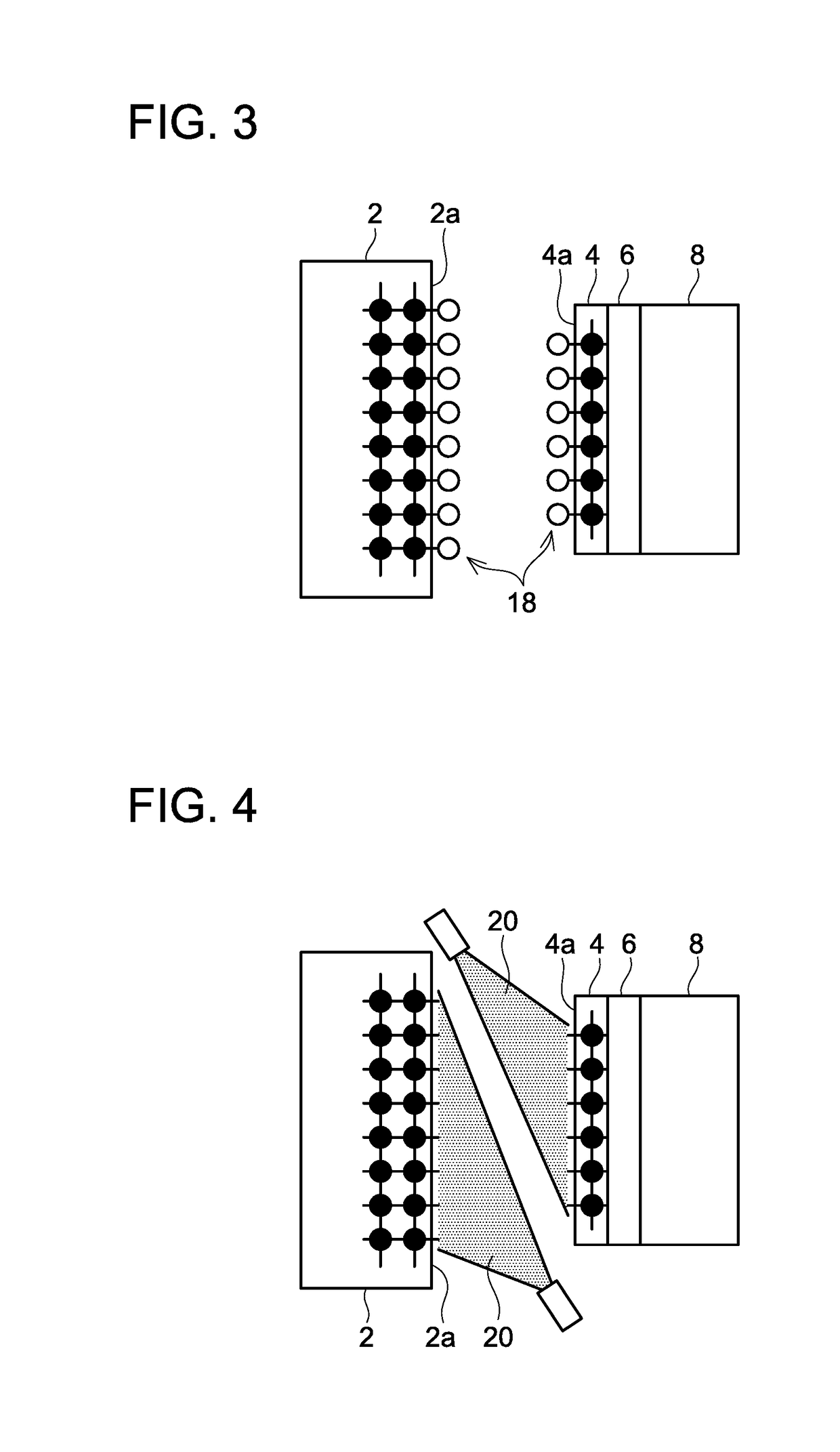

Laser apparatus and manufacturing method thereof

InactiveUS20170358898A1Decrease length of resonatorImprove thermal stressOptical resonator shape and constructionActive medium materialOptoelectronicsLaser

A technique which is suitable in joining an end surface of a laser medium to a transparent heat sink for maintaining thermal resistance therebetween low and avoiding large thermal stress from acting on the laser medium is to be provided. An end coat is provided on the end surface of the laser medium, a same-material layer constituted of a same material as the heat sink is provided on a surface of the end coat, a surface of the same-material layer and an end surface of the heat sink are activated in a substantially vacuum environment, and those activated surfaces are bonded in the substantially vacuum environment. A laser apparatus having low thermal resistance between the laser medium and the heat sink and high transparency at a joint interface therebetween, and no large thermal stress acting on the laser medium is thereby obtained.

Owner:INTER UNIV RES INST NAT INST OF NATURAL SCI

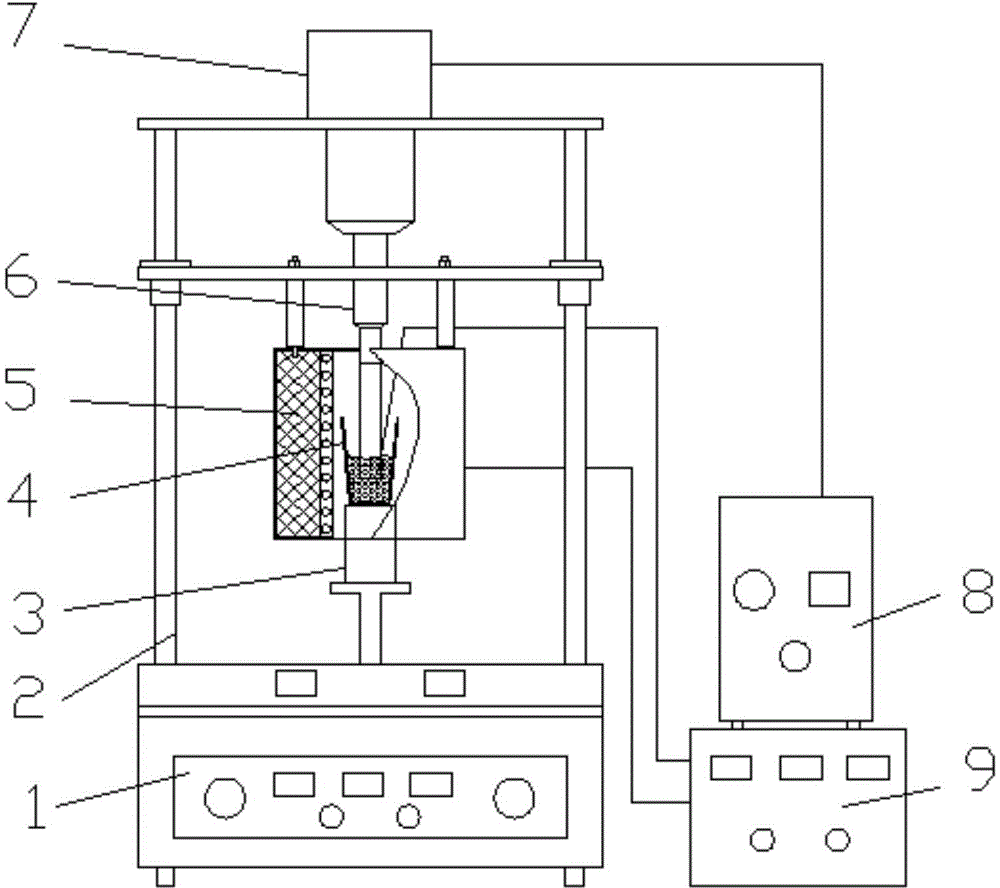

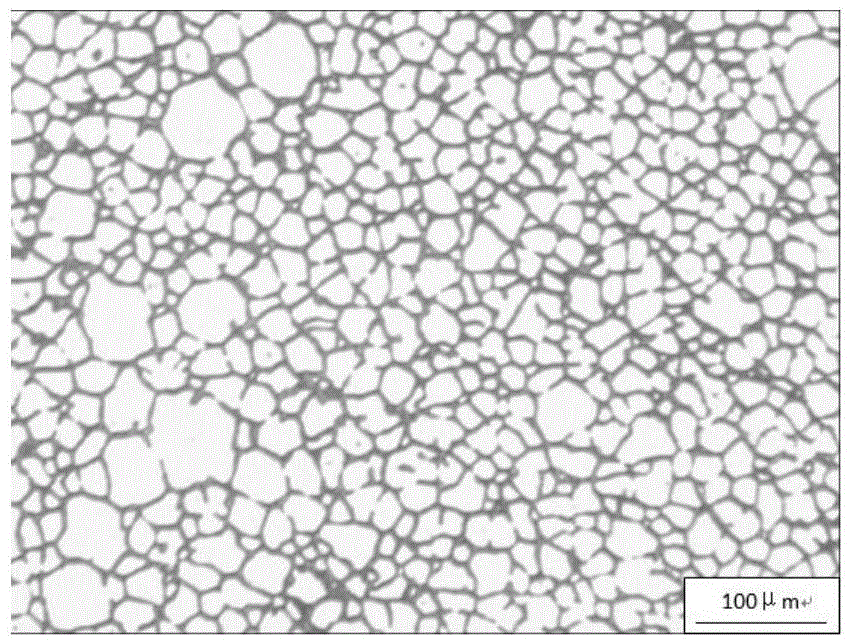

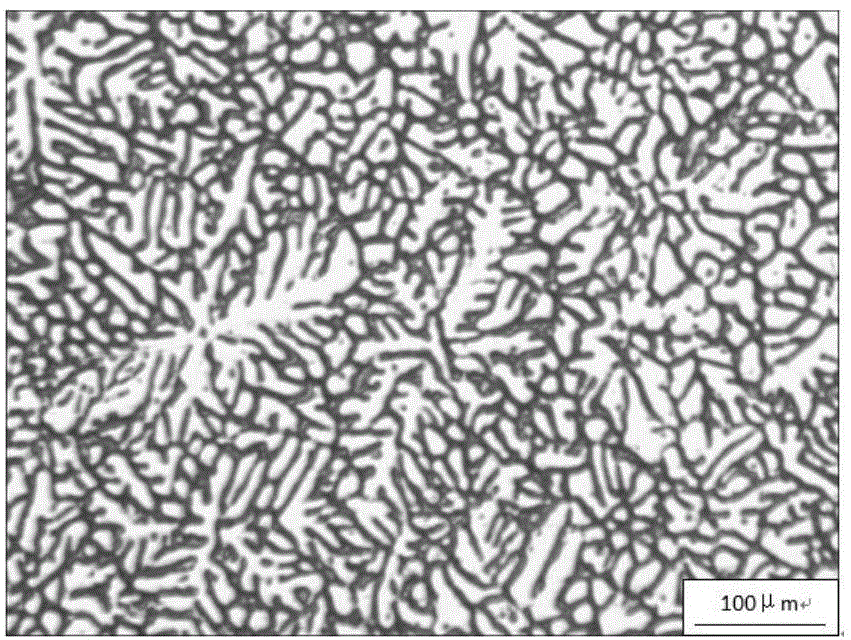

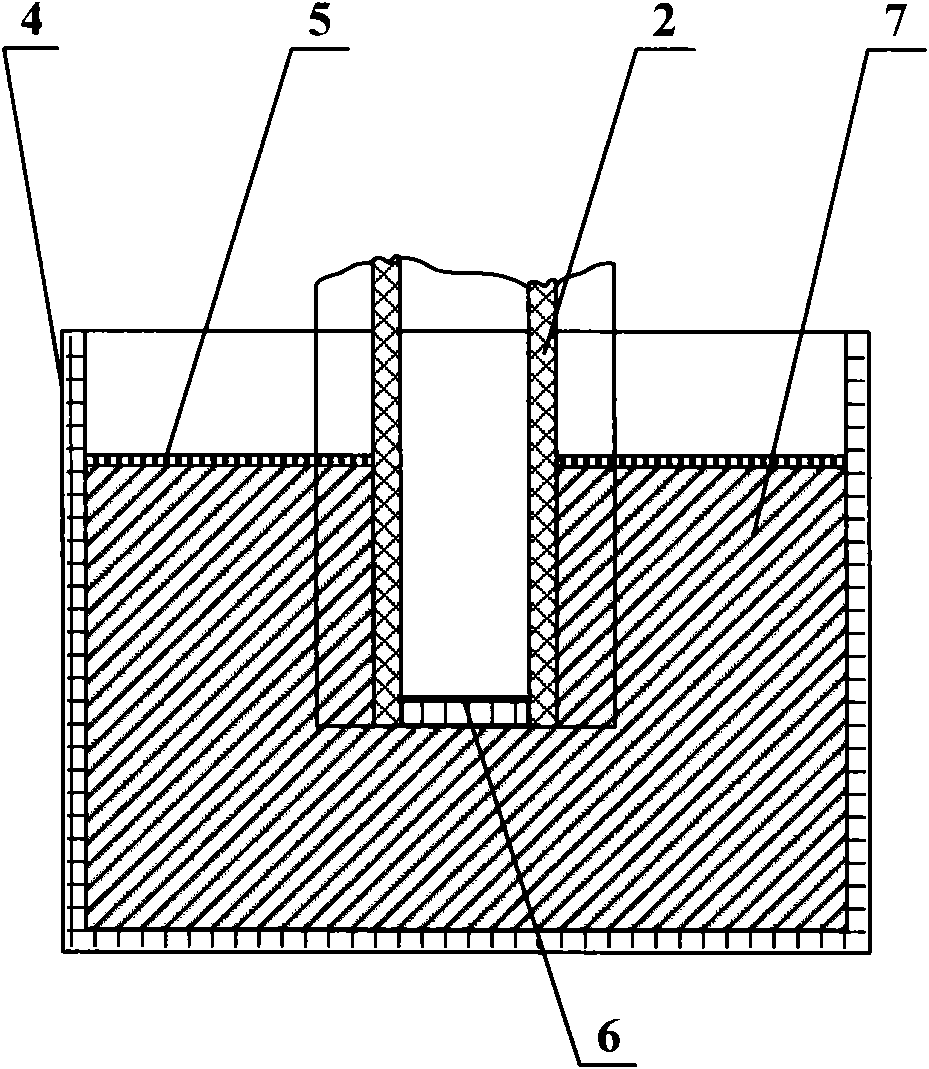

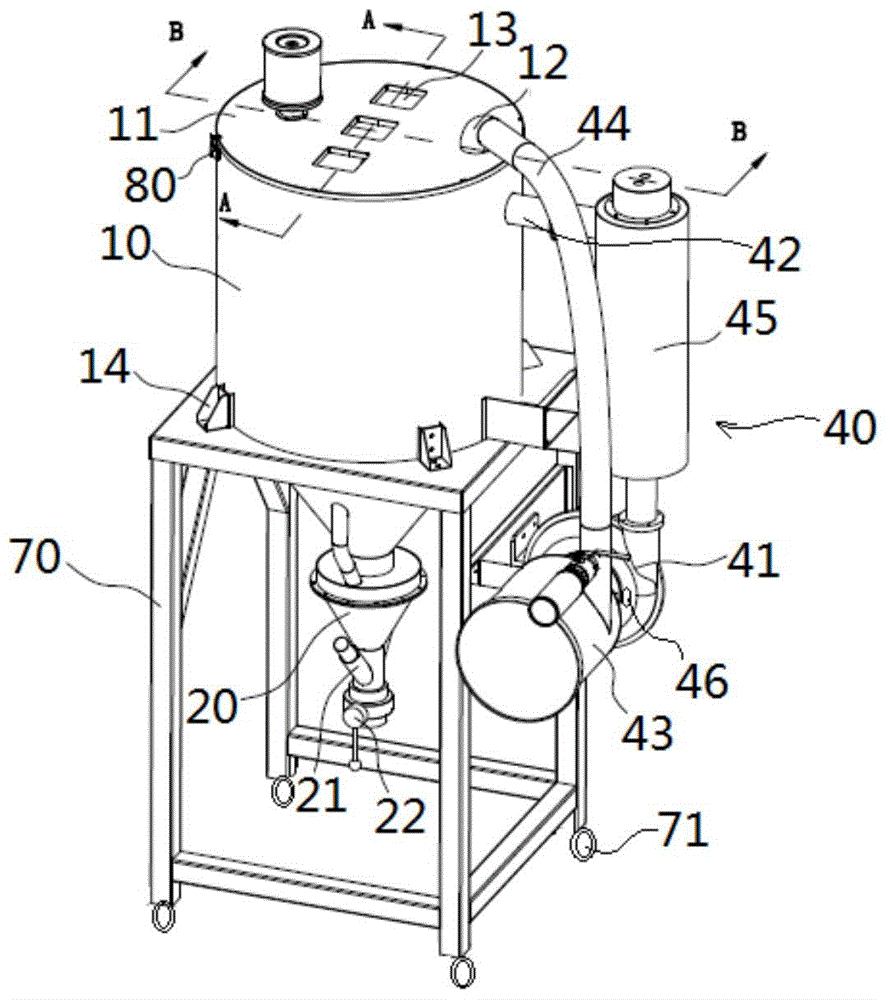

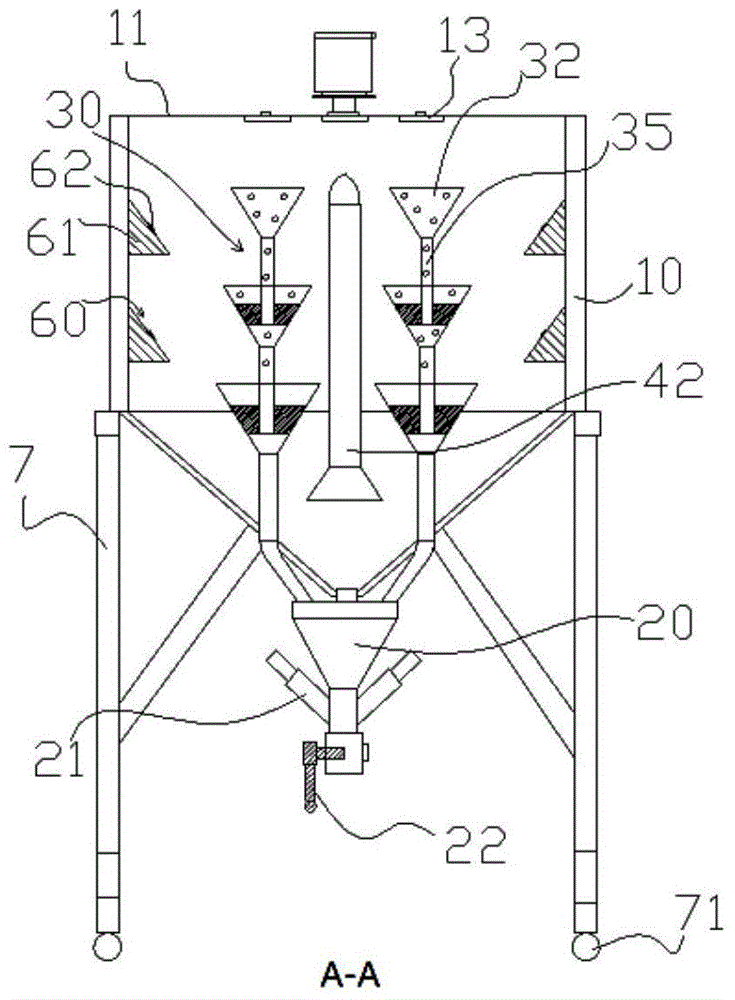

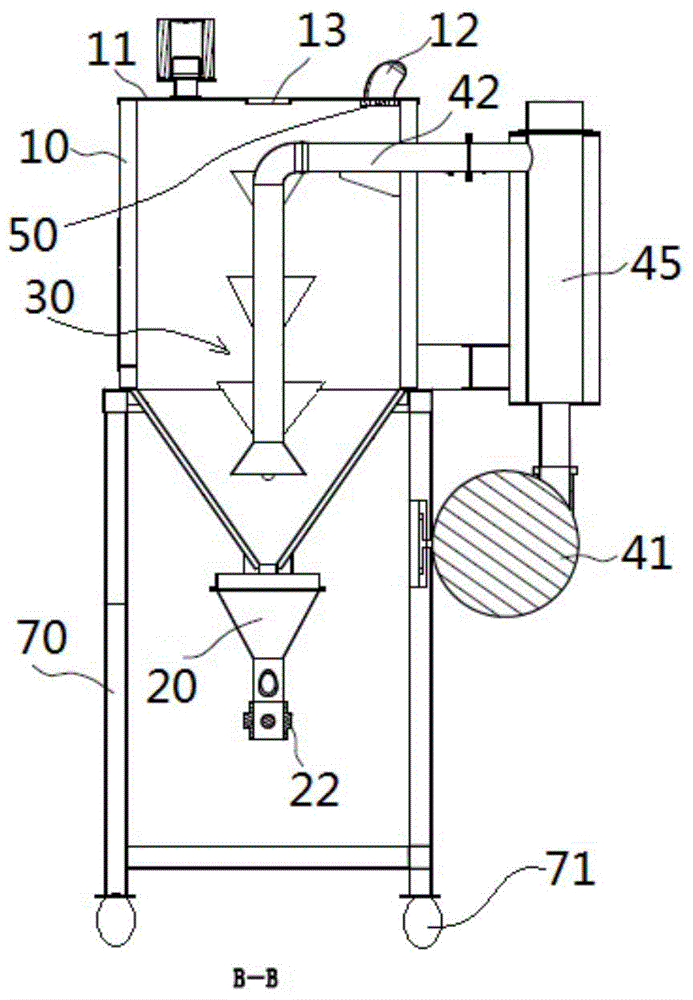

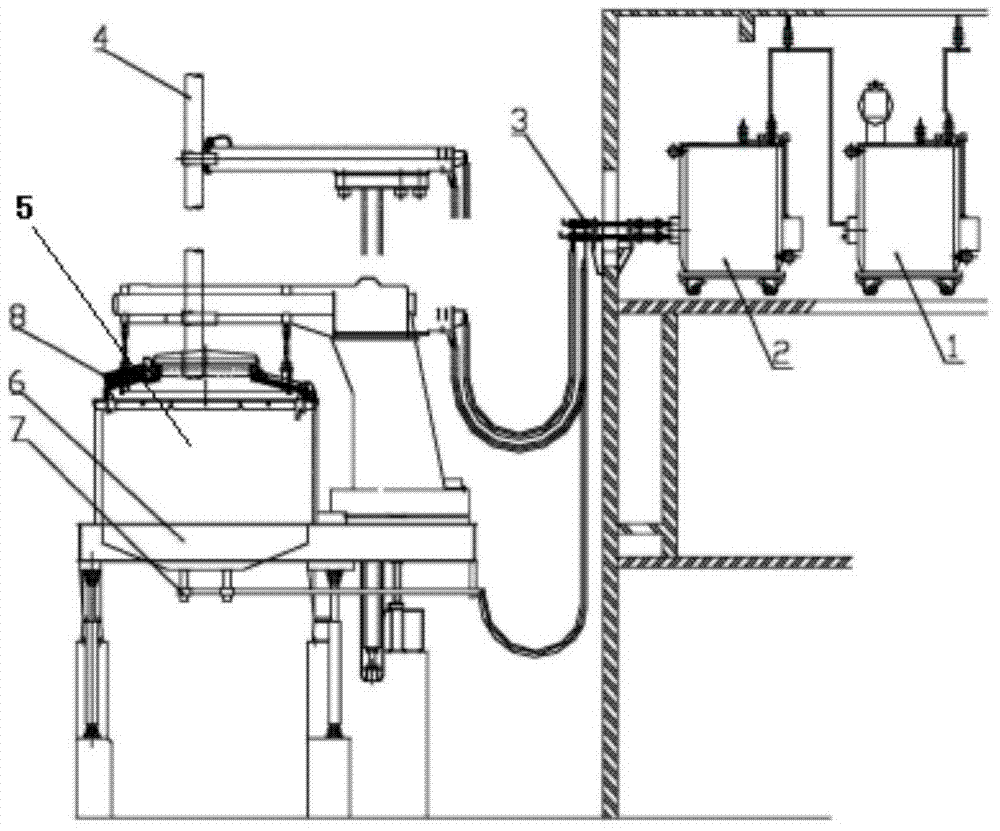

Compound smelting equipment ultrasonically stirring low-melting-point alloy

The invention discloses compound smelting equipment ultrasonically stirring low-melting-point alloy, which is applicable for the smelting and preparation of the low-melting-point alloy, in particular to various tin-bismuth series alloy at the low melting point of below 300 DEG C. The equipment comprises a crucible, a heat-preservation and heating device, a temperature control device, an ultrasonic stirring device, an ultrasonic wave generation and control device and a mechanical stirring device, wherein molten metal is put in the crucible. The equipment is simple in structure and practical; the mechanical stirring device and the ultrasonic stirring device are mutually perpendicular without intervention; ultrasonic waves are imported to the molten metal from the side of the crucible; the efficiency is high, the ultrasonic energy loss is low, and moreover, the solid rate of the molten metal is higher; even when metal stirring fails, the ultrasonic waves still can be applied till metal solidification; through the compound ultrasonic and mechanical stirring, grains can be refined, so that a non-dendritic structure is obtained; homogenizing of the ingredients and the temperature of the fused molten metal is sped up; the plasticity of prepared alloy is improved greatly in comparison with the plasticity of alloy prepared by a traditional method.

Owner:GUANGDONG UNIV OF TECH

Method for refinement of rare earth-rich phase of rare earth-magnesium alloy

ActiveCN104313370AIncrease the number ofReduce the degree of enrichmentProcess efficiency improvementRare-earth elementSlurry

The invention belongs to the technical field of metal material preparation and casting formation, and relates to a method for refinement of a rare earth-rich phase of a rare earth-magnesium alloy. Rare earth in the rare earth-magnesium alloy comprises one, two or more of 0.5-4% of RE (which is mixture of Ce and La and comprises 50-70% by mass of Ce and the balance La), 0.5-2% of Y, 2-3% of Nd and 1-5% of Gd. The method comprises pouring a magnesium alloy liquid with the temperature 0-40 DEG C higher than that of a liquidus line into a slurry container pre-heated to a preset temperature, dropping an amplitude-change pole to a position 1-25mm lower than a metal liquid surface, simultaneously, starting ultrasonic vibration, carrying out ultrasonic vibration for 1-8min, then controlling a metal melt temperature 5-50 DEG C lower than a liquidus line temperature and carrying out molding on the metal melt subjected to ultrasonic vibration to obtain a magnesium alloy part. Crystal grain size and rare earth-rich phase size are greatly reduced than size of the microstructure before ultrasonic vibration. The method can be used for a rare earth-magnesium alloy pulping process, a follow-up rheocasting process and a rare earth-magnesium alloy part molding process.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for controlling blank casting quality of phi-280mm 37Mn circular tube blank

ActiveCN105695659AImprove purityHomogenization of ingredientsManufacturing convertersMolten steelParameter control

The invention discloses a method for controlling the internal quality of a 37Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, RH vacuum treatment and continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

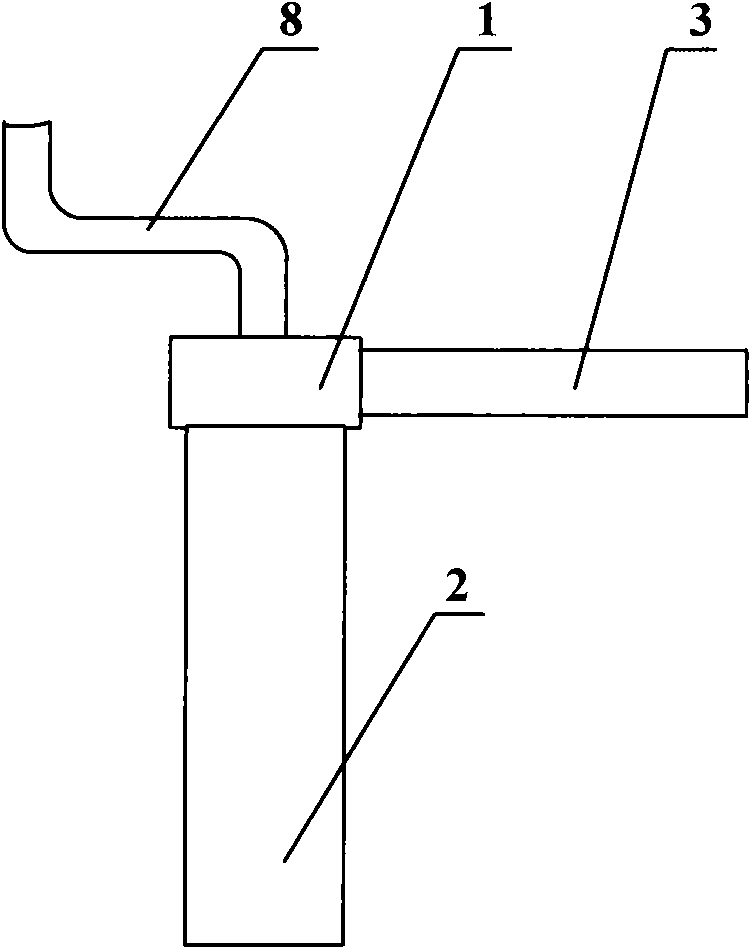

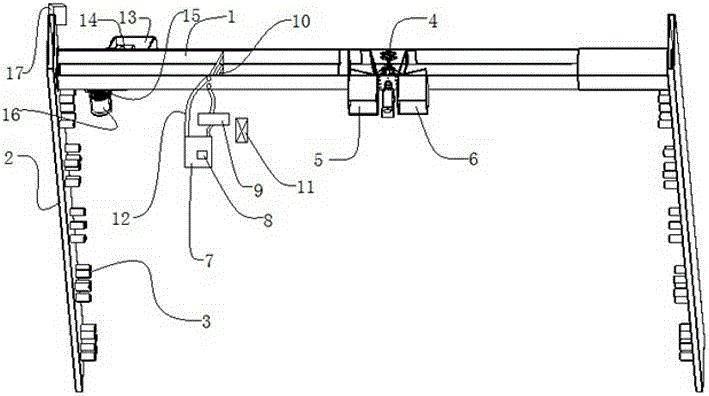

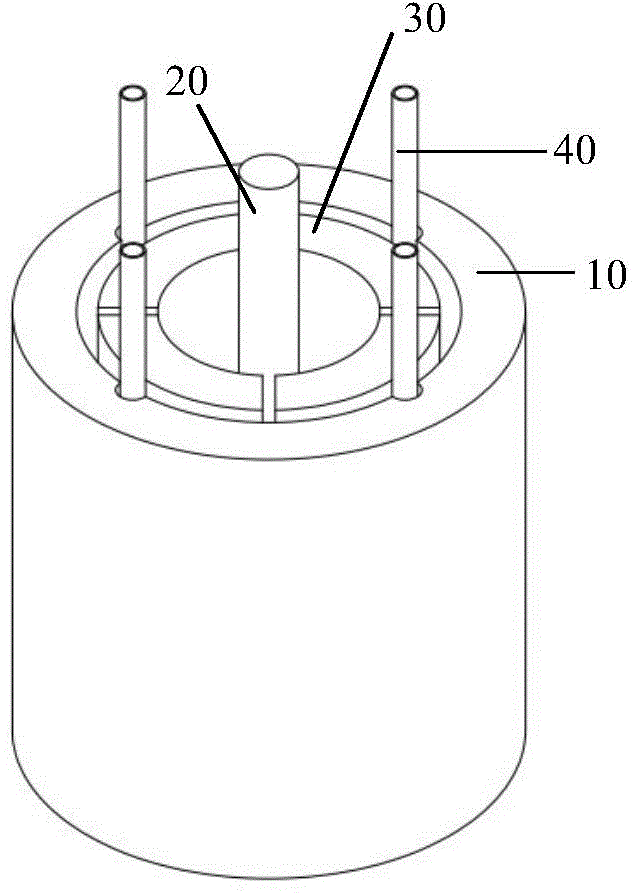

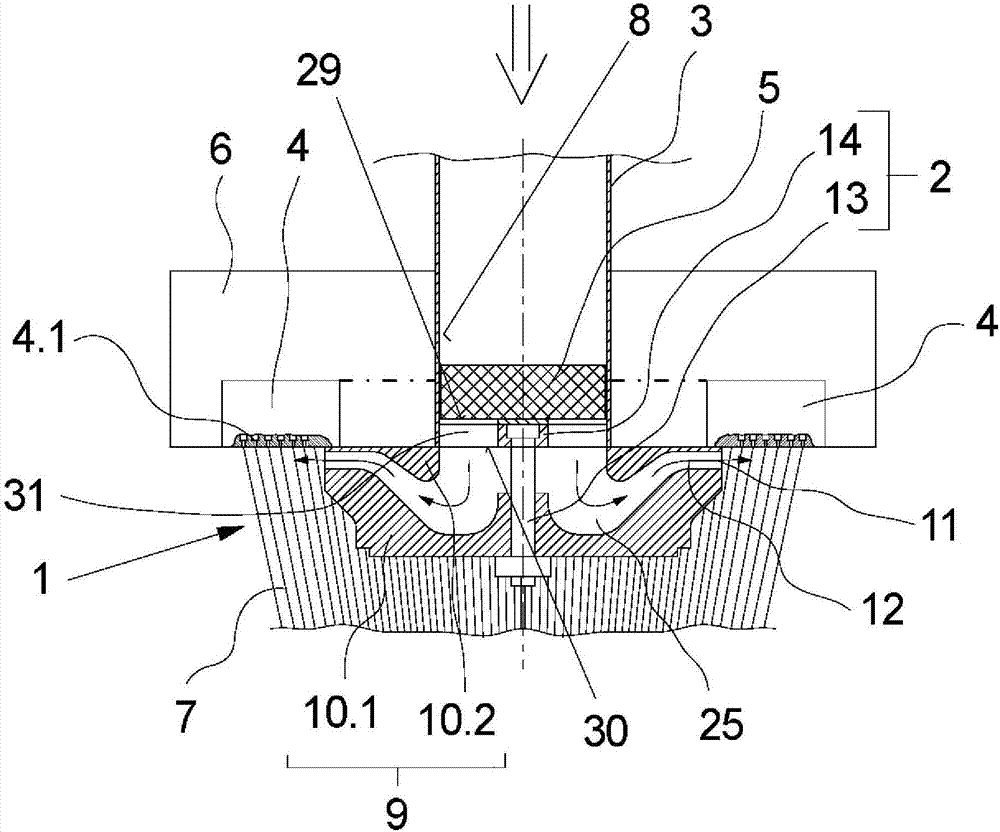

Argon blowing and powder injection device and ladle refining furnace

InactiveCN101942541AReduce dustImprove working environmentCharge manipulationFurnace typesPower flowControl valves

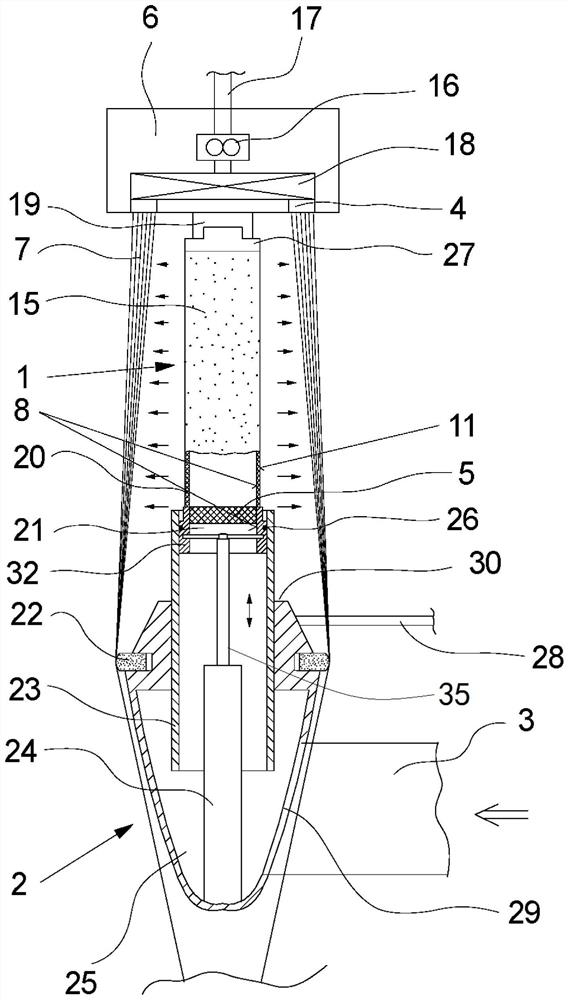

The embodiment of the invention discloses an argon blowing and powder injection device which comprises a gas source (17), a gas source channel control valve (16) connected with a gas outlet of the gas source (17), a closed pressure blanking hole (12) used for blanking, a gas mixing tank (10), a conveying pipe (8) and an electrode clamping chuck (1), wherein a blanking hole control valve (11) is installed at a discharge hole of the closed pressure blanking hole (12), the feeding hole of the gas mixing tank (10) is respectively connected with the gas source channel control valve (16) and the blanking hole control valve (11), a gas mixing tank channel control valve (9) is arranged at a discharge hole of the gas mixing tank (10), one end of the conveying pipe (8) is connected with a discharge hole of the gas mixing tank channel control valve (9), one end of the electrode clamping chuck (1) is connected with the other end of the conveying pipe (8), the electrode clamping chuck (1) is connected with an electrode tube (2) and supplies currents to the electrode tube (2), a central aperture used for conveying argon to the electrode tube (2) is formed inside the electrode clamping chuck (1), and the end of the electrode tube (2) is arranged below a liquid level of molten steel (7).

Owner:SHANDONG IRON & STEEL CO LTD

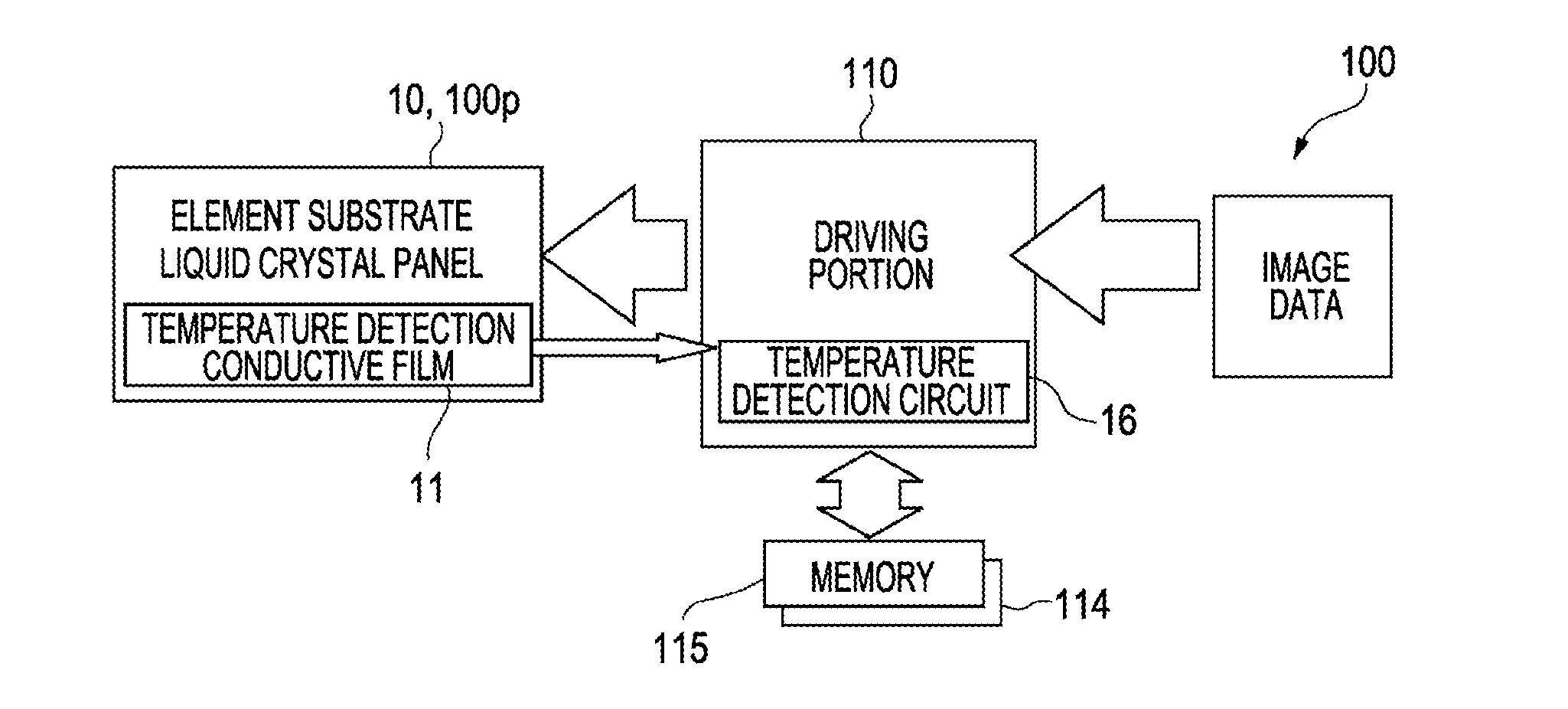

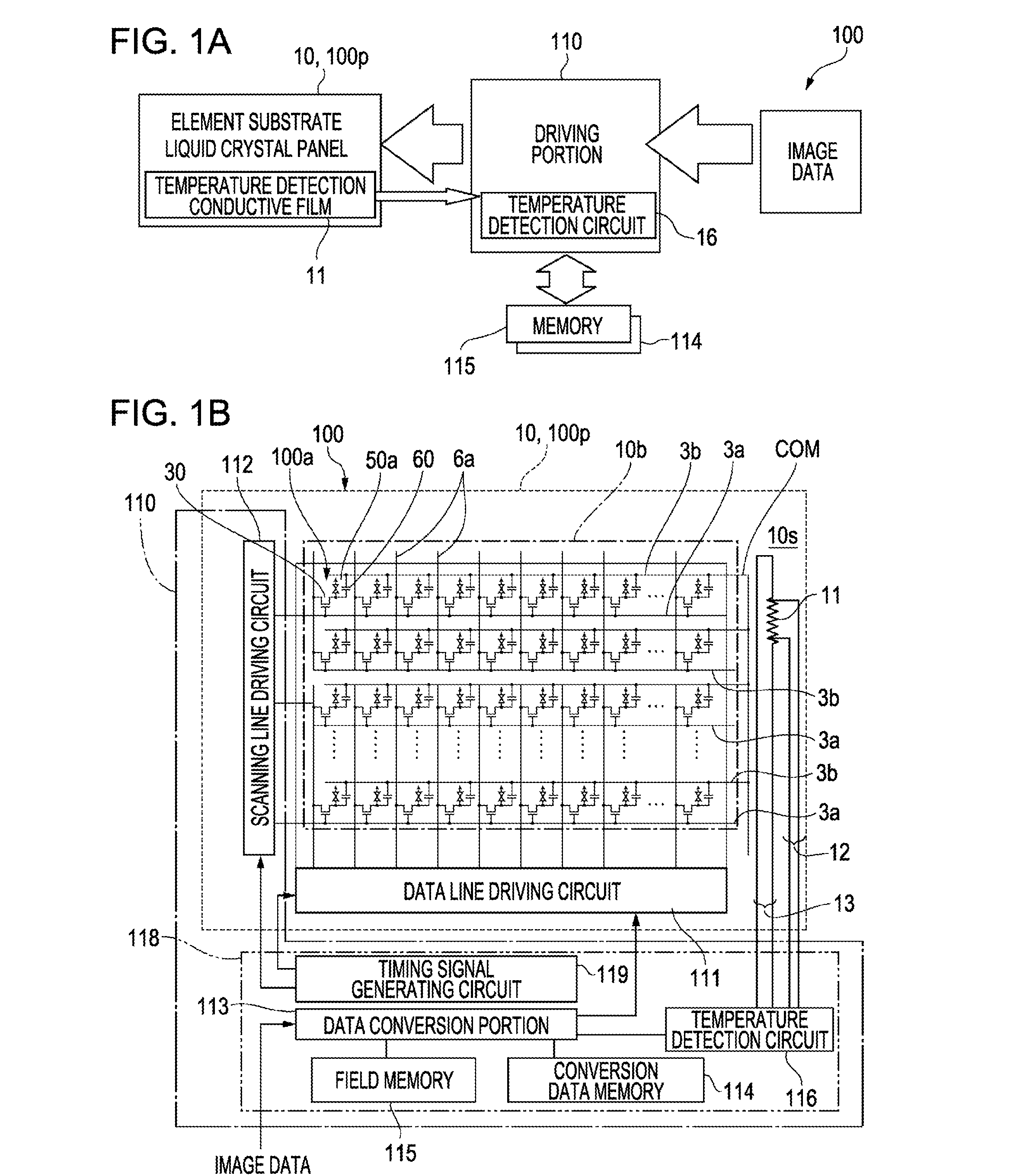

Electro-optical device, electronic apparatus and projection display device

ActiveUS20110141157A1Avoid it happening againImprove the display effectOpticsCathode-ray tube indicatorsElectrical resistance and conductanceEngineering

An electro-optical device includes an element substrate having a temperature detection conductive film formed by doping with an impurity in the same semiconductor layer as a semiconductor layer of transistor; and a driving portion for supplying a driving signal, wherein the driving portion includes a data conversion portion for converting image data and generating, as the driving signal, a digital driving signal made of an ON-voltage in which the brightness of the pixel is saturated and an OFF-voltage in which the pixel becomes a light-off state in each of a plurality of subfields in which a field period is divided on a time axis, and the data conversion portion performs a correction corresponding to a change in resistance in the temperature detection conductive film when generating the digital driving signal.

Owner:SEIKO EPSON CORP

Method for continuously producing organic isocyanate

ActiveCN101735109BReduce manufacturing costIncrease production capacityIsocyanic acid derivatives preparationOrganic compound preparationOrganic solventRetention time

The invention discloses a method for continuously preparing organic isocyanate. The method comprises the steps of: preparing an impinging stream reactor and a static mixer, wherein the impinging stream reactor comprises an outer cylinder, feed nozzles are arranged on the upper part of the outer cylinder, and a discharge outlet is arranged on the bottom of the outer cylinder; dissolving organic primary amine and phosgene into the same inert organic solvent respectively, adding the obtained solution into the outer cylinder through the feed nozzles for a phosgenation reaction, and ensuring that the average retention time of materials does not exceed 30s; and introducing the material discharged from the discharge outlet of the impinging stream reactor from a feed inlet of the static mixer provided with a heat exchange device for a reaction to generate a crude product of the organic isocyanate, wherein the average retention time of the material is less than 30min. The method of the invention utilizes good micromixing property of the impinging stream reactor to improve the mixing efficiency of raw materials, reduce the production cost of isocyanate and improve the production capacity of the isocyanate. The reactor of the invention has a simple structure, reduces the danger of solid blockage, is easy to seal, and reduces the danger of phosgene leakage.

Owner:SEDIN ENG +1

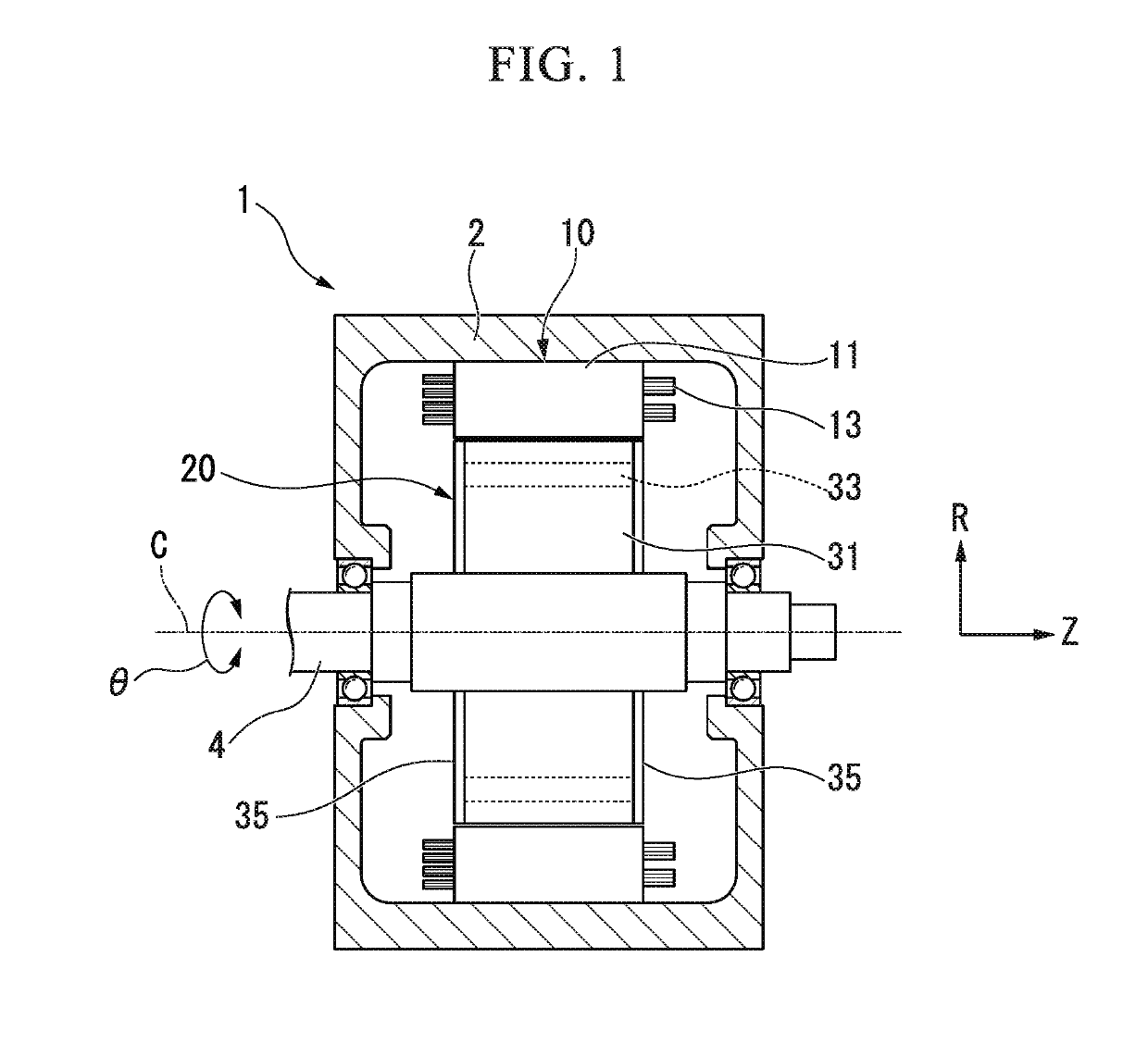

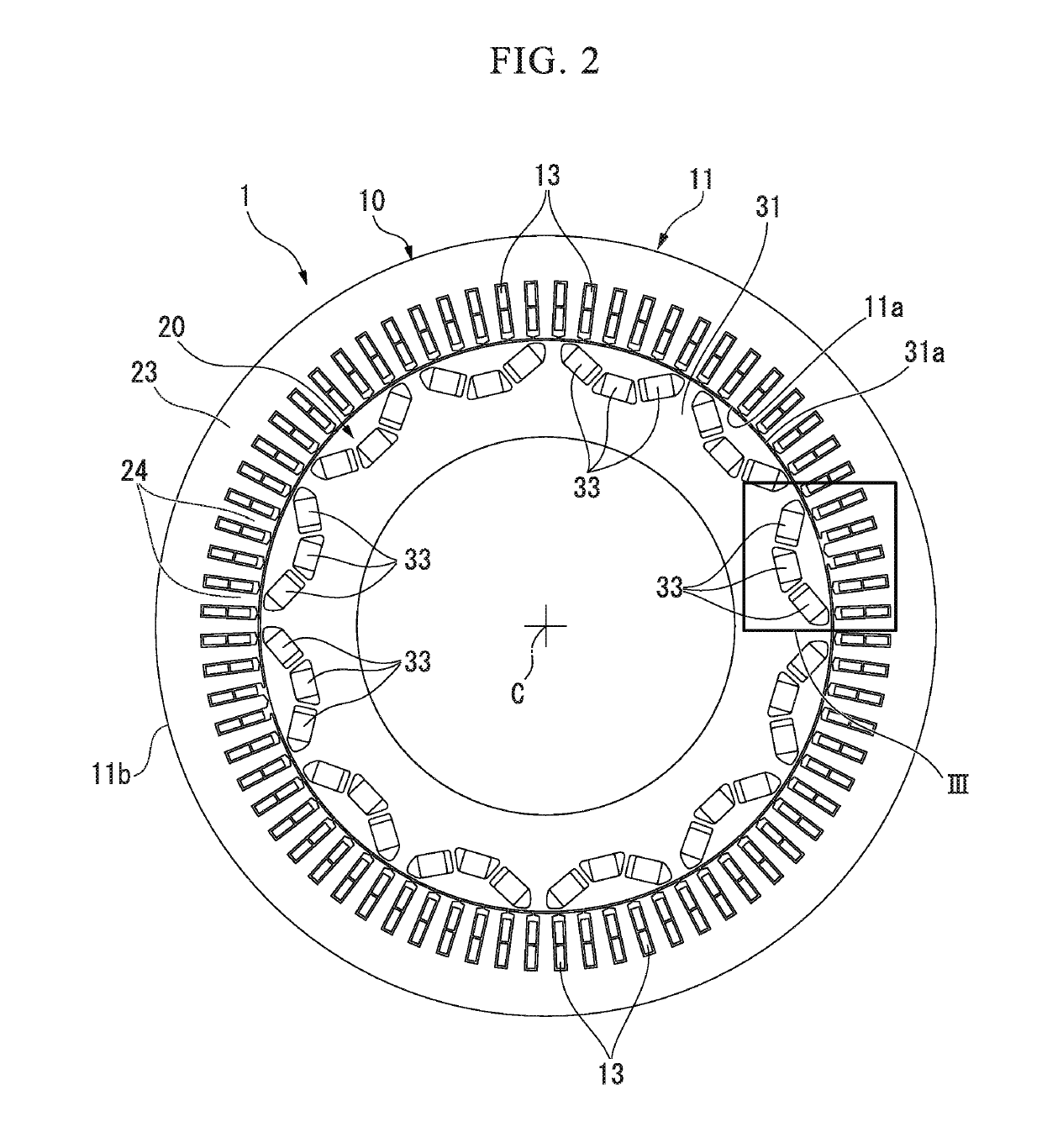

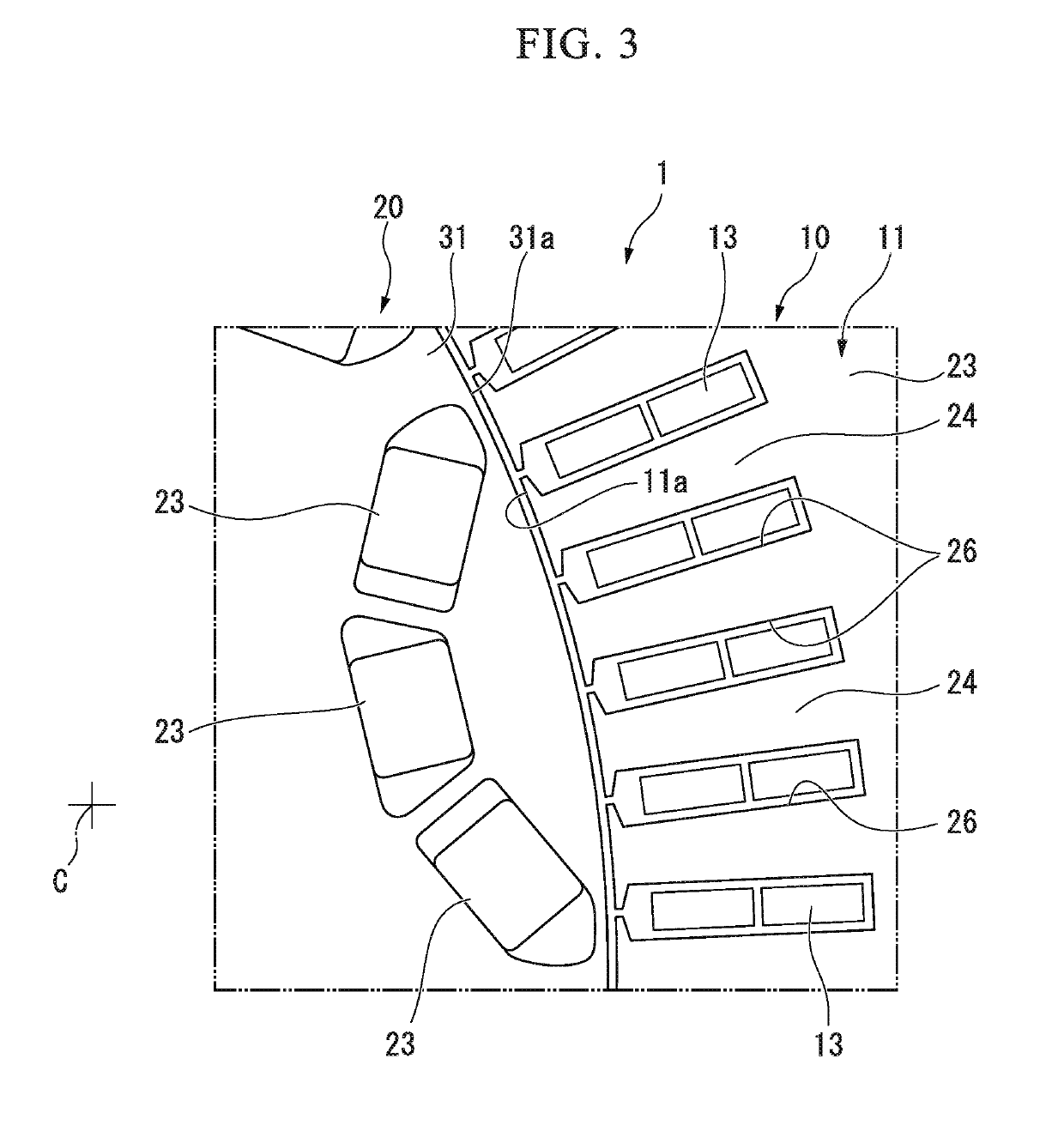

Rotary electric machine

ActiveUS20190280549A1Improve heat generationEfficient transferWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineEngineering

A rotary electric machine includes a stator. A plurality of slots are formed in a stator core of the stator, and a coil and an insulating sheet layer are inserted into the slots. A first coil side surface and a second coil side surface of the coil inserted into the slots serve as adhesive regions, which are adhered to a slot inner circumferential surface via the insulating sheet layer. In addition, a first coil end surface and a second coil end surface of the coil inserted into the slots serve as non-adhesive regions, which are maintained in a non-contact manner with respect to the slot inner circumferential surface.

Owner:HONDA MOTOR CO LTD

Temperature and humidity control device used for airtight space

InactiveCN104482618AStable temperatureConstant humidityMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention discloses a temperature and humidity control device used for an airtight space. The temperature and humidity control device comprises an air circulation device, a temperature regulation device and a humidification device. The air circulation device comprises a ventilation pipeline, ventilation holes, an airflow switching controller, an air inlet and an air outlet, wherein the ventilation holes are formed in the side wall of the ventilation pipeline, the airflow switching controller is installed on the ventilation pipeline, and the air inlet and the air outlet are formed in the ventilation pipeline. According to the temperature and humidity control device, the air temperature and humidity in the airtight space can be constant, the temperature and humidity in the airtight space can be uniformized, and meanwhile internal and external air exchange can be achieved.

Owner:HENAN ECO GREENERY AGRI CO LTD

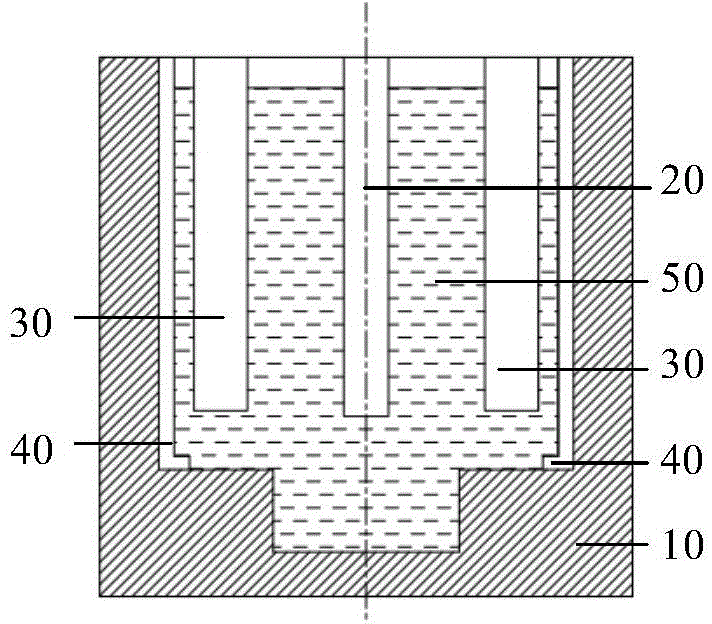

Hot air circulating drying machine

InactiveCN104964544ATemperature homogenizationEvenly heatedDrying gas arrangementsDrying chambers/containersEngineeringAir blower

The invention discloses a hot air circulating drying machine. The hot air circulating drying machine comprises a drying oven provided with a containing cavity, an end cover and a collection tank, wherein the drying oven is airtightly covered with the end cover; the collection tank is communicated with a discharge port of the drying oven; the end cover is provided with an air outlet and at least one feed port; a funnel unit is arranged under each feed port; each funnel unit comprises at least two funnels which are communicated; each funnel comprises an inverted conical part, the inverted conical part of the lower funnel is larger than that of the upper funnel; and the upper inverted conical parts are provided with a plurality of drying through holes; the drying oven is connected with a hot air circulating unit. The hot air circulating unit comprises a hot air blower, an air supply pipe, a filter and an air outlet pipe connected with the filter. A filter screen is fixed to the air outlet. At least one fan unit is fixedly arranged on the inner sidewall of the drying oven and located on one side of the funnel units. By adopting the hot air circulating drying machine, materials are heated evenly, the drying effect is good, and drying hot air can be cyclically utilized.

Owner:SUZHOU HONGHENG CHEM

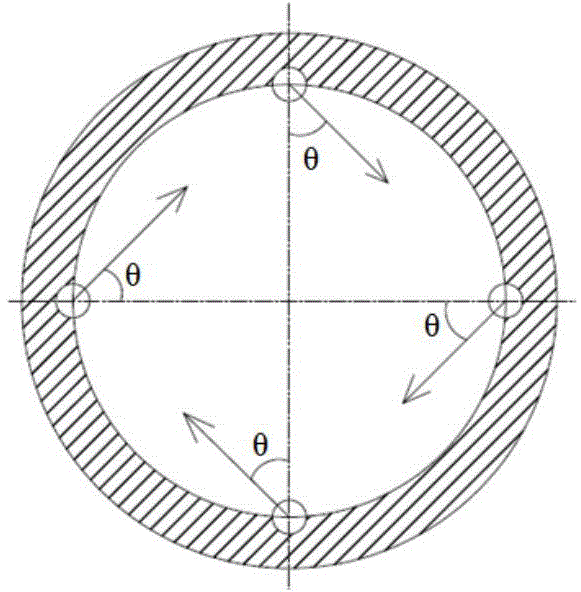

Electrolysis device and method

ActiveCN106337193AImprove liquidityImprove heat transfer performanceElectrolysis componentsElectrolysisEddy current

The invention provides an electrolysis device and method. The electrolysis device comprises an electrolysis tank, at least one cathode in the electrolysis tank, multiple anodes arranged around the cathode in intervals and multiple air blowing pipes symmetrically arranged on the inner wall of the electrolysis tank, wherein bottom outlets of the air blowing pipes stretch out of the bottom surface of the electrolysis tank and are arranged along a horizontal direction. An electrolyte at the bottom of the electrolysis tank is stirred through gas and a gas outlet direction and a cathode center direction form an a certain angle in air blowing so that the electrolyte on the bottom produces eddy currents along a horizontal direction and the electrolyte in all zones in the electrolysis tank can circularly flow and thus heat transfer and mass transfer in the electrolysis tank are improved, inner temperatures and components are uniformed, product quality is improved and furnace conditions are improved.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Refrigeration system

ActiveUS8151584B2Reduce operating powerGood energy saving effectMechanical apparatusCompression machines with non-reversible cycleEngineeringRefrigeration

When during a first action of a refrigeration system the internal cold storage temperature is held at a desired temperature by an evaporator, the refrigeration system performs a second action of increasing the cooling capacity of the evaporator to decrease the internal cold storage temperature. When during the second action the internal cold storage temperature reaches a minimum temperature Tmin, the refrigeration system stops a compressor and performs a third action. When during the third action the internal cold storage temperature reaches a maximum temperature Tmin, the refrigeration system drives the compressor and performs the first action.

Owner:DAIKIN IND LTD

Quality Control Method of 37mn Round Tube Billet with φ280mm

ActiveCN105695659BImprove purityHomogenization of ingredientsManufacturing convertersMolten steelParameter control

The invention discloses a method for controlling the internal quality of a 37Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, RH vacuum treatment and continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

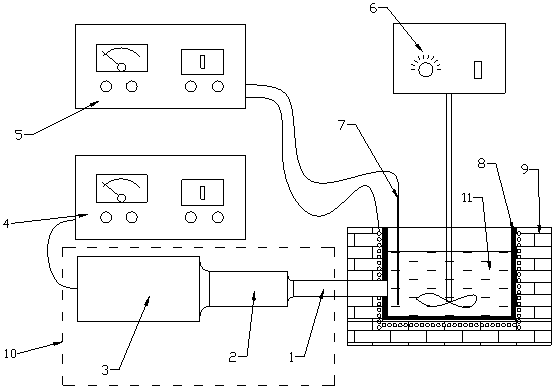

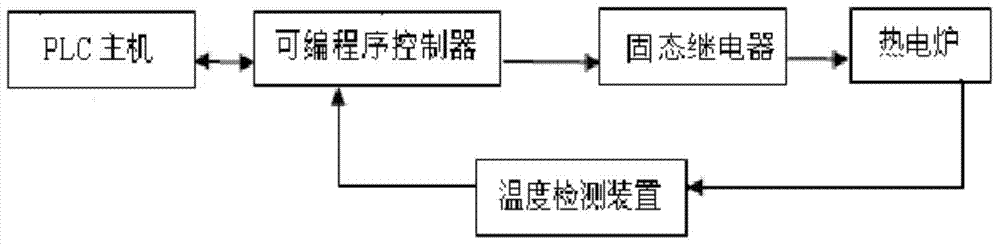

Thermoelectric furnace provided with temperature control system

InactiveCN103575091ARealize automatic controlTemperature homogenizationLighting and heating apparatusAutomatic controlCombustion chamber

The invention discloses a thermoelectric furnace provided with a temperature control system. The thermoelectric furnace comprises a furnace body, a power unit and the temperature control system, wherein the furnace body consists of a combustion chamber, a furnace bottom and a furnace cover; and the power unit comprises a transformer, a rectifier, a short net system and power supply electrodes, the power supply electrodes consist of the negative electrode and the positive electrode, the negative electrode is arranged on the furnace cover, and the positive electrode is arranged at the furnace bottom. According to the thermoelectric furnace, smelted metal is located inside the combustion chamber between the negative electrode and the positive electrode, the metal is smelted by direct-current arcs produced between the negative electrode and the positive electrode, and strong electromagnetic stirring is formed in the molten liquid metal, so that the temperature and the composition of a metal solution are uniform. According to the thermoelectric furnace, a programmable controller is used, so that automatic control of the temperature of the thermoelectric furnace can be realized, the temperature control is accurate, and the operation cost of the whole system is low.

Owner:ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

Center porosity control method for 35CrMo round blooms with cross section diameter being 280 mm

ActiveCN105803151AImprove purityGood exit conditionsManufacturing convertersPorosityCrystal structure

The invention discloses a center porosity control method for 35CrMo round steel casting blooms with cross section diameter being 280 mm. The method comprises the following steps: converter smelting, LF molten steel refining, RH refining and continuous casting of molten steel, and is characterized in that crystallizer electromagnetic stirring and solidification end electromagnetic stirring are combined in the continuous casting step. The method has the benefits that first, in the molten steel smelting step, control is carried out according to reasonable parameters, so as to improve the impurity of molten steel and ensure that the discharging conditions of the molten steel are optimal; and then, in the molten steel casting step, crystallizer electromagnetic stirring and solidification end electromagnetic stirring are combined to ensure that molten steel ingredients and temperature are homogenized, a blank shell grows uniformly, and columnar crystal structures are consistently scoured and fused in the stirring process, so that the areas of center porosity in the casting blooms are reduced, and the density is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for controlling blank casting quality of phi-280mm 30Mn circular tube blank

ActiveCN105695657AImprove purityHomogenization of ingredientsManufacturing convertersMolten steelSteel casting

The invention discloses a method for controlling the internal quality of a 30Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

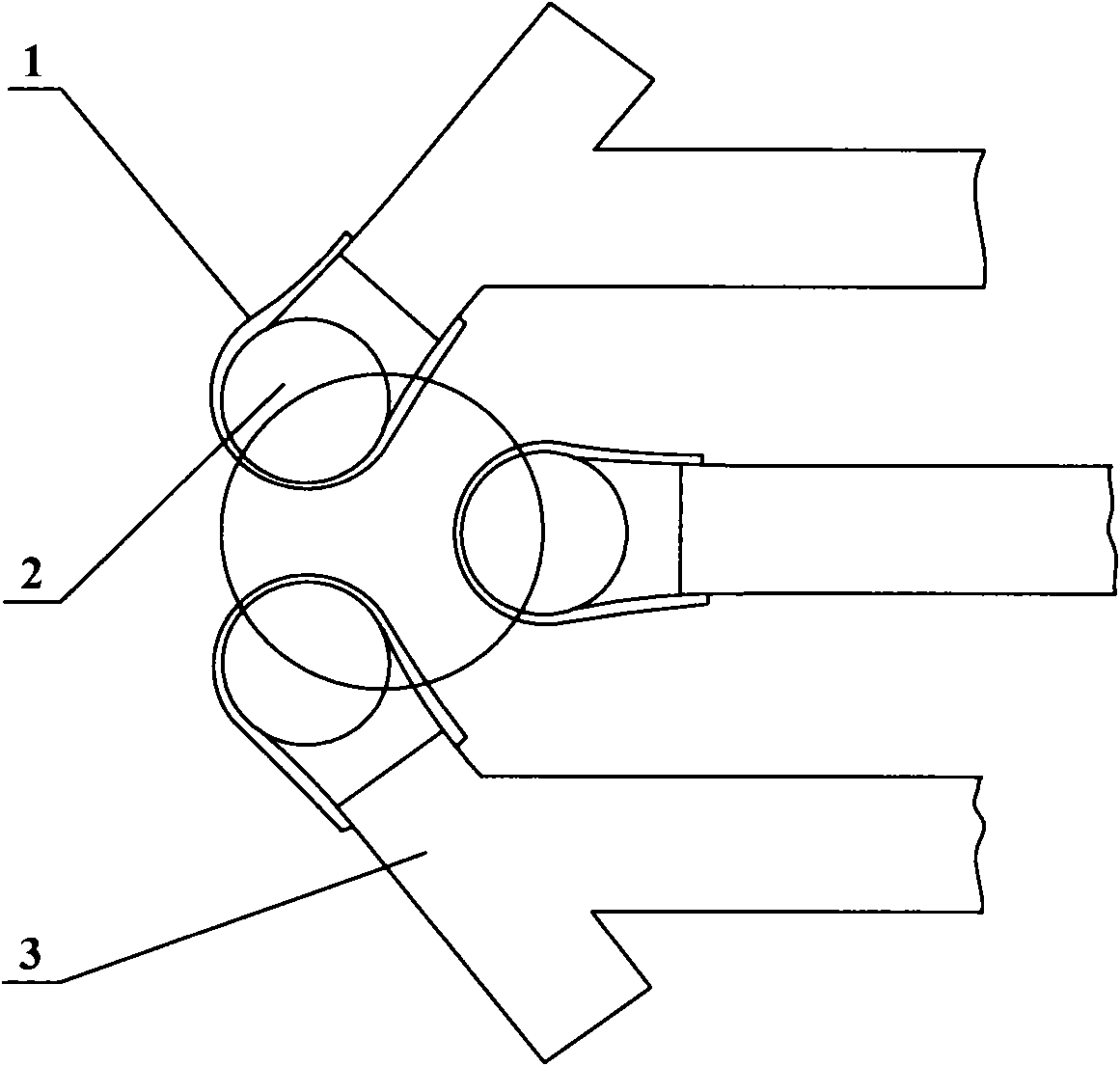

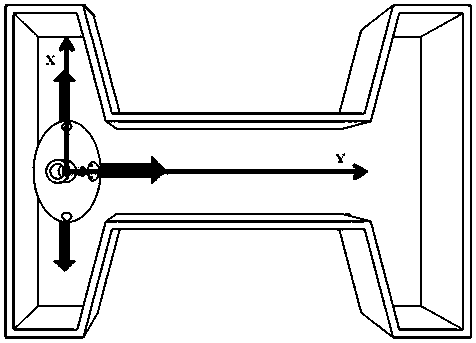

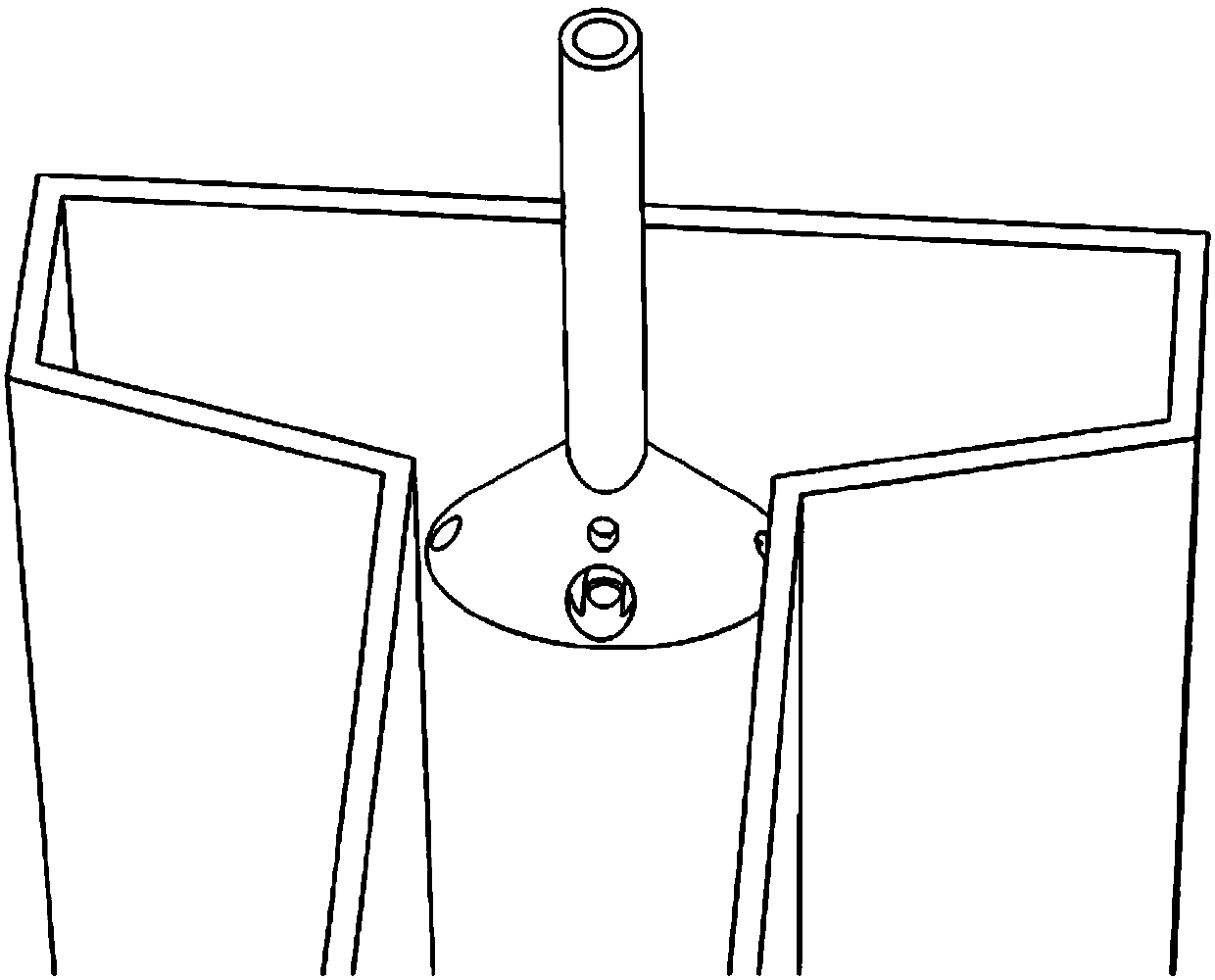

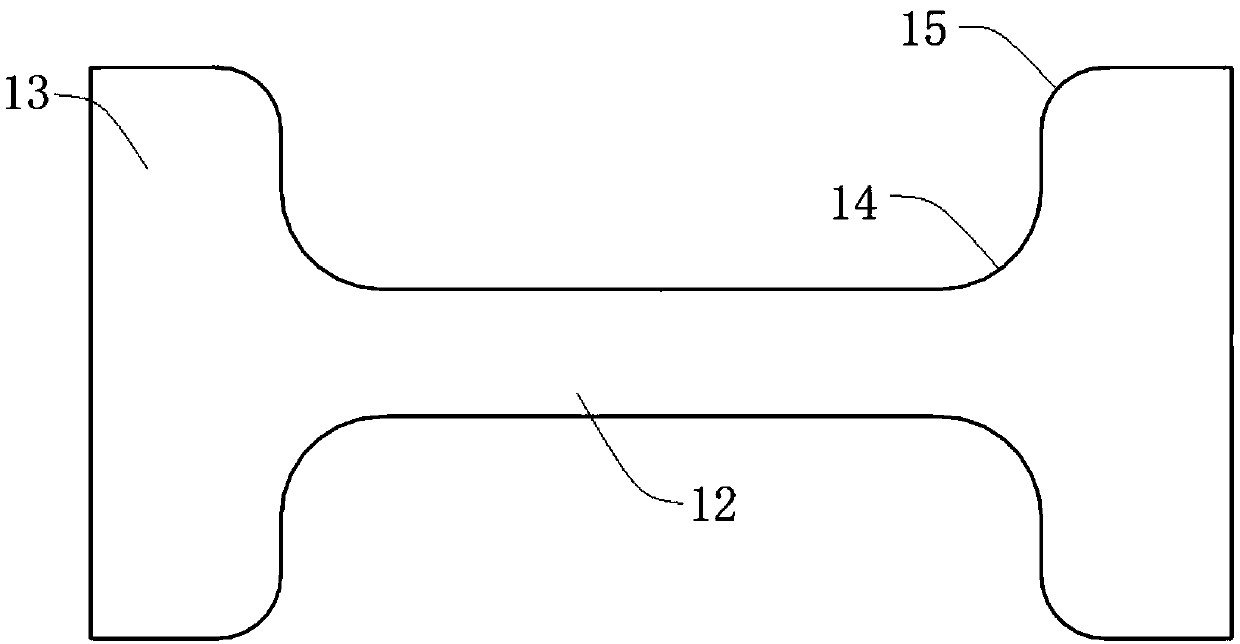

Crystallizer submersed nozzle of beam blank single-point nonequilibrium protective casting and using method

The invention discloses a crystallizer submersed nozzle of beam blank single-point nonequilibrium protective casting and a using method and belongs to the technical field of beam blank continuous casting. The nozzle comprises an isometric section and a reducing section, wherein the cross section of the inner side of the isometric section is round, the isometric section and the reducing section areconnected to form a submersed nozzle body, the cross section of the inner side of a joint of the isometric section and the reducing section is round, the inner cross section of an free end of the reducing section is oval; and a through hole X, a through hole Y and a through hole Z are formed in the reducing section in the X direction, the Y direction and the Z direction. During the beam blank single-point nonequilibrium protective casting, flow speed of molten steel can be reduced, the impact depth of the molten steel in a crystallizer is reduced, a flow field and a temperature field are homogenized, the washout to a wall surface of the crystallizer is not caused, and casting blank condensation is not influenced, an obtained product is few in defects and high in quality, and the crystallizer submersed nozzle has the advantages of being simple in structure, convenience in using method and easy in implementation.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

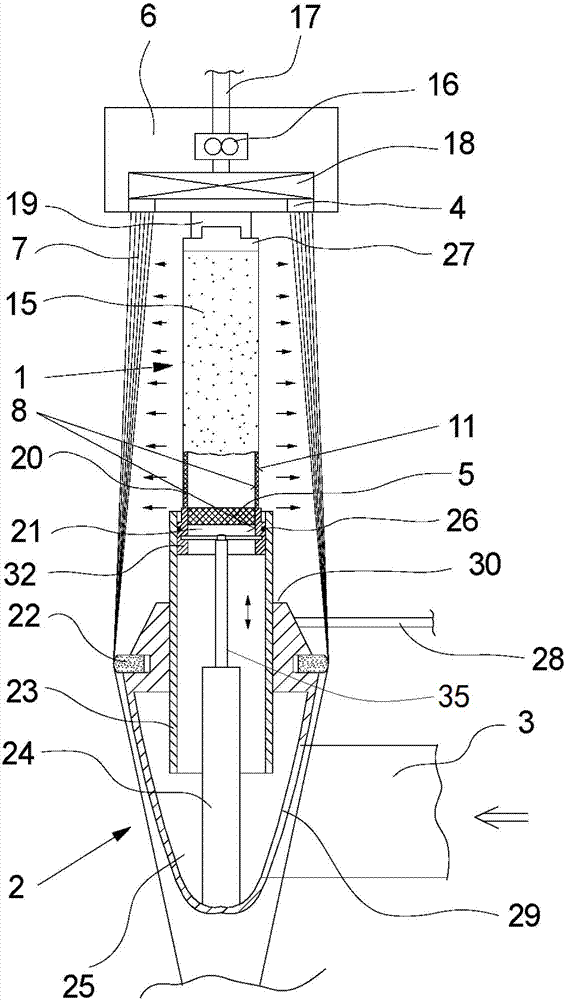

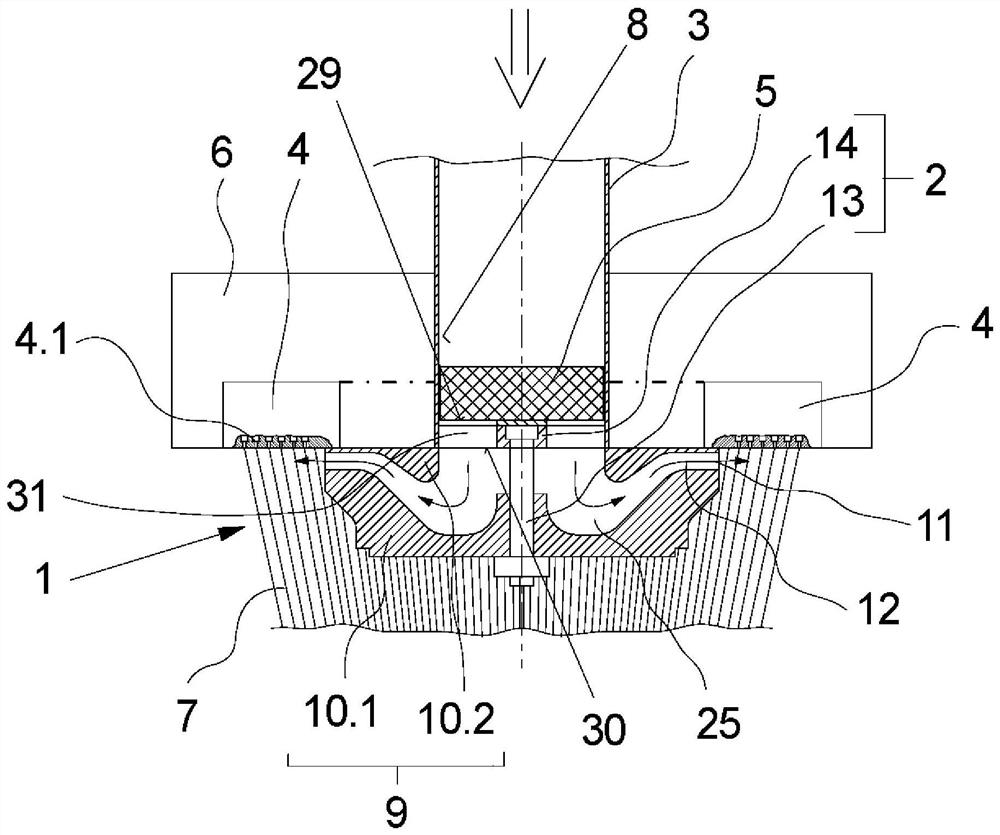

Apparatus for cooling an annular extruded filament bundle

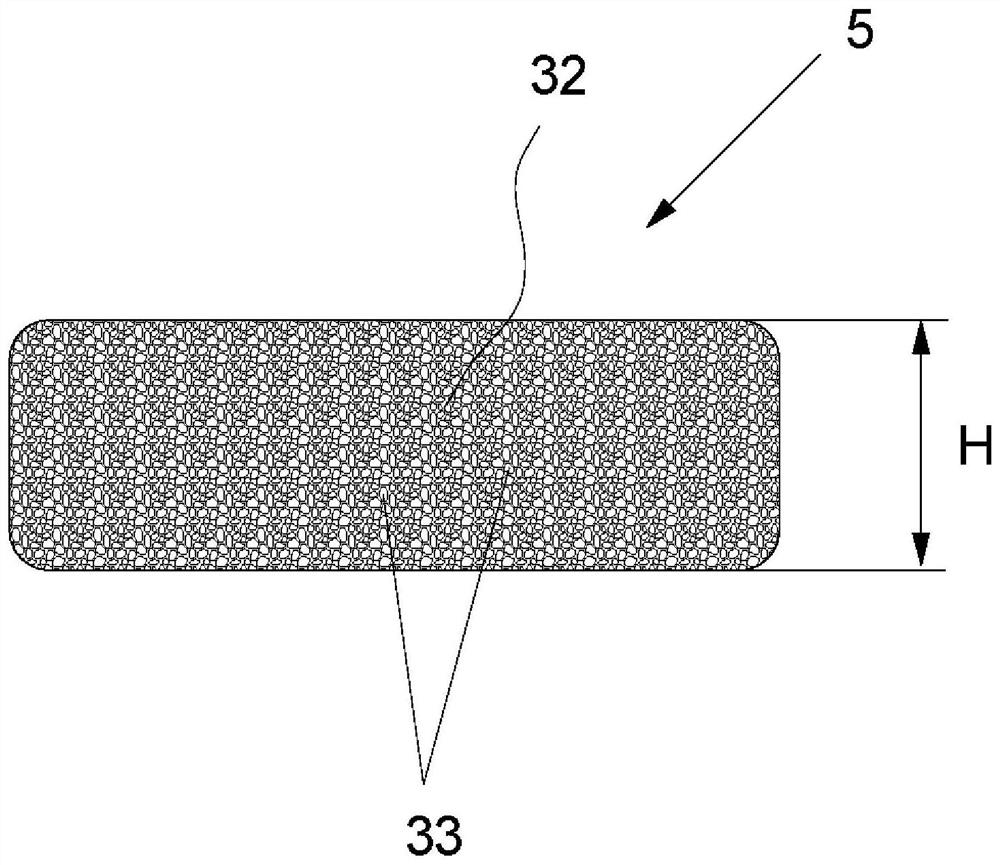

ActiveCN107304487AUniform temperatureTemperature coordinationFilament/thread formingMetal foamAir temperature

The invention relates to a device for cooling a ring-shaped extruded filament bundle, which are extruded through a plurality of nozzle bores of a ring spinning nozzle. The device has a blower power generator, which has a radially encircling blower outlet and is arranged centrally below the ring spinning nozzle. The blower generator is held by a connection adapter which connects the blower generator with a supply air duct. In order to equalize the supplied cooling air immediately before entering the blower power generator, in particular with regard to a cooling air temperature, a flow barrier is made of an open-pore metal foam is preferably assigned to the connection adapter, preferably an open-pore aluminum foam.

Owner:OERLIKON TEXTILE GMBH & CO KG

Semiconductor packaging stack combination construction with movable outer terminal

InactiveCN101431066BSolder joint cracking will not occurIncrease interface heat conductionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorElectrical connection

Owner:POWERTECH TECHNOLOGY INC

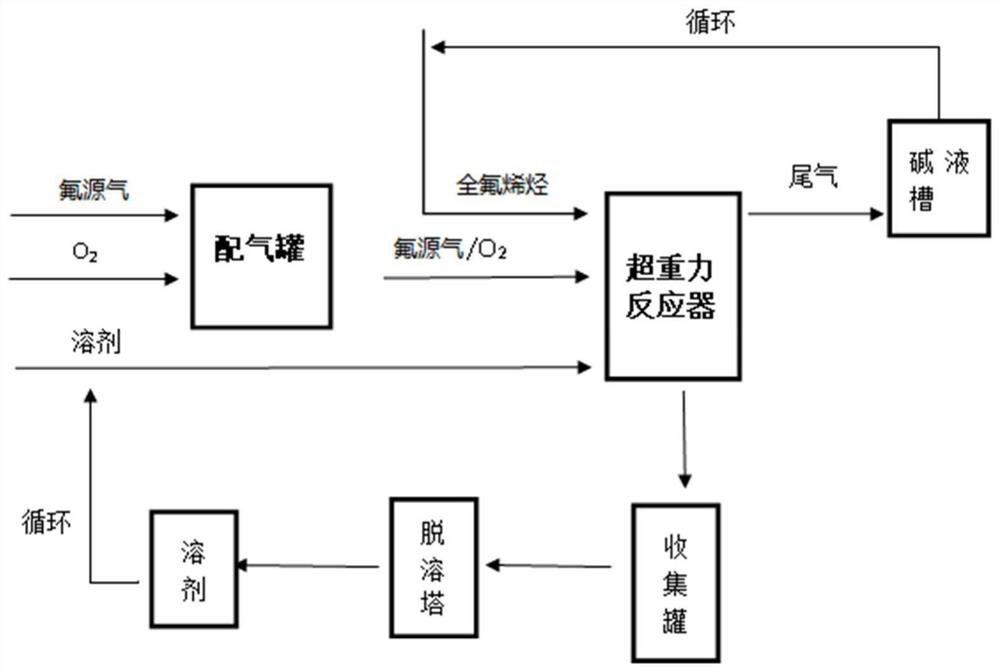

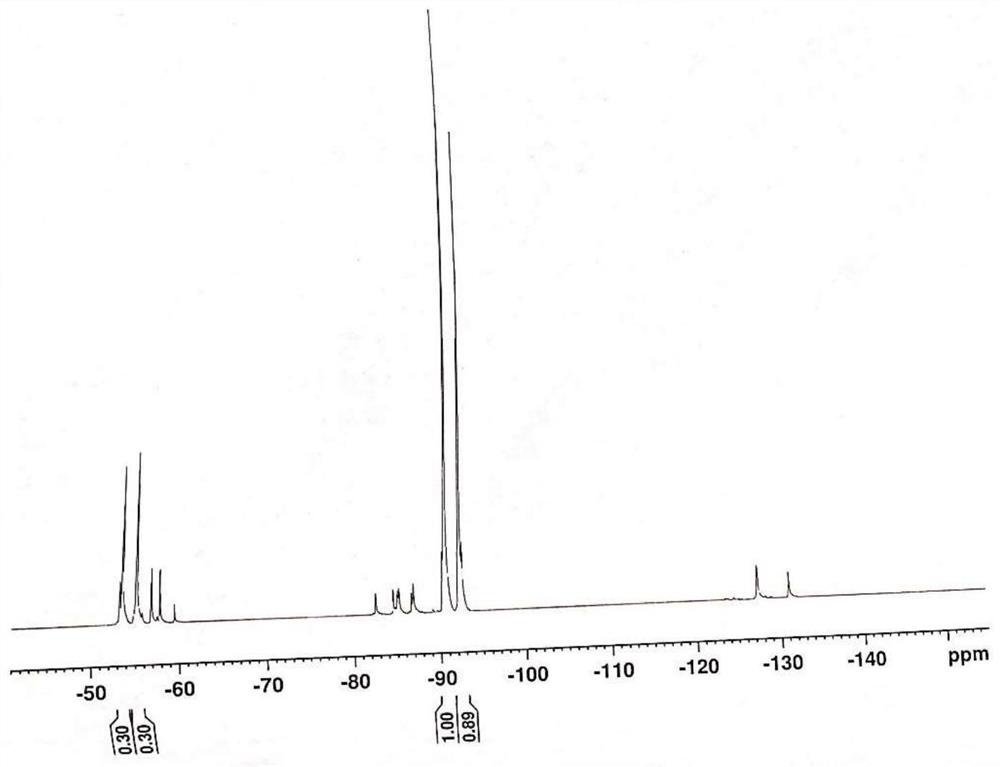

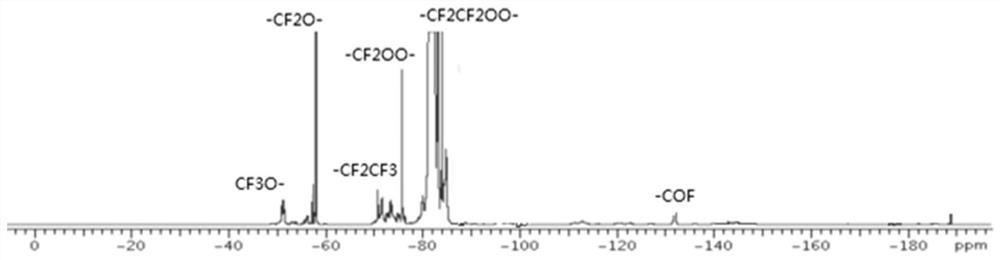

Preparation method of perfluoropolyoxyalkylene peroxide and perfluoropolyether

PendingCN112940237AAchieve stable control and adjustableRegulatory decentralizationOrganic compound preparationChemical/physical/physico-chemical moving reactorsChemical industryPerfluoropolyether

The invention discloses a preparation method of perfluoropolyoxyalkylene peroxide and perfluoropolyether, and relates to the technical field of fluorine chemical industry. The preparation method of perfluoropolyoxyalkylene peroxide comprises the step of synthesizing perfluoropolyoxyalkylene peroxide from perfluoroalkene and oxygen in a supergravity reactor. According to the preparation method, the problems that perfluoropolyoxyalkylene peroxide with high number-average molecular weight cannot be efficiently prepared, the yield is low and the reaction safety is low in the existing preparation method are solved, the number-average molecular weight of the perfluoropolyoxyalkylene peroxide compound can be stably controlled and adjusted between 600 and 50000, the reaction safety and the yield are high, and the preparation method is suitable for industrial continuous production.

Owner:JUHUA GROUP TECH CENT

Equipment for cooling monofilament tufts for annular extrusion

ActiveCN107304487BUniform temperatureTemperature coordinationFilament/thread formingSpinningEngineering

The invention relates to a device for cooling an annular extruded monofilament tuft extruded through a plurality of nozzle openings of an annular spinning nozzle. The device has a blow air generator which has a radially surrounding blow air outlet and is arranged centrally below the annular spinning nozzle. The blow flow generator is held by a connection adapter which connects the blow flow generator to the intake channel. In order to homogenize the incoming cooling air immediately before entering the blowing flow generator, in particular with respect to the temperature of the cooling air, according to the invention, the connection adapter is equipped with a porous metal foam, preferably porous aluminum foam - a flow barrier made of aluminum.

Owner:OERLIKON TEXTILE GMBH & CO KG

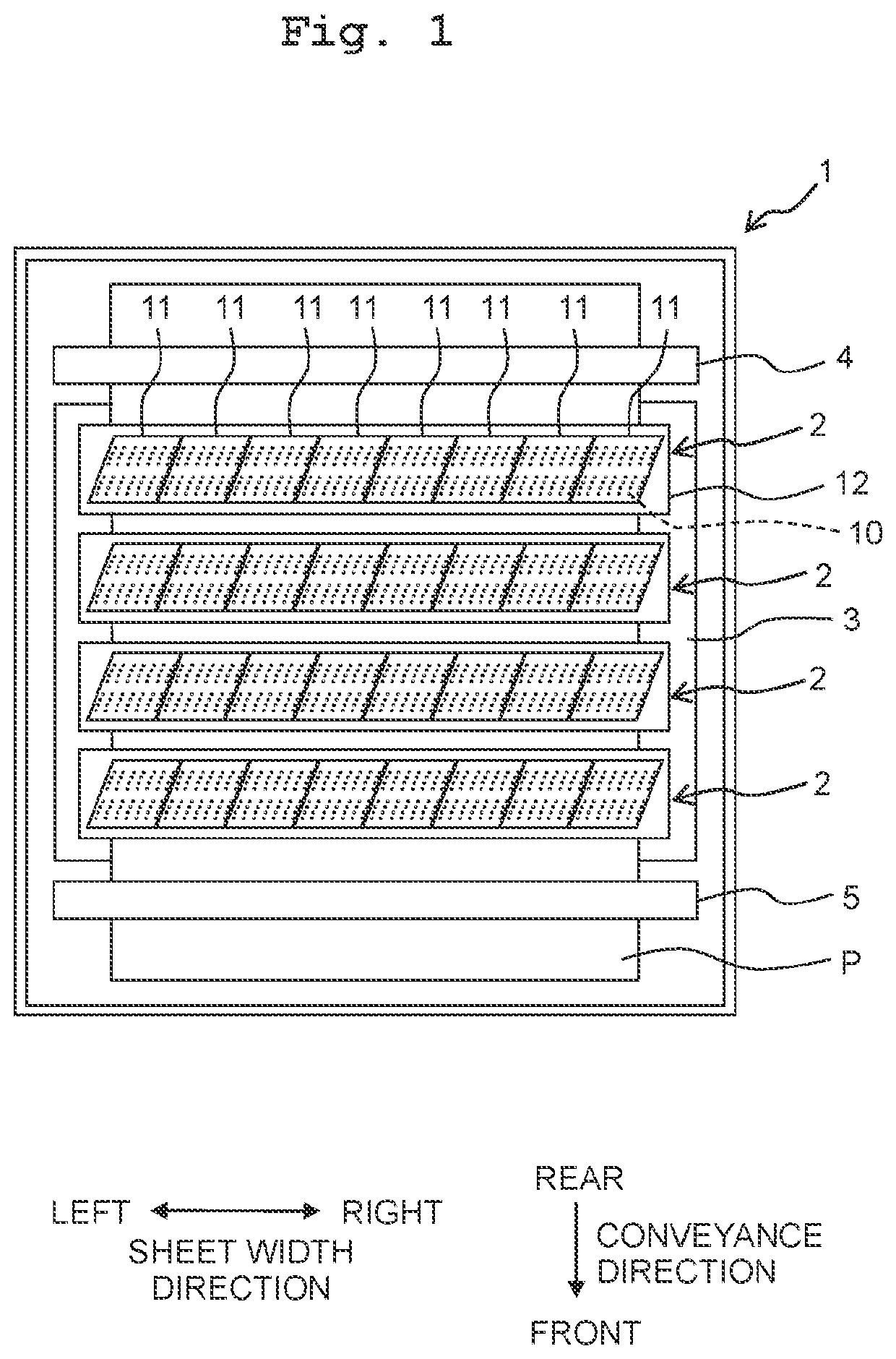

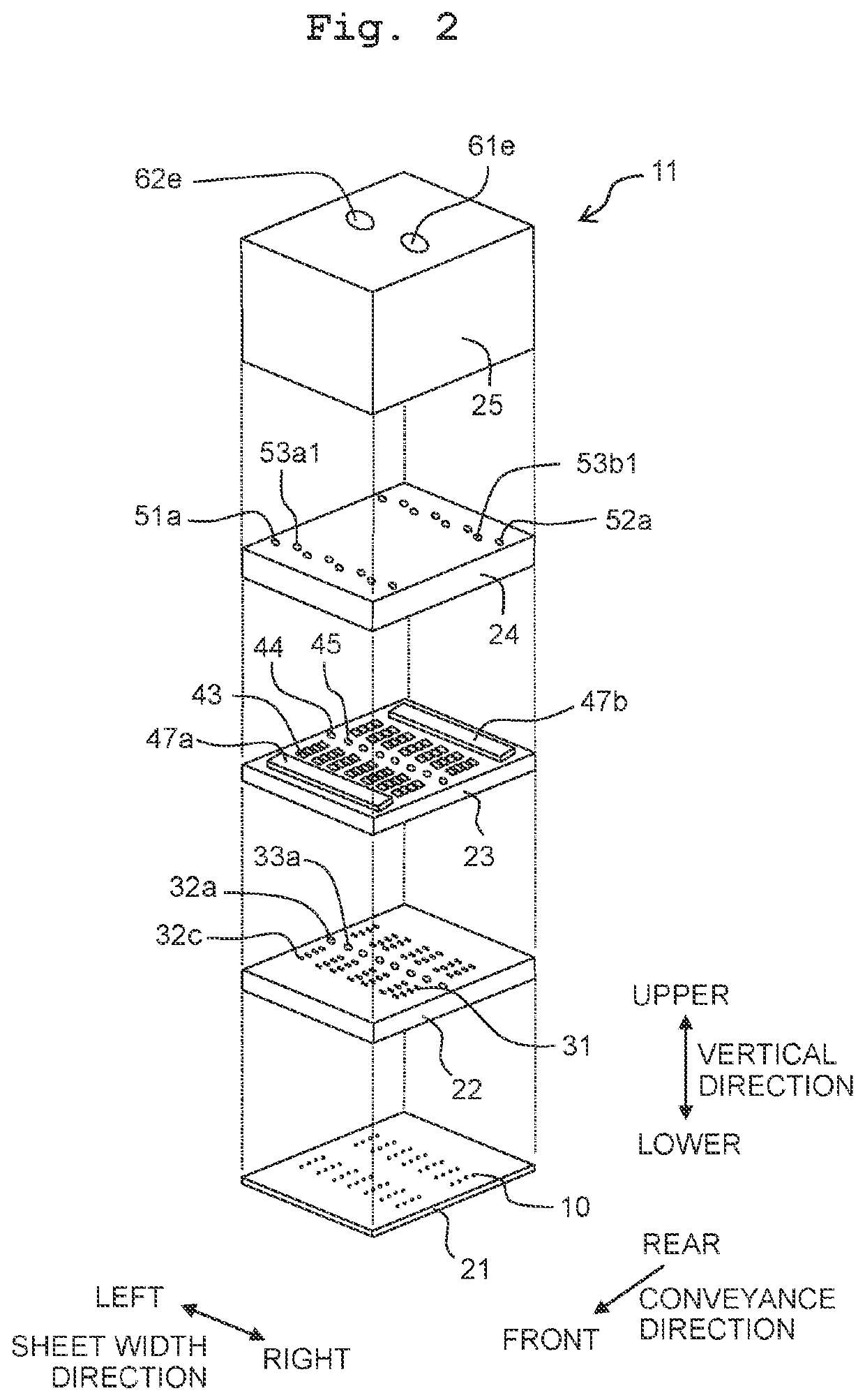

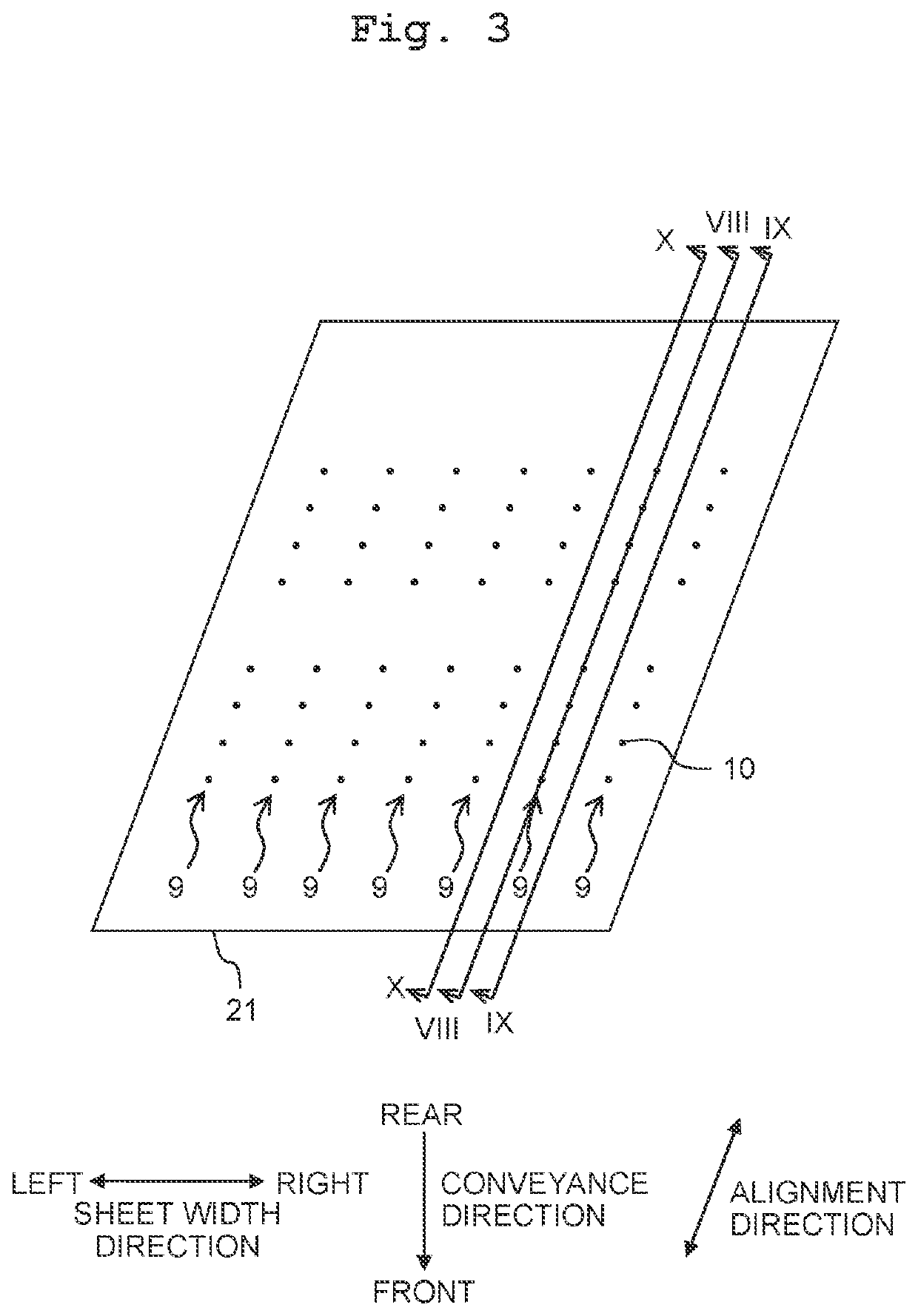

Liquid Discharge Head

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com