Method for refinement of rare earth-rich phase of rare earth-magnesium alloy

A technology of rare earth-rich phases and rare earth master alloys, which is applied in the field of rare earth-rich phases in rare earth magnesium alloys, can solve the problems of reducing the strengthening effect of rare earth elements on magnesium alloys, coarseness, etc., and achieve cost improvement, refinement of rare earth phase size, and improved The effect of rheological shaping technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

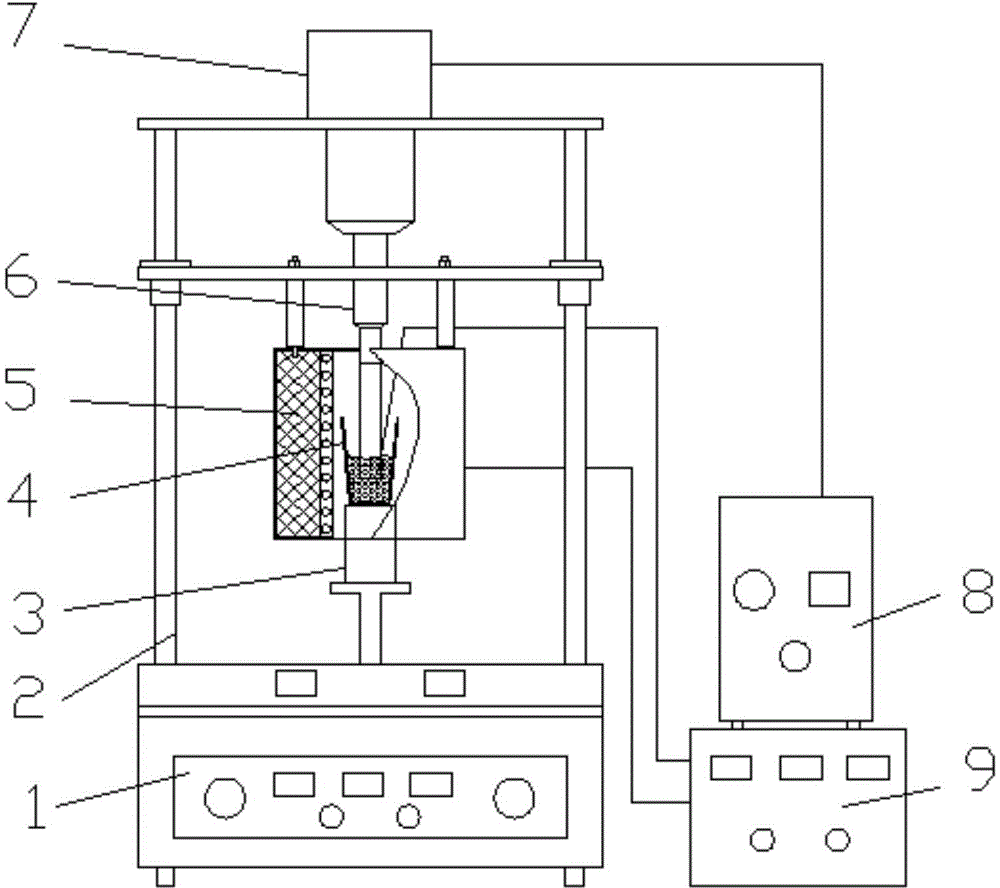

Method used

Image

Examples

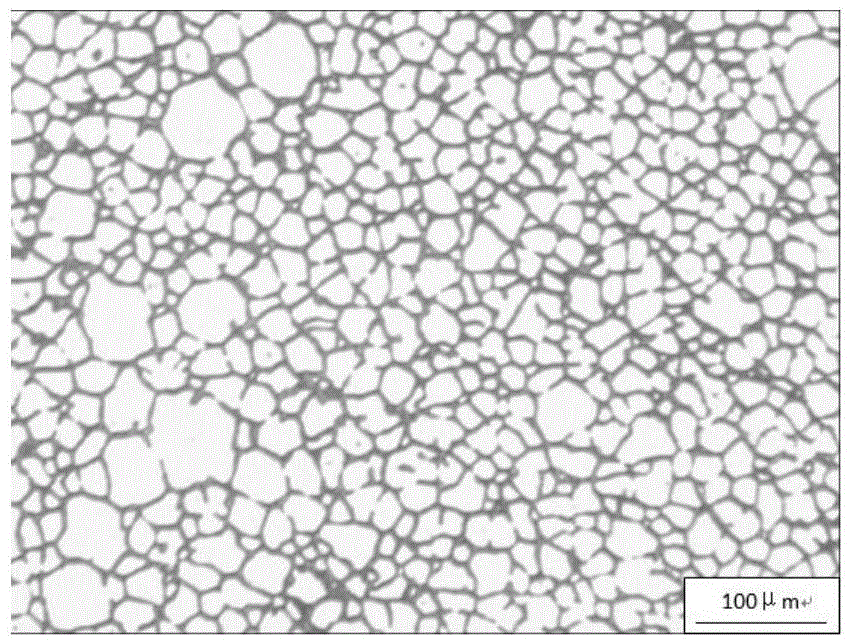

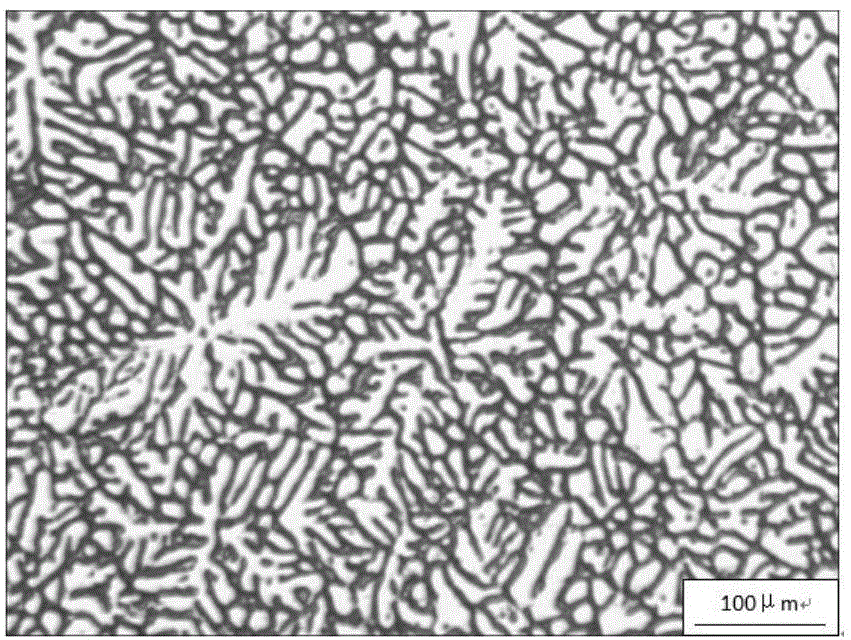

example 1

[0036] Mg-6Zn-3RE-1.4Y rare earth magnesium alloy was prepared by using pure Zn (99.9%, mass fraction, the same below), pure Mg (99.9%), Mg-RE master alloy, Mg-Y master alloy, etc. as raw materials. The melting and refining process is as follows: all tools in contact with the alloy melt are painted in advance, and tools, raw materials, and sampling water-quenched quartz tubes are all preheated at 200°C for about 1 hour. Turn on the resistance furnace, add magnesium ingots when the crucible is preheated to about 150°C, and feed N when the temperature reaches 300°C 2 +SF 6 Protective gas, adjust the temperature to 700°C, add pure metal Zn, Mg-RE master alloy, and Mg-Y master alloy in sequence after the magnesium ingot is completely melted, adjust the temperature to 750°C, feed high-purity Ar gas for refining for 10 minutes, and degas scum, and then remove the scum. Use the temperature control device to keep the temperature of the alloy liquid at about 690-700°C. Take an appro...

example 2

[0039] The Mg-4Al-2RE rare earth magnesium alloy (the content of each alloy component is in mass percentage, the same below) is treated by ultrasonic vibration, and formed in a gravity metal mold. The melting and refining process is as follows: all tools in contact with the alloy melt are painted in advance, and tools, raw materials, and sampling water-quenched quartz tubes are all preheated at 200°C for more than half an hour. Turn on the resistance furnace, add magnesium ingots when the crucible is preheated to about 150°C, and feed N when the temperature reaches 300°C 2 +SF 6 Protective gas, adjust the temperature to 700°C, after the magnesium ingot is completely melted, add pure metal Al, Mg-RE intermediate alloy, and then adjust the temperature to 750°C, feed high-purity Ar gas for refining for 15 minutes, degas and remove slag, and then remove scum. The temperature of the alloy liquid is kept at about 700°C by means of a temperature control device. Take an appropriate...

example 3

[0042] The Mg-3Zn-1.2Nd-0.6Y rare-earth magnesium alloy (the content of each alloy component is in mass percentage, the same below) is treated by ultrasonic vibration, and formed in a gravity metal mold. The melting and refining process is as follows: all tools in contact with the alloy melt are painted in advance, and tools, raw materials, and sampling water-quenched quartz tubes are all preheated at 200 ° C for more than 1 hour. Turn on the resistance furnace, add magnesium ingots when the crucible is preheated to about 150°C, and feed N when the temperature reaches 300°C 2 +SF 6 Protective gas, adjust the temperature to 700°C, add pure metal Zn, Mg-Nd master alloy, and Mg-Y master alloy in turn after the magnesium ingot is completely melted, adjust the temperature to 750°C, and feed high-purity Ar gas after the melt is completely melted Refining for 10 minutes, degassing and removing slag, and then removing scum. The temperature of the alloy liquid is kept at about 700°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com