Electrolysis device and method

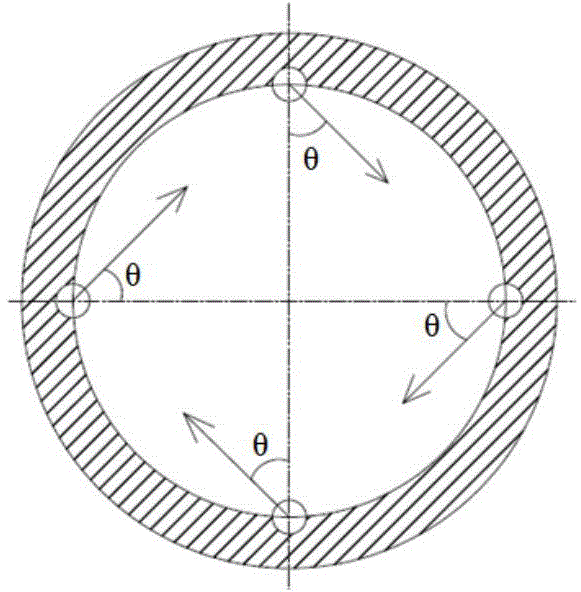

A technology of an electrolysis device and an electrolysis method, applied in the field of electrolysis, can solve problems such as the dead zone of the electrolysis cell, and achieve the effects of enhancing heat and mass transfer, slowing down nodules, and enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

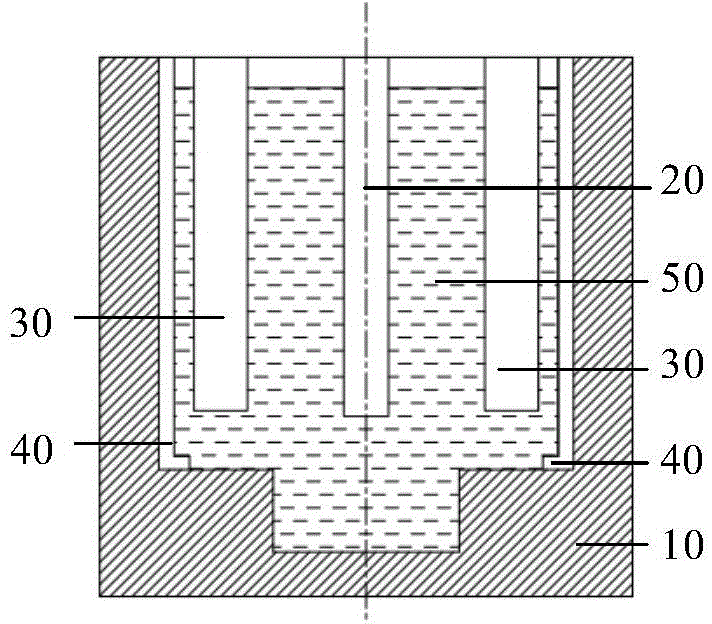

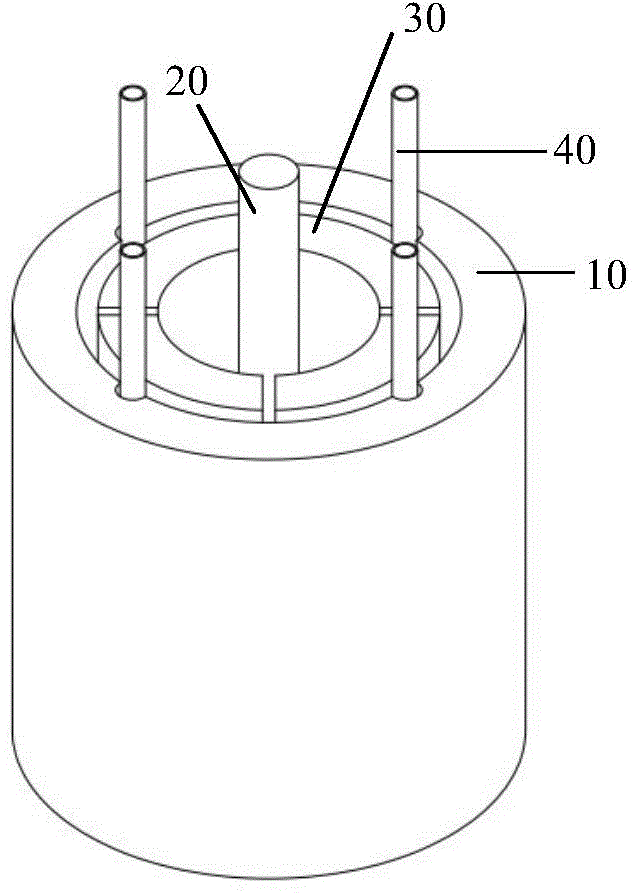

Embodiment 1

[0068] Take NdF 3 and LiF mixture as a molten salt electrolyte, where NdF 3 The mass ratio to LiF is 7:1, graphite is used as anode, molybdenum rod is used as cathode, electrolysis is performed at 1050°C, the electrolysis voltage is 8.8V, under the action of direct current, the added Nd 2 o 3 Nd in 3+ precipitated on the surface of the cathode. The metal droplets are formed and fall into the molybdenum crucible at the bottom of the electrolytic cell. After 2 hours of electrolysis, the metal droplets are scooped out and poured into the mold. Nodules appear on the bottom of the side wall of the furnace body after about 24 hours of operation, requiring manual stirring.

[0069] Main technical indicators: current efficiency is 72.7%, carbon content is 330ppm, iron content is 1250ppm, and the service life of a single anode is 48-56h.

Embodiment 2

[0071] Take NdF 3 and LiF mixture as a molten salt electrolyte, where NdF 3 The mass ratio to LiF is 7:1, with graphite as the anode and molybdenum rod as the cathode, electrolyze at 1050°C, the electrolysis voltage is 8.5V, under the action of direct current, the added Nd 2 o 3 Nd in 3+ precipitated on the surface of the cathode. The metal droplets are formed and fall into the molybdenum crucible at the bottom of the electrolytic cell. After 2 hours of electrolysis, the metal droplets are scooped out and poured into the mold. Nodules appear on the bottom of the side wall of the furnace body after about 24 hours of operation, requiring manual stirring.

[0072] Main technical indicators: current efficiency is 70.6%, carbon content is 315ppm, iron content is 1020ppm, and the service life of a single anode is 48-56h.

Embodiment 3

[0080] to DyF 3 and LiF mixture as a molten salt electrolyte, where DyF 3 The mass ratio to LiF is 6:1, with graphite as the anode and iron rod as the cathode, electrolyze at 1080°C, the electrolysis voltage is 10.0V, under the action of direct current, the added Dy 2 o 3 Dy in 3+ It precipitates on the surface of the cathode and interacts with the iron cathode to form DyFe alloy droplets, which fall into the iron crucible at the bottom of the electrolytic cell. After 2 hours of electrolysis, the iron crucible is lifted out, and the alloy droplets obtained by electrolysis are poured into the mold. The bottom of the side wall of the furnace body has accumulated material after 20 hours of operation, and it needs to be manually stirred with an iron rod.

[0081] Main technical indicators: current efficiency 70%, carbon content in DyFe alloy 325ppm, mass percentage content of Fe in alloy 19.4%, service life of a single anode is 48-56h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com