A homogenization deformation heat treatment method for rapid refinement and homogenization of as-cast aluminum-lithium alloy

A deformation heat treatment and homogenization treatment technology, applied in the direction of improving process efficiency, can solve the problems of limited control of component particles and grain growth, and achieve the effect of short treatment time, fine grain size and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A homogenization deformation heat treatment method for rapid refinement and homogenization of cast aluminum-lithium alloy, as follows:

[0039] Step 1: according to the mass percentage of elements: Li is 1.5%, Cu is 2.8%, Mg is 0.25%, Zr is 0.12%, Mn is 0.3% and the balance is aluminum. The proportioning raw materials of pure magnesium block, pure lithium particle, Al-50Cu master alloy, Al-5Zr master alloy, Al-20Mn master alloy and pure aluminum block are weighed.

[0040]Step 2: Smelting: Add pure aluminum block, aluminum-copper master alloy, aluminum-zirconium master alloy, and aluminum-manganese master alloy into the graphite crucible, sprinkle high-purity LiF-LiCl flux with a mass ratio of 1:4 on the surface to cover and Introduce Ar gas protection gas, melt in a well-type resistance furnace at 730°C for 20-30 minutes; remove slag after melting, add pure magnesium and pure lithium wrapped in aluminum foil, and sprinkle covering agent (mass ratio: 1 :4 high-purity L...

Embodiment 2

[0052] A homogenization deformation heat treatment method for rapid refinement and homogenization of cast aluminum-lithium alloy, as follows:

[0053] Step one to step five are the same as embodiment 1.

[0054] Step 6: The plate sample obtained in step 5 is subjected to a first-level homogenization treatment at 540° C. for 1.5 h in a tubular heating furnace, and water quenched after the homogenization treatment to obtain the final plate.

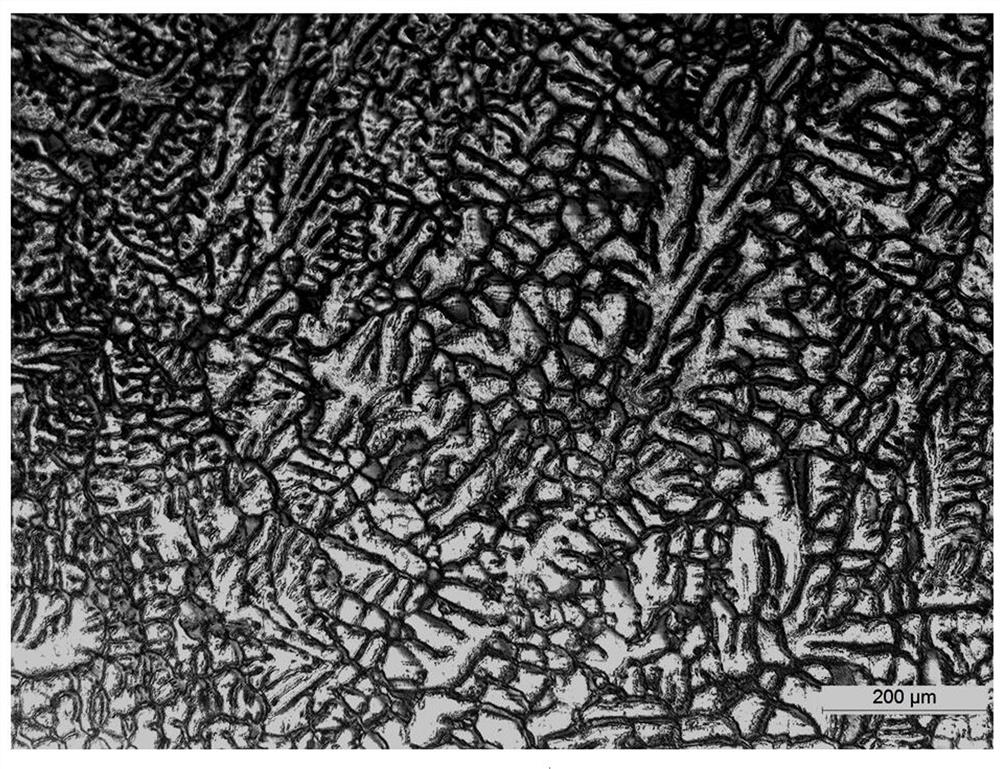

[0055] Microstructure characterization of aluminum-lithium alloy plates, Figure 5 It is the metallographic microstructure image after the homogenization treatment in Example 2, the second phase remains on some grain boundaries, and is distributed continuously or intermittently, and the grain boundaries are thicker than figure 2 And the grain size also increases sharply.

Embodiment 3

[0057] A homogenization deformation heat treatment method for rapid refinement and homogenization of cast aluminum-lithium alloy, as follows:

[0058] Step one to step five are the same as embodiment 1.

[0059] Step 6: The plate sample obtained in Step 5 is subjected to primary homogenization treatment at 350°C×1h in a tubular heating furnace.

[0060] Step 7: Heat the plate obtained in step 6 to the secondary homogenization temperature with the furnace, perform secondary homogenization treatment at 520° C. for 1 hour, and water quench after the secondary homogenization treatment to obtain the final plate.

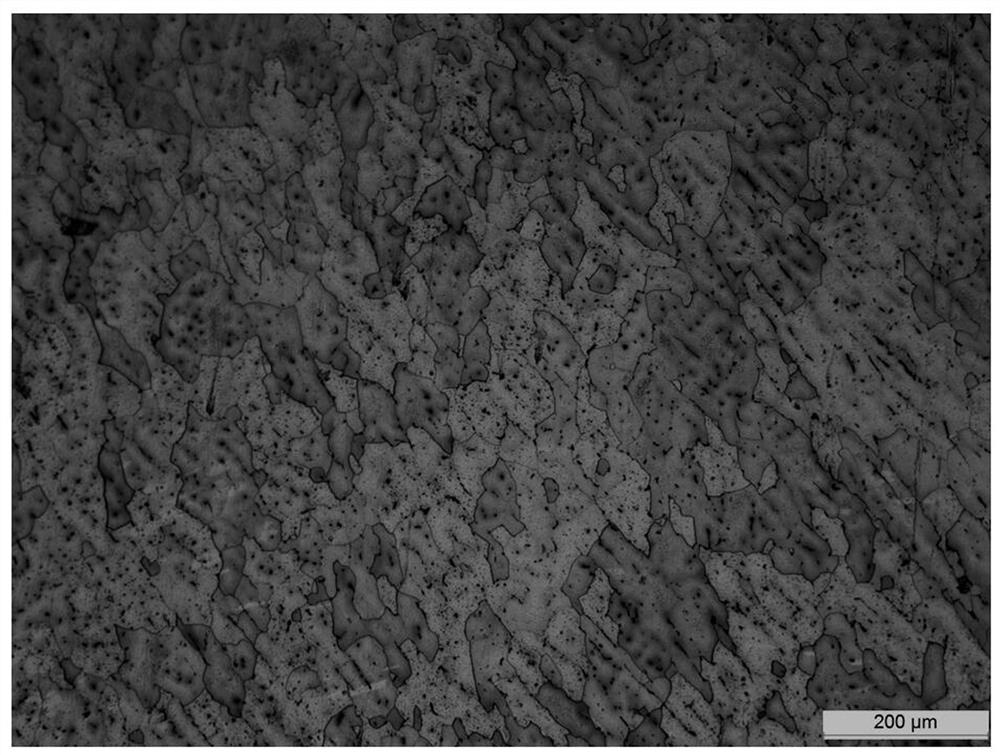

[0061] Microstructure characterization of aluminum-lithium alloy plates, Image 6 This is the metallographic microstructure image after the homogenization treatment in Example 3, the grain boundaries are relatively clear, the second phase basically dissolves back into the matrix, and the solid solution effect is better, but the grain size is much larger than figure 2 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com