Method and device for performing electric magnetization arc welding-braze welding compounding on dissimilar materials

A technology of electromagnetic excitation and dissimilar materials, applied in welding equipment, metal processing equipment, metal processing, etc., can solve the problems of unfavorable liquid molten pool metal uniform mixing, small heat input, etc., to improve connection quality, increase strength, and promote mutual Effect of Diffusion and Homogenization of Composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

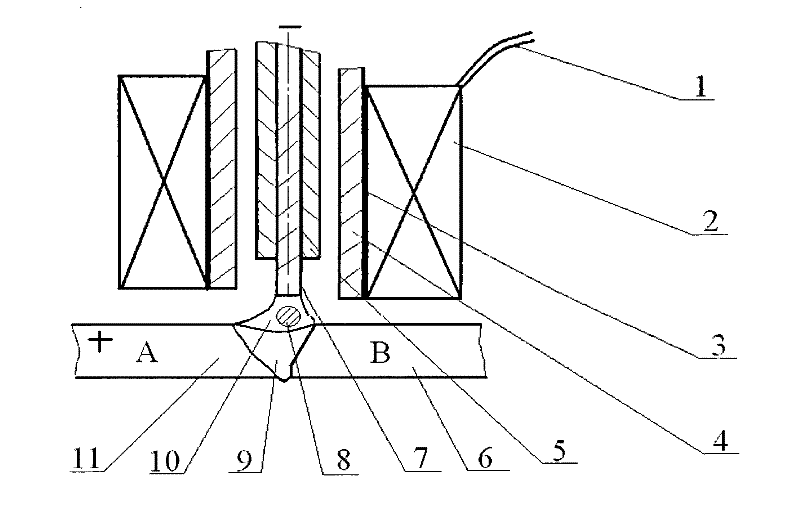

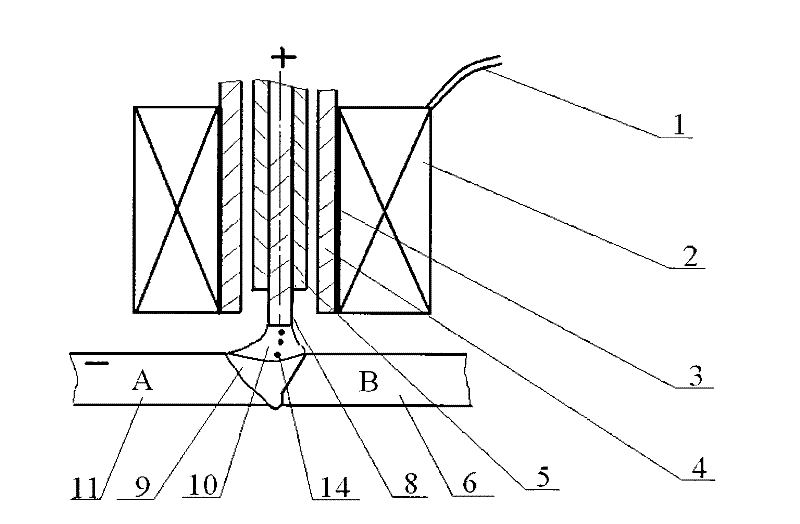

[0036] Steel-aluminum dissimilar material electromagnetically excited TIG arc melting-brazing composite method and equipment, using an external magnetic field assisted arc composite TIG brazing method, the welding thickness is 3.6mm Q345 steel and LD10 aluminum alloy workpiece docking, V-shaped groove, slope The mouth angle is 60°, and the process parameters are: AC manual TIG welding; tungsten pole diameter Φ3.2mm; welding current 60-140A; auxiliary magnetic field strength 500-600Gs; joint performance.

Embodiment 2

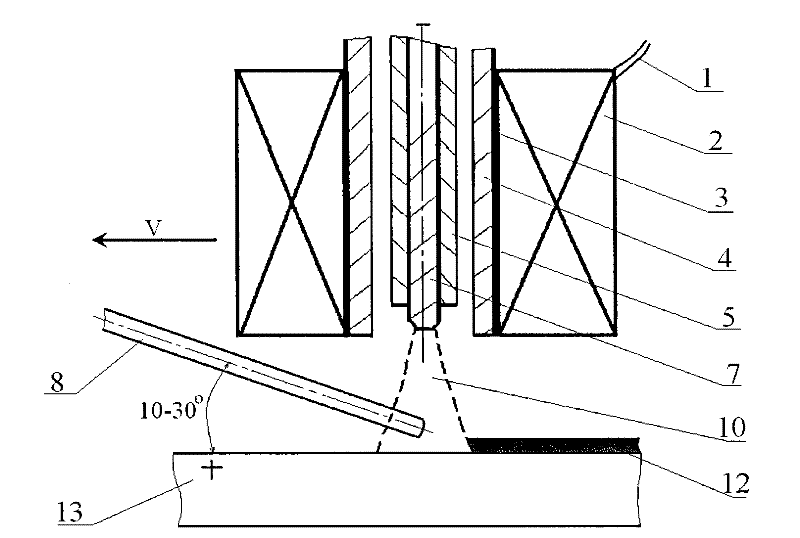

[0038] Steel-magnesium alloy dissimilar material electromagnetic excitation TIG arc melting-brazing compound method and equipment, using external magnetic field assisted arc compound MIG brazing method, welding thickness is 4.2mm ZK60 magnesium alloy and 35CrMnSi steel workpiece docking, Y-shaped groove, root Height 1mm. The process parameters are: welding current 120-160A, DC reverse connection; auxiliary magnetic field strength 650-720Gs; brazing wire diameter Φ1.2mm, through parameter optimization, the required structure and performance can be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com