Heating technology for avoiding surface defects of steel plate

A heating process and defect technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the difficulties in controlling the surface quality and internal quality of hot coils, the lack of awareness and attention to surface temperature control and heating process control, heating and uniformity Heat time, final product performance fluctuates greatly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

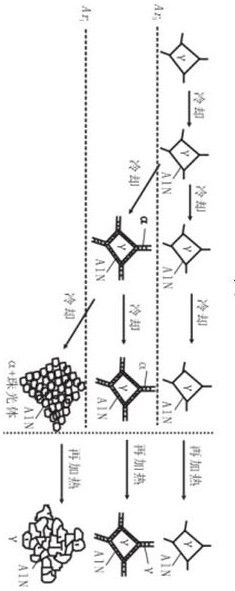

Method used

Image

Examples

Embodiment 1

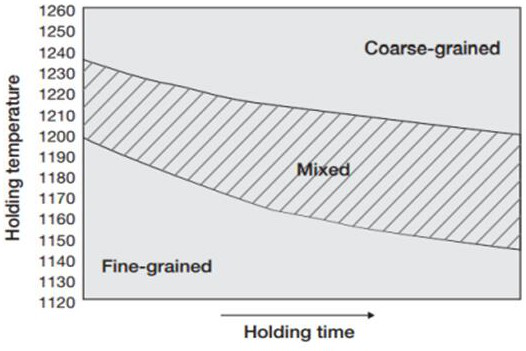

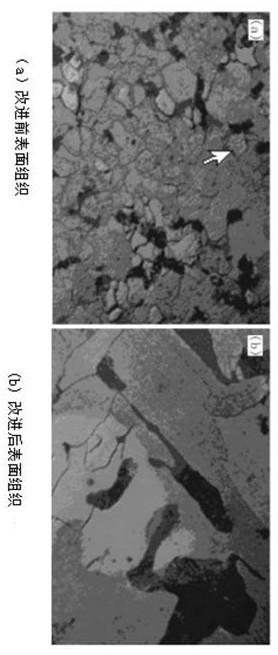

[0045] A steel mill uses the slab hot delivery and hot charging and heating process of the present invention for 230mm×1300mm ultra-low carbon non-interstitial atomic steel, namely IF steel. The surface temperature of the IF steel continuous casting slab is ≥300℃ but lower than the Ar1 temperature of the IF steel 600 ℃ into the heating furnace, and the heating time of the slab in the heating furnace is controlled at 240 minutes. When the heating furnace is deheating, the first heating section is heated rapidly, and the second heating and soaking section slowly rises. Control the temperature at the end of the first heating section to be greater than 1060°C. The temperature at the end of the second addition stage is greater than 1160℃, and the temperature at the end of the furnace is less than 1220℃. The thickness of the steel plate after rolling is 0.2-0.4mm, and the surface of the steel plate has no surface defects such as slag and cracks. Compared with the continuous casting b...

Embodiment 2

[0047] A steel plant used the slab hot delivery, hot charging and heating process of the present invention for 230mm×950mm low carbon tin plate steel. The surface temperature of the tin plate steel continuous casting slab is ≥200℃ but lower than the Ar1 temperature of the tin plate steel 550 ℃ into the heating furnace, the heating time of the slab in the heating furnace is controlled at 245 minutes. When the heating furnace deheats, the first heating section is heated up quickly, and the second heating and soaking section slowly rises. Control the temperature at the end of the first heating section to be greater than 1030°C. The temperature at the end of the second addition section is greater than 1150°C, and the temperature at the outlet is less than 1200°C. The thickness of the steel plate after rolling is 0.3-0.6mm, and the surface of the steel plate has no surface defects such as slag inclusions and cracks. Compared with the continuous casting billet of the cold charging fu...

Embodiment 3

[0049] A steel mill uses the slab hot delivery, hot charging and heating process of the present invention for the 230mm×1200mm high carbon tool steel 65Mn. The 65Mn steel continuous casting secondary cooling process adopts the weak cooling process, and the heat preservation cover is added during transportation to keep the slab cut. After 3 hours transfer to the heating furnace, the surface temperature of the slab before loading into the heating furnace is ≥750°C (Ar3 temperature), and the heating time of the slab in the heating furnace is controlled at 260 minutes. Slowly increase the temperature in the heating and soaking section, control the temperature at the end of the first addition section to be less than 1090℃, control the temperature at the end of the second addition section to be less than 1170℃, and the temperature of the furnace to be less than 1220℃. The thickness of the steel plate after rolling is 6.0mm, and the surface of the steel plate has no surface defects suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com