Forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks

A compound forming and quality technology, applied in the direction of tension/pressure control, temperature control, metal processing equipment, etc., can solve the problems of affecting the mechanical properties of steel, scrapping, failure of flaw detection, etc., to achieve improved dimensional accuracy, good economy, crystal grains beneficial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

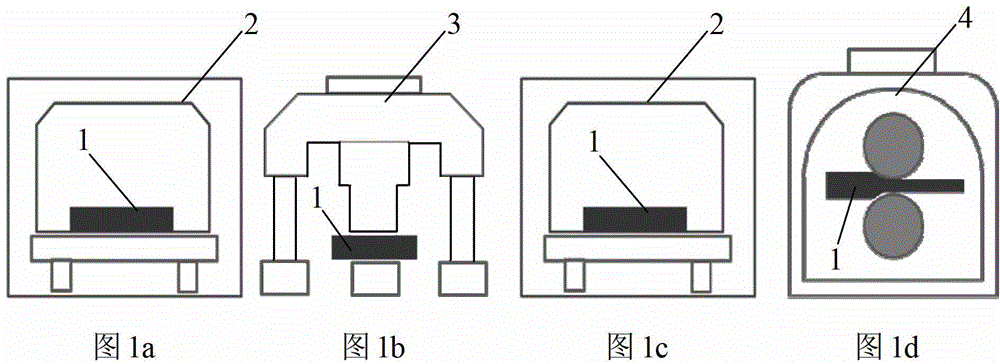

Method used

Image

Examples

Embodiment 1

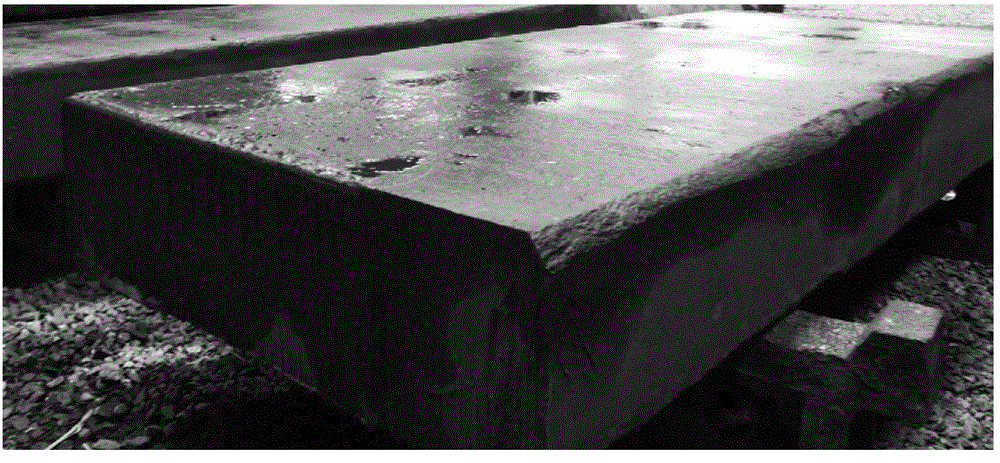

[0110] The wide and thick slab used in this embodiment has an original size of about 840 mm thick x 2100 mm wide x 3200 mm long, and its material is SA517GrQ, which is used for rack plates of jack-up offshore platforms. The billet heating temperature is 1200°C, and the first fire holding time is 15h. A wide anvil of 850mm is used for forging. First, one step is drawn along the Y direction, and then four times are drawn along the X direction. The blank is turned 180° between each pass to ensure uniform deformation. According to formula (2) and formula (3), the process parameters of the forging process are calculated as shown in Table 1:

[0111] Table 1 Process parameters of forging process before rolling

[0112] times

ω

ΔX

DX

ΔY

Dy

ΔZ

DZ

0

-

-

840

-

2100

-

3200

1

0°

-

890

200

1900

-

3340

2

180°

-

950

200

1700

-

3500

3

180° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com