Preparation process of high-performance low-cost titanium alloy

A preparation technology, titanium alloy technology, applied in the field of high-performance and low-cost titanium alloy preparation technology, can solve the problems of uncommon application of titanium alloy, insufficient application accumulation, and insufficient strength, etc., to achieve alloy cost reduction, simple process, and reduced forging The effect of fire times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation process of a high-performance low-cost titanium alloy, the specific preparation steps are as follows:

[0032] Step 1. Put a small amount of sponge Ti on the bottom and cap, and spread a layer of sponge Ti, recycled materials, intermediate alloy mixture, Al bean and Cr mixture, repeat the above laying 3~4 times, and extrude into an electrode block after the ingredients are completed. ;

[0033] Step 2: Melt the electrode block twice, weld the ingot head-to-tail for the first smelting, and put it in an oven for drying. After smelting the ingot for the second smelting flaw detection, wire cutting removes the shrinkage cavity at the arc-receiving end, and peels off the skin on both ends and sides to obtain Blank;

[0034] Step 3, the billet in step 2 is sequentially subjected to no less than 3 times of forging and 3 to 4 times of rolling to obtain a titanium alloy plate blank;

[0035] Step 4: Cut the titanium alloy plate billet into the required size and a...

Embodiment 1

[0046]Select O-grade sponge Ti, 20% TA5 sheet material, Cr50Fe, Mo50Fe, Cr and Al beans to press electrodes, and use German ALD vacuum consumable electric arc furnace for two smelting, the diameter of the first casting ingot is 220mm, and the second casting The diameter of the ingot is 290 mm. In the present invention, the composition of the ingot is Ti-8.2Al-1.4Cr-0.95Fe-0.86Mo. After 3 times of forging and face milling, the flaw detection grade A is obtained, and the low-magnification structure is fuzzy crystal. Titanium alloy slab, the size of the slab is 90×950×1200mm.

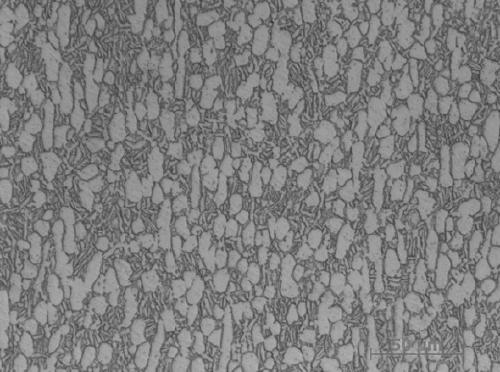

[0047] According to the test of DSC thermal analyzer, the phase transition point of Ti-8.2Al-1.4Cr-0.95Fe-0.86Mo alloy is 1012°C, the first-fire rolling temperature is 1025°C, the first-fire rolling thickness is 17mm, and the deformation rate is 82%. , peeling and polishing after rolling to remove superficial crack defects on the surface; second-fire rolling thickness 7mm, deformation rate 59%, polishing a...

Embodiment 2

[0052] The alloy ingot was prepared by the method of Example 1, and O-grade sponge titanium, 30% TA1 sheet material, Cr50Fe, Mo50Fe, Cr and Al beans were used to press electrodes, and the German ALD vacuum consumable electric arc furnace was used for two smelting. The diameter of the primary ingot is 220mm, and the diameter of the second ingot is 290mm. The composition of the ingot is Ti-8.1Al-1.2Cr-1.05Fe-0.91Mo, and the O content is 0.1%. After 3 times of forging and milling, it is obtained Flaw detection grade A grade, alloy slab with fuzzy grain in low-magnification structure, the size of the slab is 90×950×1200mm.

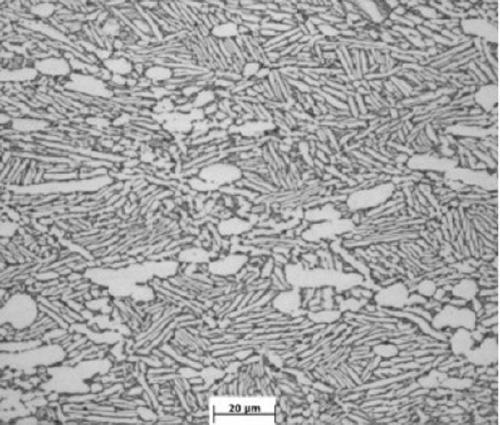

[0053] According to the test of DSC thermal analyzer, the phase transition point of Ti-8.1Al-1.2Cr-1.05Fe-0.91Mo alloy is 1010°C, the first-fire rolling temperature is 1025°C, the first-fire rolling thickness is 17mm, and the deformation rate is 82%. Peeling and polishing after rolling to remove superficial crack defects on the surface; second-fire rolling thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com