Machining method for tube expansion hole of diesel engine rack

A processing method and diesel engine technology, which are applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problem of low machining accuracy of frame expansion holes, reduce maneuvering and auxiliary time, improve processing quality, The effect of ensuring the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The processing method for the expansion tube hole of the diesel engine frame according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but this should not limit the protection scope of the present invention.

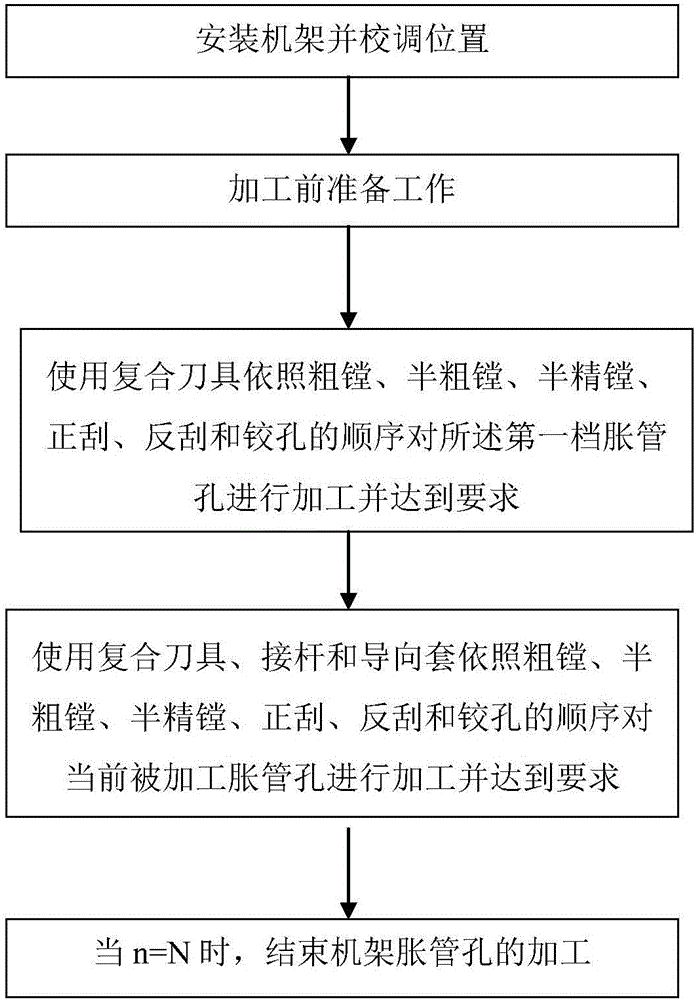

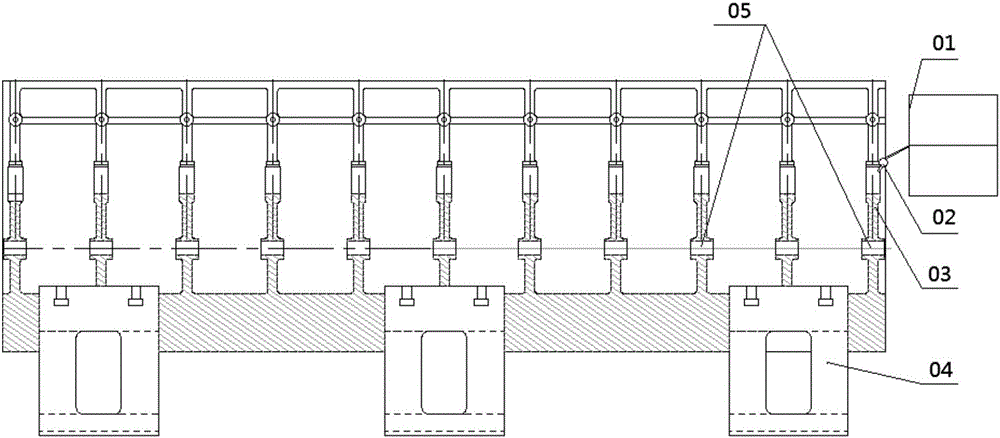

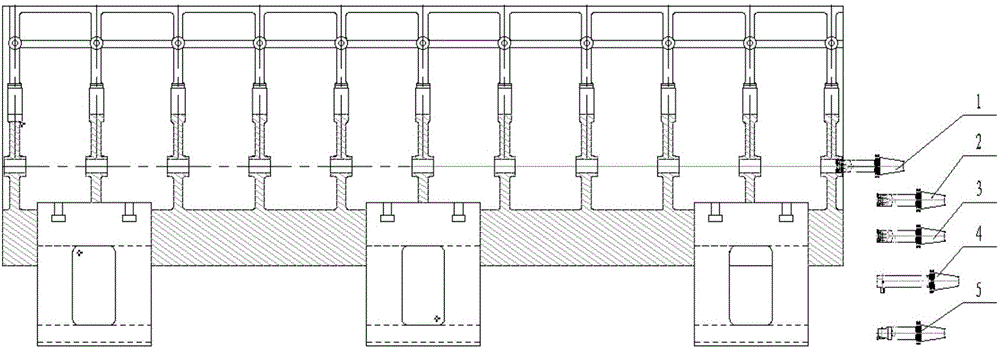

[0032] The following examples process the frame expansion holes of a 956 high-speed diesel engine with the processing method for the frame expansion holes of the diesel engine according to the present invention. see figure 2 , the frame 03 of the 956 high-speed diesel engine has 11 coaxial expansion tube holes 05 to be processed. For details, please refer to the following steps figure 1 :

[0033] 1) Put the rack 03 upside down and put it on the inclined iron 04, see figure 2 , After installing the angle ruler attachment 01, use the dial indicator 02 to straighten the bearing seat to open the gear, level the upper plane of the frame 03, and complete the calibration work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com