Compound fixture for processing matched seam allowance on upper body of motor car bogie axle box

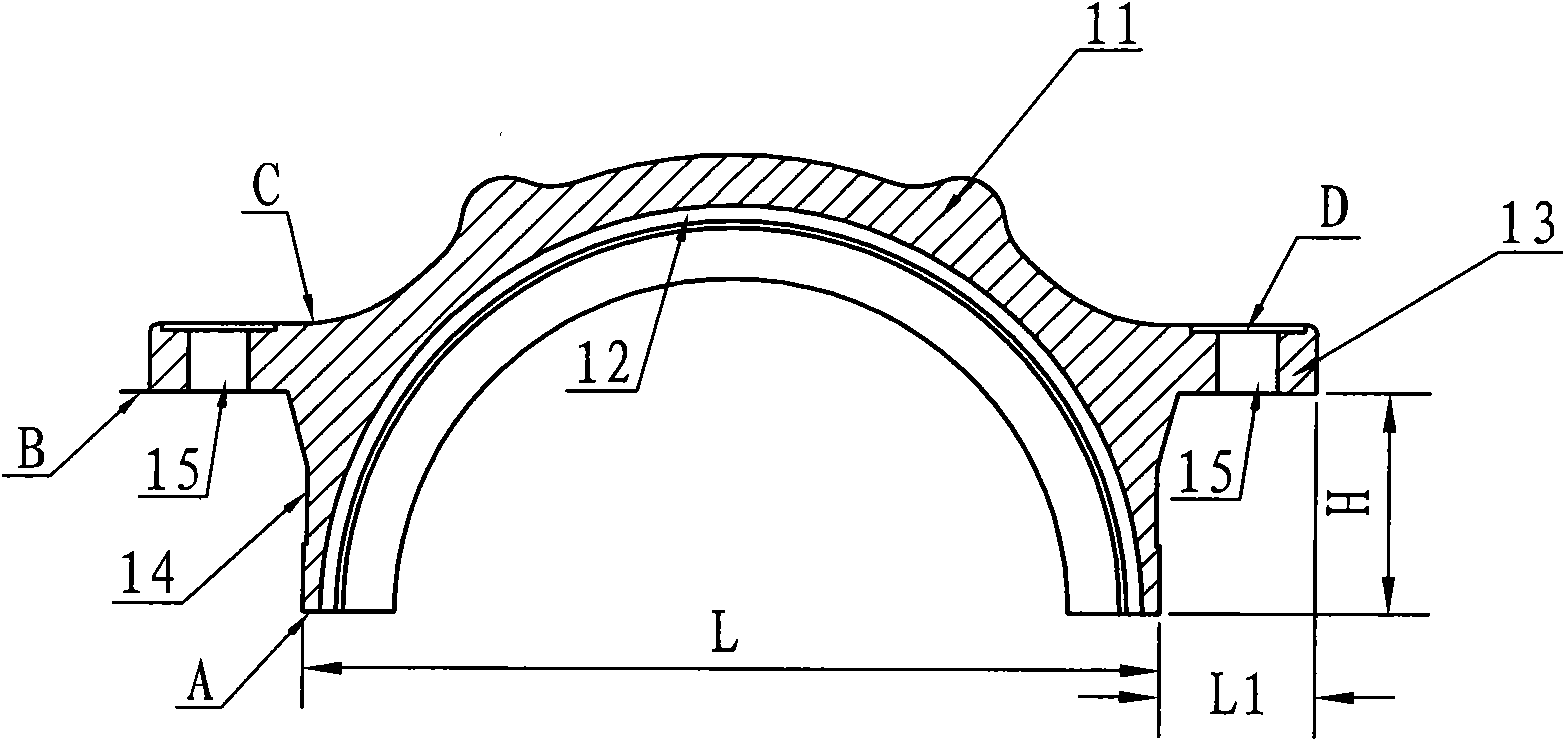

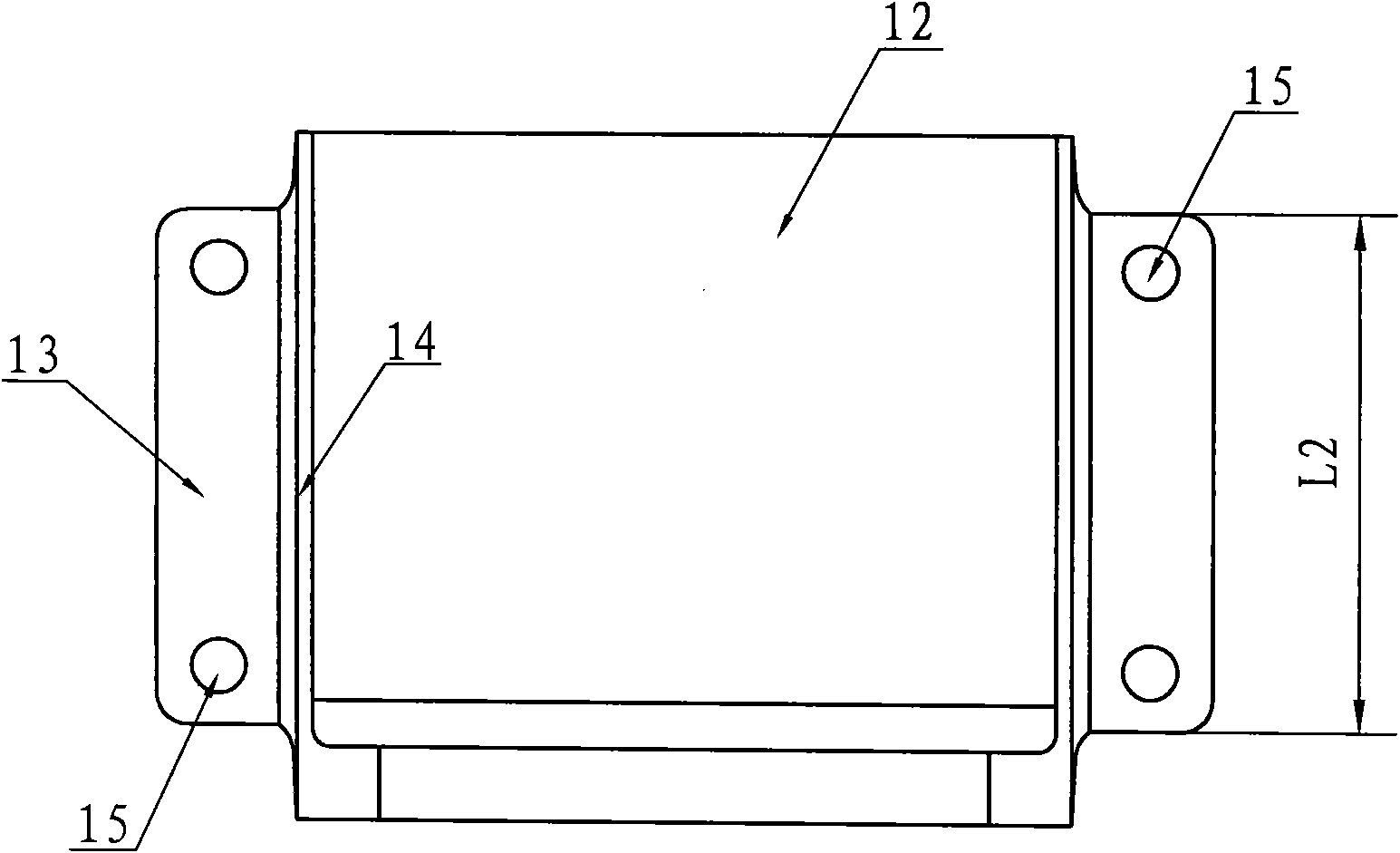

A bogie and movable fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machine parts, etc., can solve unevenness, low parts genuine rate, and poor surface quality of the upper end surface of bearing shell 11 and connecting ear seat 13 and other problems, to achieve the effect of uniform machining allowance and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

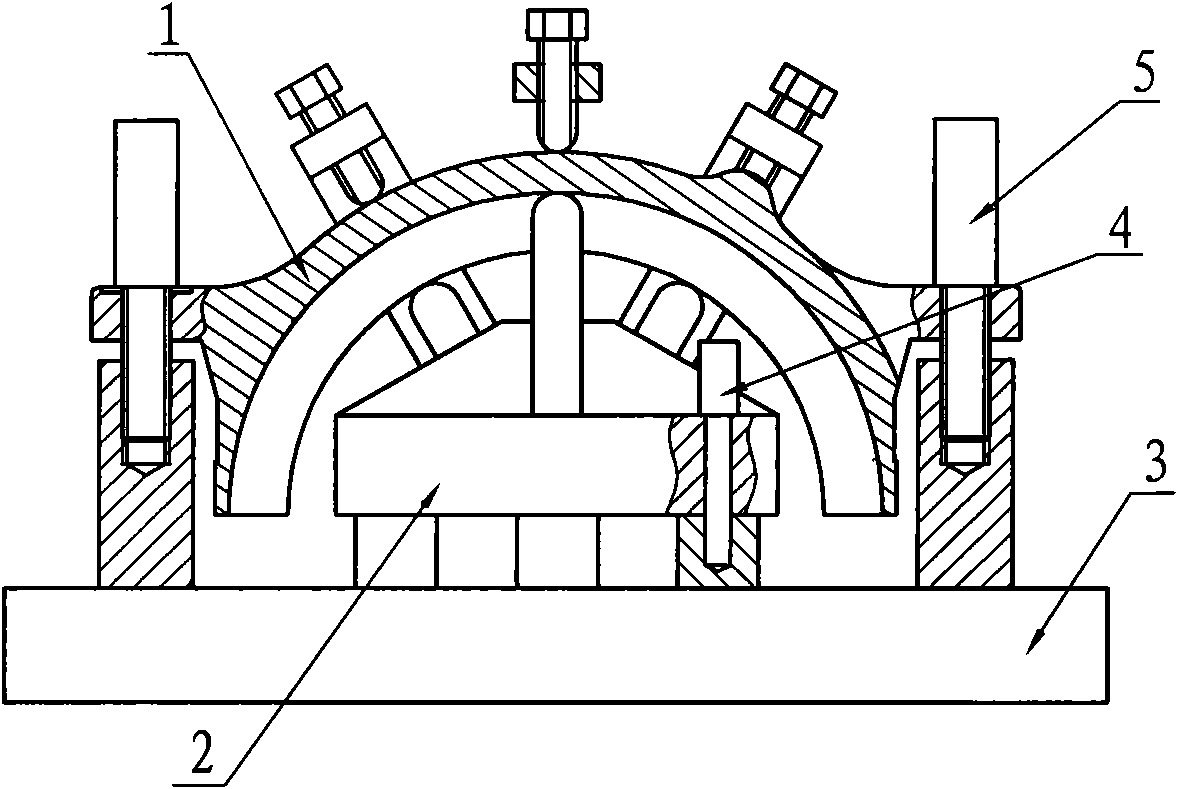

[0034] According to the present invention, a compound fixture for cooperating with the notch milling of the upper body of the bogie axle box of a motor vehicle includes a movable fixture 2, an adjustment fixture 3, a movable bottom plate positioning rod 4, a workpiece positioning mandrel 5 and a fixed bracket 6, such as Figure 3 ~ Figure 6 As shown, the movable fixture 2 includes a movable bottom plate 21 and three arc positioning clamping devices 22, and two inclined surfaces 211, an intermediate plane 212, two mounting planes 213 and three positioning installations are arranged on the movable bottom plate 21. Holes 214, two inclined surfaces 211 are symmetrically arranged on the left side of the movable base plate 21, two installation planes 213 are symmetrically arranged on the right side of the movable base plate 21, and a positioning installation hole 214 is respectively provided on the two installation planes 213, A positioning installation hole 214 is provided on the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com