Design optimization method of blisk electrolytic preliminary molding machining path parameters

A technology of integral blisk and processing track, which is applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of thin blade, long processing cycle, narrow passage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, what is done is explanation of the present invention rather than limitation:

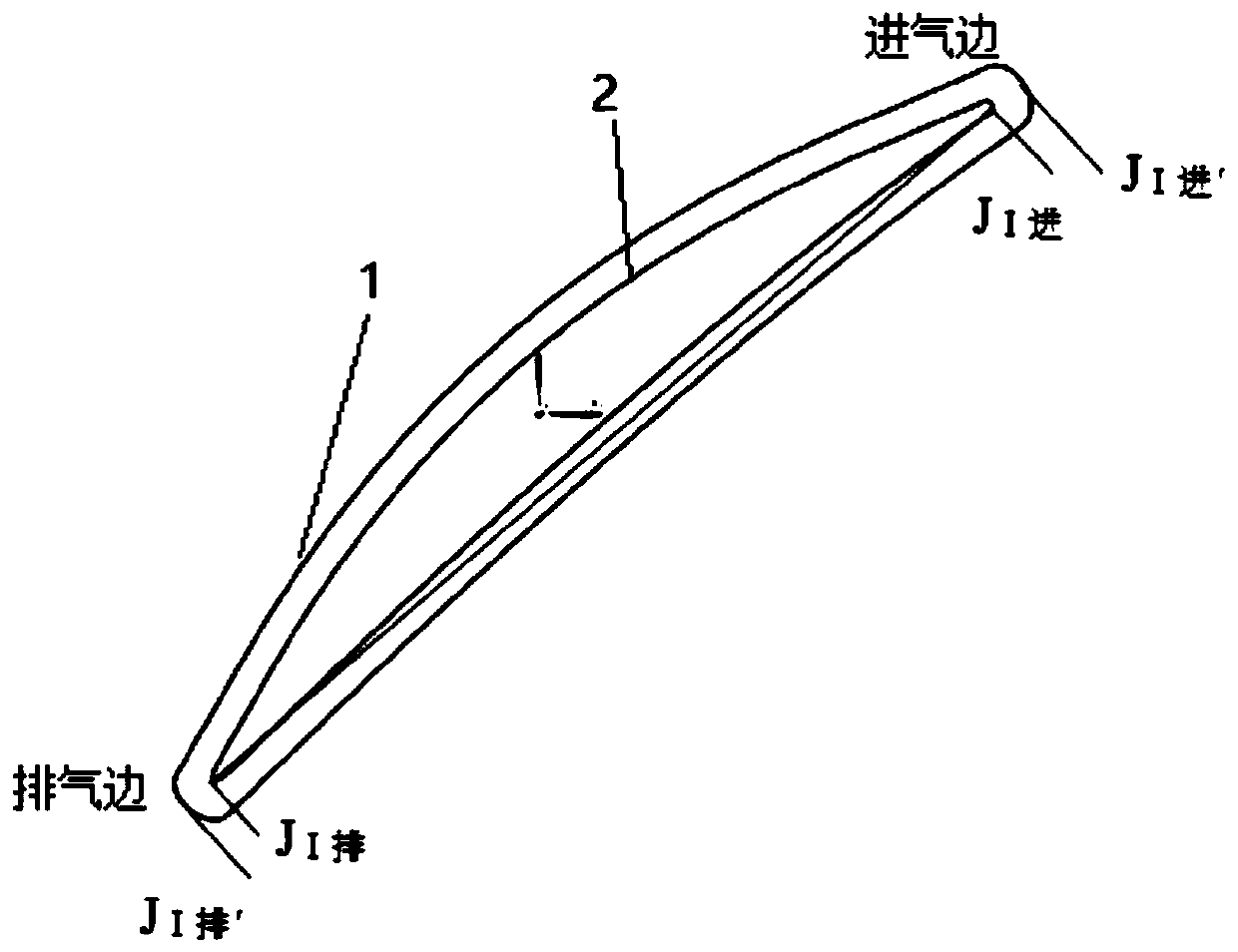

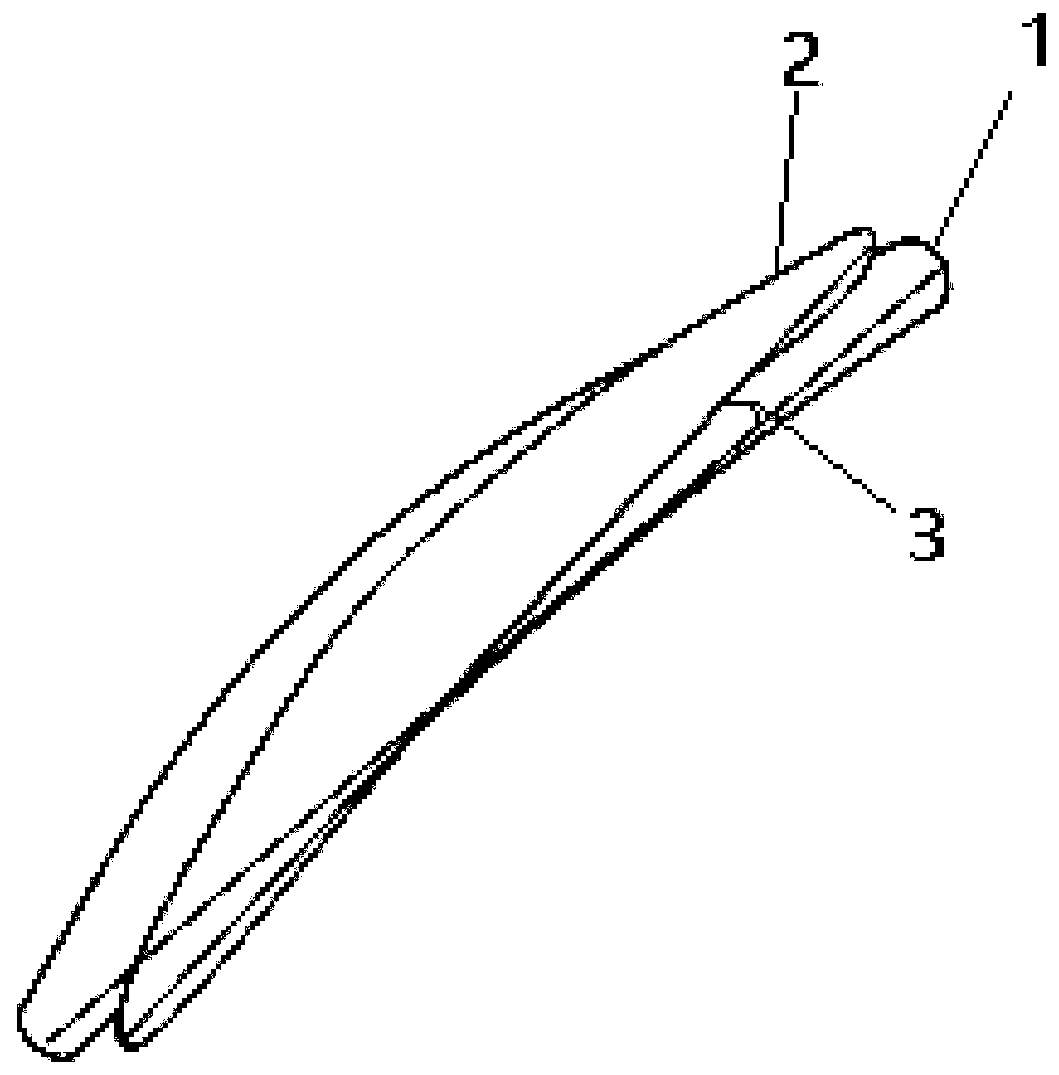

[0043] The blisk is a typical complicated surface part due to its complex structure, large blade shape and narrow passage. The technical solution of the present invention can also be applied to parts similar to the blisk structure. The embodiment of electrolytic preforming processing is taken as an example to further explain the present invention, and the explanation is not a limitation of the present invention:

[0044] The electrolytic primary forming process of a blisk of a certain specification includes the following steps:

[0045] Step 1: In the UG software, project the design section characteristic curve I of the overall blisk onto the plane M to form a two-dimensional closed-loop curve L Ⅰ ;The design section characteristic curve of the overall blisk refers to the curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com