Method for milling titanium alloy fan blade profiles

A technology for fan blades and titanium alloys is applied in the field of profile milling of titanium alloy fan blades. Efficiency and machining accuracy, reduced skill requirements, reduced burn effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0024] The specific implementation steps of the present invention are as follows:

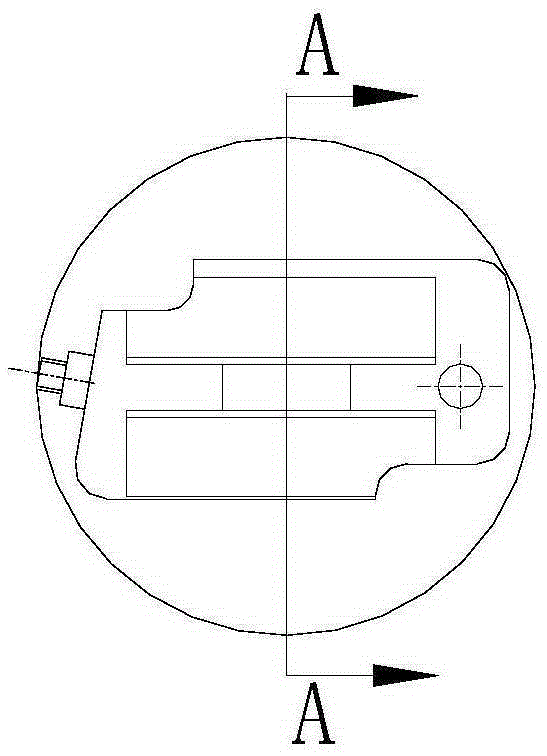

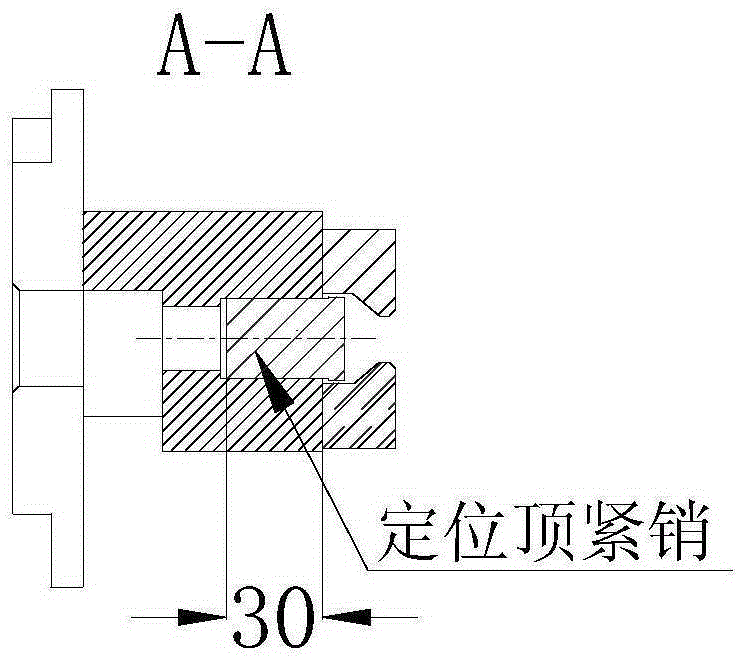

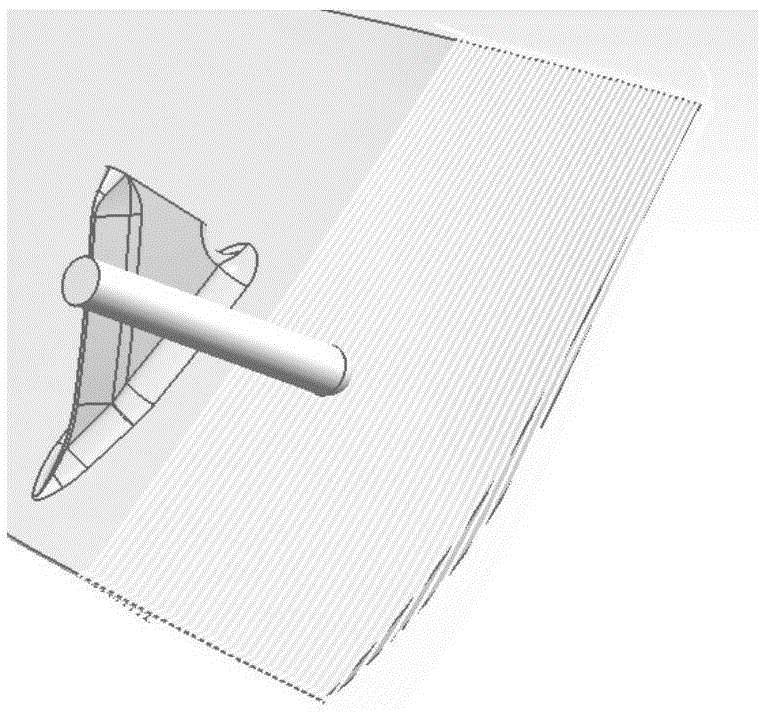

[0025] Step 1: Use tenon double-degree surface positioning, bottom surface positioning and clamping method, the guiding length of the positioning jacking pin is 30mm, the matching clearance is required to be less than 0.01mm, and the positioning length of the pressing surface is 14.19mm, so the positioning error of the bottom surface = 0.01 *14.19 / 30=0.00473mm, which can meet the clamping requirements, as shown in Figure 1.

[0026] Step 2: After the rough machining of the blade, the margin of the blade body profile is between 1.2 mm and 2 mm, and the semi-finishing process is added to make the margin of the parts even, and the margin of the blade profile after the semi-finishing process is 0.5 mm.

[0027] Step 3: Machining the airfoil profiles with different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com