Technological method for reducing deformation of sectioning thin-walled cylinder type workpieces

A process method and technology of thin-walled tubes, which are applied in the field of reducing deformation of split-valve thin-walled tubes, can solve problems such as deformation, processing efficiency, and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is a process method for reducing deformation of a split thin-walled cylindrical part. The process method includes the following steps:

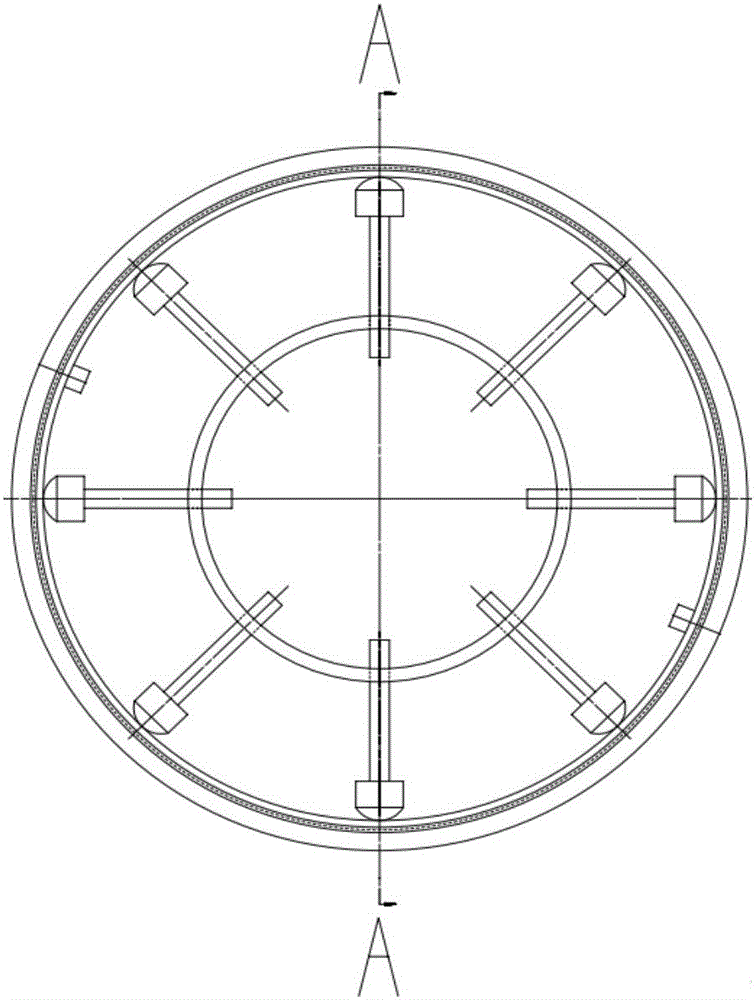

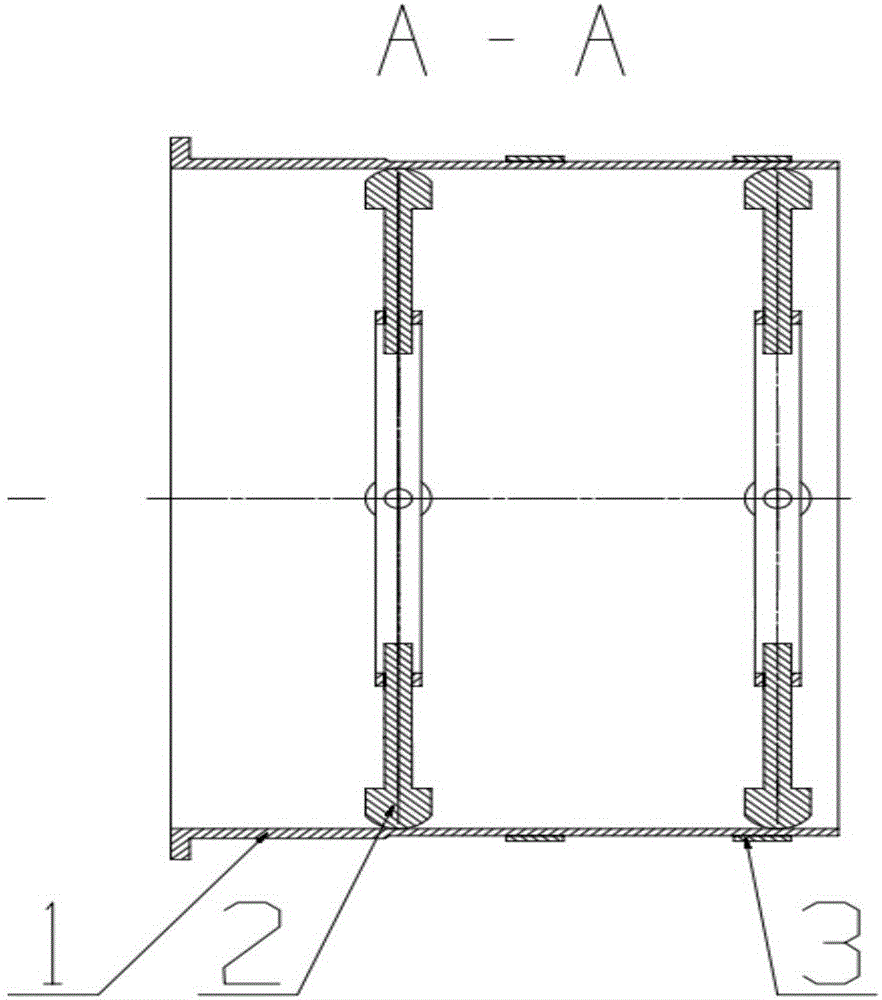

[0017] 1) if figure 1 As shown, combine the petaled cylindrical parts 1, and check the combined petaled cylindrical parts 1 by scribing lines. When the machining allowance is insufficient due to workpiece deformation, such as figure 2 The supporting tool 2 and the fastening tool 3 are installed as shown, and the shape of the split-valve cylindrical part 1 is corrected, and the tool is kept for more than 24 hours after correcting the shape;

[0018] 2) Disassemble the fastening tool 3, rough turn the two end surfaces and outer circle of the split cylinder part 1, etc., and do not rough turn the inner circle of the workpiece;

[0019] 3) Disassemble the supporting tool 2, and rough turn the inner circle of the split-petal cylindrical part 1;

[0020] 4) Disassemble the valve-splitting cylindrical part 1, and perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com