Hydraulic straightening machine with movable type pressure head

A mobile, pressure head technology, applied in the field of pressure head mobile hydraulic straightening machines, can solve the problems of poor quality consistency, time-consuming and laborious manual straightening, and high labor intensity of workers, so as to achieve uniform machining allowance and high straightening efficiency. , The effect of reducing machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

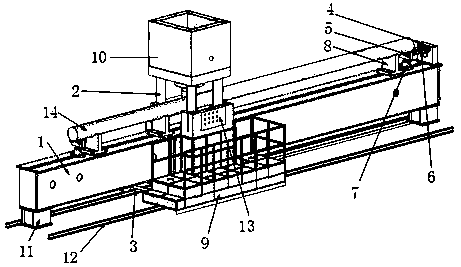

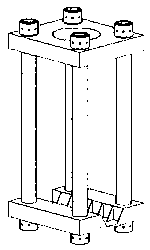

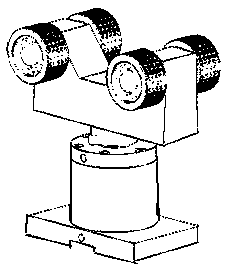

[0013] Such as figure 1 , figure 2 and image 3 As shown, a pressure head mobile hydraulic straightening machine is composed of a bed 1, a gantry mechanism 2, a gantry supporting base 3, a rolling adjustment device, a gantry hydraulic drive mechanism 10, a control panel 13 and a moving table 9. The body 1 has a box-shaped structure welded by steel plates. A V-shaped iron 8 for placing workpieces 14 is arranged on the top of the bed 1. Both ends of the bed 1 are connected with the bed legs 11. Mounting holes are provided on the bed legs 11. Buried bolt connection, the gantry mechanism 2 is a closed gantry structure spanning the bed, and the upper and lower bottom plates are connected by four high-strength circular columns. The two ends of the columns are fixed with high-strength double nuts. The gantry mechanism 2 is equipped with a gantry supporting base 3. The gantry supporting base 3 is equipped with four rollers, and the four rollers fit the guide rails 12 provided on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com